TABLE OF CONTENTS

1 INTRODUCTION����������������������������������������������������������������������������������������������������������������������������������� 1

1�1 Overview�������������������������������������������������������������������������������������������������������������������������������������� 1

1�2 Intended Use And Foreseeable Misuse ������������������������������������������������������������������������������������ 2

2 SAFETY ������������������������������������������������������������������������������������������������������������������������������������������������ 3

2�1 Safety Alert Symbol And Safety Words������������������������������������������������������������������������������������ 3

2�2 Operational Hazards������������������������������������������������������������������������������������������������������������������� 4

Prepare For Emergencies ���������������������������������������������������������������������������������������������������������� 5

Replace Safety Signs ����������������������������������������������������������������������������������������������������������������� 5

Do Not Allow Riders ������������������������������������������������������������������������������������������������������������������� 5

Lower Operating Speed ������������������������������������������������������������������������������������������������������������� 5

Avoid Rollover ���������������������������������������������������������������������������������������������������������������������������� 5

Avoid Powerlines & Underground Utilities ������������������������������������������������������������������������������ 5

Detach Brush Mulcher Safely���������������������������������������������������������������������������������������������������� 6

Hazards From Modifying Equipment ���������������������������������������������������������������������������������������� 6

2�3 Maintenance Hazards����������������������������������������������������������������������������������������������������������������� 7

Maintenance�������������������������������������������������������������������������������������������������������������������������������� 7

3 SAFETY SIGNS ������������������������������������������������������������������������������������������������������������������������������������ 8

4 OPERATION ��������������������������������������������������������������������������������������������������������������������������������������� 10

4�1 Preparation For Use ����������������������������������������������������������������������������������������������������������������� 10

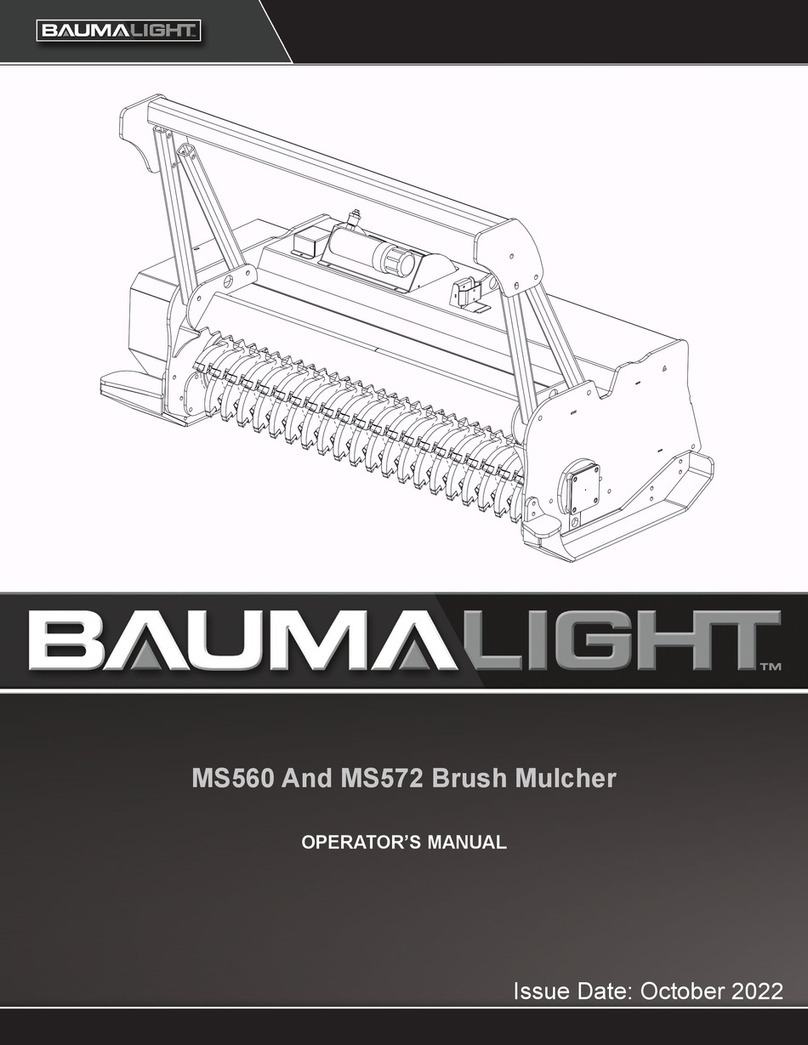

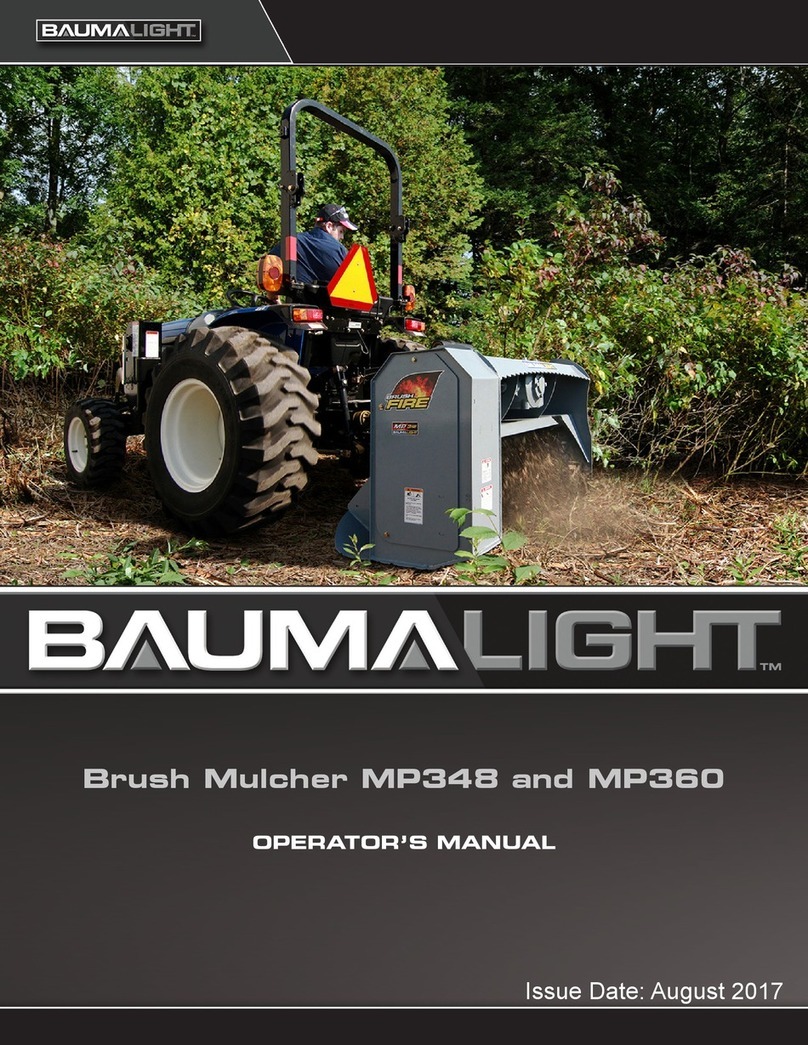

4�2 Machine Components �������������������������������������������������������������������������������������������������������������� 10

4�3 Pre-Operation Check List ���������������������������������������������������������������������������������������������������������11

4�4 Attach Brush Mulcher ���������������������������������������������������������������������������������������������������������������11

4�5 Detach Brush Mulcher ��������������������������������������������������������������������������������������������������������������11

4�6 Transporting������������������������������������������������������������������������������������������������������������������������������ 12

4�7 Carbide Teeth Break-In������������������������������������������������������������������������������������������������������������� 12

4�8 First Time User Tips ����������������������������������������������������������������������������������������������������������������� 13

4�9 Field Operation ������������������������������������������������������������������������������������������������������������������������� 13

4�10 Clearing Jams ������������������������������������������������������������������������������������������������������������������������� 14

5 SERVICE AND MAINTENANCE��������������������������������������������������������������������������������������������������������� 15

5�1 Maintenance������������������������������������������������������������������������������������������������������������������������������ 15

5�2 Inspections�������������������������������������������������������������������������������������������������������������������������������� 15

5�3 Motor Shaft Seal ����������������������������������������������������������������������������������������������������������������������� 15

5�4 Check Belt Tension������������������������������������������������������������������������������������������������������������������� 16

5�5 Replace Belt ������������������������������������������������������������������������������������������������������������������������������ 17

5�6 Rotate Cutting Teeth MX330 ���������������������������������������������������������������������������������������������������� 18

5�7 Replace Cutting Teeth MX230�������������������������������������������������������������������������������������������������� 18

5�8 Replace Cutting Teeth MX330�������������������������������������������������������������������������������������������������� 19

5�9 Replace Tooth Holder MX330 �������������������������������������������������������������������������������������������������� 19

6 TROUBLESHOOTING������������������������������������������������������������������������������������������������������������������������ 20

7 STORAGE������������������������������������������������������������������������������������������������������������������������������������������� 20

7�1 Storing Mulcher ������������������������������������������������������������������������������������������������������������������������ 20

7�2 Removing Mulcher From Storage ������������������������������������������������������������������������������������������� 20

8 WARRANTY���������������������������������������������������������������������������������������������������������������������������������������� 21

ii