Bavaria BCD 18/1 Li User manual

Original operating instructions

Cordless Drill

Art.-Nr.: 45.135.82 I.-Nr.: 11013 BCD 18/1 Li

Anleitung_BT_CD_18_1_Li_SPK1:_ 10.03.2010 15:34 Uhr Seite 1

1

2

1

6910

5

11

4

32

11

5

4

9

3

4

8

8

2

a7

6

9

10

1

4

2

3

5

6

3

â

Change the gear only when the drill is at a standstill. If you fail to observe this

point, the gearing may be damaged.

Caution

Read the operating instructions to reduce the risk of injury.

Wear ear-muffs.

The impact of noise can cause damage to hearing.

Wear safety goggles.

Sparks generated during working or splinters, chips and dust emitted by

the device can cause loss of sight.

Wear a breathing mask.

Dust which is injurious to health can be generated when working on

wood and other materials. Never use the device to work on any materials

containing asbestos!

4

1. General Safety Rules

WARNING! Read all instructions Failure to follow all

instructions listed below may result in electric shock,

re and/or serious injury. The term ’’power tool’’ in all

of the warnings listed below refers to your mains-

operated (corded) power tool or battery-operated

(cordless) power tool.

SAVE THESE INSTRUCTIONS

CAUTION

Read all safety regulations and instructions.

Any errors made in following the safety regulations

and instructions may result in an electric shock, re

and/or serious injury.

Keep all safety regulations and instructions in a

safe place for future use.

1. Work area

a. Keep work area clean and well lit. Cluttered and

dark areas invite accidents.

b. Do not operate power tools in explosive

atmospheres, such as in the presence of

ammable liquids, gases or dust. Power tools

create sparks which may ignite the dust or fumes.

c. Keep children and bystanders away while

operating a power tool. Distractions can cause you

to lose control.

2. Electrical safety

a. Power tool plugs must match the outlet. Never

modify the plug in any way. Do not use any

adapter plugs with earthed (grounded) power tool.

Unmodied plugs and matching outlets will reduce

risk of electric shock.

b. Avoid body contact with earthed or grounded

surfaces such as pipes, radiators, ranges and

refrigerators. There is an increased risk of electric

shock if your body is earthed or grounded.

c. Do not expose power tools to rain or wet

conditions. Water entering a power tool will

increase the risk of electric shock.

d. Do not abuse the cord. Never use the cord for

carrying, pulling or unplugging the power tool.

Keep cord away from heat, oil, sharp edges

or moving parts. Damaged or entangled cords

increase the risk of electric shock.

e. When operating a power tool outdoors, use an

extension cord suitable for outdoor use. Use of

a cord suitable for outdoor use reduces the risk of

electric shock.

f. If operating a power tool in a damp location

is unavoidable, use a residual current device

(RCD) protected supply. Use of an RCD

reduces the risk of electric shock.

3. Personal safety

a. Stay alert, watch what you are doing and use

common sense when operating a power tool. Do

not use a power tool while you are tired or under

the inuence of drugs, alcohol or medication. A

moment of inattention while operating power tools

may result in serious personal injury.

b. Use safety equipment. Always wear eye

protection. Safety equipment such as dust

mask, non-skid safety shoes, hard hat, or hearing

protection used for appropriate conditions will

reduce personal injuries.

c. Avoid accidental starting. Ensure the switch is

in the off-position before plugging in. Carrying

power tools with your nger on the switch or

plugging in power tools that have the switch on

invites accidents.

d. Remove any adjusting key or wrench before

turning the power tool on. A wrench or a key left

attached to rotating part of the power tool may result

in personal injury.

e. Do not overreach. Keep proper footing and

balance at all times. This enables better control of

the power tool in unexpected situations.

f. Dress properly. Do not wear loose clothing or

jewellery. Keep your hair, clothing and gloves

away from moving parts. Loose clothes, jewellery

or long hair can be caught in moving parts.

g. If devices are provided for the connection of

dust extraction and collection facilities, ensure

these are connected and properly used. Use of

these devices can reduce dust-related hazards.

4. Power tool use and care

a. Do not force the power tool. Use the correct

power tool for your application. The correct power

tool will do the job better and safer at the rate for

which it was designed.

b. Do not use the power tool if the switch does not

turn it on and off. Any power tool that cannot be

controlled with the switch is dangerous and must be

repaired.

c. Disconnect the plug from the power source and/

or the battery pack from the power tool before

making any adjustments, changing accessories,

or storing power tools. Such preventive safety

measures reduce the risk of starting the power tool

accidentally.

d. Store idle power tools out of the reach of

children and do not allow persons unfamiliar

with the power tool or these instructions to

operate the power tool. Power tools are dangerous

in the hands of untrained users.

e. Maintain power tools. Check for misalignment or

binding of moving parts, breakage of parts and

any other condition that may affect the power

tools operation. If damaged, have the power tool

repaired before use. Many accidents are caused by

poorly maintained power tools.

f. Keep cutting tools sharp and clean. Properly

maintained cutting tools with sharp cutting edges are

less likely to bind and are easier to control.

g. Use the power tool, accessories and tool bits

etc. in accordance with these instructions and

in the manner intended for the particular type

of power tool, taking into account the working

conditions and the work to be performed. Use

of the power tool for operations different from those

intended could result in a hazardous situation.

5

5. Service

a. Have your power tool serviced by a qualied

repair person using only identical replacement

parts. This will ensure that the safety of the power

tool is maintained.

6. Recommendation

We recommend that the tool always be supplied via

residual curtrent device with a rated residual current of 30

mA or less.

2. Additional Safety Rules

Hold the equipment by the insulated handles

when carrying out work during which the screw

or the plug-in tool could strike concealed power

cables. Contact with a live cable may also make

the metal parts of the equipment live and cause

an electric shock.

We pay a great deal of attention to the design

of every battery pack to ensure that we supply

you with batteries which feature maximum

power density, durability and safety. The battery

cells have a wide range of safety devices. Each

individual cell is initially formatted and its

electrical characteristic curves are recorded.

This data is then used exclusively to be able to

assemble the best possible battery packs. Despite

all the safety precautions, caution must always be

exercised when handling batteries. The following

points must be obeyed at all times to ensure safe

use.

Safe use can only be guaranteed if undamaged

cells are used. Incorrect handling can cause cell

damage.

Important! Analyses confirm that incorrect use

and poor care are the main causes of the damage

caused by high performance batteries.

Information about the battery

1. The battery pack supplied with your cordless

tool is not charged. The battery pack has to

be charged before you use the tool for the

first time.

2. For optimum battery performance avoid low

discharge cycles. Charge the battery pack

frequently.

3. Store the battery pack in a cool place, ideally

at 15°C and charged to at least 40%.

4. Lithium-ion batteries are subject to a natural

ageing process. The battery pack must be

replaced at the latest when its capacity

falls to just 80% of its capacity when new.

Weakened cells in an aged battery pack are

no longer capable of meeting the high power

requirements and therefore pose a safety

risk.

5. Do not throw battery packs into an open fire.

There is a risk of explosion!

6. Do not ignite the battery pack or expose it

to fire.

7. Do not exhaustively discharge batteries.

Exhaustive discharge will damage the battery

cells. The most common cause of exhaustive

discharge is lengthy storage or non-use of

partly discharged batteries. Stop working

as soon as the performance of the battery

falls noticeably or the electronic protection

system triggers. Place the battery pack in

storage only after it has been fully charged.

8. Protect batteries and the tool from

overloads. Overloads will quickly result in

overheating and cell damage inside the

battery housing without this overheating

actually being apparent externally.

9. Avoid damage and shocks. Replace batteries

which have been dropped from a height of

more than one meter or which have been

exposed to violent shocks without delay,

even if the housing of the battery pack

appears to be undamaged. The battery cells

inside the battery may have suffered serious

damage. In this respect, please also read the

waste disposal information.

10. If the battery pack suffers overloading and

overheating, the integrated protective cut-

off will switch off the equipment for safety

reasons. Important! Do not press the ON/

OFF switch any more if the protective cut-off

has actuated. This may damage the battery

pack.

11. Use only original battery packs. The use

of other batteries may result in injuries,

explosion and a fire risk.

Information on chargers and the charging

process

1. Please check the data marked on the rating

plate of the battery charger. Be sure to

connect the battery charger to a power

supply with the voltage marked on the rating

plate. Never connect it to a different mains

voltage.

2. Protect the battery charger and its cable

from damage and sharp edges. Have

damaged cables repaired without delay by a

qualified electrician.

3. Keep the battery charger, batteries and the

cordless tool out of children’s reach.

4. Do not use damaged battery chargers.

5. Do not use the supplied battery charger to

charge other cordless tools.

6. In heavy use the battery pack will become

warm. Allow the battery pack to cool to

room temperature before commencing with

the charging.

6

m

7. Do not over-charge batteries. Do not

exceed the maximum charging times. These

charging times only apply to discharged

batteries. Frequent insertion of a charged

or partly charged battery pack will result in

overcharging and cell damage. Do not leave

batteries in the charger for days on end.

8. Never use or charge batteries if you suspect

that the last time they were charged was

more than 12 months previously. There is

a high probability that the battery pack

has already suffered dangerous damage

(exhaustive discharge).

9. Charging batteries at a temperature below

10°C will cause chemical damage to the cell

and may cause a fire.

10. Do not use batteries which have heated

during the charging process, as the battery

cells may have suffered dangerous damage.

11. Do not use batteries which have suffered

curvature or deformation during the charging

process or which show other non-typical

symptoms (gassing, hissing, cracking,…)

12. Never fully discharge the battery pack

(recommended depth of discharge max.

80%) A complete discharge of the battery

pack will lead to premature ageing of the

battery cells.

13. Never charge the batteries unsupervised.

Protection from environmental influences

1. Wear suitable work clothes. Wear safety

goggles.

2. Protect your cordless tool and the battery

charger from moisture and rain. Moisture and

rain can cause dangerous cell damage.

3. Do not use the cordless tool or the battery

charger near vapors and inflammable liquids.

4. Use the battery charger and cordless tools

only in dry conditions and an ambient

temperature of 10-40°C.

5. Do not keep the battery charger in places

where the temperature is likely to reach over

40°C. In particular, do not leave the battery

charger in a car that is parked in the sun.

6. Protect batteries from overheating.

Overloads, over-charging and exposure to

direct sunlight will result in overheating and

cell damage. Never charge or work with

batteries which have been overheated –

replace them immediately if possible.

7. Storage of batteries, battery chargers and

cordless tools. Store the charger and your

cordless tool only in dry places with an

ambient temperature of 10-40°C. Store your

lithium-ion battery pack in a cool, dry place

at a temperature of 10-20°C. Protect them

from humidity and direct sunlight. Only place

fully charged batteries in storage (charged to

at least 40%).

8. Prevent the lithium-ion battery pack from

freezing. Battery packs which were stored

below 0°C for more than 60 minutes must be

disposed of.

9. When handling batteries be aware of

electrostatic discharge: Electrostatic

discharges cause damage of the electronic

protection system and the battery cells.

Avoid electrostatic charging and never touch

the battery poles.

Important!

When using equipment, a few safety precautions

must be observed to avoid injuries and damage.

Please read the complete operating manual with

due care. Keep this manual in a safe place, so that

the information is available at all times. If you give

the equipment to any other person, give them

these operating instructions as well.

We accept no liability for damage or accidents

which arise due to non-observance of these

instructions and the safety information.

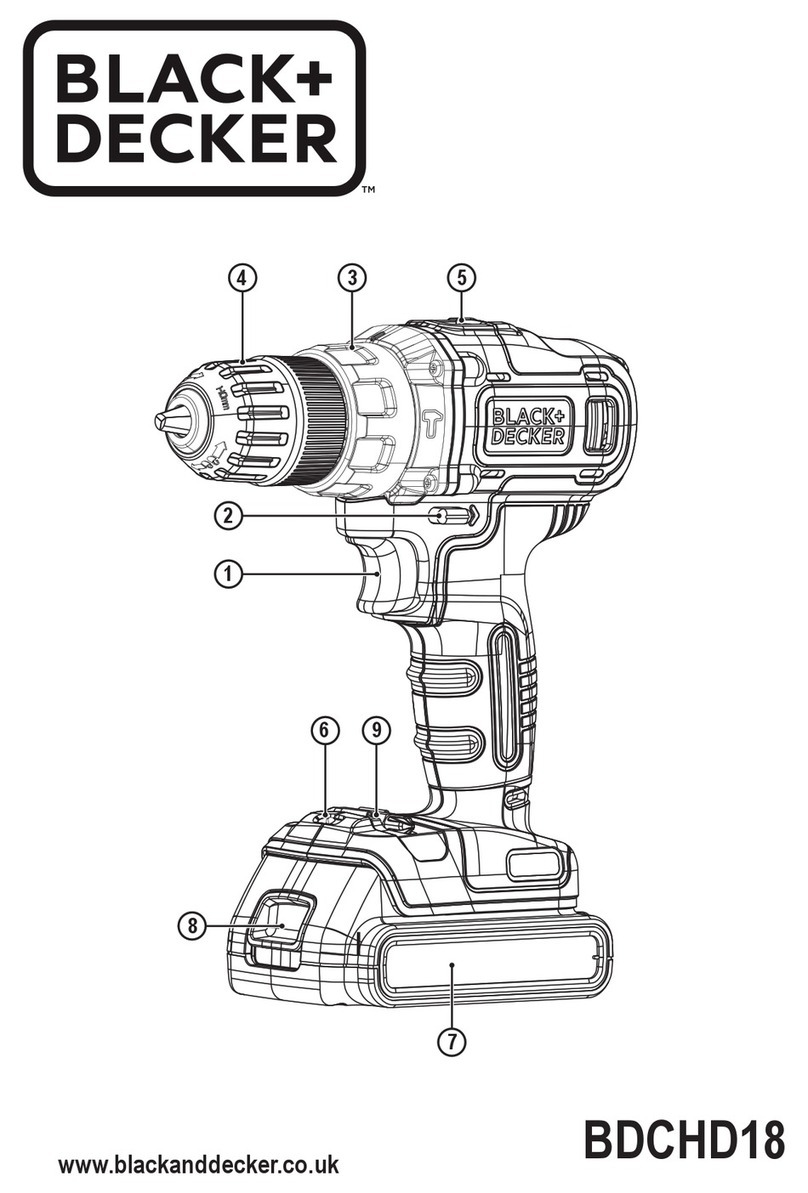

3. Layout (Fig. 1)

1. Torque selector

2. Forward / Reverse switch

3. ON/OFF switch

4. Battery pack

5. Pushlock button

6. Selector switch for 1st gear or 2nd gear

7. Keyless chuck

8. Battery charger

9. Battery capacity indicator

10. Switch for battery capacity indicator

11. LED light

4. Proper use

The tool is designed for tightening and undoing screws,

as well as for drilling in wood, metal and plastic.

The machine is to be used only for its prescribed

purpose. Any other use is deemed to be a case of

misuse. The user / operator and not the manufacturer will

be liable for any damage or injuries of any kind caused as

a result of this.

Please note that our equipment has not been

designed for use in commercial, trade or industrial

applications. Our warranty will be voided if the

machine is used in commercial, trade or industrial

businesses or for equivalent purposes.

7

5. Technical data

Voltage supply 18 V d.c.

Idling speed 0-350/0-1200 rpm

Torque settings 19 + 1

Forward and reverse rotation yes

Chuck capacity max. 10 mm

Battery charging voltage 14.4–18V d.c.

Battery charging current 1500 mA

Mains voltage for charger 230–240 V ~ 50–60

Hz

Weight 1.7 kg

Max. screw diameter 6 mm

Sound and vibration

Sound and vibration values were measured in

accordance with EN 60745.

LpA sound pressure level 72 dB(A)

KpA uncertainty 3 dB

LWA sound power level 83 dB(A)

KWA uncertainty 3 dB

Wear ear-muffs.

The impact of noise can cause damage to hearing.

Total vibration values (vector sum of three directions)

determined in accordance with EN 60745.

Total vibration values (vector sum of three directions)

determined in accordance with EN 60745.

Drilling in metal.

Vibration emission value ah≤ 2.5 m/s2

K uncertainty = 1.5 m/s2

Screwing without hammer action

Vibration emission value ah≤ 2.5 m/s2

K uncertainty = 1.5 m/s2

Additional information for power tools.

Warning!

The specied vibration value was established in

accordance with a standardised testing method. It may

change according to how the electric equipment is

used and may exceed the specied value in exceptional

circumstances.

The specied vibration value can be used to compare

the equipment with other electric power tools.

The specied vibration value can be used for initial

assessment of a harmful effect.

Keep the noise emissions and vibrations to a

minimum.

• Only use appliances which are in perfect working

order.

• Clean the tool regularly.

• Adapt your working style to suit the tool.

• Do not overload the tool.

• Switch the tool off when it is not in use.

• Wear protective safety equipment.

Residual risks.

Even if you use this power tool in accordance with

instructions, certain residual risks cannot be ruled out.

The following hazards may arise in connection with the

equipment’s construction and layout:

1. Lung damage if no suitable protective dust mask

is used.

2. Damage to hearing if no suitable ear protection is

used.

3. Health damage caused by hand-arm vibrations if

the equipment is used over a prolonged period or is

not properly guided and maintained.

6. Before starting the equipment

Be sure to read the following information before you

use your tool for the rst time:

1. Charge the battery pack with the charger supplied.

An empty battery pack requires a charging period of

approximately 1 hour.

2. Only ever use sharp drill bits and screwdriver bits

which are suitable for the purpose and in faultless

condition.

3. Always check for concealed electric cables and gas

and water pipes when drilling and screwing in walls.

7. Operation

7.1 Charging the LI battery pack (Fig. 2/3)

The battery is protected from exhaustive discharge.

An integrated protective circuit automatically switches off

the equipment when the battery is at. In this case the

chuck will cease to turn.

Warning! Do not press the ON/OFF switch any more

if the protective circuit has actuated. This may damage

the battery.

1. Remove the battery pack (4) from the handle,

pressing the pushlock button (5) downwards to do

so.

2. Check that your mains voltage is the same as that

marked on the rating plate of the battery charger.

(230V - 240V). Plug the mains plug of the charger

(8) into the mains socket outlet.

8

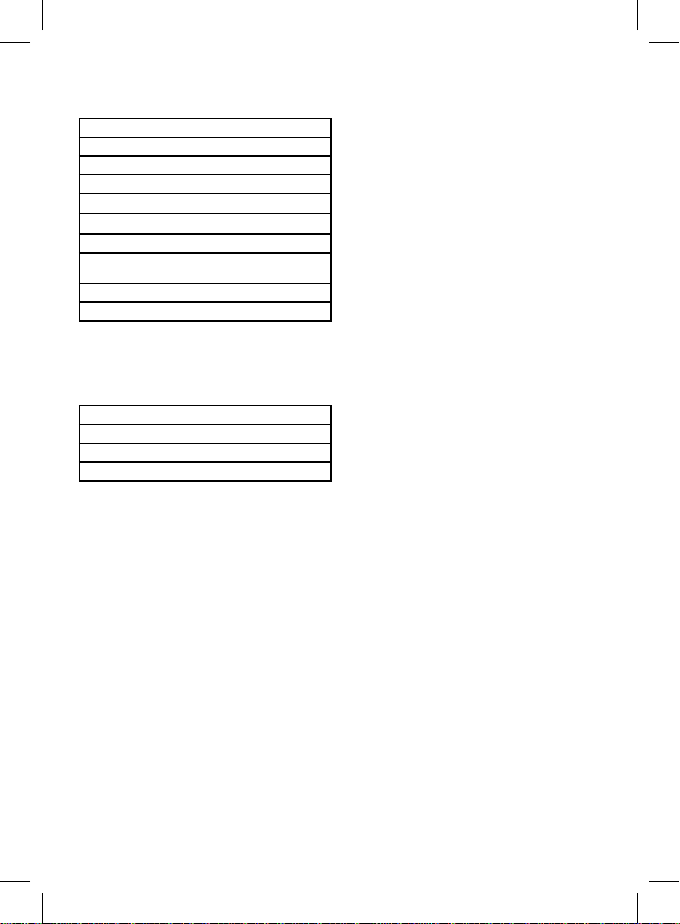

Indicator status Explanations and actions

Red Green

LED LED

OFF Flashing Ready for use

The charger is connected to the

mains and is ready for use; there is no

battery pack in the charger

ON OFF Charging

The charger is charging the battery

pack in quick charge mode.

OFF ON The battery pack is fully charged

(charging completed)

Action: Take the battery pack out of

the charger. Disconnect the charger

from the mains supply.

Flashing OFF Adapted charging

The charger is in gentle charging

mode. For safety reasons the charg-

ing is performed less quickly and

takes more than 1 hour. The reasons

can be:

• The battery pack has not been used

for a very long time or an already

at battery was further discharged

(exhaustive discharge)

• The battery pack temperature is

10°C and 45°C).

Action: Wait for the charging to be

completed; you can still continue to

charge the battery pack.

Flashing Flashing Fault

Charging is no longer possible.The

battery pack is defective.

Action: Never charge a defective bat-

tery pack. Take the battery pack out of

the charger.

ON ON Temperature fault

The battery pack is too hot (e.g. due

to direct sunshine) or too cold (below

0°C).

Action: Remove the battery pack and

keep it at room temperature (approx.

20°C) for one day.

Important!

At temperatures below 0°C the battery will not be

charged.

If the battery pack fails to become charged, please check

• whether there is voltage at the socket-outlet

• whether there is good contact at the charging

contacts of the battery charger (8)

If the battery still fails to become charged, please call our

After Sales Support number 1300 922 271.

To ensure that the Li battery pack provides long service

you should take care to recharge it promptly.You must

recharge the battery pack when you notice that the power

of the tool drops.

7.2 Torque setting (Fig. 4)

The tool is tted with a mechanical torque selector.

The torque for a specic size of screw is selected

with the torque selector (1). The correct torque depends

on several factors:

• On the type and hardness of material in question.

• On the type and length screws used.

• On the requirements needing to be met by the

screwed joint.

The clutch disengages the chuck by preventing rotation,

therefore indicates when the set torque is reached.

Important! The tool must be at a standstill when

you set the torque with the setting ring.

7.3 Drilling

For drilling purposes, move the torque selector

(Fig. 4/Item 1) to the last step “Drill“. In this setting the slip

clutch is inactive. The maximum torque is available in

drilling mode.

7.4 Forward/Reverse switch (Fig. 5 )

With the forward / reverse switch (2) you can select the

direction of rotation of the tool. You can choose between

clockwise and counter clockwise rotation. To avoid

causing damage to the gearing it is advisable to

change the direction of rotation only when the tool is at

a standstill. The On/Off switch (3) is blocked when the

forward / reverse switch (2) is in centre position. This

protects the tool against being switched on accidently.

7.5 On/Off switch (Fig. 5)

Innitely variable speed control is possible with the

On/Off switch (3). The further you press the switch, the

higher the speed.

7.6 Battery capacity indicator (Fig. 4)

Press the switch for the battery capacity indicator (10).

The battery capacity indicator (9) indicates the charge

state of the battery on 3 colored LEDs.

All LEDs illuminate:

The battery is fully charged.

The yellow and red LED illuminate:

The battery has an adequate remaining charge.

Red LED illuminates:

The battery is empty, recharge the battery.

7.7 Changing the accessory (Fig. 6)

Important! Set the forward / reverse switch (Fig. 5/Item

2) to its centre position whenever you carry out any work

(for example changing the accessory, maintenance work,

etc.) on the tool.

• The tool is tted with a chuck (7) with an automatic

spindle stop.

• Open the chuck (7) by rotating it counter-clockwise.

The chuck opening (a) must be large enough to

hold the tool (drill bit or screwdriver bit).

• Select the suitable accessory. Place the accessory

into the chuck opening (a).

• Tighten the chuck (7) by rotating it clockwise and

then check that the tool is secure. 9

7.8 Screwdriving

We recommend using self-centering screws (e.g. Torx

screws, recessed head screws) designed for reliable

working. Be sure to use a bit that matches the screw in

shape and size. Set the torque as per Section 7.2 of the

user guide.

7.9 Selecting 1st gear or 2nd gear (Fig. 4)

By adjusting the selector switch (6), you can work with a

faster or slower turning speed. Change the gear only

when the drill is at a standstill. If you fail to observe this

point, the gearing may be damaged.

7.10 LED lamp (Fig. 2)

The LED lamp (11) can be used in poor lighting

conditions to illuminate the area where you want to

drill or screw. The LED lamp (11) will be lit automatically

as soon as you press the ON/OFF switch (Fig. 1/Item 3).

8. Cleaning, maintenance and

ordering of spare parts

Always pull out the mains power plug before starting

any cleaning work.

8.1 Cleaning

Keep all safety devices, air vents and the motor housing

free of dirt and dust as far as possible. Wipe the tool

with a clean cloth or blow it with compressed air at low

pressure.

We recommend that you clean the tool immediately each

time you have nished using it. Clean the tool regularly

with a moist cloth and some soft soap. Do not use

cleaning agents or solvents; these could attack the plastic

parts of the tool. Ensure that no water can seep

into the tool.

8.2 Maintenance

There are no parts inside the equipment which

require additional maintenance.

8.3 Ordering Spare Parts

Contact our After Sales Support on 1300 922 271 and

quote the following data when ordering replacement

parts:

• Type of machine

• Article number of the machine

• Identication number of the machine

• Replacement part number of the part required

9. Disposal and recycling

The unit is supplied in packaging to prevent its being

damaged in transit. This packaging is raw material

and can therefore be reused or can be returned to

the raw material system.

The unit and its accessories are made of various

types of material, such as metal and plastic.

Defective components must be disposed of as

special waste.

10. Disposal of batteries

Batteries contain substances that can be harmful to the

environment. Never place batteries in your household

refuse, in re or in water. Batteries should

be collected, recycled or disposed of in an

environmentally friendly way. Seek advice on correct

disposal from local waste authorities or your local council.

10

Anleitung_BT_CD_18_1_Li_SPK1:_ 10.03.2010 15:35 Uhr Seite 71

The guarantee provided in this Guarantee Certificate is given by Einhell Australia Pty Limited

ACN 134 632 858 of 6/166 Wellington Street, Collingwood, Victoria (Telephone number 1300 922 271)

GUARANTEE

CERTIFICATE

EINHELL AUSTRALIA PTY LTD

6/166 Wellington Street

Collingwood VIC 3066

Australia

Phone: 1300 922 271

Dear

Customer,

All of our products undergo strict quality checks. In the unlikely event that your device develops a fault, please

contact our service department at the address shown on this guarantee certificate. Of course, if you would

prefer to call us then we are also happy to offer our assistance under the service number printed below.

Please note the following terms under which claims under the Einhell Express Guarantee can be made:

1. The benefits conferred by the Einhell Express Guarantee are in addition to all rights and remedies which

you may be entitled to under the Australian Consumer Law, and any other statutory rights you may have

under other applicable laws. This Einhell Express Guarantee does not exclude, restrict or modify any

We do not charge you for the Einhell Express Guarantee.

2. Our goods come with guarantees that cannot be excluded under the Australian Consumer Law. You are

entitled to a replacement or refund for a major failure and for compensation for any other reasonably

foreseeable loss or damage. You are also entitled to have the goods repaired or replaced if the goods

fail to be of acceptable quality and the failure does not amount to a major failure.

3. The Einhell Express Guarantee only covers problems caused by material or manufacturing defects, and

our liability under the Einhell Express Guarantee is limited, at our discretion, to the rectification of these

defects or replacement of the product. Please note that the product has not been designed for use in

commercial, trade or industrial applications. Consequently, the Einhell Express Guarantee will not apply

if the product is used in commercial, trade or industrial applications or for other equivalent activities.

4. The following are also excluded from the Einhell Express Guarantee: compensation for transport

damage, damage caused by failure to comply with the installation/assembly instructions or damage

caused by unprofessional installation, failure to comply with the operating instructions (e.g. connection to

the wrong mains voltage or current type), misuse or inappropriate use (such as overloading of the

product or use of non-approved tools or accessories), failure to comply with the maintenance and safety

regulations, ingress of foreign bodies into the product (e.g. sand, stones or dust), effects of force or

external influences (e.g. damage caused by the product being dropped) and normal wear resulting from

proper operation of the product. The Einhell Express Guarantee will also not apply if any attempt is made

5. The Einhell Express Guarantee is valid for a period of 2 years starting from the purchase date of the

product. Claims made under the Einhell Express Guarantee should be submitted before the end of this

guarantee period and within two weeks of the defect being noticed. No claims under the Einhell Expres

Guarantee will be accepted if submitted after the end of this guarantee period. The original guarantee

period remains applicable to the device even if repairs are carried out or parts are replaced. In such

cases, the work performed or parts fitted will not result in an extension of the guarantee period for the

Einhell Express Guarantee, and the Einhell Express Guarantee will not apply for the work performed or

6. To make a claim under the Einhell Express Guarantee, please send the relevant product postage-free

the address shown below and enclose either the original or a copy of your sales receipt or another date

proof of purchase. It would help us if you could describe the nature of the problem in as much detail as

possible. If the defect is covered by the Einhell Express Guarantee, your product will be repaired

immediately and returned to you, or we will send you a new device (at our election).

Any costs incurred by you in making a claim under this Einhell Express Guarantee, unless specified

otherwise in this guarantee certificate, must be borne by you.

Of course, we are also happy to offer a chargeable repair service for any defects which are not covered by the

scope of the Einhell Express Guarantee or for products which are no longer covered by the Einhell Express

Guarantee. To take advantage of this service, please send the product to our service address.

such rights or remedies.

to tamper with the product.

parts fitted. This also applies when an on-site service is used.

(Einhell Express Guarantee).

EH05/2013(01)

This manual suits for next models

1

Table of contents

Other Bavaria Power Screwdriver manuals