Baxter Verticut 115 C User manual

B

BA

AX

XT

TE

ER

R

VERTICUT MITERCUT SAW

Model No: 115 C

Serial No:

Operation Manual

W

WE

ES

ST

TW

WA

AY

Y

M

Ma

ac

ch

hi

in

ne

er

ry

y

L

Lt

td

d.

.

“Exclusive Canadian Import Agent”

2370 Cawthra Road, Mississauga, ON L5A 2X1

Tel: (905) 803-9999 Fax: (905) 803-9109

Toll Free 1-800-263-1199

Website: westwaymachinery.com

A

B>qXTER

l/ERTICUf

INC.

BANOSAW

MACHINES

VERTICUT

odel

115C

instruction

Manual

l^ll^mbers:

6429

TO

6433

inclusive

27

Kenhar

Drive,

North

York,

Ontario

Canada

M9L

1M9

(416)

741-7100

fax

(416)

741-7114

www.verticut.com

B>qXTER

ZwA

MERTICUr

Table

of

Contents

1.

Forward

2.

Notes

3.

Safety

Instructions

4.

Machine

Specifications

5.

Machine

Views

5.1.1

Front

View

5.1.2

Left

Side

View

6.

Installation

Instructions

7.

Operating

Instructions

7.1

Electric

Control

7.1.1

Electric

Control

Panel

View

7.1.2

Saw

Operation—Electrical

7.2

Material

Clamping

7.2.1

Work

Table

View

7.2.2

Miter

Block

7.2.3

C-Clamp

7.2.4

Material

Stop

7.3

Saw

Carriage

Movement

7.3.1

Carriage

Handles

/

Foot

Pedal

View

•

7.3.2

Carriage

Handle

7.3.3

Foot

Pedal

7.4

Saw

Operation

7.5

Cutting

Force

7.5.1

Adjust

Cutting

Force

View

7.5.2

Cutting

Pressure

Adjustment

7.6

Saw

Travel

Adjustment

7.6.1

Travel

Adjustment

Limit

Setting

View

7.6.2

Carriage

Travel

8.

Blade

Information

8.1

Blade

Size

8.2

Blade

Tensioning

8.3

Blade

Installation

8.4

Blade

Break-In

Instructions

9.

Cutting

Speed

9.1

Machine

Speeds

9.2

Adjusting

Blade

Speed

9.3

Blade

Speed

Chart

10.

Cutting

Trouble-Shooting

Guide

11.

Warranty

12.

Lubrication

13.

Blade

Alignment

13.1

Alignment—Guide

Housing

with

Blade

13.2

Alignment—Blade

with

Table

13.3

Alignment

_

Blade

with

Miter

Block

14.

Assembly

Drawings

14.1

Table,

Clamp

Material

Stop

Assembly

14.2

Blade

Guide

Assembly

14.3

Slide

Assembly

14.4

Drive

Assembly

14.5

Carriage

Roller

Assembly

14.6

Electric

Schematic—Single

Phase

115/1/60

■■

14.7

Electric

Schematic—Three

Phase

14.8

Electric

Schematic—Single

Phase

230/1/06

••

INC.

BANDSAW

MACHINES

27

Kenhar

Drive,

Toronto,

Ontario

Canada

M9L

1M9

tel

(416)741-7100

fax

(416)

741-7114

email

February

12,

2016

S#

6429

TO

6433

inclusive

Page

115C-2

B>1XTER

Z^A

l/ERTICUf

1.

Forward:

INC.

Verticut

model

115-C

has

been

designed

and

built

to

meet

the

cutting

needs

of

the

majority

of

shops.

Care

has

been

taken

to

ensure

the

quality

of

all

parts

and

components

so

that

the

machine

will

provide

you

with

years

of

use.

This

manual

will

provide

all

specifications,

dimensions

and

maintenance

procedures.

2.

Notes:

•

Before

operating

the

machine

you

must

read

the

manual

thoroughly

to

familiarize

yourself

with

the

machine.

•

Machine

must

be

electrically

connected

through

a

fused

electrical

disconnect,

fused

to

the

rating

on

the

name

plate

and

conforming

to

all

local

electric

codes.

The

work

must

be

done

by

a

qualified

electrician.

•

For

information,

general

inquiries

or

the

name

of

the

nearest

dealer

please

call

Baxter

Verticut

Inc.

27

Kenhar

Drive

Weston

(Toronto),

Ontario

Canada

M9L

1M9

tel

(416)741-7100

fax

(416)741-7114

email

•

This

manual

is

copyrighted

by

Baxter

Verticut

and

no

parts

of

it

may

be

reproduced

without

the

written

consent

of

Baxter

Verticut.

3.

Safety

Instructions:

This

machine

is

a

powerful

metal

cutting

saw

It

would

have

no

problem

to

cut

you.

You

as

the

operator

must

treat

the

machine

with

respect

to

avoid

any

injures.

BE

CAREFUL!

WORK

SAFELY!

1.

Do

not

operate

this

machine

until

you

have

read

the

manual

and

been

instructed

on

all

standard

shop

safety

precautions.

2.

Keep

away

from

all

moving

parts.

Including

but

not

limited

to

the

following;

saw

blade,

blade

wheels,

pulleys,

v-belts,

motor,

etc.

3.

Never

operate

the

machine

unless

all

guards

are

in

place.

4.

The

machine

is

designed

for

use

by

only

one

operator,

do

not

let

two

people

work

on

the

machine

at

the

same

time.

5.

Always

keep

the

machine

and

your

work

area

clean

and

remove

all

obstacles.

6.

Never

load,

unload

stock

or

remove

cut

parts

from

the

machine

while

the

blade

is

running.

7.

Support

long

or

heavy

stock

in

the

front

and

rear

of

the

machine.

8.

Always

clamp

the

stock

securely

before

operating

the

machine.

9.

When

changing

the

blade

always

wear

gloves

and

safety

glasses.

Do

not

throw

the

blade

into

the

air

to

uncoil.

If

you

do

not

know

how

to

uncoil

the

blade

get

instructions

from

your

blade

supplier.

10.

Do

not

wear

jewelry,

gloves,

loose

clothing

or

have

long

hair

unconfined

while

operating

this

machine.

11.

When

performing

maintenance

work

on

the

bandsaw

machine

always

disconnect

the

power

supply.

12.

Use

the

proper

speeds,

feeds

and

coolant

as

required.

More

information

on

this

is

the

subsequent

chapters.

27

Kenhar

Drive,

Toronto,

Ontario

Canada

M9L

1M9

tel

(416)741-7100

fax

(416)

741-7114

email

February

12,

2016

S#

6429

TO

6433

inclusive

Page

1150-3

BylXTER

WA

U^RTICUf

4.

Machine

Specifications:

Cutting

Capacity

Round

@90°

Round

@90°

8

1/2"

length

limit

13"

Round

@

45°

Square

Blade

Dimensions

Blade

Speed

Blade

Tension

Blade

Guides

Wheel

Diameter

Blade

Drive

Voltage

Table

Height

Work

Table

Material

Clamping

Vise

Miter

Cutting

Machine

Weight

Maximum

Work

Load

Overall

Dimensions

5.

Views

of

Machine:

INC.

BANDSAW

MACHINES

7

1/2"

10"

1/4"

to

3/4"

X

10'

75,

130,

215,

350ft/min

30,000

psi

Hardened

Rollers

15

1/4"

3/4

hp

115

volts,

1

phase

30"

1"

X

18"

X

30"

ground

c-clamp

4"

diameter

+/-

45°

1,000

lbs.

1,600

lbs.

34"W

X

48"

D

X

68"H

255

mm

330

mm

190

mm

330

X

255

mm

6

mm

to

19

mm

x

3050

mm

22,40,

66,

107

m/min

387

mm

0.5

kW

762

mm

25

mm

x

457

mm

x762

mm

460

kg

680

kg

860x

1220x

1730

mm

5.1.1

Front

View

B

ade

Tension

Hand

e

Saw

Head

Door

Knob

1

A

aoasT

I

Blade

Guard

".1

Miter

Block

&

C-Clamp

Material

Stop

Motor

Starter

Carnage

Handle

Saw

Base

Foot

Pedal

Figure

1—Front

View

27

Kenhar

Drive,

Toronto,

Ontario

Canada

M9L

1M9

tel

(416)741-7100

fax

(416)

741-7114

email

February

12,

2016

S#6429

TO

6433

inclusive

Page

115C-4

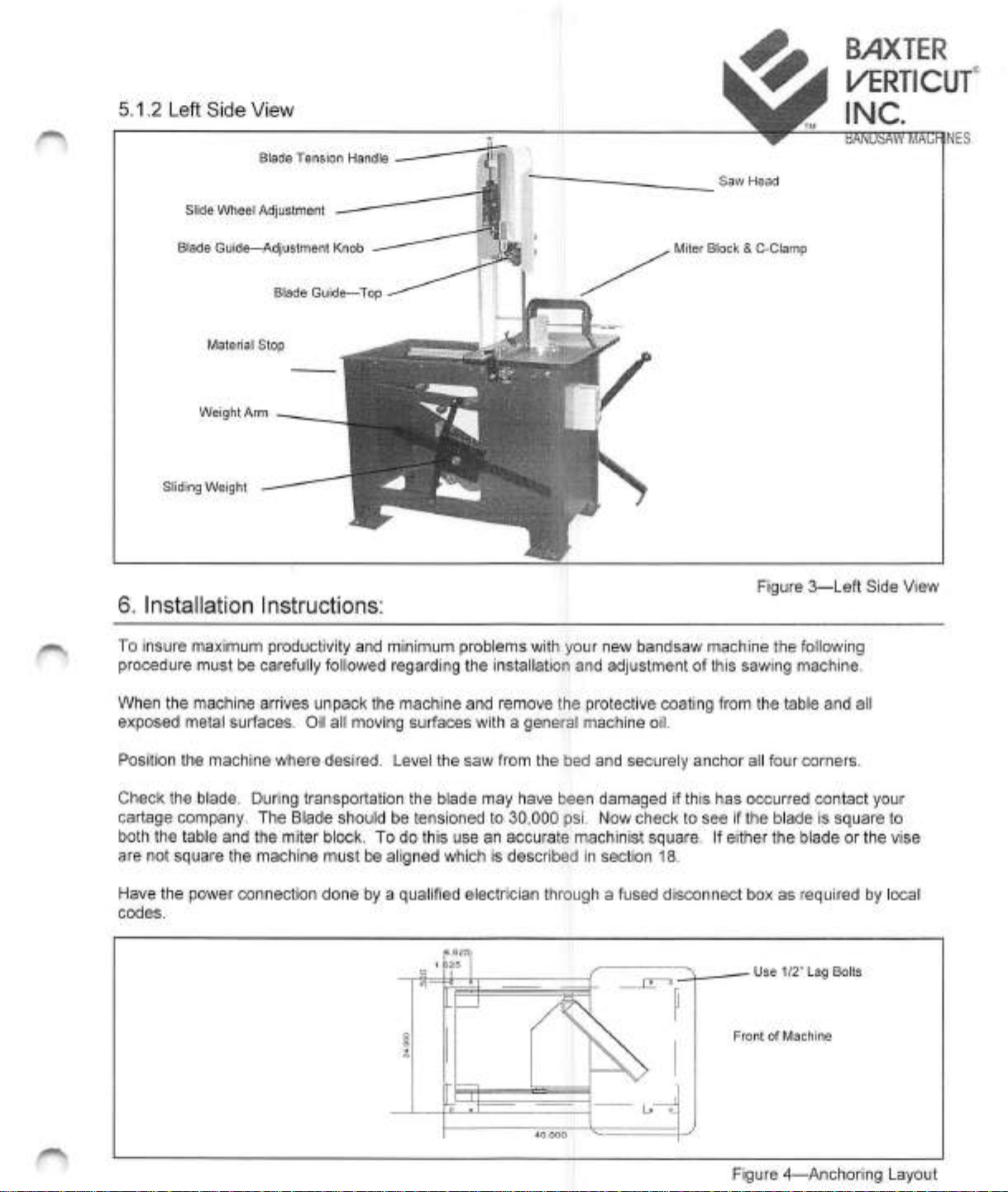

5.1.2

Left

Side

View

B>iXTER

U^RTICUr

INC.

Blade

Tension

Handle

Slide

Wheel

Adjustment

Blade

Guide—Adjustment

Knob

Blade

Guide—^Top

Saw

Head

Miter

Block

&

C-Clamp

Material

Stop

Weight

Arm

Sliding

Weight

6.

Installation

Instructions:

Figure

3—Left

Side

View

To

insure

maximum

productivity

and

minimum

problems

with

your

new

bandsaw

machine

the

following

procedure

must

be

carefully

followed

regarding

the

installation

and

adjustment

of

this

sawing

machine.

When

the

machine

arrives

unpack

the

machine

and

remove

the

protective

coating

from

the

table

and

all

exposed

metal

surfaces.

Oil

all

moving

surfaces

with

a

general

machine

oil.

Position

the

machine

where

desired.

Level

the

saw

from

the

bed

and

securely

anchor

all

four

corners.

Check

the

blade.

During

transportation

the

blade

may

have

been

damaged

if

this

has

occurred

contact

your

cartage

company.

The

Blade

should

be

tensioned

to

30,000

psi.

Now

check

to

see

if

the

blade

is

square

to

both

the

table

and

the

miter

block.

To

do

this

use

an

accurate

machinist

square.

If

either

the

blade

or

the

vise

are

not

square

the

machine

must

be

aligned

which

is

described

in

section

18.

Have

the

power

connection

done

by

a

qualified

electrician

through

a

fused

disconnect

box

as

required

by

local

codes.

Use

1/2

Lag

Bolts

Front

of

Machine

Figure

4—Anchoring

Layout

27

Kenhar

Drive,

Toronto,

Ontario

Canada

M9L

1M9

tel

(416)741-7100

fax

(416)

741-7114

email

February

12,

2016

S#

6429

TO

6433

inclusive

Page

1150-5

7.

Operating

Instructions:

7.1

Electric

Control

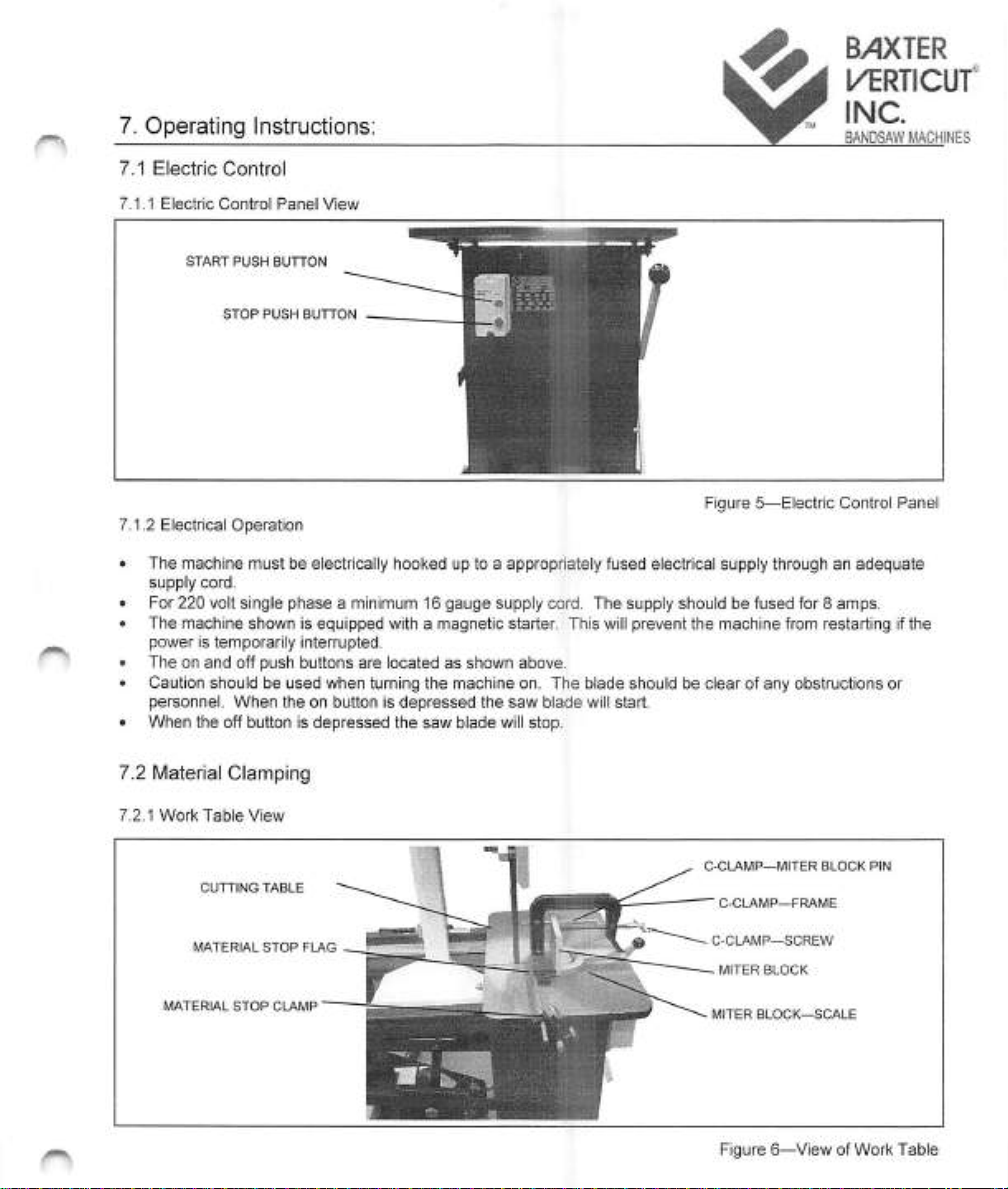

7.1.1

Electric

Control

Panel

View

START

PUSH

BUTTON

STOP

PUSH

BUTTON

BAXTER

l/^RTICUr

INC.

BANOSAW

MACHINES

Figure

5—Electric

Control

Panel

7.1.2

Electrical

Operation

•

The

machine

must

be

electrically

hooked

up

to

a

appropriately

fused

electrical

supply

through

an

adequate

supply

cord.

•

For

220

volt

single

phase

a

minimum

16

gauge

supply

cord.

The

supply

should

be

fused

for

8

amps.

•

The

machine

shown

is

equipped

with

a

magnetic

starter.

This

will

prevent

the

machine

from

restarting

if

the

power

is

temporarily

interrupted,

•

The

on

and

off

push

buttons

are

located

as

shown

above.

•

Caution

should

be

used

when

turning

the

machine

on.

The

blade

should

be

clear

of

any

obstructions

or

personnel.

When

the

on

button

is

depressed

the

saw

blade

will

start.

•

When

the

off

button

is

depressed

the

saw

blade

will

stop.

7.2

Material

Clamping

7.2.1

Work

Table

View

CUTTINGTABLE

MATERIAL

STOP

FLAG

MATERIAL

STOP

CLAMP

C-CLAMP—MITER

BLOCK

PIN

C-C

LAMP—FRAME

C-CLAMP—SCREW

MITER

BLOCK

MITER

BLOCK—SCALE

Figure

6—View

of

Work

Table

27

Kenhar

Drive,

Toronto,

Ontario

Canada

I\/I9L

1M9

tel

(416)741-7100

fax

(416)

741-7114

email

February

12.

2016

S#

6429

TO

6433

inclusive

Page

1150-6

B/IXTER

WA

l/ERTICUr

7.2.2

Miter

Block

INC.

BANDSAW

MACHINES

•

The

miter

block

is

used

to

brace

the

material

to

be

clamped.

•

The

miter

block

can

be

set

at

0°

or

between

±45°

for

miter

cutting.

•

The

scale

is

on

the

miter

block

and

the

zero

is

punched

onto

the

work

table.

•

The

miter

block

is

held

in

place

with

a

dowel

pin

and

a

bolt.

A

9/16"

wrench

is

required

to

loosen

the

bolt.

7.2.3

C-Clamp

•

The

c-clamp

is

used

to

hold

clamp

the

material

against

the

work

vise.

•

The

c-clamp

can

be

located

on

either

side

of

the

saw

blade

and

is

located

by

pushing

the

pin

through

the

miter

block.

•

The

c-clamp

can

clamp

material

up

to

4"

in

diameter.

7.2.4

Material

Stop

•

The

material

clamp

is

used

to

do

repetitive

cutting.

•

The

distance

is

set

by

clamping

the

material

flag

to

the

desired

distance.

•

The

material

clamp

assembly

is

held

in

a

block

under

table.

7.3

Saw

Carriage

Movement

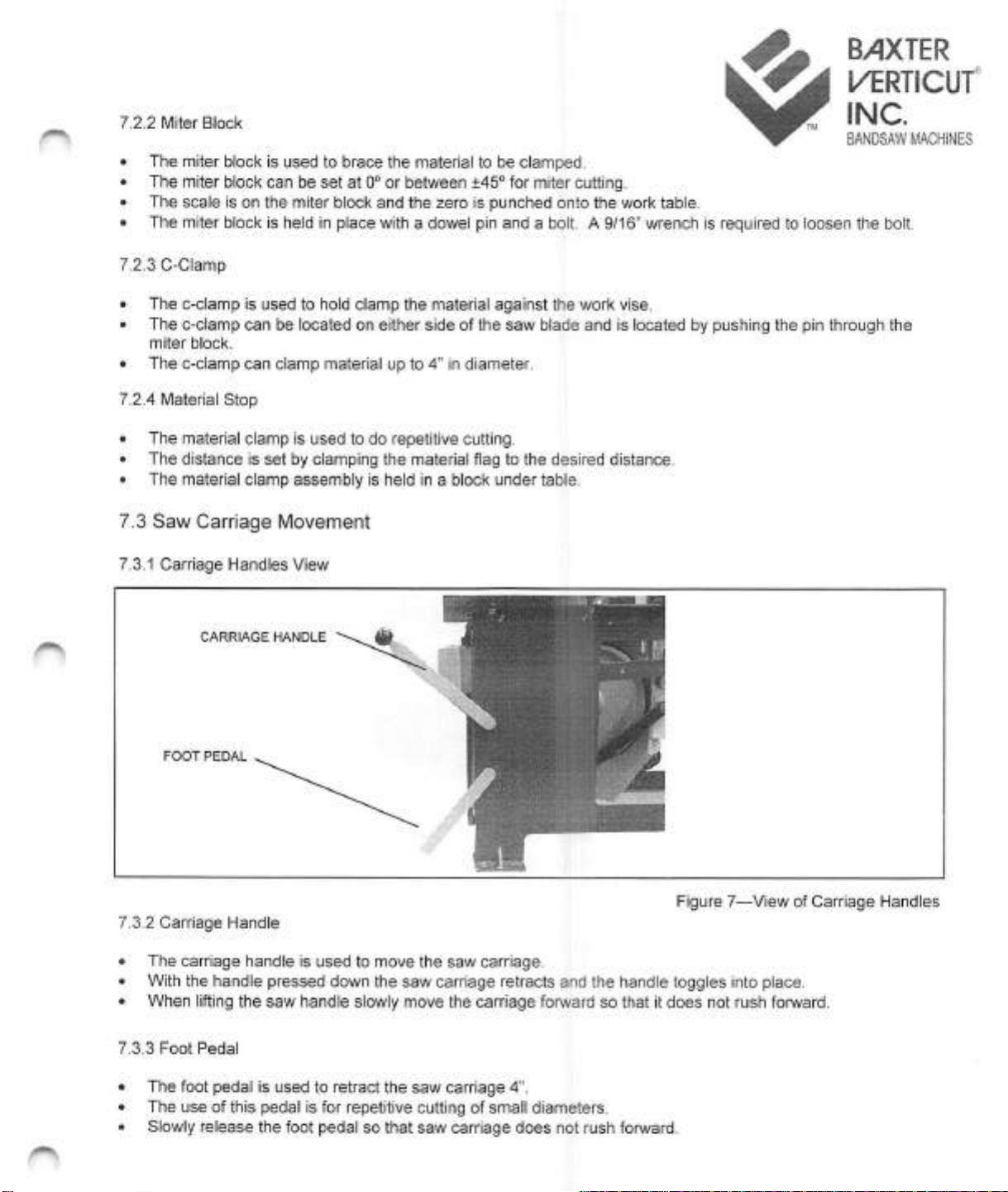

7.3.1

Carnage

Handles

View

CARRIAGE

HANDLE

Figure

7—View

of

Carriage

Handles

7.3.2

Carriage

Handle

•

The

carriage

handle

is

used

to

move

the

saw

carriage.

•

With

the

handle

pressed

down

the

saw

carriage

retracts

and

the

handle

toggles

into

place.

•

When

lifting

the

saw

handle

slowly

move

the

carriage

forward

so

that

it

does

not

rush

forward.

7.3.3

Foot

Pedal

•

The

foot

pedal

Is

used

to

retract

the

saw

carriage

A".

•

The

use

of

this

pedal

is

for

repetitive

cutting

of

small

diameters.

•

Slowly

release

the

foot

pedal

so

that

saw

carriage

does

not

rush

forward.

27

Kenhar

Drive,

Toronto,

Ontario

Canada

M9L

1M9

tel

(416)741-7100

fax

(416)

741-7114

email

February

12,

2016

S#

6429

TO

6433

inclusive

Page

115C-7

^

BAXTER

WA

l^RTICUr

7.4

Saw

Operation

INC.

^

8ANDSAW

MACHINES

•

Clamp

material

firmly

making

certain

that

the

material

is

level

and

square

with

the

machine.

•

To

assure

good

blade

life,

use

a

blade

that

has

at

least

three

teeth

in

contact

with

the

material

at

all

times.

•

Start

the

saw.

•

Advance

the

saw

blade

do

not

release

the

handle

until

the

cut

has

begun.

Lack

of

care

at

this

point

could

result

in

loss

of

blade

alignment.

•

The

counter

weight

on

the

left

side

of

the

machine

will

adjust

the

cutting

pressure

to

suit

the

thickness

of

material

and

the

blade

size.

•

When

the

saw

cut

is

finished

press

the

stop

button

to

turn

the

machine

off.

7.5

Cutting

Force

7.5.1

Adjusting

Cutting

Force

View

7.5.2

Cutting

Pressure

Adjustment

Figure

8—Hydraulic

Control

Panel

View

The

cutting

pressure

is

adjusted

by

positioning

the

weight

on

the

weight

cross

arm.

Position

the

weight

to

the

front

on

the

machine

for

a

greater

cutting

pressure,

while

towards

the

back

decreases

the

cutting

pressure.

Low

cutting

pressure

is

used

for

soft

materials

such

as

aluminum,

while

higher

pressure

are

used

for

tool,

and

machinery

steels

and

materials

which

work

harden.

7.6

Saw

Travel

Adjustment

7.6.1

Travel

Adjustment

Limit

Setting

View

SAW

CARRIAGE

AUTOMATIC

STOP

LIMIT

SWITCH

(optional)

CARRIAGE

STOP

DEPTH

OF

CUT

SCALE

Figure

9—Travel

Limit

Switches

View

27

Kenhar

Drive,

Toronto,

Ontario

Canada

IVI9L

11VI9

tel

(416)741-7100

fax

(416)

741-7114

email

info(gverticut.com

February

12,

2016

S#

6429

TO

6433

inclusive

Page

115C-8

B/IXTER

I/ERTICUf

7.6.2

Carriage

Travel

INC.

^

BANOSAW

MACHINES

The

carriage

travel

can

be

set

to

stop

the

carriage

from

cutting

all

the

way

through

the

material,

used

for

notching

blocks.

This

is

accomplished

by

moving

carriage

stop

clamp.

The

depth

of

cut

is

shown

on

the

scale

mounted

on

the

saw

base.

To

contour

cut

the

saw

head

is

locked

In

the

front

position.

To

do

this

move

the

carriage

to

the

front,

undo

the

stop

clamp

and

remove

it

from

the

base

rail,

reposition

the

stop

clamp

so

that

It

Is

behind

the

saw

carriage

and

then

tighten

the

screw,

thereby

locking

it

Into

place.

If

the

saw

Is

equipped

with

the

automatic

shut

off

the

saw

will

stop

whenever

the

carriage

strikes

the

stop

clamp.

Also

the

head

can

not

be

locked

in

the

forward

position

because

the

stop

clamp

will

Interfere

with

the

limit

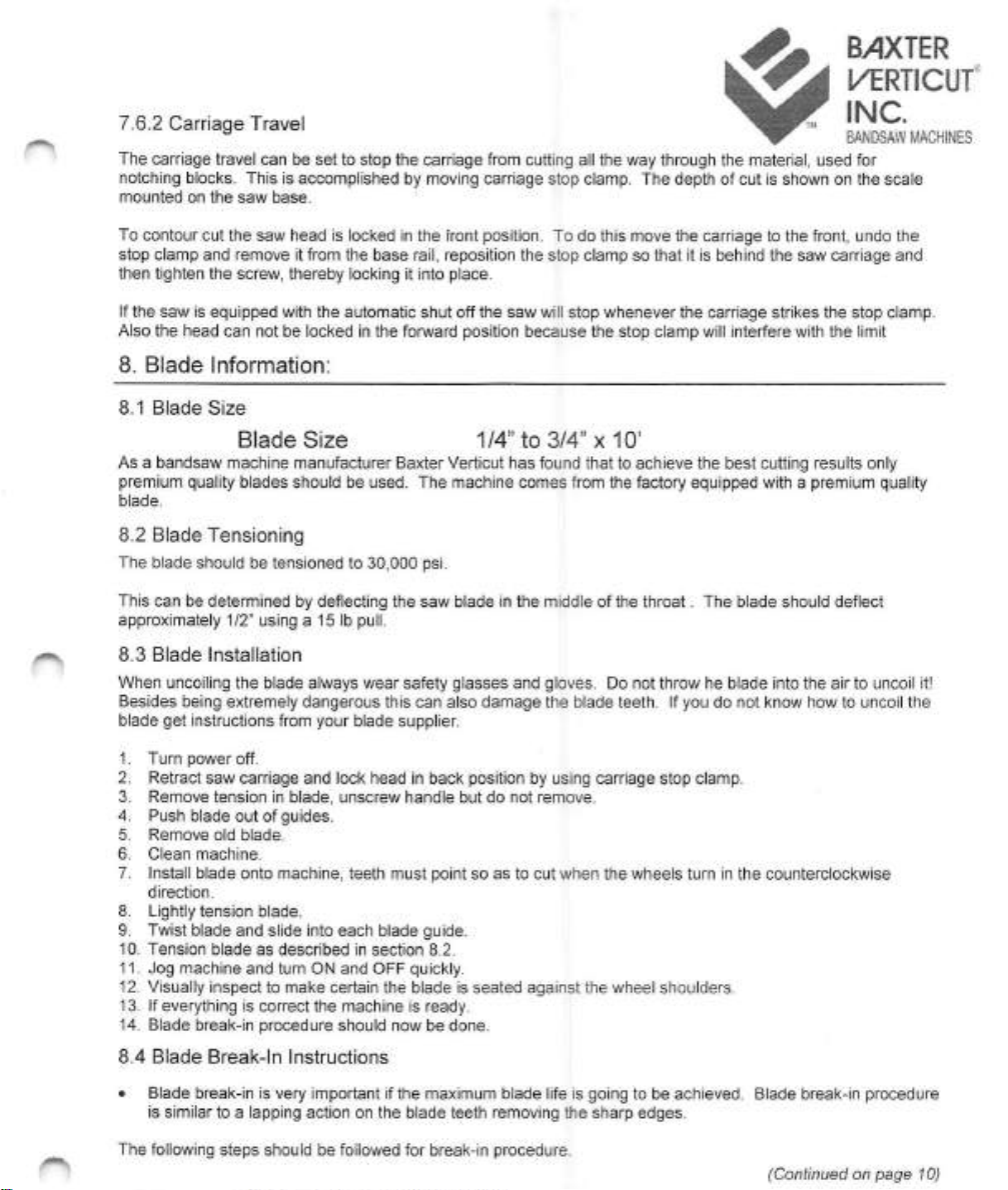

8.

Blade

Information:

8.1

Blade

Size

Blade

Size

1/4"

to

3/4"

x

10'

As

a

bandsaw

machine

manufacturer

Baxter

Vertlcut

has

found

that

to

achieve

the

best

cutting

results

only

premium

quality

blades

should

be

used.

The

machine

comes

from

the

factory

equipped

with

a

premium

quality

blade.

8.2

Blade

Tensioning

The

blade

should

be

tensioned

to

30,000

psi.

This

can

be

determined

by

deflecting

the

saw

blade

In

the

middle

of

the

throat.

The

blade

should

deflect

approximately

1/2"

using

a

15

lb

pull.

8.3

Blade

Installation

When

uncoiling

the

blade

always

wear

safety

glasses

and

gloves.

Do

not

throw

he

blade

into

the

air

to

uncoil

it!

Besides

being

extremely

dangerous

this

can

also

damage

the

blade

teeth.

If

you

do

not

know

how

to

uncoil

the

blade

get

instructions

from

your

blade

supplier.

1.

Turn

power

off.

2.

Retract

saw

carriage

and

lock

head

In

back

position

by

using

carriage

stop

clamp.

3.

Remove

tension

in

blade,

unscrew

handle

but

do

not

remove.

4.

Push

blade

out

of

guides.

5.

Remove

old

blade.

6.

Clean

machine.

7.

Install

blade

onto

machine,

teeth

must

point

so

as

to

cut

when

the

wheels

turn

in

the

counterclockwise

direction.

8.

Lightly

tension

blade.

9.

Twist

blade

and

slide

into

each

blade

guide.

10.

Tension

blade

as

described

in

section

8.2.

11.

Jog

machine

and

turn

ON

and

OFF

quickly.

12.

Visually

inspect

to

make

certain

the

blade

is

seated

against

the

wheel

shoulders.

13.

If

everything

Is

correct

the

machine

Is

ready.

14.

Blade

break-In

procedure

should

now

be

done.

8.4

Blade

Break-In

Instructions

•

Blade

break-in

is

very

important

if

the

maximum

blade

life

is

going

to

be

achieved.

Blade

break-In

procedure

is

similar

to

a

lapping

action

on

the

blade

teeth

removing

the

sharp

edges.

The

following

steps

should

be

followed

for

break-in

procedure.

(Continued

on

page

10)

27

Kenhar

Drive,

Toronto,

Ontario

Canada

M9L

1M9

tel

(416)741-7100

fax

(416)

741-7114

email

February

12,

2016

S#

6429

TO

6433

Inclusive

Page

115C-9

BAXTER

1/ERTiCUf

(Continued

from

page

9)

BAN

1.

Select the

proper

cutting

speed

for

the

material

to

be

cut.

2.

Cut

a

25%

of

the

normal

cutting

pressure

setting

for

10

minutes

3.

Increase

cutting

pressure

to

50%

of

normal

setting

and

cut

for

10

minutes

4.

Increase

cutting

pressure

to

75%

of

normal

setting

and

cut

for

10

minutes.

5.

Increase

cutting

pressure

to

100%

of

normal

and

proceed

to

cut.

Check

with

you

blade

supplier

for

specific

instructions.

The

blade

equipped

on

the

machine

from

the

factory

has

already

been

broken-in

for

your

convenience.

9.

Cutting

Speed:

9.1

Machine

Speeds

Machine

Speeds

mSS

75.

130,

215,

350

ft/min

^

GEARBOX

PULLEY

23,

40,

65,

107

m/min

V-BELT

3VX-335

OTOR

PULLEY

BELT

TENSION

SETTING

SCREW

9.2

Adjusting

Blade

Speed

Figure

10—Drive

Pulleys

1.

Turn

machine

off

and

lock

out.

2.

Move

carriage

forward.

3.

Lift

up

motor

and

move

belt

to

desired

speed.

Belt

must

be

on

pulley

steps

which

are

in

line

with

each

other.

4.

Lower

motor.

5.

Machine

is

ready.

9.3

Blade

Speed

Chart

(for

bimetal

blades)

MATERIAL

CARBON

STEEL—LOW

&

MEDIUM

130—215

CARBON

STEEL—HIGH

75—130

STRUCTURAL

STEEL

130—215

FREE

CUTTING

MATERIAL

215

DIE

STEEL

75

TOOL

STEEL

75

HOT

WORK

STEEL

75—130

STAINLESS

STEEL

75

CAST

IRON

130

ALUMINUM

350

SPEED

(FEET

PER

MINUTE)

27

Kenhar

Drive,

Toronto.

Ontario

Canada

M9L

1M9

tel

(416)741-7100

fax

(416)

741-7114

email

February

12,

2016

S#6429

TO

6433

inclusive

Page

115C-10

10.

Cutting

Trouble-Shooting

Guide:

B>1XTER

l/ERTiCUf

INC.

BANDSAW

MACHINES

PROBLEM

excessive

blade

breakage

not

cutting

square

blade

twisting

teeth

stripping

PROBABLE

CAUSE

teeth

too

coarse

misalignment

of

guides

excessive

tension

blade

speed

too

fast

excessive

feed

vise

not

square

material

not

square

excessive

pressure

improper

blade

tension

blade

dull

excessive

blade

pressure

blade

jamming

in

cut

SOLUTION

use

finer

pitch

adjust

blade

guides

adjust

blade

tension

lower

speed

reduce

feed

square

vise

clamp

material

correctly

reduce

feed

pressure

adjust

tension

change

blade

adjust

feed

pressure

decrease

feed

pressure

blade

not

in

alignment

with

guide

check

guide

for

wear

and

adjust

material

not

clamped

securely

in

vise

gullets

filling

13

teeth

not

in

contact

with

'

material

^

excessive

feed

clamp

material

firmly

use

coarser

pitch

use

finer

pitch

reduce

feed

early

tooth

wear

excessive

speed

blade

too

coarse

feed

too

low

j

decrease

speed

'

use

finer

pitch

increase

feed

blade

will

not

cut

blade

teeth

pointing

in

the

wrong

remove

blade,

turn

blade

inside

direction

out,

teeth

must

point

in

direction

of

travel

motor

fails

to

develop

full

power,

low

voltage

overload

power

line

overload

under

size

wire

air

circulation

to

motor

is

restricted

correct

supply

voltage

reduce

load

on

line

trips

increase

wire

size

and

or

diameter

clean

air

vents

in

motor

27

Kenhar

Drive,

Toronto.

Ontario

Canada

M9L

1M9

tel

(416)741-7100

fax

(416)

741-7114

email

February

12,

2016

S#

6429

TO

6433

inclusive

Page

1150-11

B>1XTER

L^RTICUf

INC.

11

Warrantv

BANDSAW

MACHINES

The

machine

is

warranted

to

be

free

from

failure

resulting

from

defective

material

and

workmanship

under

proper

use

and

service

for

a

period

of

one

year,

single

shift

use,

from

the

date

of

shipment

to

the

end

user.

Baxter

Verticut's

sole

obligation

under

this

warranty

is

limited

to

repair

or

replacement

without

charge

of

any

part

which

our

inspection

discloses

to

be

defective,

all

work

is

done

at

Baxter

Verticut's

factory.

A

return

goods

authorization

number

must

be

first

obtained

and

return

freight

must

be

prepaid.

The

warranty

does

not

cover

maintenance

and

wear

items,

including

but

not

limited

to;,

saw

blade,

belts,

filters,

oil,

etc.

Electric

motor,

pumps,

electric

components,

hydraulic

components,

hoses

and

any

other

items

used

in

the

construction

of

the

machine,

but

not

made

by

Baxter

Verticut

are

subject

to

the

warranty

of

the

original

equipment

makers

warranty.

Liability

and

or

obligation

by

Baxter

Verticut

for

damages,

whether

general,

special

or

for

negligence

and

expressly

including

any

incidental

and

consequential

damages

is

herby

disclaimed.

Baxter

Verticut's

sole

obligation

to

repair

or

replace

shall

be

the

limit

of

its

liability

under

this

warranty.

Baxter

Verticut

Inc.

is

not

responsible

for

any

consequential

damage

resulting

from

the

failure

of

our

machine,

regardless

of

the

cause.

This

is

the

only

warranty

which

applies.

12.

Lubrication:

ITEM

LUBRICANT

QUANTITY

FREQUENCY

Gearbox

Argon

EP1

1

Kilogram

Yearly

General

Oil

ESSO

Febis

K68

As

required

Dally

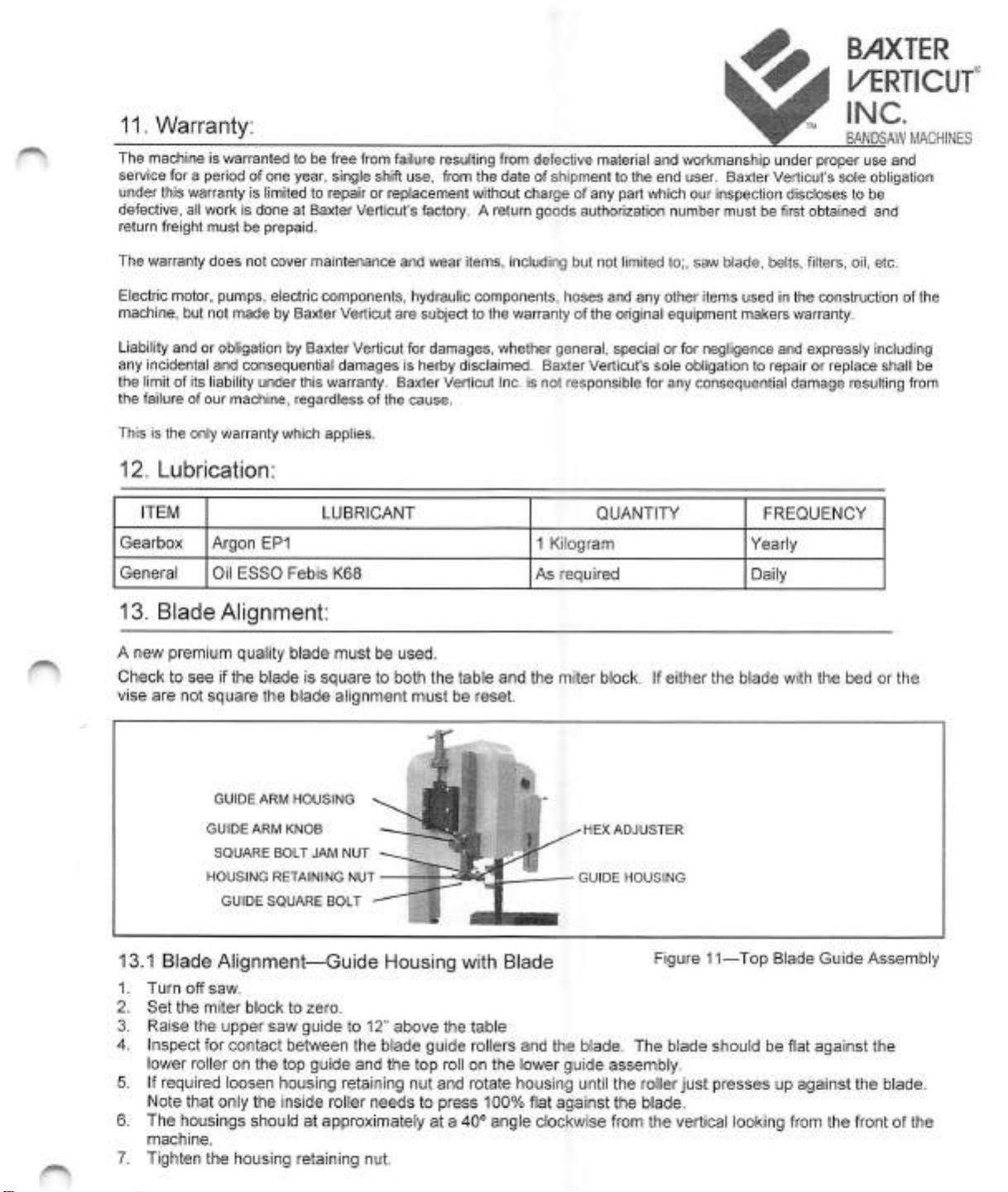

13.

Blade

Alignment:

A

new

premium

quality

blade

must

be

used.

Check

to

see

If

the

blade

Is

square

to

both

the

table

and

the

miter

block.

If

either

the

blade

with

the

bed

or

the

vise

are

not

square

the

blade

alignment

must

be

reset.

HEX

ADJUSTER

GUIDE

HOUSING

GUIDE

ARM

HOUSING

GUIDE

ARM

KNOB

SQUARE

BOLT

JAM

NUT

HOUSING

RETAINING

NUT

GUIDE

SQUARE

BOLT

13.1

Blade

Alignment—Guide

Housing

with

Blade

Figure

11—Top

Blade

Guide

Assembly

1.

Turn

off

saw.

2.

Set

the

miter

block

to

zero.

3.

Raise

the

upper

saw

guide

to

12"

above

the

table

4.

Inspect

for

contact

between

the

blade

guide

rollers

and

the

blade.

The

blade

should

be

flat

against

the

lower

roller

on

the

top

guide

and

the

top

roll

on

the

lower

guide

assembly.

5.

If

required

loosen

housing

retaining

nut

and

rotate

housing

until

the

roller

just

presses

up

against

the

blade.

Note

that

only

the

inside

roller

needs

to

press

100%

flat

against

the

blade.

6.

The

housings

should

at

approximately

at

a

40°

angle

clockwise

from

the

vertical

looking

from

the

front

of

the

machine.

7.

Tighten

the

housing

retaining

nut.

27

Kenhar

Drive,

Toronto,

Ontario

Canada

M9L

1M9

tel

(416)741-7100

fax

(416)

741-7114

email

February

12,

2016

S#

6429

TO

6433

Inclusive

Page

1150-12

B/IXTER

l/ERTICUf

13.2

Blade

Alignment—Blade

with

Table

INC.

BANDSAW

MACHINES

1.

Turn

off

saw.

2.

Set

the

miter

block

to

zero.

3.

Move

the

saw

carriage

to

the

forward

position.

4.

Raise

the

upper

saw

guide

to

12"

above

the

table

5.

Check

to

see

if

the

blade

Is

square

to

the

table.

6.

If

not

square

release

the

square

bolt

jam

nut

and

rotate

the

guide

square

bolt

until

the

blade

is

square

to

the

table.

7.

Tighten

jam

nut.

13.3

Blade

Alignment—Blade

with

Miter

Block

1.

Turn

off

saw.

2.

Set

the

miter

block

to

zero.

3.

Move

the

saw

carriage

to

the

forward

position.

4.

Raise

the

upper

saw

guide

to

12"

above

the

table

5.

Check

to

see

if

blade

is

square

to

the

miter

block.

6.

Readjust

miter

block

to

make

square.

7.

Hold

square

on

miter

block

and

against

blade.

Retract

carriage

and

see

if

movement

is

parallel

to

square.

8.

If

still

not

square

start

over

as

described

in

section

13.1

and

13.2.

9.

If

problems

still

exist

contact

the

factory

for

further

assistance.

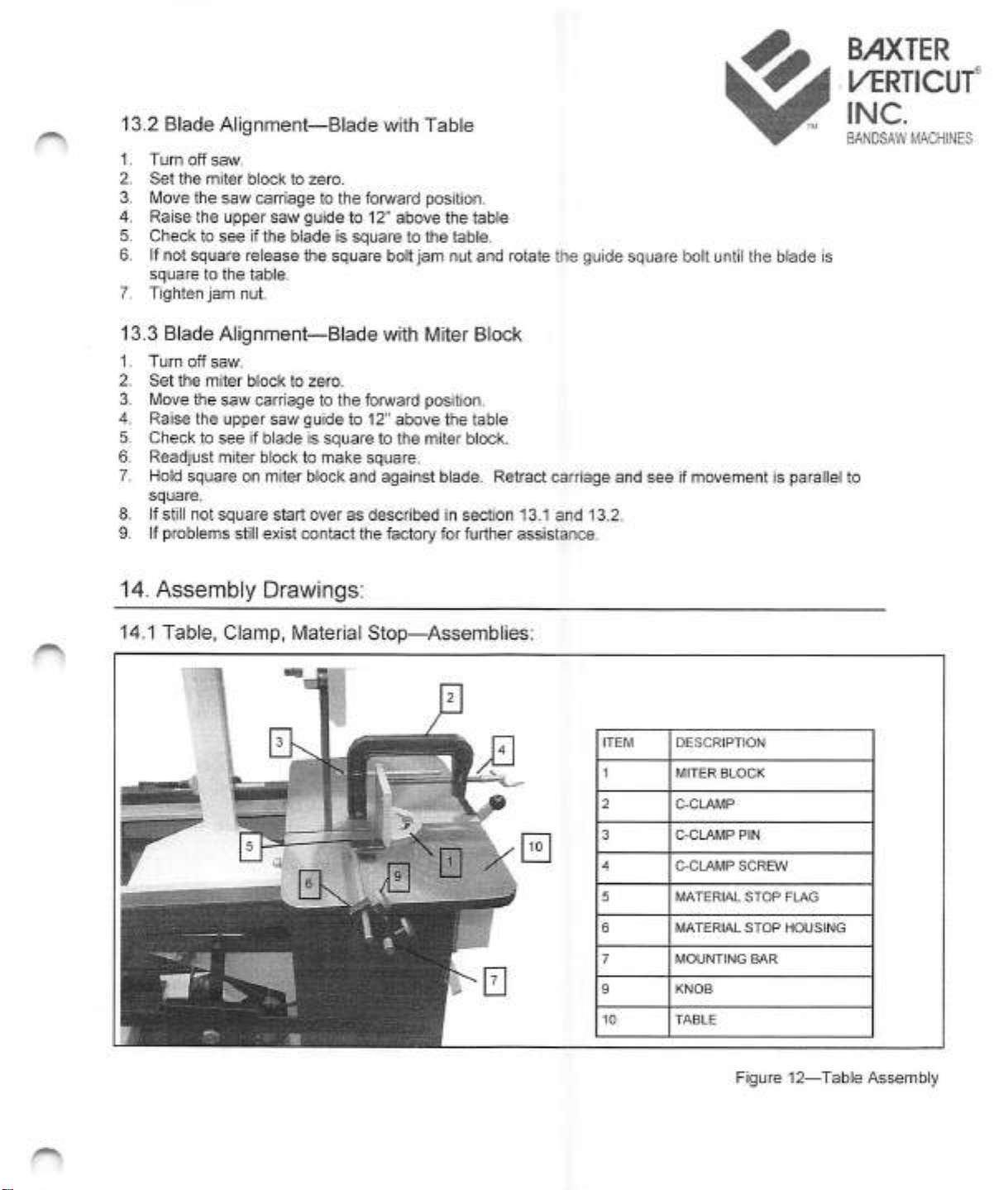

14.

Assembly

Drawings:

14.1

Table,

Clamp.

Material

Stop—^Assemblies;

DESCRPTON

MITER

BLOCK

C-CLAMP

C-CLAMP

PIN

C-CLAMP

SCREW

MATERIAL

STOP

FLAG

MATERIAL

STOP

HOUSING

MOUNTING

BAR

Figure

12—Table

Assembly

27

Kenhar

Drive,

Toronto,

Ontario

Canada

M9L

1M9

tel

(416)741-7100

fax

(416)

741-7114

email

February

12,

2016

S#6429

TO

6433

inclusive

Page

1150-13

14.2

Blade

Guide

Assembly

14.3

Slide

Assembly:

TM

BAXTER

L/ERTICUr

INC.

BANDSAW

MACHINES

QTY

DESCRIPTION

BLADE

GUIDE

ROLLER

BLADE

GUIDE

HOUSING

HEX

ADJUSTING

BOLT

SWING

BOLT

GUIDE

ARM

BAR

BEARING

1011562

ARM

HOUSING

HOUSING

BASE

GUIDE

ARM

KNOB

LOWER

TEE

BLOCK

SWING

ARM

JAM

NUT

HOUSING

LOCKING

NUT

WASHER

Figure

13—Blade

Guide

Assembly

DESCRIPTION

WHEEL—SLIDE

WASHER

BEARING

6011526

RETAINING

RING

BEAR

NG

SPACER

SLIDE

PLATE

SL

DERAILS

HANDLE

BODY

HANDLE

BLOCK

RUBBER

BAND

Figure

14—Slide

Assembly

27

Kenhar

Drive,

Toronto,

Ontario

Canada

M9L

1M9

tel

(416)741-7100

fax

(416)

741-7114

email

February

12,

2016

S#

6429

TO

6433

Inclusive

Page

1150-14

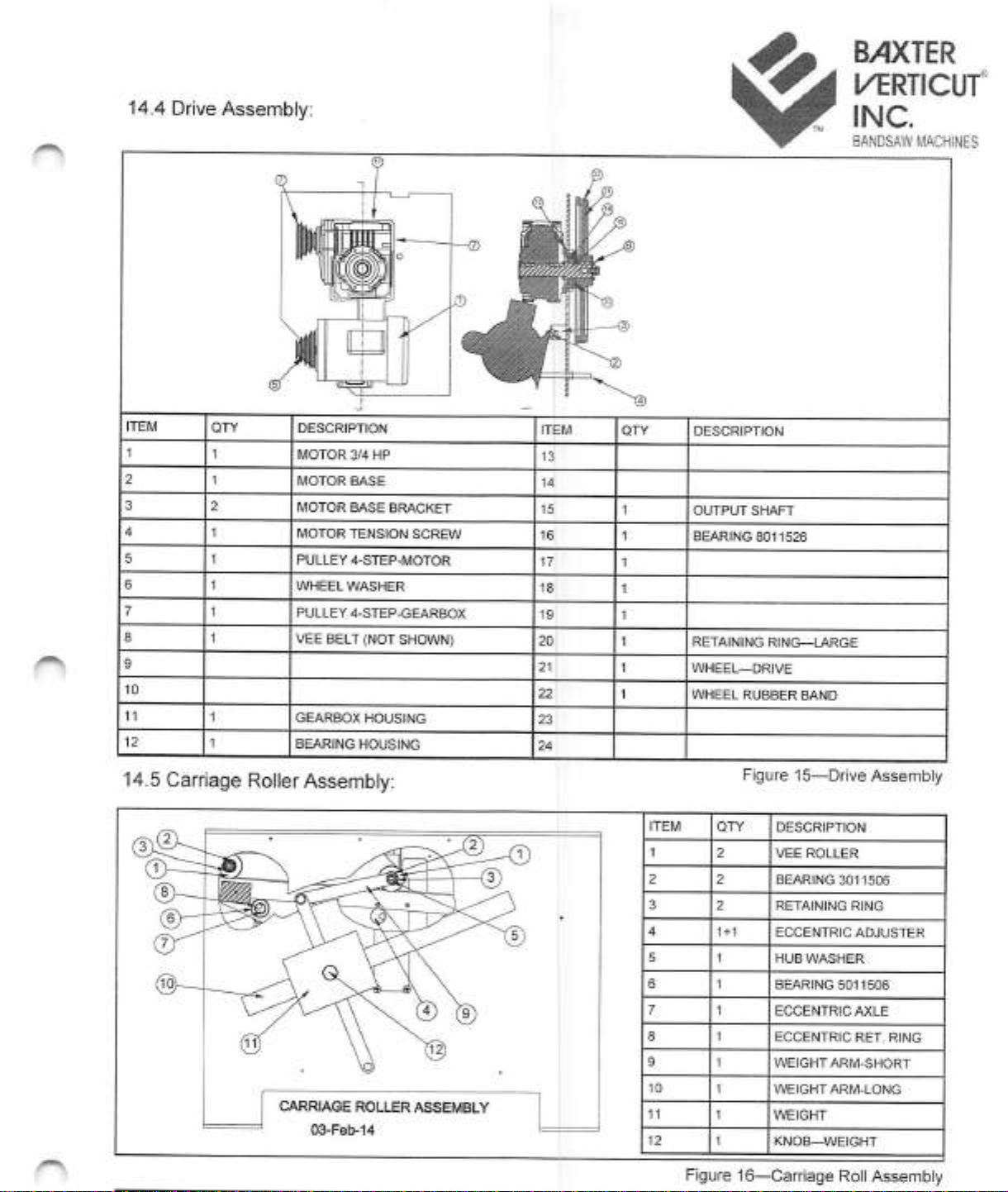

14.4

Drive

Assembly:

BAXTER

U^RTICUf

INC.

BANDSAW

MACHINES

DESCRIPTION

DESCRIPTON

MOTOR

3/4

HP

MOTOR

BASE

MOTOR

BASE

BRACKET

OUTPUT

SHAFT

MOTOR

TENSION

SCREW

BEARING

8011526

PULLEY

4-STEP-MOTOR

WHEEL

WASHER

PULLEY

4-STEP-GEARBOX

VEE

BELT

(NOT

SHOWN)

RETAINING

RING—LARGE

WHEEL—DRIVE

WHEEL

RUBBER

BAND

GEARBOX

HOUSING

BEARING

HOUSING

Figure

15—Drive

Assembly

14.5

Carriage

Roller

Assembly:

DESCRIPTION

VEE

ROLLER

BEARING

3011506

RETAINING

RING

ECCENTRIC

ADJUSTER

HUB

WASHER

BEARING

5011506

ECCENTRIC

AXLE

ECCENTRIC

RET,

RING

WEIGHT

ARM-SHORT

WEIGHT

ARM-LONG

CARRIAGE

ROLLER

ASSEMBLY

WEIGHT

03-Feb-14

KNOB—WEIGHT

Figure

16—Carriage

Roll

Assembly

27

Kenhar

Drive,

Toronto,

Ontario

Canada

M9L

1M9

tel

{416)741-7100

fax

(416)

741-7114

email

info(@verticut,com

February

12,

2016

S#

6429

TO

6433

inclusive

Page

115C-15

B>IXTER

ZwA

l/ERTICI

l/ERTICU

14.6

Electric

Schematic-Single

Phase-115/1/60

T

INC.

BANDSAW

MACHINES

OPTIONAL

MACHINE

SERIAL

NUMBEf

IPAGE

1

OF

1

1

FILE

DIR.:

C:\DC\MISC\ELEC^

6403

TO

6415

INCLUSIVE

1

DWG.NO.

115C-S#64D3TO

6415INCL-151105-12H

27

Kenhar

Drive,

Toronto.

Ontario

Canada

M9L

1I\/19

tel

(416)741-7100

fax

(416)

741-7114

email

February

12,

2016

S#

6429

TO

6433

inclusive

Page

1150-16

Table of contents

Popular Saw manuals by other brands

DeWalt

DeWalt DWS5100 manual

TYROLIT Hydrostress

TYROLIT Hydrostress FSD1274 Series operating instructions

Wen

Wen CT1274 instruction manual

Mafell

Mafell MS 55 / 36 V Original operating instructions

Bosch

Bosch 1671K - Litheon 36V 6 1/2? Circular Saw parts list

Feider Machines

Feider Machines FSOR20V-U instruction manual