BAYKON BX11 User manual

BX11

Smart Process Indicator

User Manual

BX11 Smart Process Indicator, User Manual, Rev. 1.8, May 2017

Pa e

1

of

48

S

AFETY

I

NSTRUCTIONS

CAUTION! READ THIS MANUAL BEFORE OPERATING OR SERVICING THIS EQUIPMENT.

FOLLOW THESE INSTRUCTIONS CAREFULLY. SAVE THIS MANUAL FOR FUTURE

REFERENCE. DO NOT ALLOW UNTRAINED PERSONNEL TO OPERATE, CLEAN, INSPECT,

MAINTAIN, SERVICE, OR TAMPER WITH THIS EQUIPMENT. ALWAYS DISCONNECT THIS

EQUIPMENT FROM THE POWER SOURCE BEFORE CLEANING OR PERFORMING

MAINTENANCE. CALL BAYKON ENGINEERING FOR PARTS, INFORMATION, AND SERVICE.

WARNING! ONLY PERMIT QUALIFIED PERSONNEL TO SERVICE THIS EQUIPMENT.

EXERCISE CARE WHEN MAKING CHECKS, TESTS AND ADJUSTMENTS THAT MUST BE

MADE WITH POWER ON. FAILING TO OBSERVE THESE PRECAUTIONS CAN RESULT IN

BODILY HARM.

WARNING! FOR CONTINUED PROTECTION AGAINST SHOCK HAZARD CONNECT TO

PROPERLY GROUNDED OUTLET ONLY. DO NOT REMOVE THE GROUND PRONG.

WARNING! DISCONNECT ALL POWER TO THIS UNIT BEFORE REMOVING ANY

CONNECTION, OPENING THE ENCLOSURE OR SERVICING.

WARNING! BEFORE CONNECTING/DISCONNECTING ANY INTERNAL ELECTRONIC

COMPONENTS OR INTERCONNECTING WIRING BETWEEN ELECTRONIC EQUIPMENT

ALWAYS REMOVE POWER AND WAIT AT LEAST THIRTY (30) SECONDS BEFORE ANY

CONNECTIONS OR DISCONNECTIONS ARE MADE. FAILURE TO OBSERVE THESE

PRECAUTIONS COULD RESULT IN DAMAGE TO OR DESTRUCTION OF THE EQUIPMENT

OR BODILY HARM.

CAUTION! OBSERVE PRECAUTIONS FOR HANDLING ELECTROSTATIC SENSITIVE

DEVICES.

RIGHTS AND LIABILITIES

All ri hts reserved.

No part of this publication may be reproduced, stored in a retrieval system, or transmitted in any form or by any

means, mechanical, photocopyin , recordin , or otherwise, without the prior written permission of BAYKON A.S.

No patent liability is assumed with respect to the use of the information contained herein. While every precaution

has been taken in the preparation of this book, BAYKON assumes no responsibility for errors or omissions. Neither

is any liability assumed for dama es resultin from the use of the information contained herein.

The information herein is believed to be both accurate and reliable. BAYKON, however, would be obli ed to be

informed if any errors occur. BAYKON cannot accept any liability for direct or indirect dama es resultin from the

use of this manual.

BAYKON reserves the ri ht to revise this manual and alter its content without notification at any time.

Neither BAYKON nor its affiliates shall be liable to the purchaser of this product or third parties for dama es,

losses, costs, or expenses incurred by purchaser or third parties as a result of: accident, misuse, or abuse of this

product or unauthorized modifications, repairs, or alterations to this product, or failure to strictly comply with

BAYKON operatin and maintenance instructions.

BAYKON shall not be liable a ainst any dama es or problems arisin from the use of any options or any

consumable products other than those desi nated as Ori inal BAYKON Products.

NOTICE: The contents of this manual are subject to chan e without notice.

Copyri ht © 2012 by BAYKON A.S. Istanbul, Turkey

BX11 Smart Process Indicator, User Manual, Rev. 1.8, May 2017

Pa e

2

of

48

Contents:

1.

K

EY FEATURES

...................................................................................................... 3

2.

T

HE

F

RONT

V

IEW AND

K

EY

F

UNCTIONS

....................................................................... 4

2.1

Display 4

2.2

Key Pad 5

2.3

Key Lock 5

3.

O

PERATION

.......................................................................................................... 6

3.1

Basic Wei hin 6

3.2

Advanced Functions 8

4.

I

NSTALLATION

..................................................................................................... 10

4.1

Recommendations 10

4.2

How to install the instrument and Scale ? 10

Step 1. Mechanical Installation ....................................................................................................... 11

Step 2. Load Cell Connection .......................................................................................................... 11

Step 3. Power Supply Connection and Groundin ............................................................................ 11

Step 4. Ener ize the instrument ...................................................................................................... 12

Step 5. Set the calibration switch to pro rammin and calibration .................................................. 12

Step 6. Pro rammin ...................................................................................................................... 13

Step 7. Calibration .......................................................................................................................... 13

Step 8. Testin the scale performance ............................................................................................ 13

Step 9. Brin the DIP switch to up position to unlock the scale adjustment ..................................... 13

Step 10. Peripheral related parameters pro rammin , if any ........................................................... 14

Step 11. Peripheral connections ...................................................................................................... 14

Step 12. Peripheral connections testin .......................................................................................... 22

5.

P

ROGRAMMING AND

C

ALIBRATION

........................................................................... 23

5.1

Enterin the Pro rammin and Calibration 23

5.2

Exitin the Pro rammin and Calibration 23

5.3

Fast Access to the Calibration 27

6.

A

NALOGUE

(

ONLY

BX11

AN

) ............................................................................... 34

7.

RS232C

AND

RS485

D

ATA

O

UTPUTS

.................................................................... 35

7.1

Continuous Data Output 35

7.2

Fast Continuous Data Output 36

7.3

Print Mode 36

7.4

BSI Data Structure 37

8.

T

ECHNICAL

S

PECIFICATIONS

................................................................................... 38

9.

H

OUSING

........................................................................................................... 42

9.1

Accessories supplied with the instrument 44

9.2

Accessories sold separately 44

10.T

ROUBLE

S

HOOTING

............................................................................................ 45

11.F

REQUENTLY

A

SKED

Q

UESTIONS

............................................................................ 46

D

ECLARATION OF

C

ONFORMITY

................................................................................... 47

BX11 Smart Process Indicator, User Manual, Rev. 1.8, May 2017

Pa e

3

of

48

1.K

EY FEATURES

BX10

BX10 MB

BX11

BX11 AN

BX11 MB

BX11 PB

BX11 PN

BX11 EN

BX11 CO

BX11 EI

BX11 EC

BX11 CC

BX11 PL

1 000 to 999 999 display resolution Yes

Yes

Yes

Yes

Yes

Yes

Yes

Yes

Yes

Yes

Yes

Yes

Yes

Hi h internal resolution up to 16 000 000 counts Yes

Yes

Yes

Yes

Yes

Yes

Yes

Yes

Yes

Yes

Yes

Yes

Yes

Up to 1600 conversion per second Yes

Yes

Yes

Yes

Yes

Yes

Yes

Yes

Yes

Yes

Yes

Yes

Yes

Serial interface RS 232C Yes

Yes

Yes

Yes

Yes

Yes

Yes

Yes

Yes

Yes

Yes

Yes

Yes

Serial interface RS 485 - Yes

Yes

Yes

Yes

Yes

Yes

Yes

Yes

Yes

Yes

Yes

Yes

Analo ue output - - - Yes

- - - - - - - - -

Profibus DPV1 interface - - - - - Yes

- - - - - - -

Profinet interface - - - - - - Yes

- - - - - -

Ethernet interface - - - - - - - Yes

- - - - -

CANopen interface - - - - - - - - Yes

- - - -

EtherNet/IP interface - - - - - - - - - Yes

- - -

EtherCAT interface - - - - - - - - - - Yes

- -

CC-Link interface - - - - - - - - - - - Yes

-

Powerlink interface - - - - - - - - - - - - Yes

Continuous data output Yes

Yes

Yes

Yes

Yes

Yes

Yes

Yes

Yes

Yes

Yes

Yes

Yes

Fast Continuous data output Yes

Yes

Yes

Yes

Yes

Yes

Yes

Yes

Yes

Yes

Yes

Yes

Yes

BSI data interface Yes

Yes

Yes

Yes

Yes

Yes

Yes

Yes

Yes

Yes

Yes

Yes

Yes

Modbus RTU - Yes

- Yes

Yes

Yes

Yes

Yes

Yes

Yes

Yes

Yes

Yes

Modbus TCP - - - - - - - Yes

- - - - -

2 pro rammable di ital in/out (non-isolated) Yes

Yes

- - - - - - - - - - -

4 di ital input and 5 relay contact output - - Yes

Yes

Yes

Yes

Yes

Yes

Yes

Yes

Yes

Yes

Yes

Error and at zero outputs (non-isolated) - - Yes

Yes

Yes

Yes

Yes

Yes

Yes

Yes

Yes

Yes

Yes

Bidirectional si nal input for force measurement Yes

Yes

Yes

Yes

Yes

Yes

Yes

Yes

Yes

Yes

Yes

Yes

Yes

Unit selection ( , k , t, lb, klb, N, kN ) Yes

Yes

Yes

Yes

Yes

Yes

Yes

Yes

Yes

Yes

Yes

Yes

Yes

Peak function - - Yes

Yes

Yes

Yes

Yes

Yes

Yes

Yes

Yes

Yes

Yes

Hold function - - Yes

Yes

Yes

Yes

Yes

Yes

Yes

Yes

Yes

Yes

Yes

Auto-zero trackin and auto-zero at power-up Yes

Yes

Yes

Yes

Yes

Yes

Yes

Yes

Yes

Yes

Yes

Yes

Yes

Motion detection Yes

Yes

Yes

Yes

Yes

Yes

Yes

Yes

Yes

Yes

Yes

Yes

Yes

Zeroin and Tarin via interface Yes

Yes

Yes

Yes

Yes

Yes

Yes

Yes

Yes

Yes

Yes

Yes

Yes

Adaptive di ital filter for faster measurin Yes

Yes

Yes

Yes

Yes

Yes

Yes

Yes

Yes

Yes

Yes

Yes

Yes

Electronic calibration (eCal) without test wei hts Yes

Yes

Yes

Yes

Yes

Yes

Yes

Yes

Yes

Yes

Yes

Yes

Yes

Electronic calibration (eCal) over field bus - Yes

- Yes

Yes

Yes

Yes

Yes

Yes

Yes

Yes

Yes

Yes

Zero and Span calibrations over field bus - Yes

- Yes

Yes

Yes

Yes

Yes

Yes

Yes

Yes

Yes

Yes

Zero adjustment Yes

Yes

Yes

Yes

Yes

Yes

Yes

Yes

Yes

Yes

Yes

Yes

Yes

Span adjustment with test wei hts Yes

Yes

Yes

Yes

Yes

Yes

Yes

Yes

Yes

Yes

Yes

Yes

Yes

Span adjustment for filled tanks Yes

Yes

Yes

Yes

Yes

Yes

Yes

Yes

Yes

Yes

Yes

Yes

Yes

3 point calibration ( linearity correction ) Yes

Yes

Yes

Yes

Yes

Yes

Yes

Yes

Yes

Yes

Yes

Yes

Yes

Pro rammin by BAYKON IndFace1X PC software Yes

Yes

Yes

Yes

Yes

Yes

Yes

Yes

Yes

Yes

Yes

Yes

Yes

8 load cells 350 Ω or 18 load cells 1100 Ω Yes

Yes

Yes

Yes

Yes

Yes

Yes

Yes

Yes

Yes

Yes

Yes

Yes

12 to 28 VDC power supply ran e Yes

Yes

Yes

Yes

Yes

Yes

Yes

Yes

Yes

Yes

Yes

Yes

Yes

BX11 Smart Process Indicator, User Manual, Rev. 1.8, May 2017

Pa e

4

of

48

2.T

HE

F

RONT

V

IEW AND

K

EY

F

UNCTIONS

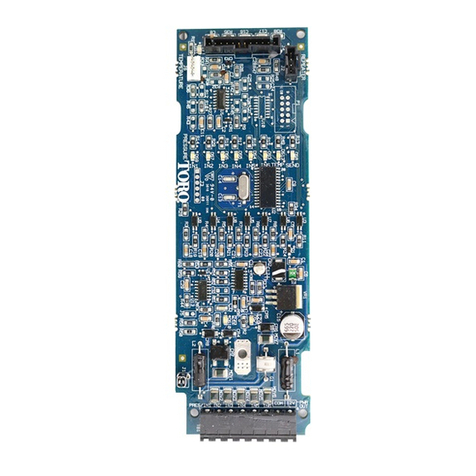

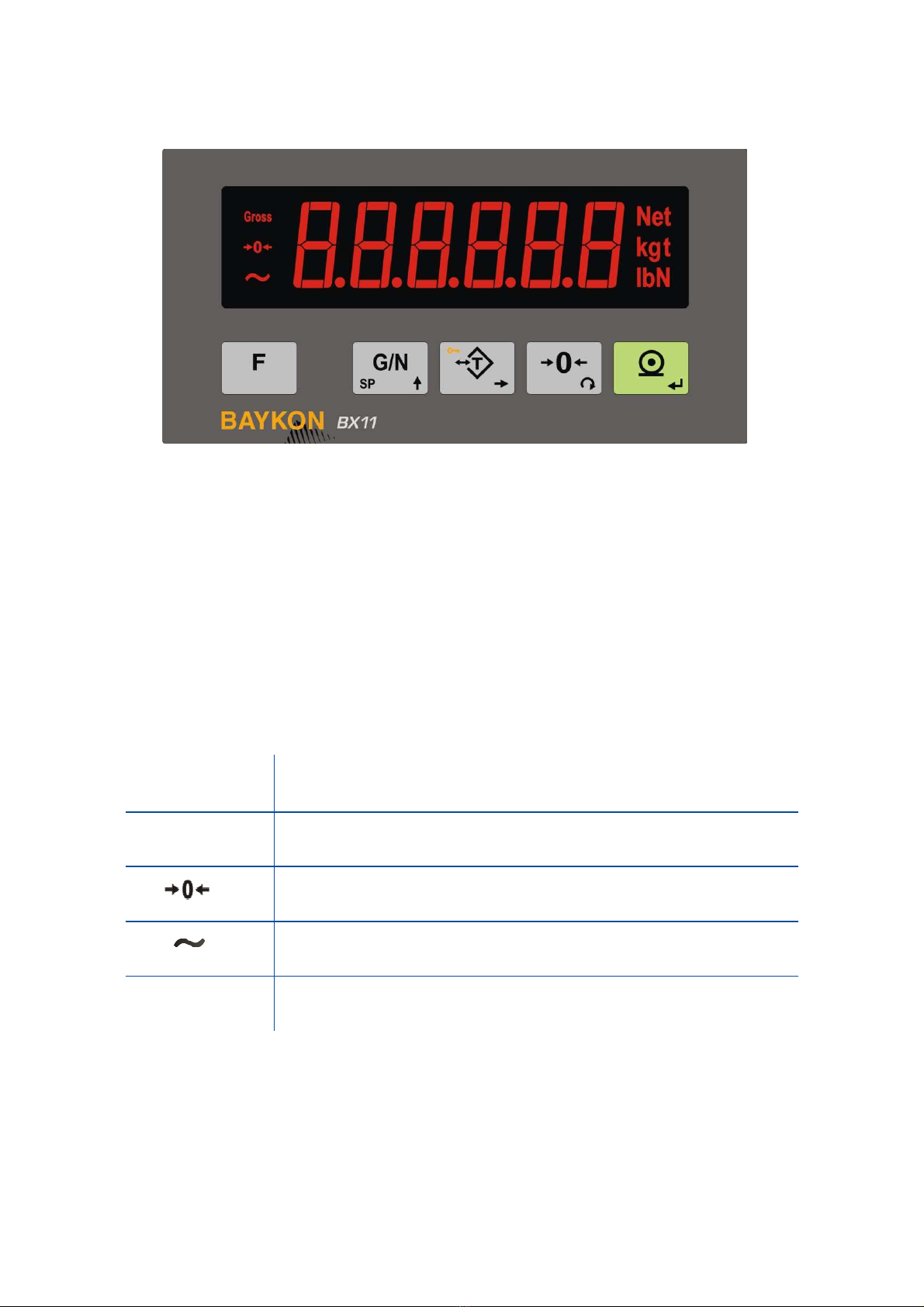

F gure 2.1

- Front panel view of BX11

2.1 D splay

The wei ht display of BX11 is seven se ments LED. At the ri ht side of the display there are three

LED’s for indicatin the net, ross and the unit ( standard k ). The meanin s of the announcement

LED’s on the display are:

Gross

Announces the indicated value is the ross wei ht.

Net

Announces the indicated value is the net wei ht.

Announces the wei ht is in the center of zero.

Announces the wei ht value on the display is unstable.

Un ts

, k , t, lb, klb, N, kN units are located on the ri ht of the

display.

BX11 Smart Process Indicator, User Manual, Rev. 1.8, May 2017

Pa e

5

of

48

2.2 Key Pad

The keys and the key functions of BX11 are:

Funct on:

Key function is pro rammable to Increased Indication, Total, Tare value

indication, CN value indication, Peak function and Hold function at parameter [ 116 ].

GN / Set Po nt: Pressin this key indicates the Gross wei ht temporarily. Press lon

time to enter the setpoint menu.

Tare / Clear

:

Pressin this key tares the scale and et into the Net mode.

Press lon

time to clear the tare.

Zero ng:

In Gross mode, if the scale doesn’t show zero while there is no load on the

pan, you can zero the scale by pressin this key.

Pr nt:

By pressin this key wei ht data and other information dependin on the setup

parameters sent to a printer or a PC via serial port.

2.3 Key Lock

BX11 has ability to lock the keys to avoid unauthorized person’s interfere. The key(s) which would

be locked are pro rammed at parameter [ 115 ].

You can activate or deactivate this function by lon pressin <F> key, press <Tare/Clear> and

<Pr nt> keys sequentially. [ Lock ] prompt appear for a short while to indicate the pressed key is

locked.

BX11 Smart Process Indicator, User Manual, Rev. 1.8, May 2017

Pa e

6

of

48

3. O

PERATION

3.1 Bas c We gh ng

Zero ng

Zeroin corrects the drifts of the unloaded scale from the zero point. Zeroin ran e is limited in the

instrument in set up mode. Refer to technical manual for details on zeroin limits.

1. Unload the scale.

2. Press < Zero > key.

3. Centre of zero appears symbol on the display.

4. Check the center of zero si n on the left of the display. If it is not appears, press < Zero >

key once more for correct zeroin .

We gh ng

1. Press < Zero > key, if [ 0.00 k ] is not displayed at unloaded scale.

2. Place wei hin item on the scale.

3. Wait until the motion annunciator disappears from the display.

4. Read the wei hin result.

If the loadin is out of the indication ran e the prompts below are displayed.

Under of ne ative indication limit Over than positive indication limit

Net we gh ng n the conta ner

Tarin is used to wei ht material in the container at basic wei hin operation.

1. Place the empty container on to the scale and press <Tare> key.

2. The display is zeroed and the NET symbol appears. Check

si n on the display. If it is not

appears, press the <Tare> key once more for correct tarin .

3. Add the material into the container and follow its wei ht in net.

Clear ng the tare

Lon press <Tare> key in net mode. The NET symbol disappears and Gross symbol appears on

the display to ether with the ross wei ht indication.

Automat c tar ng

The scale tares automatically and NET is displayed, after placin a wei ht on the empty scale, if this

feature is enabled. Refer to parameter [ 043 ]. The wei ht should be heavier than the value entered

to the parameter [ 042 ] for automatic tarin .

BX11 Smart Process Indicator, User Manual, Rev. 1.8, May 2017

Pa e

7

of

48

Automat c clear

The tare is automatically cleared after emptyin the scale, if this feature is enabled. Refer to

parameter [ 113 ].

Automat c zero po nt correct on

Zero point is corrected automatically for minor deviations if the chan e is within the ran e of limited

zeroin ran e value. Disable this correction at the applications like tank wei hin , batchin , fillin

etc. a ainst wron zeroin at feedin . Refer to Automatic Zero Trackin parameter [ 214 ].

Automatic zero point correction ran e is limited to ether with zeroin ran e above.

Automat c zero at power on

Warning: Automatic zeroin at power on can be enabled only if the scale is always unloaded

before power on. This function should be disabled at tank / silo wei hin applications.

Zero point is corrected automatically at power on the instrument to compensate zero drifts of the

scale if the scale is always power on when unloaded. This feature should be disabled for tank, silo,

hopper scales etc.

Power on zero has a limited ran e and the instrument announces [ E E E ] error prompt in case of

out of ran e. Press < F > key to read the residual drift and to start indication without zeroin and

call service.

Restore Tare at Power on

This function saves the tare at power off and the instrument start to operate Net after power on as

before power off. This feature should be enabled, if tarin is used at tank wei hin applications.

Refer to parameter [ 112 ].

Pr nt ng

Press < Pr nt > key when the item is on the pan and wei ht is stable to print the label. Refer to

Page 36 for details.

BX11 Smart Process Indicator, User Manual, Rev. 1.8, May 2017

Pa e

8

of

48

3.2 Advanced Funct ons

Force measurement

The instrument should be set to force mode for the bidirectional force measurement from

–Maximum to +Maximum. The force unit N or kN can be displayed. BX11 is very fast force

measurement instrument with its hi h conversion rate, up to 1600. Refer to parameter [ 210 ].

H gh resolut on ( Default )

If you pro ram < F > key for hi h resolution, the wei ht value is displayed 10 times hi her

resolution temporary 5 seconds.

Temporary Gross nd cat on n Net

Pressin < G/N > key indicates the Gross wei ht temporarily for 5 seconds in Net mode.

Total

If you pro ram < F > key for totalization, the printed wei hts are accumulated and displayed by

pressin < F > key. Press < Pr nt > key to transfer total or press < Zero > key to erase the total

while the total is displayin .

Funct onal cutoff outputs

The instrument can be set to various basic setpoint functions like absolute, numerical, control

outputs. Refer to Page 16 for details. Besides these basic functions you may set di ital outputs for

usa e at various applications easily. This feature of instrument eliminates PLC from control

cabinets. Below you will find some examples of BX11 advanced setpoint functions.

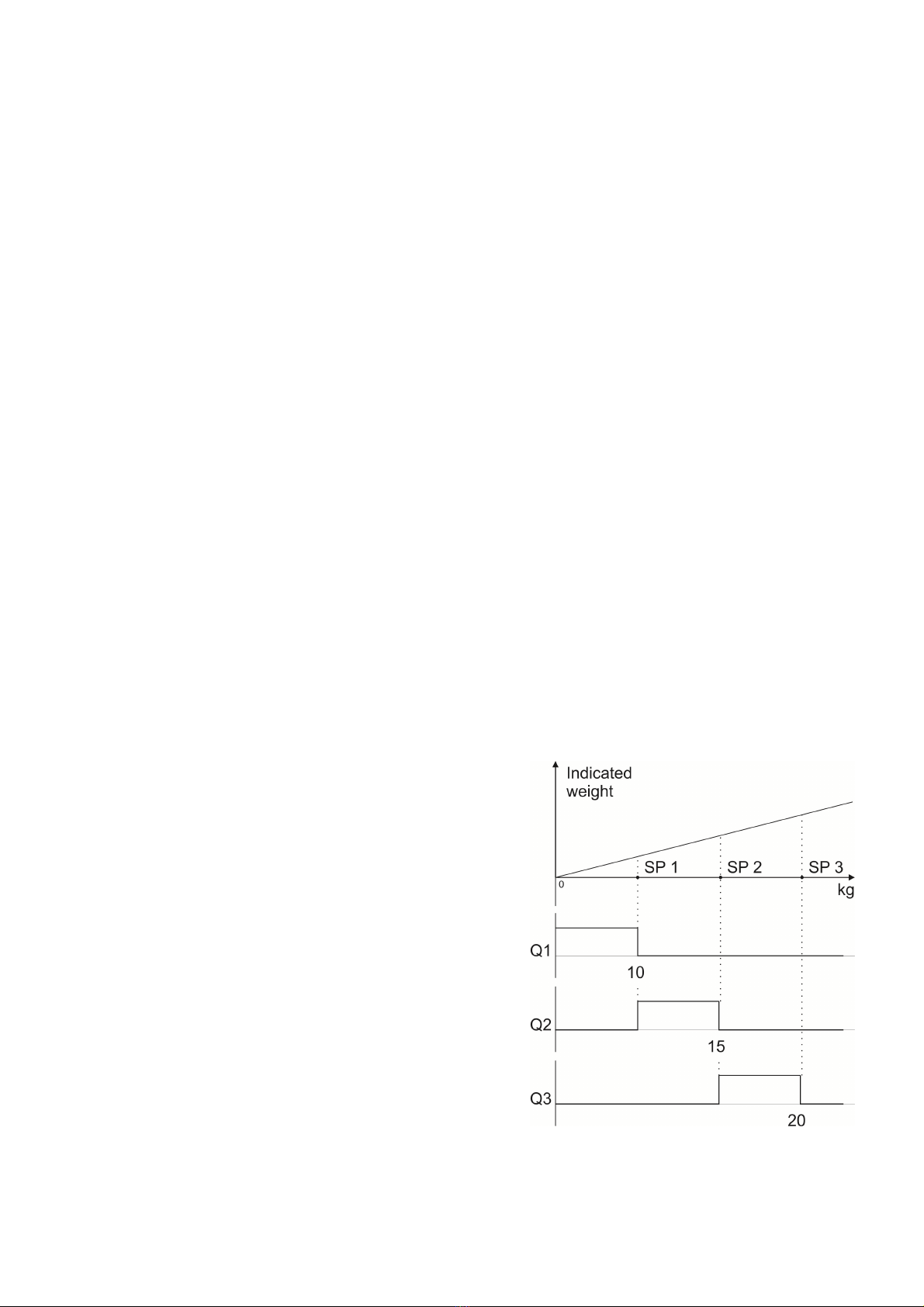

Example 1: Bas c F ll ng. 3 speed. if you want

wei ht the hopper for fillin the container or ba , you

may set the setpoints to Control mode-2. After

enterin the coarse, medium and fine speeds cutoff

points to SP1, SP2 and SP3 in sequence, outputs will

chan e as shown on the ri ht to fill 20 k ba s

basically.

BX11 Smart Process Indicator, User Manual, Rev. 1.8, May 2017

Pa e

9

of

48

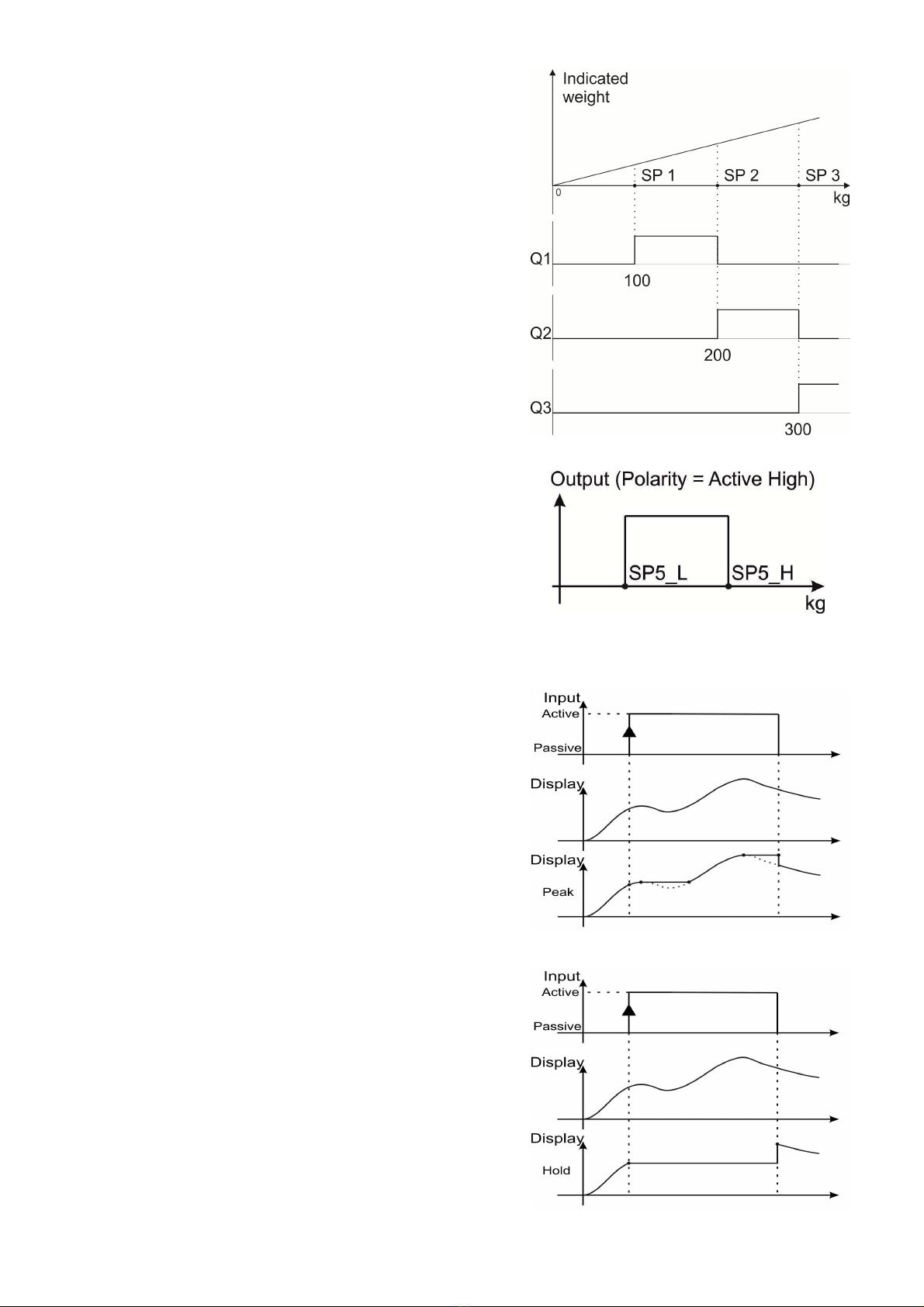

Example 2: Sort ng or Checkwe gh ng. if you want

checkwei hin or sortin the items basically, you

may set the setpoints to Control mode-1. After

enterin the sortin wei hts to SP1, SP2 and SP3 in

sequence, outputs will chan e as shown on the ri ht.

Examp

le 3:

Produc ng alarm.

if you want to produce

alarm si nal between to wei ht values, e. . between

200.0 and 300.0 k , additional to your other cutoff

needs, you may set setpoint 5 to functional output

and active window. After enterin SP5L = 200.0 and

SP5H=300.0, the di ital output will be as shown on

the ri ht to control valves, lambs etc.

Peak Hold

BX11 has ability to hold the peak of the loadin durin

the di ital input active, if pro rammed. After applyin

the di ital input, the instrument follows the loadin to

hold its peak and displayed wei ht / force increases

to ether with increasin loadin . Holds the peak

followin hi her loadin s as shown on the drawin .

Hold D splayed value

BX11 has ability to hold the displayed value durin the

di ital input active, if pro rammed. Durin the di ital

input, the instrument holds the displayed value, even

the loadin chan es as shown on the drawin .

BX11 Smart Process Indicator, User Manual, Rev. 1.8, May 2017

Pa e

10

of

48

4. I

NSTALLATION

PRECAUTION: Please read this section carefully before installation of the instrument. Applying the

recommendations in this section will increase your system reliability and long term performance.

4.1 Recommendat ons

Control Cab net Des gn

Warning: Please care the following warnings for designing the control cabinet which will increase

your system reliability.

The control cabinet should be desi ned so that Analo Di itizer can operate safely. The panel

should be placed clean area, not ettin direct sun li ht if possible, with a temperature between

-15 ºC and +55 ºC, humidity not exceedin 85% non-condensin . All external cables should be

installed safely to avoid mechanical dama es.

BX11 instruments are very low level si nal measurin instruments. To avoid electrical noise, BX11

should be separated from the equipments that produce electrical noise. Preferable use metal

cabinet a ainst radio frequency interference and the cabinet shall be connected to round a ainst

the electroma netic disturbances. Load cell cable trays must be separated from others, if possible.

If there are noise- eneratin equipments such as heavy load switches, motor control equipments,

inductive loads etc., please be careful a ainst the EMC interference in the cabinet. If possible

protect BX11 instruments with the faraday ca e or install them in separate section or install them

far a way from this kind of equipments. Connect parallel reverse diodes to the DC inductive loads

like relays, solenoids etc. to minimize volta e peaks on the DC power lines.

Cabl ng

All cables comin to the control cabinet shall be shielded. Please use separate cable tray for these

low si nal level cables. Distance from load cell cables, interface cables and DC power supply cables

to power line cables shall be minimum 50 cm.

Warning: Please always remember that BX11 instruments are very low voltage measuring

instruments. Your control cabinet design and proper installation increases reliability and

performance of the instrument. Please do not forget that the instrument must be powered off before

inserting or removing any peripheral connector.

4.2 How to nstall the nstrument and Scale ?

Please follow the installation and commissionin steps described below carefully to prevent

unwanted results after installation.

BX11 Smart Process Indicator, User Manual, Rev. 1.8, May 2017

Pa e

11

of

48

Step 1. Mechan cal Installat on

Take care to the housin dimensions and the su ested panel hole dimensions iven in the Page

2. Install the indicator on the panel with its panel fixin accessories. Be sure, all mechanical

installation of your mechanical system and panel are finalizin before startin the next step.

Step 2. Load Cell Connect on

Warning: After load cell connection to the instrument, the welding on the mechanical constriction is

not recommended. Disconnect all connectors from indicator before welding on the mechanical

hardware.

Load cell connection detail is shown in Fi ure 4.1. In 4-wire installations the sense and excitation

pins with the same polarity should be short c rcu ted at the connector side. If you have junction

box, use 6 wire cable between BX11 and the junction box, and short circuit these pins at junction

box for better performance.

4 w re LC connect on

6 w re LC connect on

F gure 4.1

-

Load cell connections

Warning: Always connect Sense pins to Excitation pins for wire connection. Non-connected

sense pins may cause the wrong Excitation voltage measurement and create an accuracy problem.

Warning: Connect the load cell cable shield to the reference ground or shield pin of the load cell

connector.

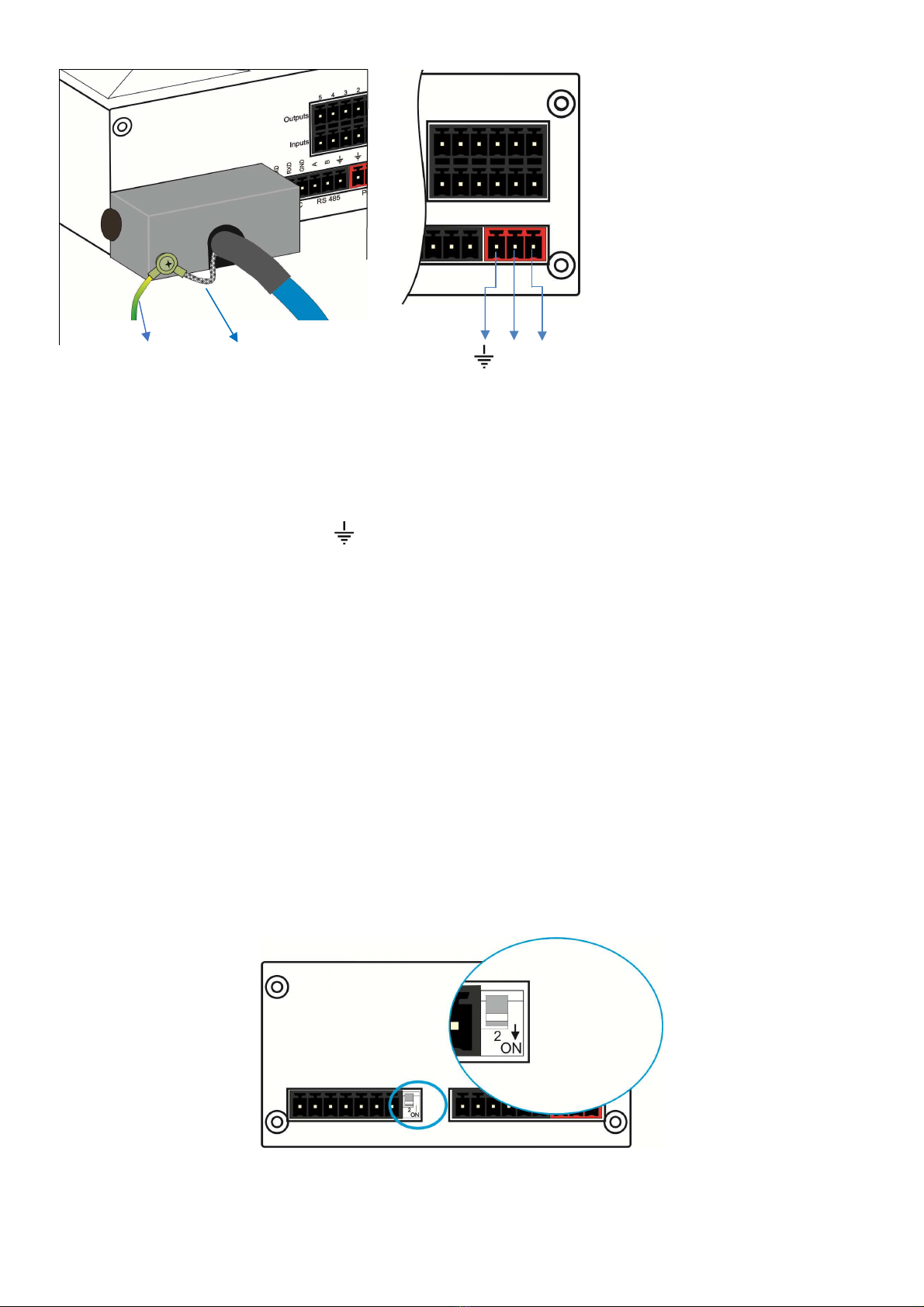

Step 3. Power Supply Connect on and Ground ng

The quality of the instrument’s round will determine the accuracy and the safety of your measurin

system. A proper round connection is needed to minimize extraneous electrical noise effects on

the measurement. A poor round can result in an unsafe and unstable operation. It is important that

the instrument should not share power lines with noise- eneratin parts such as heavy load

switchin relays, motor control equipments, inductive loads, etc. If the condition of the power line in

the plant is poor, prepare a special power line and roundin .

Power supply volta e of the instrument shall be between 12 VDC and 28 VDC. The pin confi uration

of the 24 VDC power supply connector located ri ht - bottom of the instrument is shown in Fi ure

4.2 below. Be sure, the power supply is switched of before connection.

BX11 Smart Process Indicator, User Manual, Rev. 1.8, May 2017

Pa e

12

of

48

The pin layout of the

24VDC connector of

BX11 Series

( rear view )

PE Protective Loadcell

0V 24V

roundin cable shield

F gure 4.2

-

The pin layout of 24VDC connector

Warning: Before interfering the instrument, turn off the power and wait at least for 30 seconds.

Warning: Connect the grounding pin to the reference ground.

Step 4. Energ ze the nstrument

Check the mechanical installation, roundin , load cell connection and power supply connection to

be sure the correct electrical installation before ener izin the instrument. If before steps are done

properly ener ize the instrument.

Step 5. Set the cal brat on sw tch to programm ng and cal brat on

Warning : If the scale is sealed before, call the authorized person before interfering the scale.

If there is a DIP switch on BX11’s rear side and its position should be “ON” ( downward ) to chan e

the metrolo ical related parameters includin calibration. No need to open the housin to chan e

the position of this DIP switch.

F gure 4.3

- The location of calibration DIP switch

BX11 Smart Process Indicator, User Manual, Rev. 1.8, May 2017

Pa e

13

of

48

Step 6. Programm ng

You will pro ram the instrument accordin to your application in this step. Adjust;

•Interface parameters in block [ 00- ] RS232 and [ 01- ] RS485 serial ports,

•Confi uration parameters in block [ 1-- ] for scale functions related with application like

savin tare before power off and restart in Net mode and di ital I/O related entries.

•Set up parameters to set up the scale in block [ 2-- ] like zeroin ran e. Please remember

these parameter values are restricted for scale usa e in trade. You have to enter the scale

capacity and division values in this block.

Warning: The programming and parameter descriptions are referred in Page 23. We recommend

you to save these parameters before next step against to lost the adjustments in this step if

calibration can not performed somehow.

Step 7. Cal brat on

You will calibrate the scale after pro rammin the parameters. You may follow one the calibration

methods below.

•eCal Electronic calibration without test wei ht

need via IndFace1x or fieldbus ( Page 26 ).

•Full calibration via keys on the instrument by usin test wei ht. Refer to Page 26.

•Zero adjustment and span adjustment in sequence via keys or fieldbus. Span calibration is

needed test wei ht. You may save the zero adjustment before startin span adjustment.

Refer to Page 28.

•Zero adjustment and span adjustment under load in sequence via keys if the scale cannot be

emptied when the span adjustment is performed. Need test wei ht for span calibration. Refer

to Page 28.

You may access to the calibration menu from operation menu by followin the description in fast

access to the calibration section ( Page 27 ). After the calibration o back to the operation menu

after savin adjustment ( Refer to Page 23 )

Remember: You may use parameter 905 to follow the load cell output voltage on loading, if you can

not perform the calibration.

Step 8. Test ng the scale performance

You have to check your scale performance by testin the scale eccentricity, scale linearity at loadin

until maximum loadin value and unloadin , repeatability etc. before usin it. If testin results are

not in your limits recheck the steps above and your hardware to find the error source.

Step 9. Br ng the DIP sw tch to up pos t on to unlock the scale adjustment

If the DIP switch is brin to the downward position for pro rammin , push it to the upward position

to lock the scale adjustment a ainst interferin the un-authorized persons in to the scale. If the

scale is used in non-trade industrial wei hin , this step is not must.

Warning: If the scale is used in trade, the scale should be sealed after bringing the DIP switch to

the upward position sealed before. Call the authorized person for sealing the scale, if need be.

BX11 Smart Process Indicator, User Manual, Rev. 1.8, May 2017

Pa e

14

of

48

Step 10. Per pheral related parameters programm ng, f any

If you will connect any peripheral to the instrument, you have to set the related parameters up.

Refer to Page 1 for di ital input/output, Page 29 for analo output pro rammin and technical

manual for fieldbus interfacin .

Step 11. Per pheral connect ons

If you will make any peripheral connection like di ital input, di ital output, RS232, RS485 and

fieldbus etc. switched off the power supply and connect you peripheral as described below and in

the related section of this manual. You will find detailed description on the peripheral connection

and interfacin details in the BX11 technical manual.

Important: Powered off the instrument before any connector installing to the instrument.

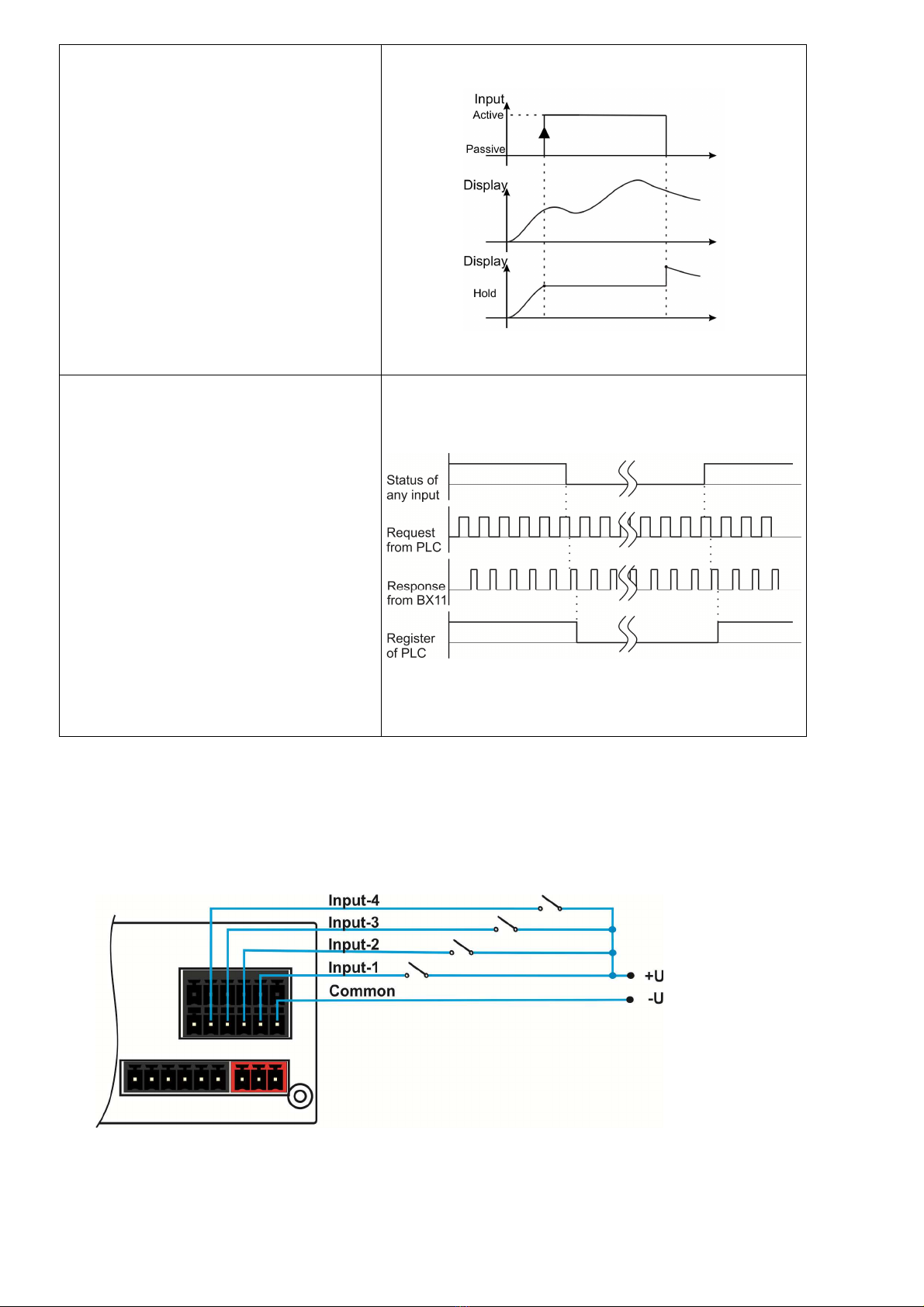

D g tal Input Connect on

BX11 inputs which are independently pro rammable for zeroin , tarin , clear, print, key lock, peak,

hold, and as a fieldbus input port. If the input is pro rammed as a fieldbus input port, the input

status is transferred to the PLC by fieldbus command.

Inputs are 12~28 VDC,10 mA.

Key funct ons v a nputs

Zero ng, Tar ng, Clear, Pr nt

The key functions are executed via

di ital inputs. Tarin via di ital input is

shown in the drawin as an example.

Refer to parameter [131, 132, 133

and 134 ] on Page 30.

Peak hold

The instrument follows the peak of the

loadin durin the active peak input.

Low input si nal allows the basic

wei hin operation.

Fieldbus interfaces have peak hold

command.

Refer to parameter [

131, 132, 133

and 134 ] on Page 30 and commands

of interfaces.

BX11 Smart Process Indicator, User Manual, Rev. 1.8, May 2017

Pa e

15

of

48

Hold

The instrument holds the wei ht

indication durin input si nal which

help the measured value to the

operator for a while. Low input

si nal allows the basic wei hin

operation.

Refer to parameter [131, 132, 133

and 134 ] on Page 30.

PLC remote port

The di ital input of the wei hin

instrument is used as

a remote port of

the PLC if the input is pro rammed as

fieldbus port.

The instrument transfers the status of

the input port to the PLC after

receivin the related command. PLC

processes the received data as a

remote di ital input port.

Refer to parameter [

131, 132, 133

and 134 ] on Page 30.

Inputs connection dia ram is shown in Fi ure 4.4.

F gure 4.4

-

BX11 Inputs connection dia ram

BX11 Smart Process Indicator, User Manual, Rev. 1.8, May 2017

Pa e

16

of

48

D g tal Output Connect on

BX11 instruments di ital outputs are can be used as a standard, threshold and window. Threshold

and window outputs are also pro rammable positive or ne ative polarity. Di ital outputs of BX11 are

also pro rammable as a fieldbus port to control them with a fieldbus commands. Refer to parameter

[ 117 ], [ 130 ] and [ 70- ].

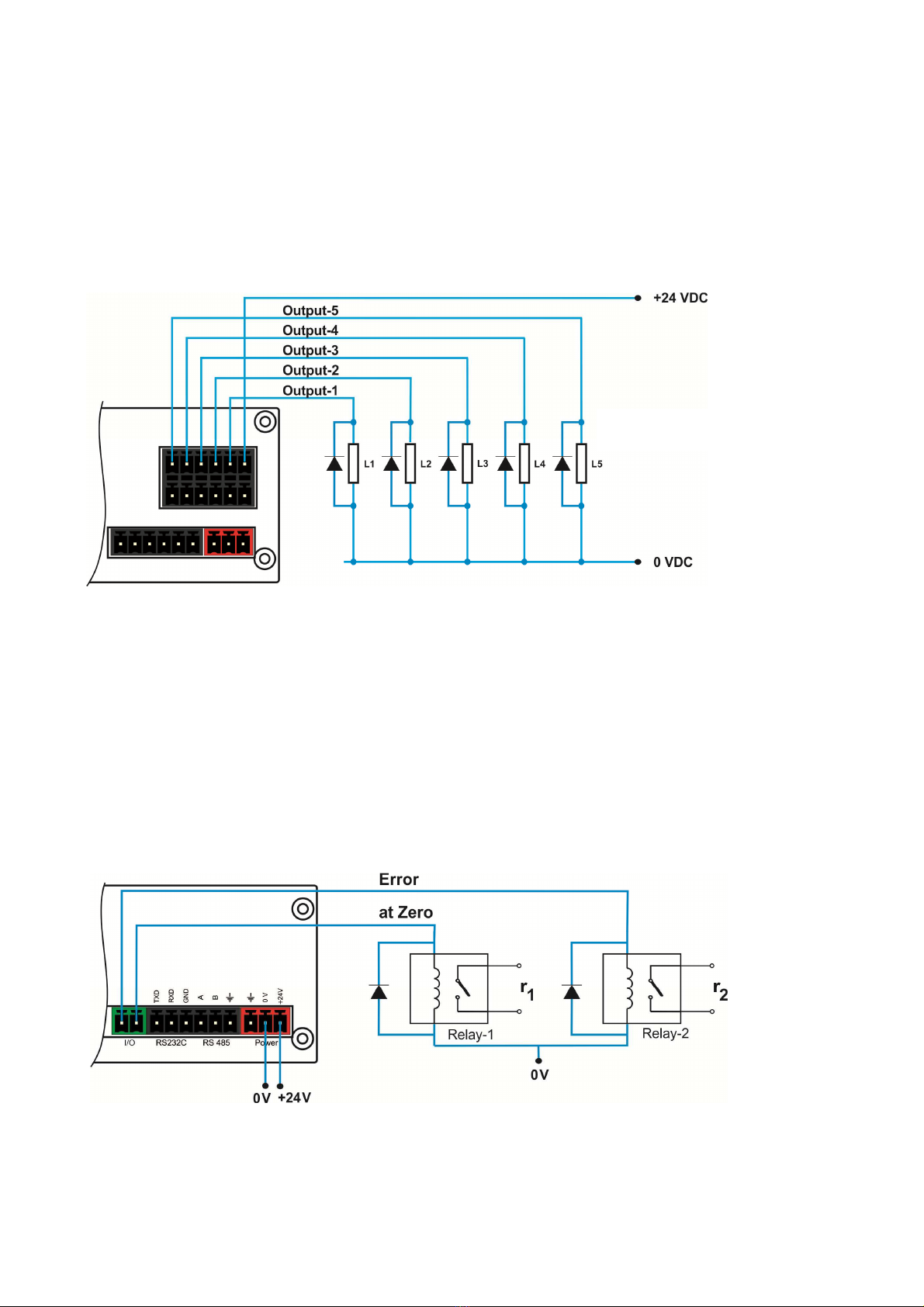

Outputs connection dia ram is shown in Fi ure 4.5 and Fi ure 4.6.

F gure 4.5

- BX11 Outputs connection dia ram

Non-isolated outputs are power supply volta e – 1.5V, 100mA. Connection dia ram is shown in

Fi ure 4.6.

F gure 4.6

- Non-isolated outputs connection dia ram

Outputs are

30 VDC, 1A

.

BX11 Smart Process Indicator, User Manual, Rev. 1.8, May 2017

Pa e

17

of

48

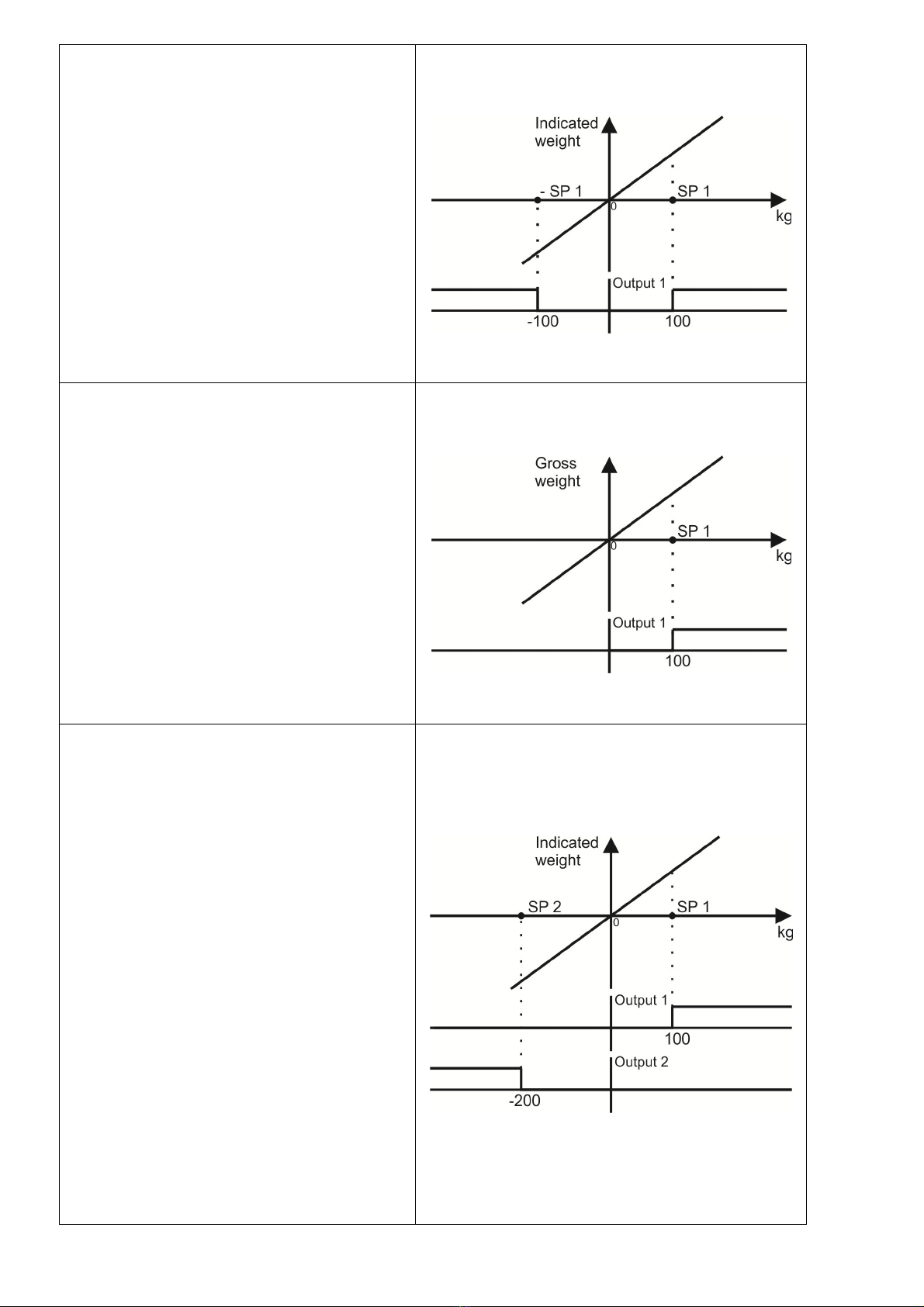

Setpo nt of absolute nd cated we ght

The absolute indicated wei ht value is

compared with the setpoint entry and the

output state is activated if the absolute

wei ht is hi her than setpoint. As an

example, setpoint 1 is 100 k in the

drawin on the ri ht.

Refer to parameter [ 130 ]=1,2,3,4 on

Page 29.

Setpo nt of gross we ght

The output state is activated durin the

hea

vier ross loadin s at ross or net

wei ht indications. This feature can be

used to produce alarm si nal at empty or

over wei hted scales, tanks etc. As an

example, setpoint 1 is 100 k in the

drawin on the ri ht.

Refer to parameter [ 130 ] on Page 29.

Setpo nt of real nd cated we ght

The + or - si n of the setpoint can be

entered. The output si nal is produced if ;

Positive setpoint : The output is activated if

the wei ht is heavier than the loadin .

Refer to setpoint 1 in the drawin .

Ne ative setpoint : The output is activated

if the ne ative net wei ht is li hter than

the setpoint. Refer to setpoint 2 in the

drawin .

As an example, setpoint 1 is 100 k and

setpoint 2 is -200 k in the drawin on the

ri ht.

To enter the ne ative or positive value,

lon press < Tare > key while the set

point value is seen on the display.

Refer to parameter [ 130 ] on Page 29.

BX11 Smart Process Indicator, User Manual, Rev. 1.8, May 2017

Pa e

18

of

48

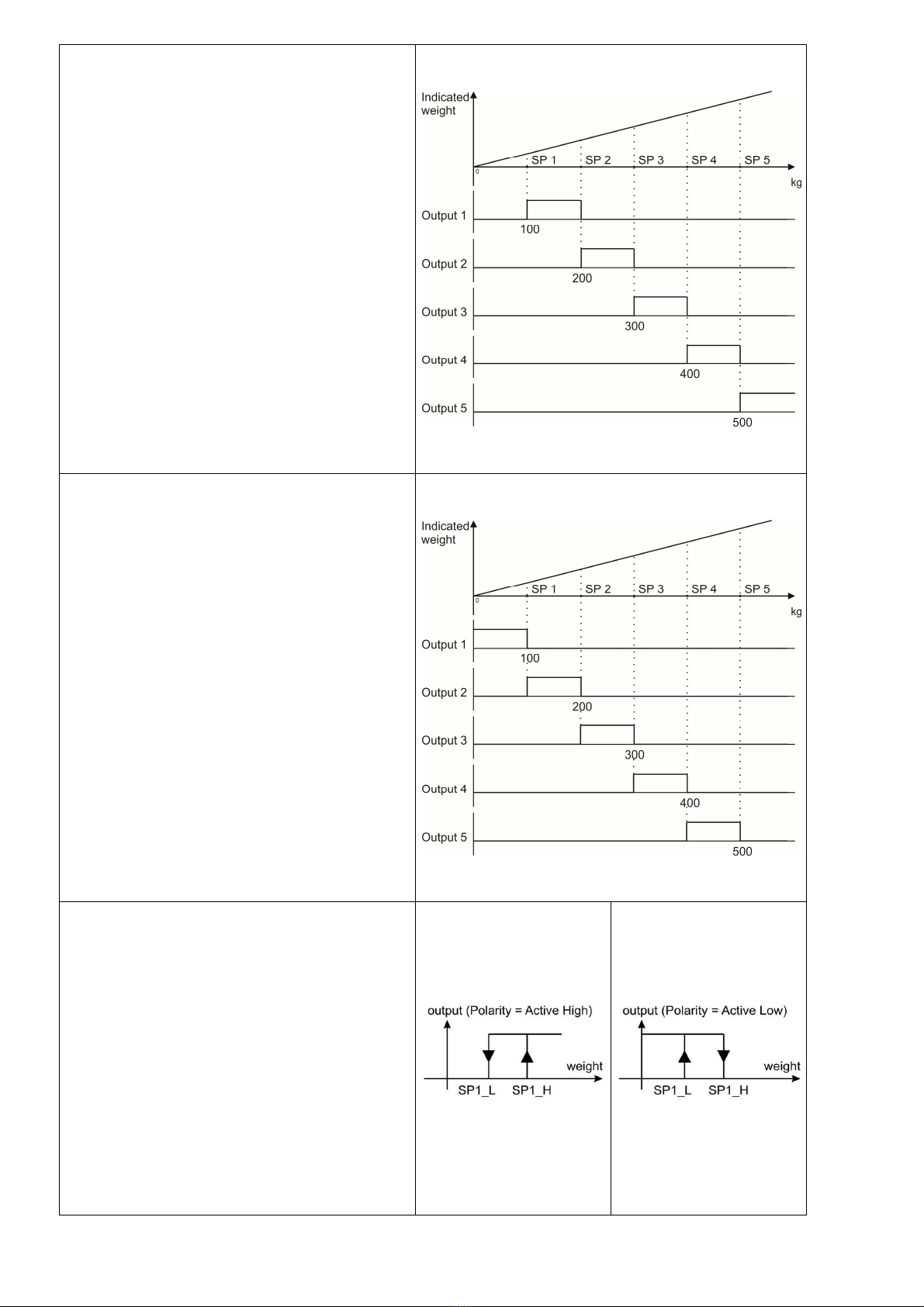

Control Mode-1:

Setpoints are entered as

SP1<SP2<SP3<SP4<SP5

and outputs are activated as indicated in

the drawin as seen on the ri ht. This

mode can be used for checkwei hin ,

sortin , fillin , multicomponent batchin

etc.

Refer to parameter [ 130 ] on Page 29.

Control Mode-2:

Setpoints are entered as

SP1<SP2<SP3<SP4<SP5

and outputs are activated as indicated in

the drawin as seen on the ri ht. This

mode can be used for checkwei hin ,

sortin , fillin , multicomponent batchin

etc.

Refer to parameter [ 130 ] on Page 29.

Threshold Output:

2 set point values are entered. SP1 is the

point that the output oes active when the

wei ht increased from SP1_H. SP1_L is

the point that the output drops to passive

state when the wei ht decreased to

SP1_L.

Inverse function is available.

Refer to parameter [ 7-- ] on Page 30.

Other manuals for BX11

1

This manual suits for next models

13

Table of contents