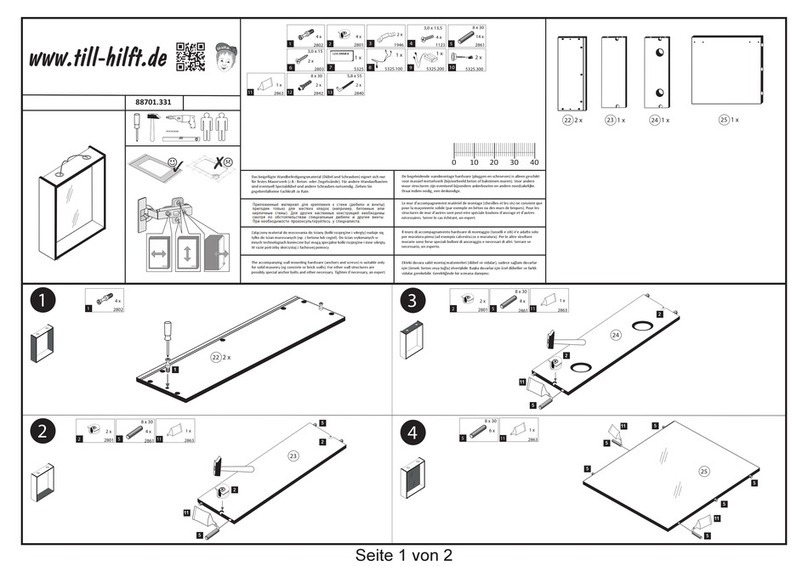

BBP BBP752-L-WML-F Series User manual

BBP752Lx-WML-Fx-r101123

Bullet-Resistant

Locking Hem Bar, Motorized Window Shade

BBP752-Lx-WML-Fx

Contents

1. Part and Hardware List......................................................................................................... 2

2. Determine Mounting Points................................................................................................. 5

3. Wall Bracket and Shade Installation ..................................................................................... 7

4. Hem Bar Lock Installation................................................................................................... 10

5. Testing and Final Adjustments ........................................................................................... 14

6. Installation Certification..................................................................................................... 17

7. Warranty and Limit of Liability Information........................................................................ 17

If there are any issues during installation, please contact us at 833-285-5380

Monday – Saturday, 6 AM to 10 PM PST

2

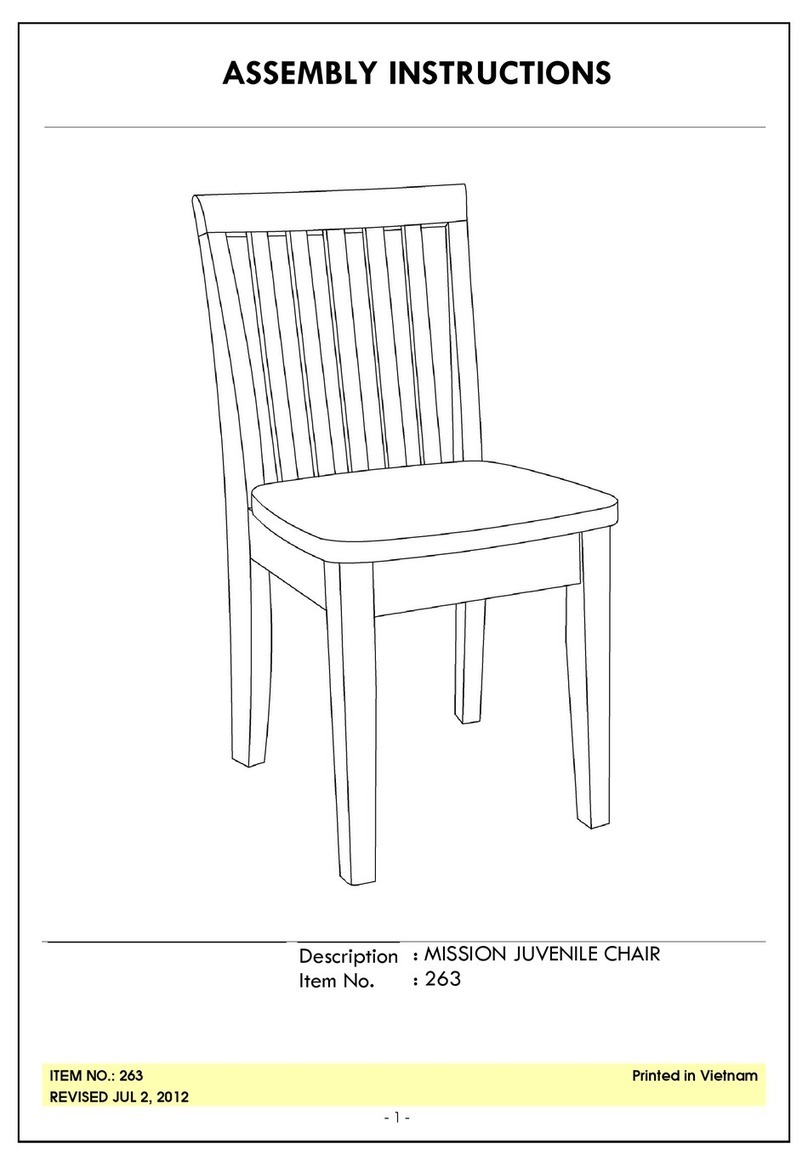

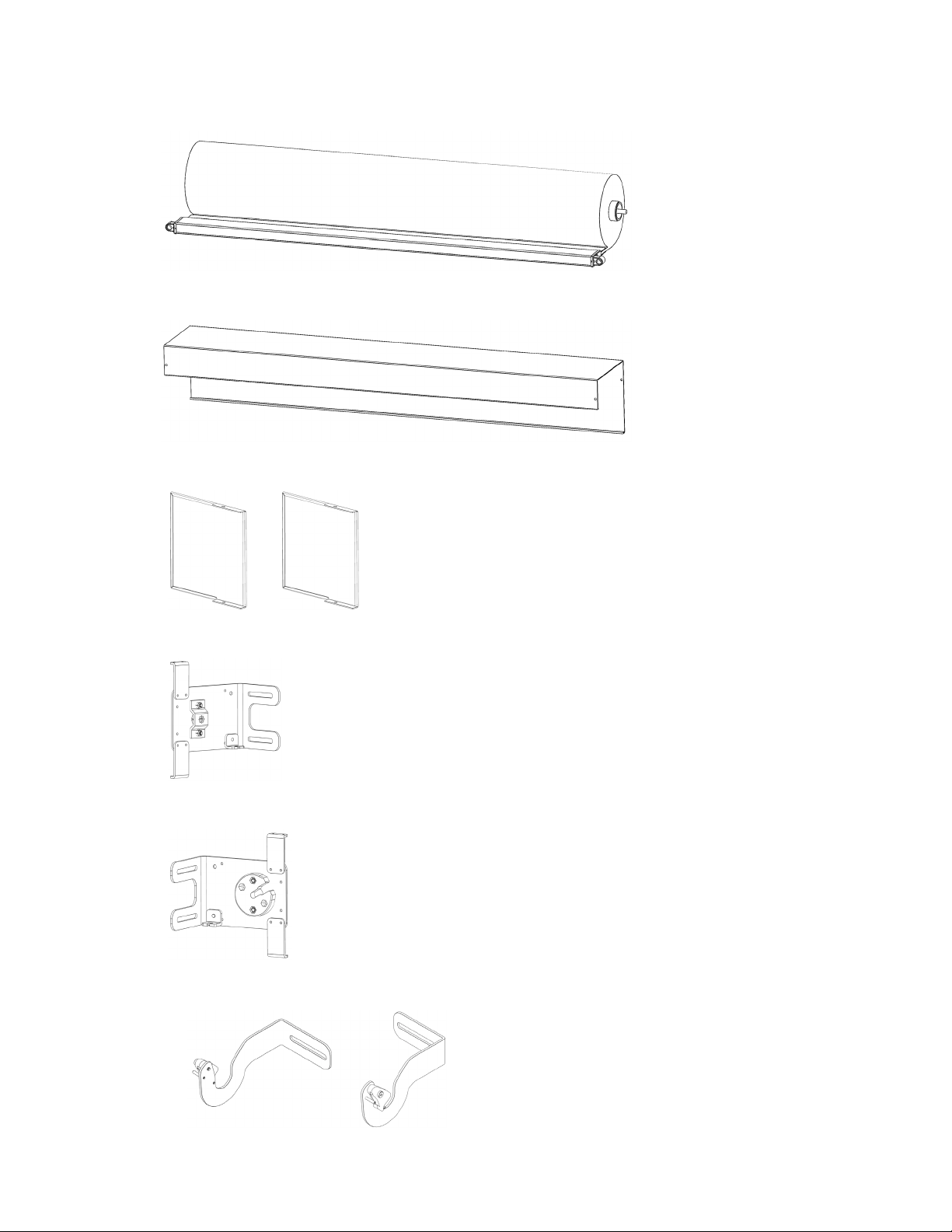

1. Part and Hardware List

1) Shade (Roll Good) with Motor

2) Fascia

3) Sheet Metal End Covers (2)

4) Motor Side Wall Bracket

5) Idler Side Wall Bracket

6) Hem Bar Locks (one left and one right side)

3

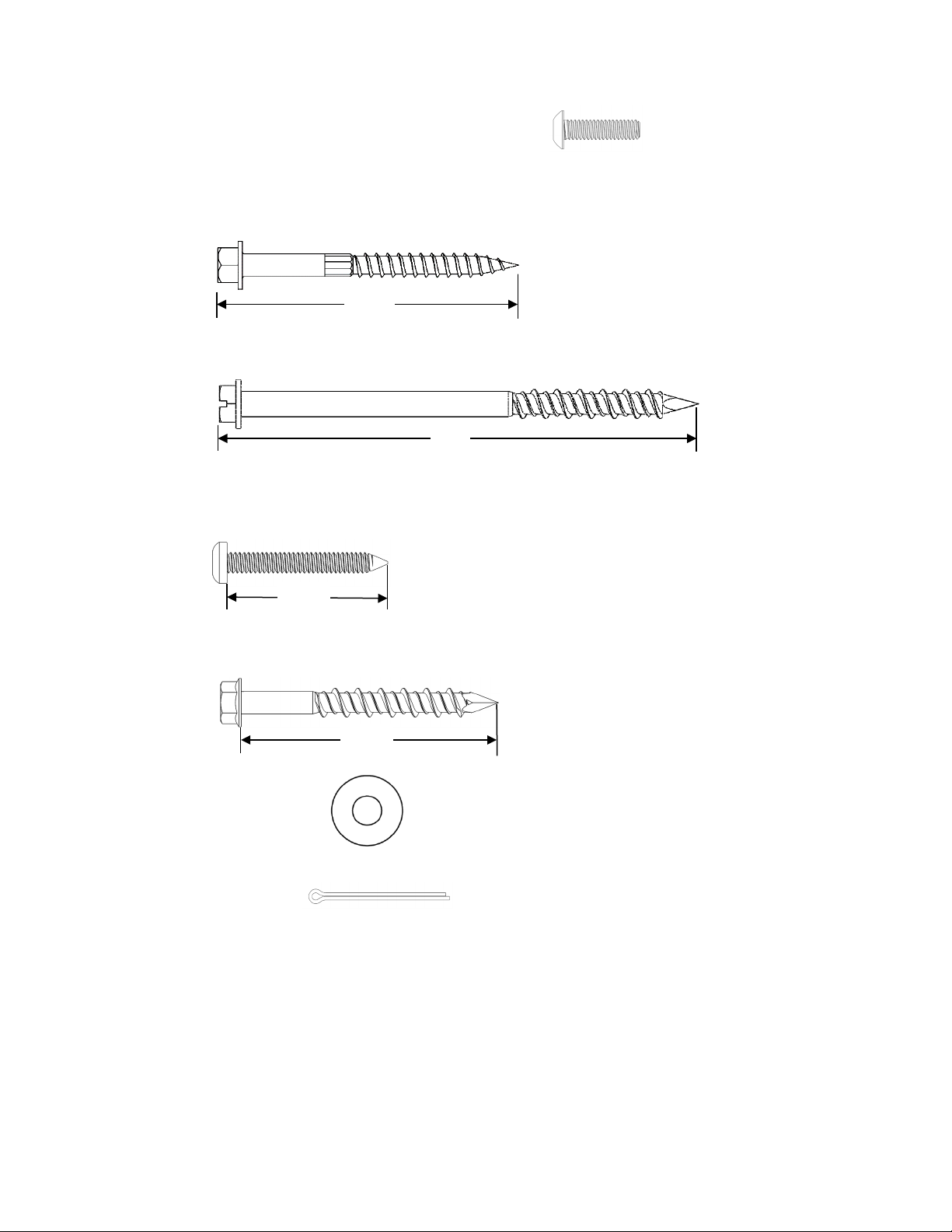

7) 8-32 Pan Head Screws x 5/8”, shown actual size (4)

8) One of the following, shown actual size:

1. For mounting into wood or steel studs, ¼” x 2½” self-drilling wood screws, qty 4.

2. For mounting into concrete or brick, ¼” x 4” concrete screw anchors, qty 4

9) One of the following, shown actual size:

1. For mounting into wood or steel studs, #10 x 1½” pan head screws, qty 4.

2. For mounting into concrete or brick, ¼” x 2¼” concrete screw anchors, qty 4

10) ¼" flat washer, qty 8

11) Steel cotter pin

4”

2½”

1½”

2¼”

4

Tools required

1) Mounting into concrete or brick, 3/16 drill bit for the 1/4” masonry bolts

2) 3/32” drill bit

3) 5/16" socket head driver

4) T25 Torx driver

5) Needle nose pliers

6) Tape measure

7) Straight edge or square for marking straight lines

8) A bubble level (at least 4 ft in length will be best)

9) Pencil for marking hole positions

10) Wood or steel stud construction: electronic stud finder or a 1/16” diameter drill

to drill test holes to find the studs.

5

2. Determine Mounting Points

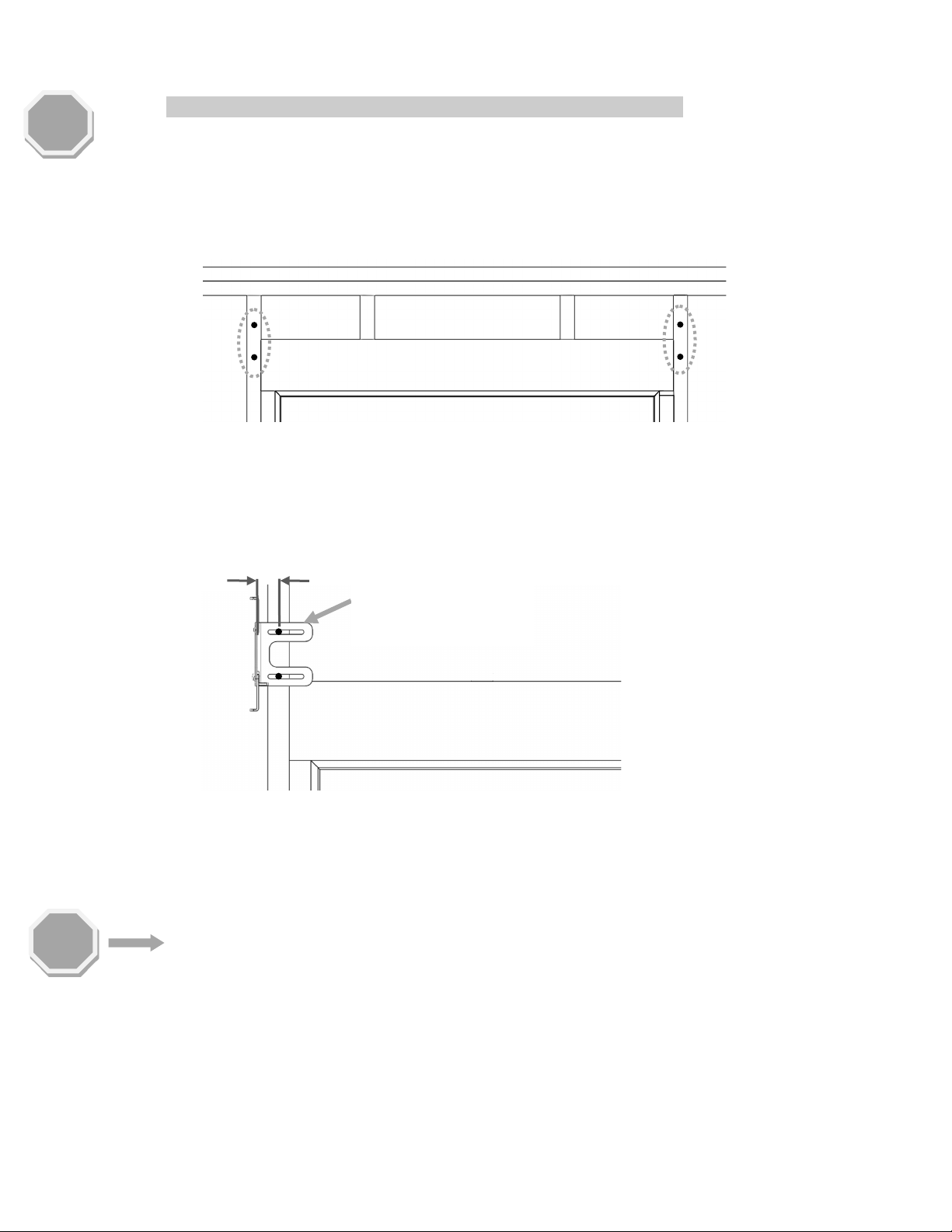

1) The Wall Brackets MUST attach to solid material in the zone depicted in the image at the

bottom of this page. This can be in either:

a) The horizontal header spanning the window frame

b) The vertical studs on the outside of the frame that run all the way to the floor

c) Solid masonry if the construction around the window frame is brick or

concrete.

2) Using the outside edges of the window frame (the vinyl, plastic, or aluminum portion) as the

starting point (not the window glass), mark the approximate locations of all four mounting

points shown on the right side of the image.

3) CRITICAL STEP:The effectiveness of the product in stopping handgun fire is dependent on

the brackets being mounted securely to the wall.

a) Confirm that the four mounting locations marked in step 2.2 will fully engage SOLID

material into which the mounting screws will be securely held (studs, headers, or

masonry construction) and NOT simply engage the sheetrock.

b) For wood or steel stud constructions, use a stud finder or drill small pilot holes to

determine the locations of the studs.

•Screws that only engage the edges of a stud will not have sufficient

holding strength and could fail in a shooting event.

c) If there is any doubt in the type of materials behind these mounting points, drill test

screws into the four locations and make sure the torque to drive these screws

reaches at least 7ft-lbs (10Nm).

d) If you are sure of the support the four mounting locations will provide, move to

Section 4; if not, finish Section 3.

STOP

STOP

6

4) If the measured mounting points do NOT allow drilling into solid material, try one of these

two methods to create a secure connection:

1If the mounting points appear to be in the area of the window frame header, but

the mounting screws are not engaging it, the header may not be flush to the near

side wall and out of reach, but a longer screw may allow proper engagement.

•Use an extended bit (3/32” dia. or smaller) and drill pilot holes at all of the

mounting points to determine if the header can be reached by simply drilling

deeper into the wall. If this is the case, longer mounting screws will be needed.

•If longer screws are purchased on your own,use a screw certified to a US

building standard, such as ICC-ES-2236.

oBBP recommends using Simpson Strong-Tie/Strong Drive® self-drilling wood

screws, available at most hardware stores.

oIf there is any issue obtaining screws of the appropriate strength or length,

contact the Ballistic Barriers helpline at (833) 285-5380.

2Hold one of the Wall Bracketsup so the slots align with the mounting locations. If

the position of any of the studs/header misses the mounting points but will sit

beneath an open area on the Wall Bracket, you may drill supplementary ⅜” holes

into the Wall Bracket that will allow screws to engage the studs/header.

•If this modification is pursued,you must photo document the placement of

the holes and submit them to Ballistic Barriers for certification.

If neither of these solutions will suffice, contact the Ballistic Barrier assistance line,

(833) 285-5380, Monday – Saturday, 6 AM to 10 PM PST. You can call this line at any

time outside of office hours and leave a message and the support team will make

every effort to return your call as soon as possible, no matter the time of day.

Most Common

Header

Header Set to

Far Wall,

Screw Cannot

Reach

Longer Screw

Engages Header

Okay to Drill New Mounting

Holes in the Areas Highlighted

In Dark Gray

Mounting Points in This Area

Will Not Fully Engage Studs or

Miss Studs Completely

STOP

STOP

7

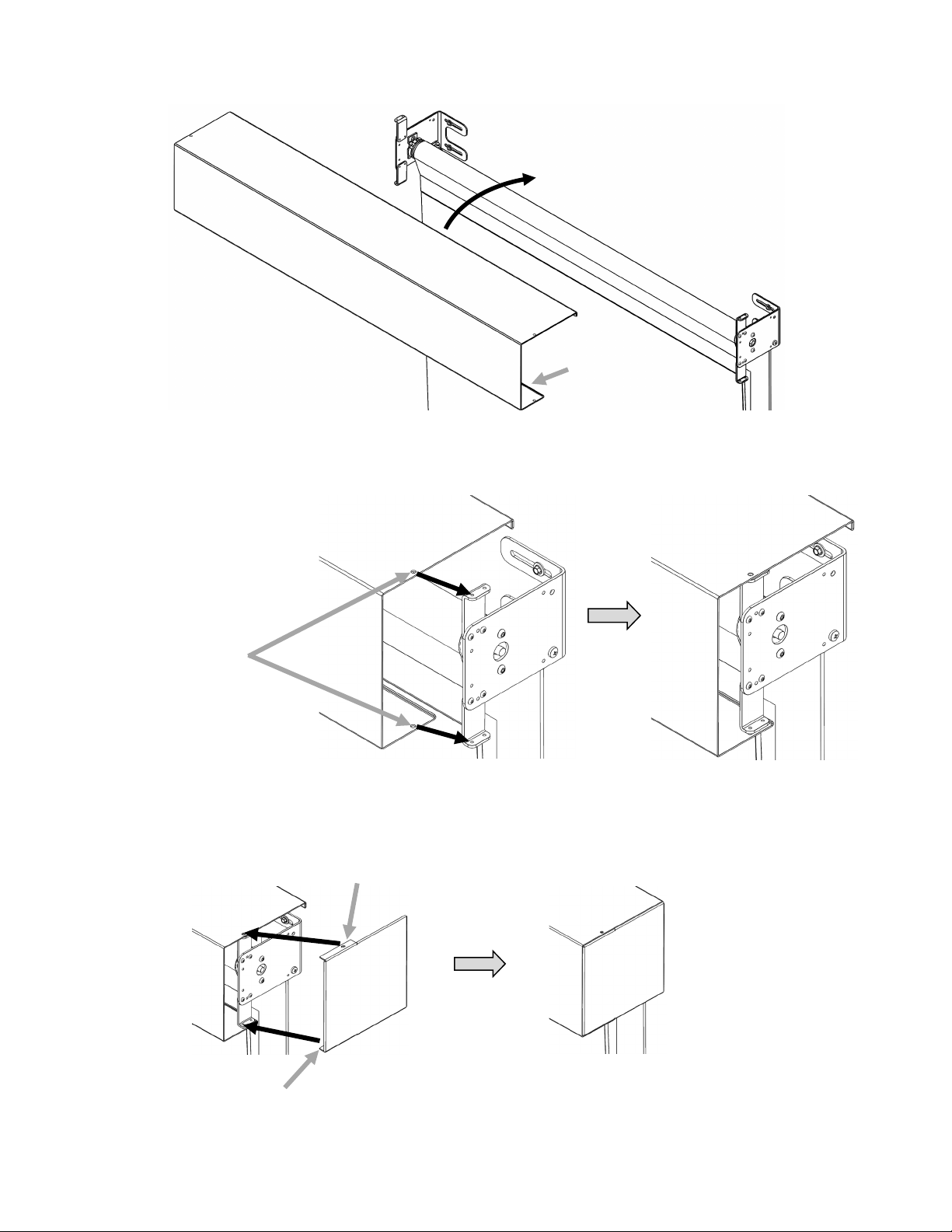

3. Wall Bracket and Shade Installation

NOTE: The following images depict a motor with a left-side power cable.

•If your product has a right-side power cable, all installation images in this section will

mirror your actual components.

1) Drill pilot holes at each of the four mounting locations marked in Section 2.

•For concrete or brick, use a 3/16” drill bit.

•For wood or steel studs, use a 3/32” drill bit.

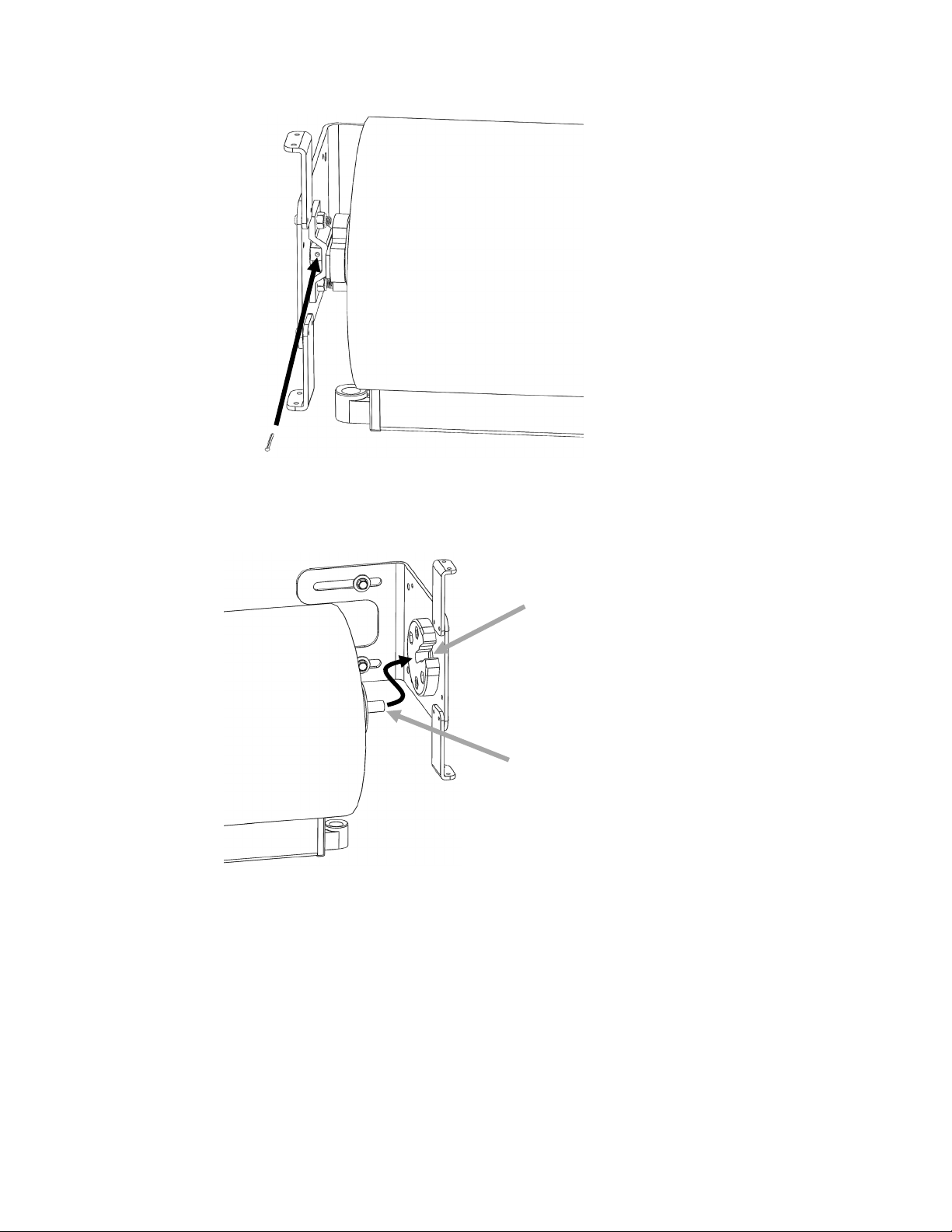

2) Align the left Wall Bracket (the Motor Side Wall Bracket for a left-side power cable

installation) so that the two slots are at the heights of the mounting points.

3) Adjust the horizontal position of the bracket so the inside face of the bracket is 1½” from

the mounting points (see image below).

4) Use a bubble level to ensure the bracket is level.

5) Drive the mounting screws into the bracket, one in each mounting slot.

•For wood or steel studs, use ¼” wood screw and washer.

•For concrete or brick, use a ¼” concrete screw anchor and washer, do not exceed 20

ft-lbs of torque when driving in the screw.

•If, for some reason, you cannot use the screws provided with the assembly, use

hardware that is certified to a high standard, such as ICC-ES-2236. As this a product

that is meant to stand up to bullet impacts, there is risk in using low-quality

hardware that is not made to meet US building codes.

For mounting screws, BBP recommends:

oSimpson Strong-Tie/Strong Drive® self-drilling wood screws

oTapcon® concrete screw anchors

6) Move to the right side of the Window and repeat the process for the right Wall Bracket.

1½”

Use a Bubble Level

to Confirm Bracket

is Level

STOP

STOP

8

7) Use a 4 ft bubble level to assure the two brackets are level with each other (if the brackets

are further than 4ft apart, span the gap with a flat, rigid material and place the level on that

material).

8) Lift the Shade up and work first on the power cable side of the roll and engage the Square

Male Motor Shaft into the mating Female Mounting Hole on the Motor Side Wall Bracket.

Use a 4ft Bubble Level

to Confirm Brackets Are Level

Square Male Motor Shaft

Mating Female Mounting Hole

Power Cable

Side of Shade

(Left-side Power Cable Shown)

9

9) Insert the Cotter Pin into the hole in the square male to hold that side of the Shade in

place.Do not bend the Cotter Pin legs yet.

10) On the opposite side of the Shade, press in the Spring-Loaded Idler Shaft and maneuver

the Shade so that shaft will sit in the mating cavity of the plastic Idler Mount.

Cotter Pin

Spring-Loaded Idler Shaft

Mating Idler Mount

Idler Side of Shade

(Left-Side Power Cable Shown)

10

4. Hem Bar Lock Installation

IMPORTANT TO UNDERSTAND:The Hem Bar Locks are optional to install; however, they are

recommended as they maximize the protection the shade will provide as they secure the

bottom of the shade in place when it is deployed.

•If the fabric is shot at, the impact of the bullet does cause the fabric to rise up as it

“catches” the bullets. The amount that it pops up is dependent on a number of

factors and is complicated enough that BBP can offer no exact data on the severity

other than to say, typically, 9mm rounds hitting a shade in quick succession from a

handgun, impacting the center of a 3ft x 4ft shade will see the shade lift up only a

few inches with each hit, and the lifting effecting is not necessarily cumulative with

each successive shot.

•If the bottom of the shade is secured by the Hem Bar Locks, the amount it can lift

up is negligible.

•The locks also keep the shade from being easily pushed out of the way by an

intruder.

•However, while the weight and momentum of the shade being lowered allows the

locks to open and engage the Hem Bar without any intervention, to raise the shade,

the locks must be disengaged manually by pushing the plastic latch back and

removing the Hem Bar from its grasp.

•If having a manual release poses a major issue, omitting the installation of the locks

can be deemed low (but not zero) risk of injury if at least three of these conditions

are met:

a) The bottom of the window is at the floor of the room and it is deemed

unlikely that a threat would be shooting that low to the ground.

b) A bullet entering the room near the bottom of the shade would pose a

threat that is manageable (the likelihood of a human target being near the

bottom of the shade is impractical).

c) The shade is well over 12 sq ft in size (large and heavy – the larger, the

better).

d) It is anticipated that the threats would be limited to lower caliber bullets

and semi-automatic only.

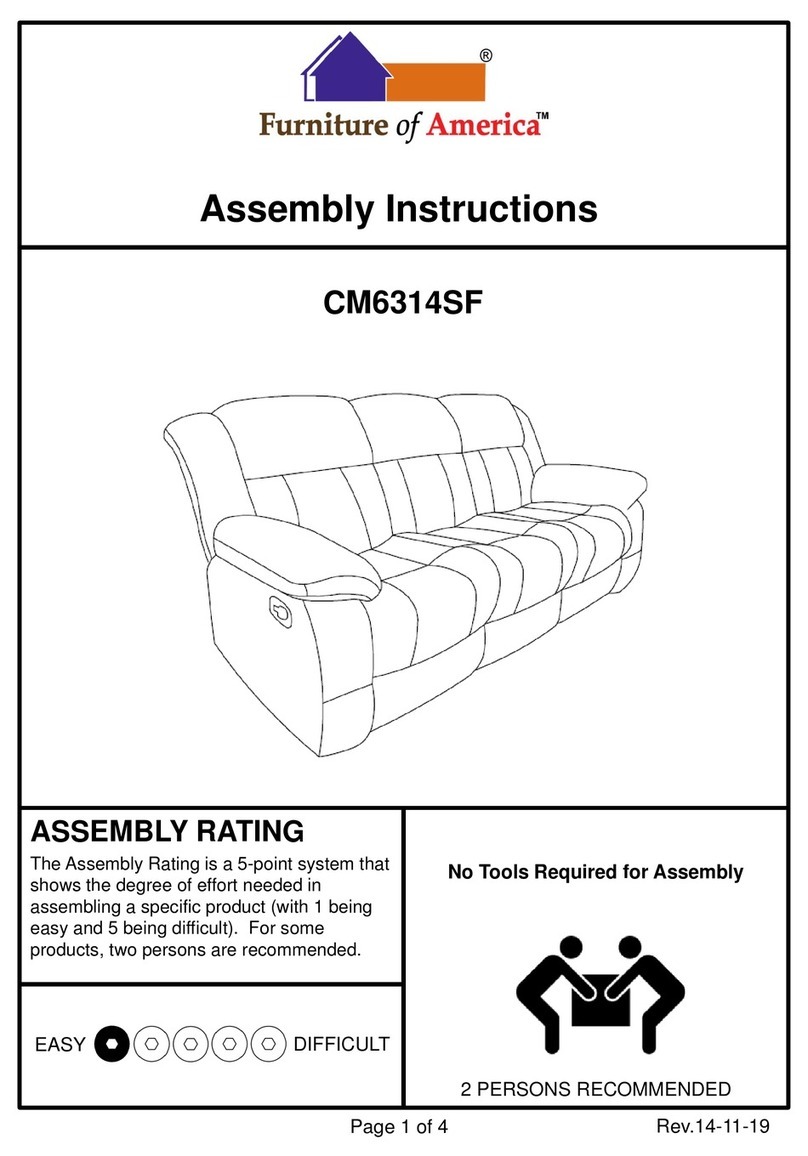

To install the Hem Bar Locks:

1) Power up the Shade and extend it to its full extent (to

operate the motor, see separate instructions for the

exact type of motor and switch model included with your

product).

11

2) IMPORTANT: Make sure the Hem Bar is centered in the shade.

3) Use the location of the Hem Bar to define the mounting position of the Hem Bar Locks:

1. Let the Shade hang down without any interference.

2. Place the left Hem Bar Lock so the latch is engaged on the Hem Bar such that

the inside edge of the sheet metal surface is approximately ¾” from the edge

of the fabric.

3. Place the mounting surface of the lock against the wall and make sure the

shade is hanging naturally in its deployed position as you do this.

4. Use a pencil to trace the interior of the mounting surface slot.

12

5. Remove the Hem Bar from the lock.

•Masonry walls: mark two drill locations within the area of the slot that

was marked on the wall and drill pilot holes with the 3/16” bit. The drill

locations can be anywhere in the slot, but should be at least 1½” apart.

•Wood or steel stud walls: use a stud finder or any other method to identify

where the wall studs lie in relation to the slot marked on the wall.Mark

two drill locations (at least 1½” apart from each other) anywhere in this

slot outline that are over the location of the wall studs.

It is critical that both of the screws are engaged into a solid mounting material

such as a stud or masonry. If you are unable to find a solid connection point

for the mounting holes, contact the Ballistic Barriers helpline at (833) 285-

5380.

4) Mount the left Hem Bar Lock to the wall by driving two of the screws with washers into the

two drill locations.

•Masonry walls: use the ¼” x 2¼” concrete anchor screws.

•Wood or steel stud walls: use the #10 x 1½”Torx pan head screws .

5) Repeat this entire process for the Hem Bar Lock on the right side of the Shade.

STOP

13

6) Test the function of the locks by raising and lowering the Shade into place several times

over. Each time it is lowered, the hem bar should lock into place on its own; each time it is

raised, the locks must be released manually by:

1. Pushing the sping-loaded latch back to disengage the bar.

2. Lifting the hem bar out of the lock.

14

5. Testing and Final Adjustments

1) Test the product and make sure that it runs fluidly, and that the cover goes all the way up

and down.

•Confirm the window can open and close satisfactorily with the cover completely

retracted.

•Once you are certain that no adjustments are needed, proceed to the next step, which

will install the Shaft Retainer and essentially lock the roll from coming out. After this

lock is in place, if there are any adjustments needed that would require removal of the

Shade, the entire product will have to be partially disassembled to remove the

Retainer as it can only be removed by sliding it out the side of the Idler Mount (it

cannot be pulled out the opposite direction it was inserted). If there is any doubt,

please contact our helpline at (833) 285-5380.

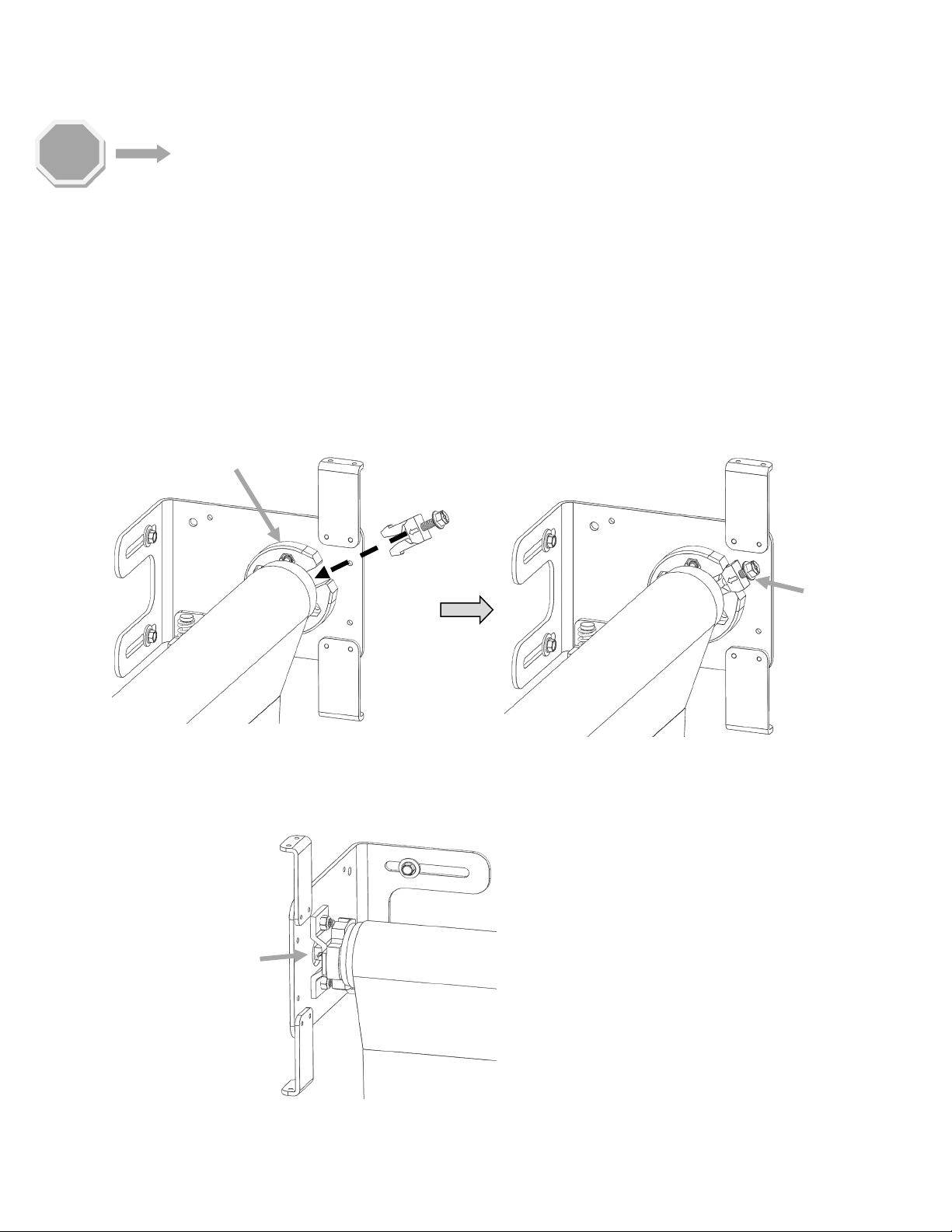

2) Place the fork-shaped Shaft Retainer into the slot of the Idler Mount and press it into place.

If the screw has not been sufficiently backed out, the two arms of the fork will not compress

enough to allow the Retainer to be pushed into place.

3) Tighten the screw on the Shaft Retainer several turns to secure it into place.

4) Use a pair of needle nose pliers to bend the legs of the motor mount Cotter Pin so it will stay

in place.

②

①

Insert Retainer

Tighten Screw

Idler Mount

Cotter Pin

STOP

15

5) Place the Fascia over the top of the Shade.

6) Align the Fascia Mounting Holes with the matching holes on the legs of the Wall Brackets

(both sides).

7) Add the End Covers by sliding them over the Wall Brackets but beneath the Fascia such that

the mounting holes align with the Fascia mounting hole and the End Cover Tabs are tucked

beneath the Fascia.

Place Fascia Over the

Top of the Roll Good

This Fascia

Edge Will Go

Up Against

Roll Good

Fascia

Mounting

Holes

End Cover Tab

End Cover Tab

16

8) Drive two 8-32x5/8” Pan Head screws on the top side (one per side) to secure the Fascia

and End Covers to the Wall Brackets.

9) Drive two more screws on the bottom side (one per side) to secure the Fascia and End

Covers to the Wall Brackets.

10) Test the product once again, making sure that it goes all the way up and down.

Top Screws

Bottom Screws

17

6. Installation Certification

In order for the installation to be certified, photograph the following area of the installation of each

window and submit them to the Ballistic Barrier sales contact.

1. At least four pictures total that will include:

a. Picture of the mounting of the window cover in the deployed position. Capture the

entire window and the mounted assembly.

b. Picture of the mounting of the window cover in the retracted position.

c. A close-up of the right-side Hem Bar Lock, as it is mounted to the wall.

d. Repeat for the left-side Hem Bar Lock.

e. If the Hem Bar Lock assemblies were omitted, an oral or written statement from

the customer must be noted, and then a WRITTEN statement from the installer to

BBP that the customer approved the installation omission.

2. Photos of any modifications, even if they are approved by Ballistic Barrier.

3. Photos or video of any element of the product that causes you concern.

7. Warranty and Limit of Liability Information

Ballistic Barrier Products, Inc. ("BBP," "we," "us" or "our") provides access to this product

(collectively, "Products") to you ("you" or "your"), subject to the following Terms of Use and

Conditions of Sale (collectively, the "Terms and Conditions") with the following limited warranty

and limit of liability, which may be revised and updated by us from time to time, with or without

notice to you. For the most up-to-date and comprehensive terms and conditions of this sale, visit

www.ballistic-barrier.com/warranty.

Limited warranty

BBP warrants that all product is sold new.

Fabricated parts will meet physical dimensions that are based on the customer-supplied

dimensions for any window or door that is intended to be protected by the product. For any

object, material, or ingress/egress that is intended to be protected by the product that does not fit

a generally acceptable definition of a window or door, BBP must agree upon warranty coverage for

said item in writing for these terms and conditions of sale to be applicable. Without expressed

consent for coverage, use of the products is deemed as unintended, and all warranties, both

express and implied are void.

Installation of the product will be performed in accordance with generally acceptable industry

standards. You agree to inspect all installation work performed by BBP within three (3) business

days from the date of installation. If any installation services are determined not to conform to

industry standards, then BBP shall, at its option, either re-install the material or refund the cost of

such installation services.

Installation services provided by BBP will be defect-free for a period of one year from the date of

the delivery of the original sale.

Installation services provided by a BBP partner will be covered in accordance with the warranty

provided by said affiliate.

If the product fails to conform to the specified warranty, BBP, at its option, will determine if onsite

repair or a replacement is best suited for a solution.

18

BBP shall assign to you any vendor/warranties and/or remedies provided to BBP by its vendor to

the extent permitted by BBP's vendors/manufacturers.

You agree not to return the products until BBP agrees that you may do so.

All warranties will be void after the product has undergone a shooting event that exceeds the bullet

caliber, velocity, angle of fire, or quantity of impacts that it was certified to resist.

In a failure to meet the certified standard in a shooting event, BBP's liability will be limited to a

maximum value that will not exceed the cost of the original sale of the product to you.

Some jurisdictions may not allow the exclusion of certain types of warranties, including, without

limitation, implied warranties. As a result, the above limitation or exclusion may not apply to you.

The mechanical aspects of the product are warranted to be free of material or workmanship

defects for a period of one year from the date of initial purchase. This warranty includes the cost

of repairing or replacing materials (at BBP's discretion) and any shipping costs involved. Outside of

this, the cost of repairs will be handled on a case-by-case basis.

The product is guaranteed to function, in its ability to resist impacts from handgun fire that are in

accordance with the product's certification, for a period of seven (7) years. In a failure to meet this

guarantee, BBP will repair onsite, replace, or refund the cost at its discretion.

See also any applicable Conditions of Sale at www.ballistic-barrier.com/warranty for any other

conditional warranty information related to specific Product sales.

Limitation of Liability

To the fullest extent permitted by law, in no event and under no theory of liability, including

contract, tort, negligence, strict liability, warranty, or otherwise, will the BBP entities be liable to

you or to any other person or entity for any indirect, consequential, exemplary, incidental, special,

or punitive damages, or lost profits arising from or relating to these terms of use or your use of the

products.

Access to, and use of, the products is at your own discretion and risk, and you will be solely

responsible for any damage or injuries resulting in the product failing to perform outside the

standards to which it is certified.

In no event will the aggregate liability of the BBP entities exceed one hundred U.S. dollars ($100).

The limitations of this section will apply to any theory of liability, including those based on

warranty, contract, statute, tort (including negligence), or otherwise, and even if the BBP entities

have been advised of the possibility of any such damage, and even if any remedy set forth herein is

found to have failed its essential purpose.

The foregoing does not affect any liability that cannot be excluded or limited under applicable law.

If you are dissatisfied with the products, or with the terms of use, your sole and exclusive remedy is

to discontinue using the products.

Any cause of action against BBP with respect to the products must be instituted within one (1) year

from the date on which the claim arose.

See the Conditions of Sale at www.ballistic-barrier.com/warranty for all other limitations of liability

information related to Products.

Table of contents

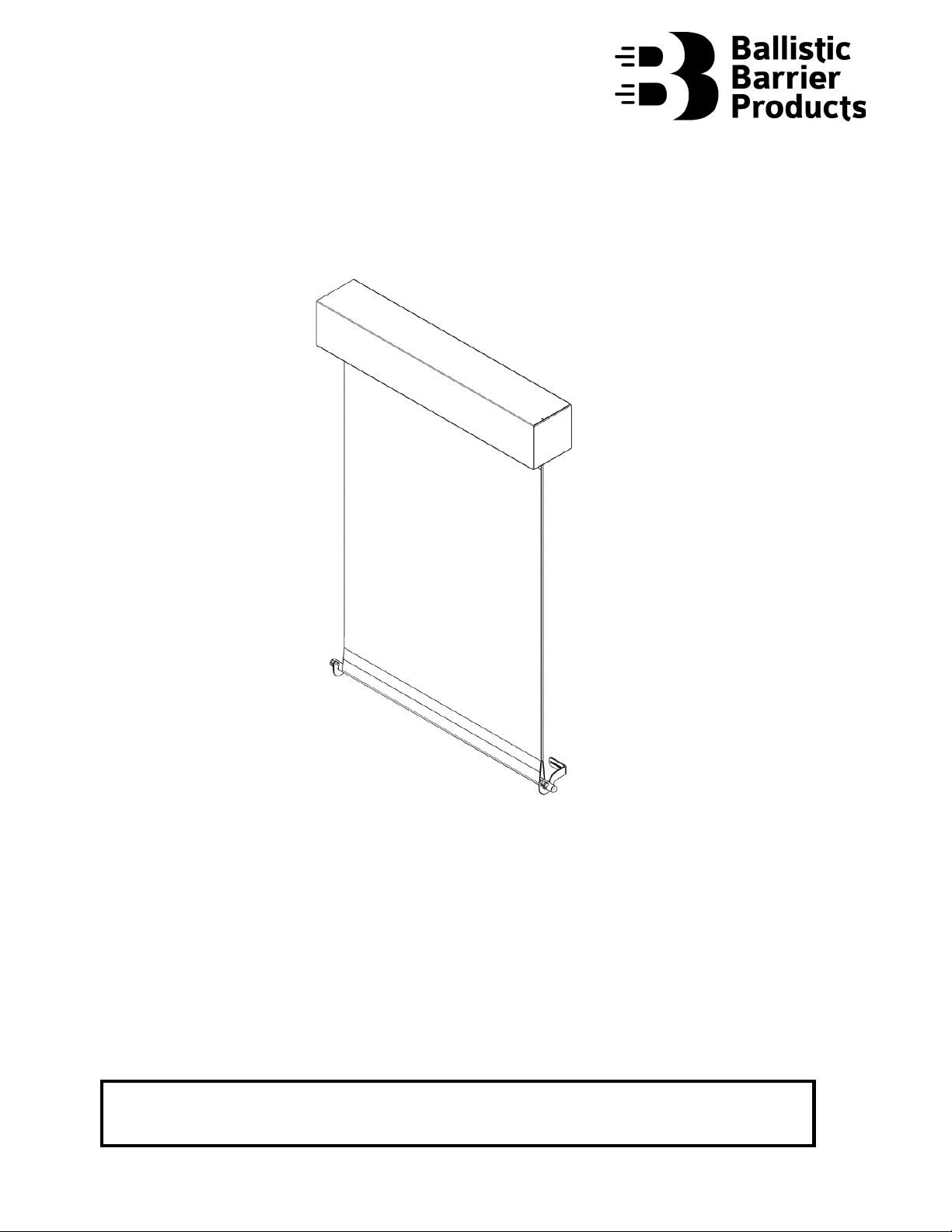

Popular Indoor Furnishing manuals by other brands

Furniture of America

Furniture of America CM6314SF Assembly instructions

Godrej

Godrej CREST DIGITAL user manual

ofichairs

ofichairs Cube How to Adjust

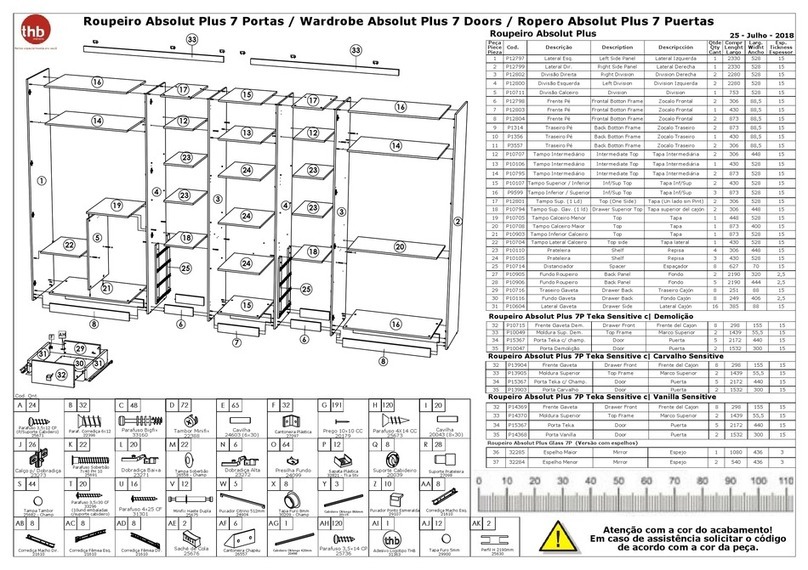

THB

THB Wardrobe Absolut Plus 7 Doors Assembly instructions

OAKWORKS MEDICAL PRODUCTS

OAKWORKS MEDICAL PRODUCTS Powerline Series user manual

Baumax

Baumax DALIA 50 Assembly instructions

LPD Furniture

LPD Furniture STOCKHOLM 1 DRAWER BEDSIDE CABINET Assembly instructions

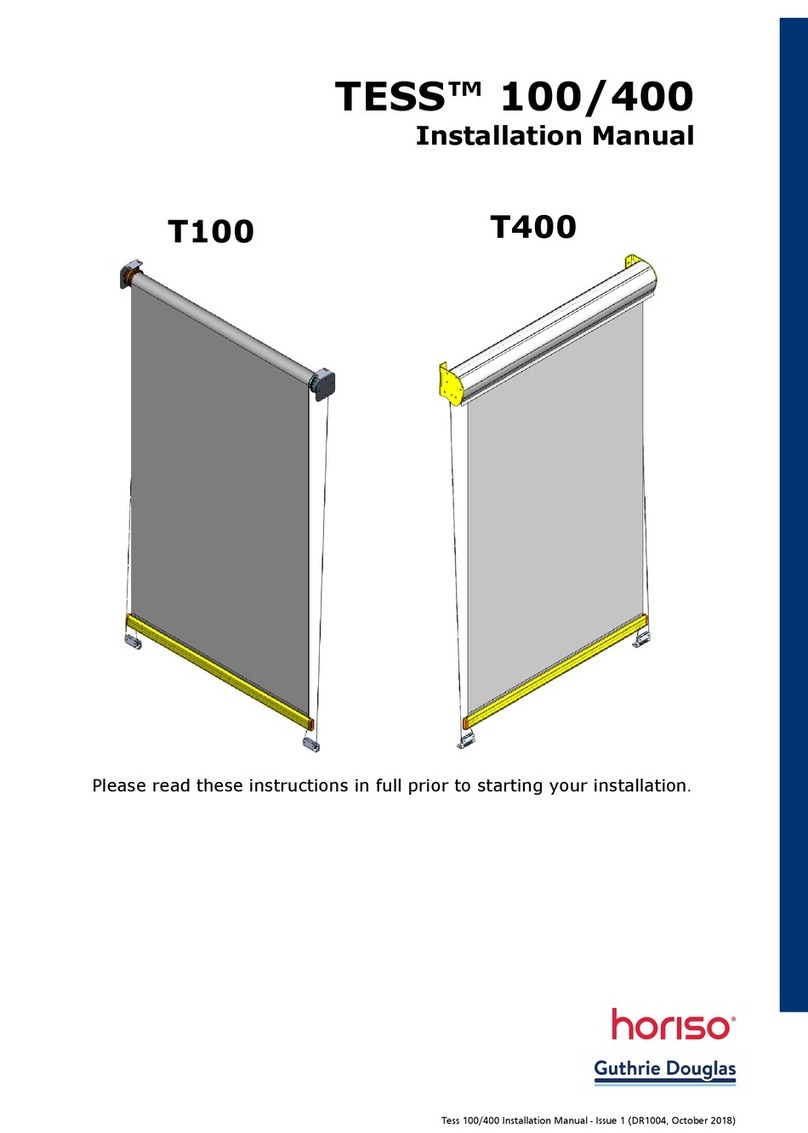

Guthrie Douglas

Guthrie Douglas Tess 100 installation manual

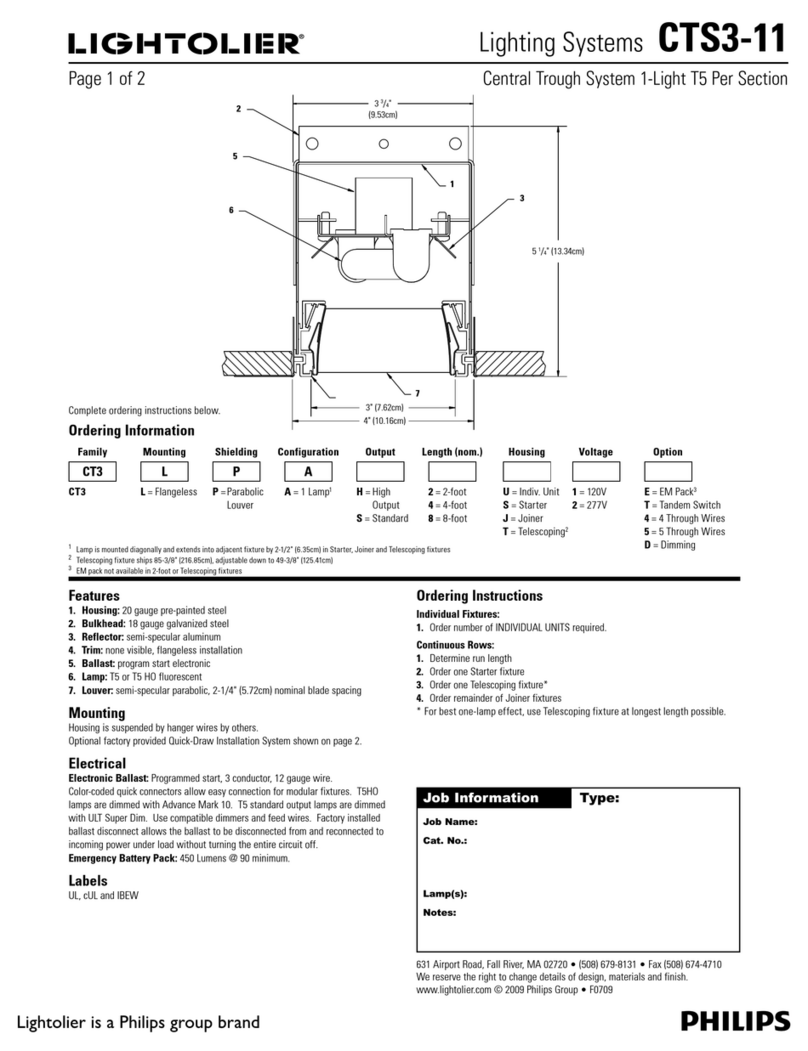

Lightolier

Lightolier CTS3-11 specification

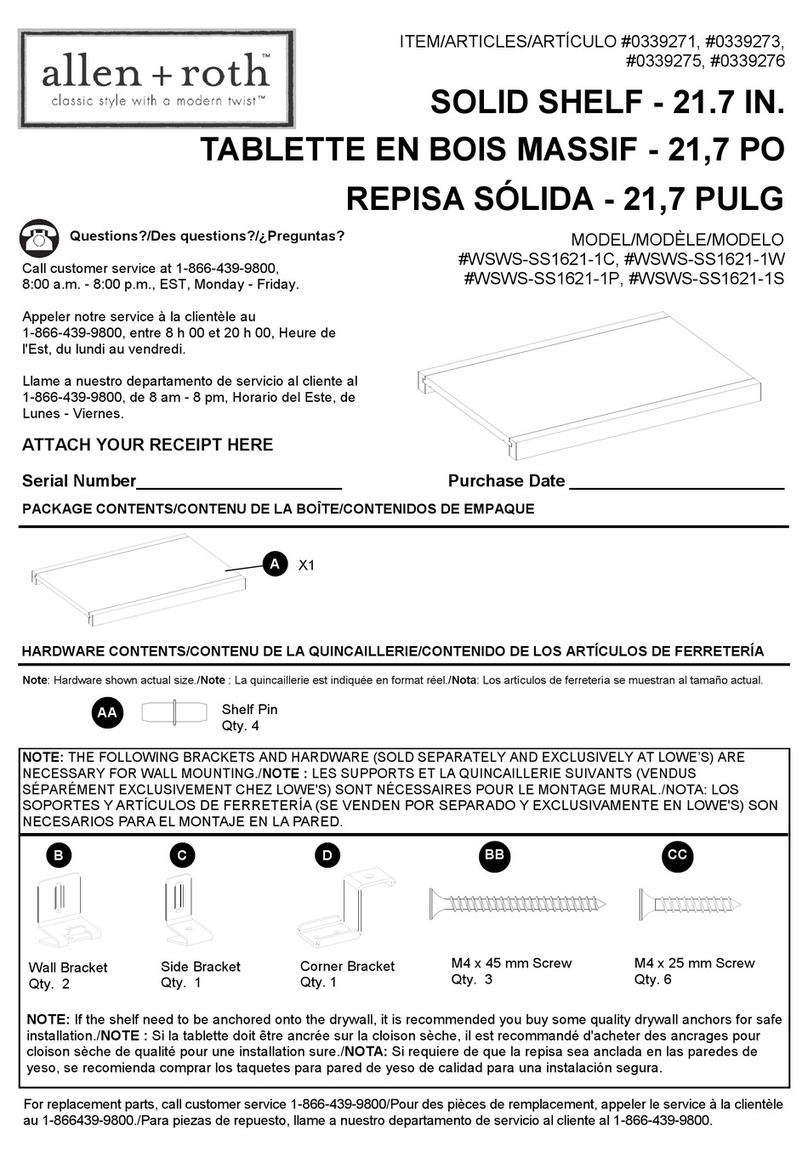

Allen + Roth

Allen + Roth WSWS-SS1621-1C manual

Threshold

Threshold Cambridge T71113-4A Assembly instructions

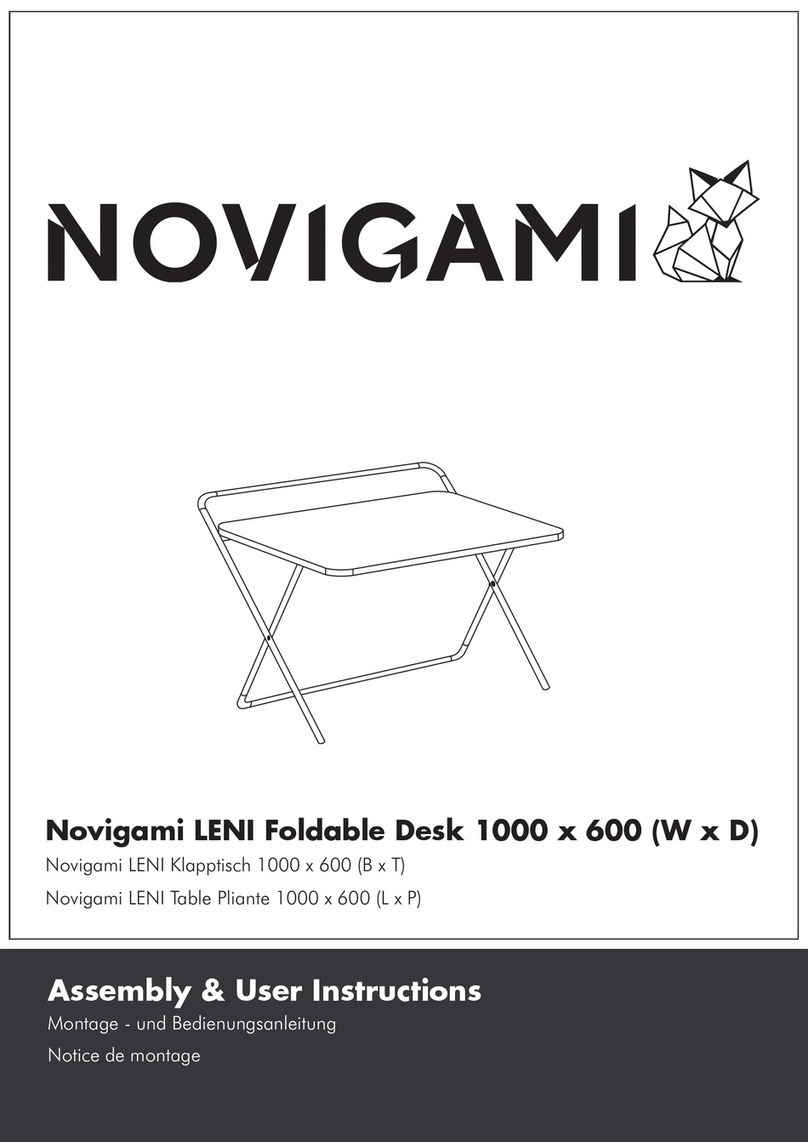

NOVIGAMI

NOVIGAMI LENI Assembly & user instructions