BCF Technology OVISCAN 6 User manual

Page - 1

BCF TECHNOLOGY LTD

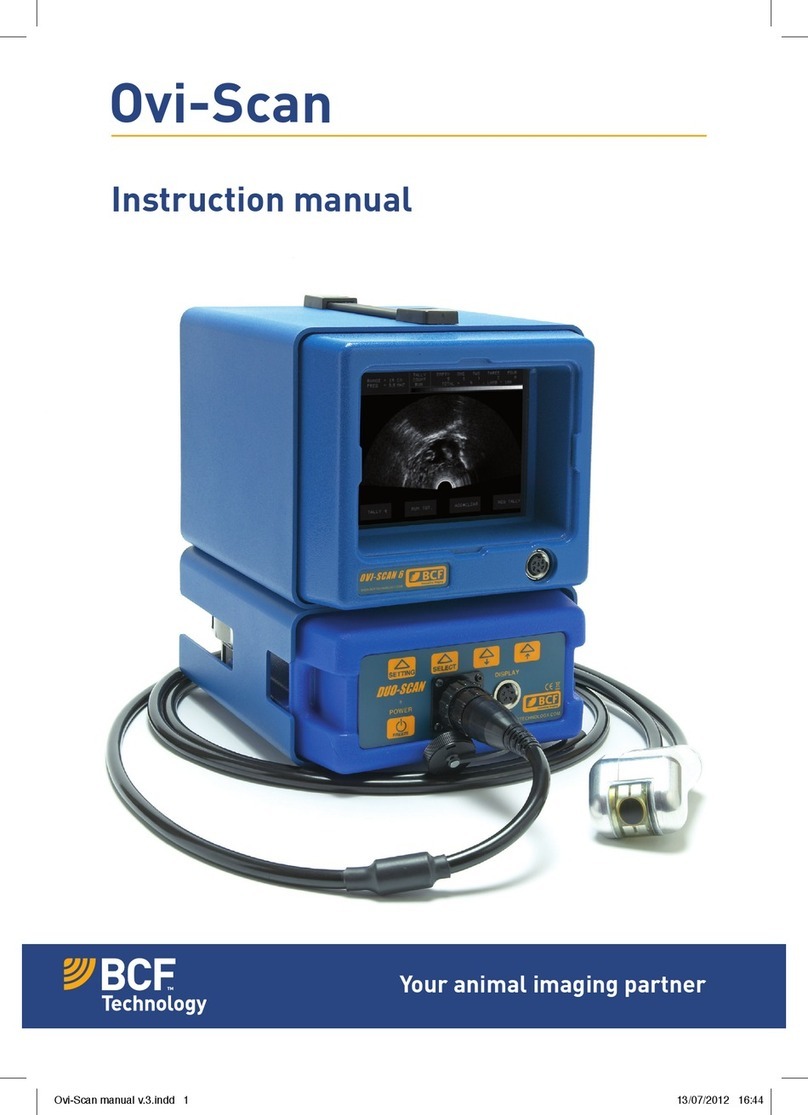

OVISCAN 6 + DUOSCAN 3

TECHNICAL MANUAL

Copyright BCF 2006

All rights reserved. Reproduction in whole or part of all material in this publication, including

drawings or diagrams is forbidden.

This manual is confidential to BCF Technology Ltd. and is supplied for use only in connection

with the operation and/or maintenance of the OVISCAN 6 as supplied by BCF Technology Ltd.

The contents must not be used for any other purposes, nor disclosed to any third party, without

prior consent of BCF Technology Ltd.

This document contains information available at the time publication. BCF Technology Ltd.

reserves the right to modify or revise its contents.

Page - 2

INTRODUCTION

This manual is intended to supplement the operators manual for the BCF OVISCAN 6 giving

more detailed technical information about the instrument and the data necessary to carry out

servicing and repair procedures.

Full information is given for the control console and module with some information being

supplied for the probes.

EQUIPMENT WARRANTY

The OVISCAN 6, including accessories is warranted against defects in design, materials or

workmanship, for a period of 12 months, from the date of commencement of the warranty period.

If any defect in design, material, or workmanship appears within the period of warranty, BCF

Technology Ltd. or its designated agent will in the case of all equipment, correct the defect by

making any necessary repairs or at its option, replacing any defective parts.

This warranty does not apply to and the company assumes no responsibility for damage or

deterioration due to any cause other than that specified above and in particular, but not by way of

limitation, this warranty does not apply to and the company assumes no responsibility for normal

wear and tear, or for damage or deterioration if the equipment has been subject to abnormal

conditions.

EQUIPMENT SERVICING

BCF Technology's products are supported by a world-wide network of highly trained technical

service representatives and engineers for prompt service of customer needs.

If required, rapid service assistance can be provided by contacting your local BCF Technology

representative, or communicating directly to:

BCF Technology Ltd.

3 Rutherford Square

Brucefield Industrial Park

Livingston

West Lothian

EH54 9BU

TEL: 44 (0) 1506 460023

FAX: 44 (0) 1506 460045

Email: office@bcftechnology.co.uk

Page - 3

CONTENTS

2DESCRIPTION AND OPERATION 4

Probe and Ultrasound Energy 4

OVISCAN 6 6

Overview 6

Console 6

CIRCUIT DESCRIPTION : Console PCB 9

Module 13

CIRCUIT DESCRIPTION : System PCB 15

CIRCUIT DESCRIPTION : Supply PCB 19

CIRCUIT DESCRIPTION : Interface PCB 21

MECHANICAL DISASSEMBLY 24

CONSOLE 24

MODULE 24

ANNUAL MAINTENANCE 25

CIRCUIT DIAGRAMS, PCB TEST AND LAYOUT 27

Console 27

Console PCB 27

Module 27

System PCB 27

Interface PCB 27

Supply PCB 27

WIRING SCHEDULES 27

Console 27

Module 27

Keypanel 27

APPENDIX : CONSOLE PCB DIAGNOSTIC INFORMATION 28

Page - 4

Description and operation

Probe and Ultrasound Energy

The standard probe has four transducers mounted in a drum which rotates in silicone fluid.

Connection to the rotating transducers is via slip rings and brushes from which four coaxial

cables carry the transducer signals to the receiver board. Only one transducer is used at any one

time.

The transmitter pulse waveform is selected to give efficient transformation from electrical energy

to ultrasound and a reduction of reverberation energy. The initial pulse at the transducer is

negative with an amplitude between 25 V. and 200 V. depending on the transmit power selected.

The negative voltage is held for a time equal to half the natural resonance period of the transducer

then released for an equal period then re-applied for a further equal period.

The system normally operates with the transmitter pulse width at the natural resonant frequency

of the transducer crystals and with the receiver filters set to the same frequency.

The system can be operated at other than the natural frequency, controlled from the menu settings.

The silicone fluid acts both as a lubricant for bearing surfaces and as a coupling medium for the

transmission of ultrasound energy to and from the face of the transducers. Ultrasound energy of

the frequency used in the OVISCAN 6 is strongly absorbed in air and will travel only a few

millimeters through it.

When the probe is not in contact with an object a characteristic reverberation pattern is displayed

on the screen. This happens because of the very large difference in acoustic impedance between

the material of the probe window and the outside air resulting in a very strong echo from the face

of the window. As this is close to the transducer, energy reflects back and forth between the

window and the transducer. This continues until the energy is reduced to an insignificant level.

When the probe is held in contact with an object which readily conducts ultrasound the

reverberation pattern disappears as the sound continues straight through the window and into the

object. In the case of using an animal as a scanned subject a couplant must be used to exclude air

from between the probe and the subject and prevent reverberation.

Because of the small distances involved in the generation of the reverberation pattern any small

distortion in the window can appear as a large distortion in the pattern. These distortions too will

disappear when the probe contacts a subject. Distortions in the window may occur as a result of

manufacturing tolerances or as a result of accidental damage to the probe.

For a similar reason, small differences in angular alignment between the transducers may appear

Page - 5

as a "flicker" in the reverberation pattern when the probe is not in contact with a subject. This

effect which shows a small random variation from probe to probe will also disappear when the

probe is scanning normally in contact with a subject.

The probe head also contains the following:

A dc motor and gear train to rotate the transducer drum.

A magnetic pick up, the resolver, sensing teeth on one of the gears to provide a signal for

rotational speed control and drum position feedback.

A magnetic pick up, the index sensor, sensing a slot cut into one of the gears providing a

signal to align the screen image with the transmitted sound.

A magnetic coupling to transmit the rotating forces through to the sealed compartment

containing the transducer drum.

A capillary tube to accommodate normal expansion and contraction of the volume of

silicone fluid without pressure changes.

Page - 6

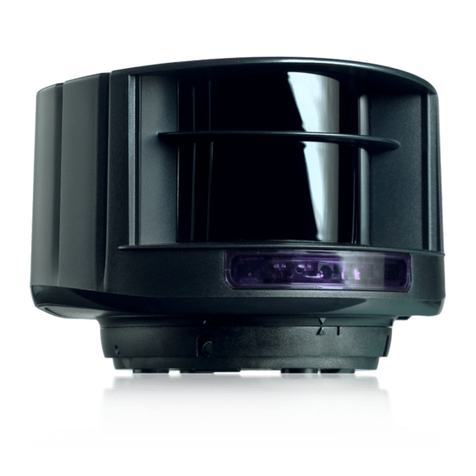

OVISCAN 6

Overview

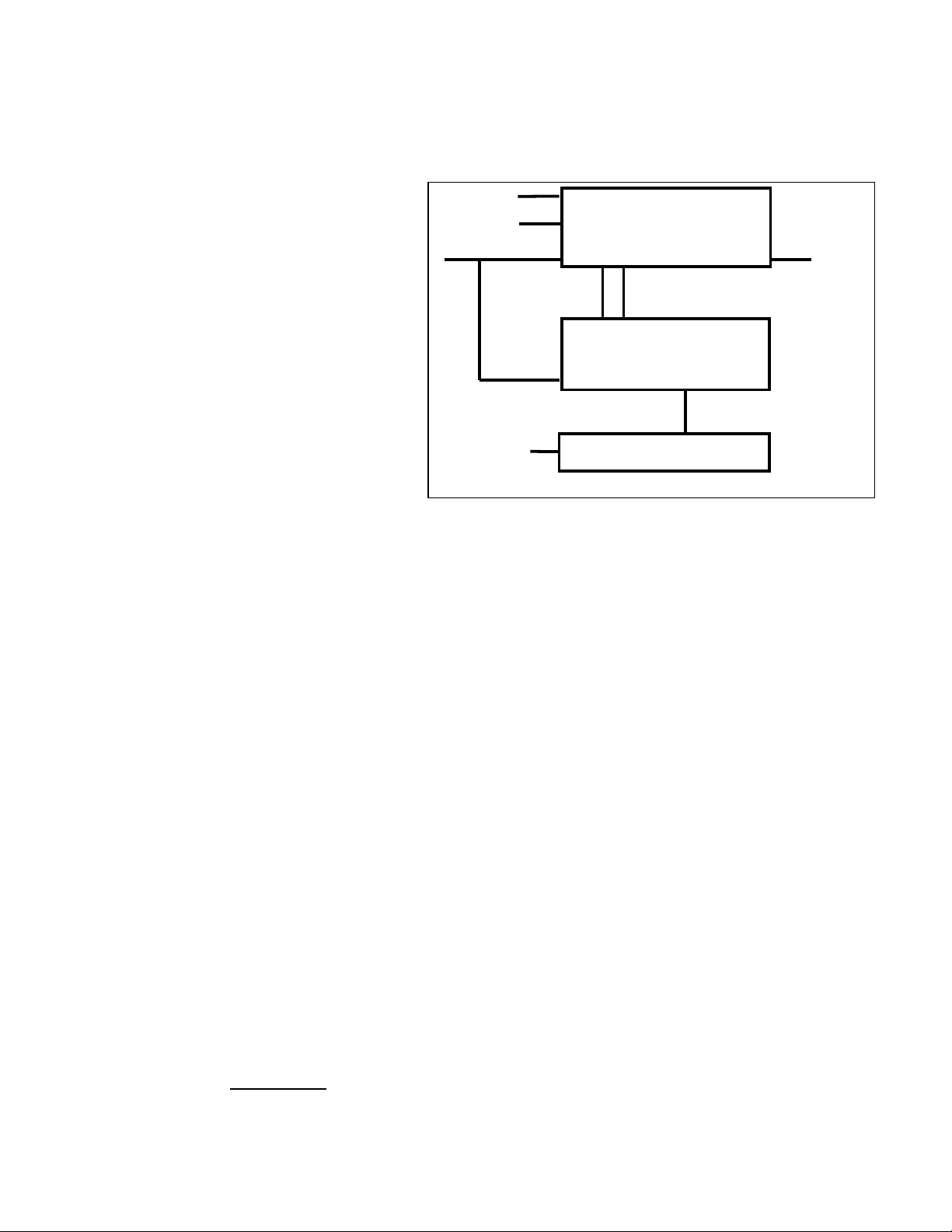

The CONSOLE provides the display and interface to tally, drafting gate, RFID reader and video

monitor while the slide-in MODULE provides the ultrasound function.

Connection to and from the module is through the securing latches which provide power to the

MODULE and 5 blind mating contacts which provide serial communication and pass video

signals between the CONSOLE and MODULE.

The module can produce an ultrasound scan as a stand-alone

unit when latched to a battery and a

portable display connected.

The console can also function as a stand-alone video monitor in the absence of a Duo-Scan.

Console

Console components are built

into an inner chassis which

slides into the outer case. This

provides good environmental

and electromagnetic protection

for system components. Further

protection is provided by a

protective carry case. The

system is resistant to dust,

vibration and water splash.

DISPLAY

The LCD display normally

displays the Ultrasound image

CONSOLE

PCB

DISPLAY

MODULE

CONSOLE

PROBE

DC

POWER

TALLY

Drafting

O/P

Video Out

Video In

CONSOLE

PCB

DISPLAY

DC Power

Tally

Drafting

O/P

Video Out

Video In Rear

Panel

Front

Panel

Blind Mate

Connectors

From module

Serial Link

Digital Video

Serial

Link

Rear

Panel

RFID

Display

Page - 7

using digital Video output fed from the module to the console PCB via the blind mating contacts

at the rear of the module. The video is a proprietary digital format, this is converted into a VGA

signal for display on the LCD panel.

The LCD can alternatively be used in Video Monitor Mode to display NTSC analogue video

input from either the console rear panel video input connector or from the internal RF Video

receiver. Analogue video inputs are converted into a VGA signal.

CONNECTIONS

The rear panel provides connectors for DC power in (2 pin Binder), video in & video out (BNC)

and Drafting Gate output (5 pin Binder). The front panel connector is for the tally controller (6

pin Binder).

CONTROLS

The only direct input control to the console is the Tally handpiece which is used to power the

console on and select one of three video sources when the console is not connected to a Duo-scan.

When connected to a Duoscan power-on commands and any setup information is transferred to

the console via the serial link. Tally keypresses are handled by the console PCB which then

transfers the information to the module via the serial link.

POWER

The Console is powered with 12V DC via the 2 pin connector on the rear panel. The 12V DC

input is distributed to;

The Module, wired to the latches on the side of the Console through a 2.5A polyfuse.

The Console PCB. Circuitry has a 2.5A polyfuse and is reverse polarity protected.

The drafting gate output (via the Console PCB) with separate 2.5A polyfuse.

Once power is applied to the console PCB it remains in a low power standby mode, waking

briefly every second to check for serial data or tally command to power on in scanner mode or

video monitor mode.

VIDEO SWITCHING

If the console is powered without the Duo-Scan module present, pressing keys 1,2 or 3 on tally

handpiece switches the console on in video monitor mode. In this mode, the tally switches

between different video inputs; tally 1 switches to the Video Input BNC on the rear panel, tally 2

switches to the RF video receiver on the console PCB, each subsequent press of tally 2 cycles

through the 4 RF channels, tally 3 selects the Digital Video Input on the blind mating connectors.

Tally 0 returns the console into low-power, standby mode.

POWER ON SEQUENCE

Following power on, the Console runs through the following sequence:

1) Checks the supply voltage, if less than 9 volts then the console will display a “Low Battery”

message for approximately 6 seconds before switching into standby.

2) Configures its on board peripherals and switches to standby mode (LED 2 illuminates briefly).

WAKEUP SEQUENCE

On waking from Standby, the Console performs the following operations:

1) Checks the supply voltage, if less than 9 volts then the console will display a “Low Battery”

message for approximately 6 seconds before switching into standby.

2) Configures its on board peripherals and displays ‘Software OK’ message

Page - 8

3) Establish communications with the Duo-Scan module, if the appropriate response is received,

the console displays a “Duo Scan OK” message and goes into Duo-Scan mode. If no (or an

incorrect) response is received, the Console displays “Check Duo Comms” and switches into

Video Monitor mode, defaulting to the digital video input.

OPERATION (DUO-SCAN MODE)

During normal operation the Console runs through the following sequence in a repeating loop.

1) Check battery voltage if less than 9 volts then the console will display a “Low Battery”

message for approximately 6 seconds before switching into standby.

2) Poll Tally input to see if a button has been pressed.

If a button is pressed, the appropriate value is sent to the Duo-Scan module and the console waits

for a reply.

If the correct reply is received, the console continues with the normal sequence.

If no (or incorrect) reply is received, the Console displays “Check Duo Comms” and switches into

Video Monitor mode, defaulting to the digital video input.

3) Poll Duo-Scan serial link for any received data, if any commands are received, the Console

executes the appropriate routine: Brightness/Contrast, Drafting Gate setup, Power Off and the

store Brightness/Contrast commands.

OPERATION (VIDEO MONITOR MODE)

In Video Monitor Mode, the console polls the Tally input to check for button presses, the buttons

have the following effects:

Tally 1: Console displays “External Video” and switches to the Video In BNC on the rear panel.

Tally 2: Console displays “RF Channel X” where X is the currently selected RF video channel,

each press of the button cycles through the 4 available channels.

Tally 3: Console displays “Duo Scan Video” and switches to the Digital Video input on the blind

mate connectors.

Tally 0: Console switches into standby mode.

OPERATION (STANDBY MODE)

In Standby mode, the Console goes into a low power ‘sleep’ mode, it wakes up every second and

performs the following checks:

1) Check battery voltage, if the console entered standby due to a low battery, the console will not

power up unless the voltage is more than 11V, otherwise the battery voltage has to be above 10V.

2) Poll Duo-Scan Serial link, if any data has been received, the console will exit standby and

perform the Power On sequence.

3) Poll Tally, if any button on the tally controller is pressed, the console will exit standby and

perform the Power On sequence.

Page - 9

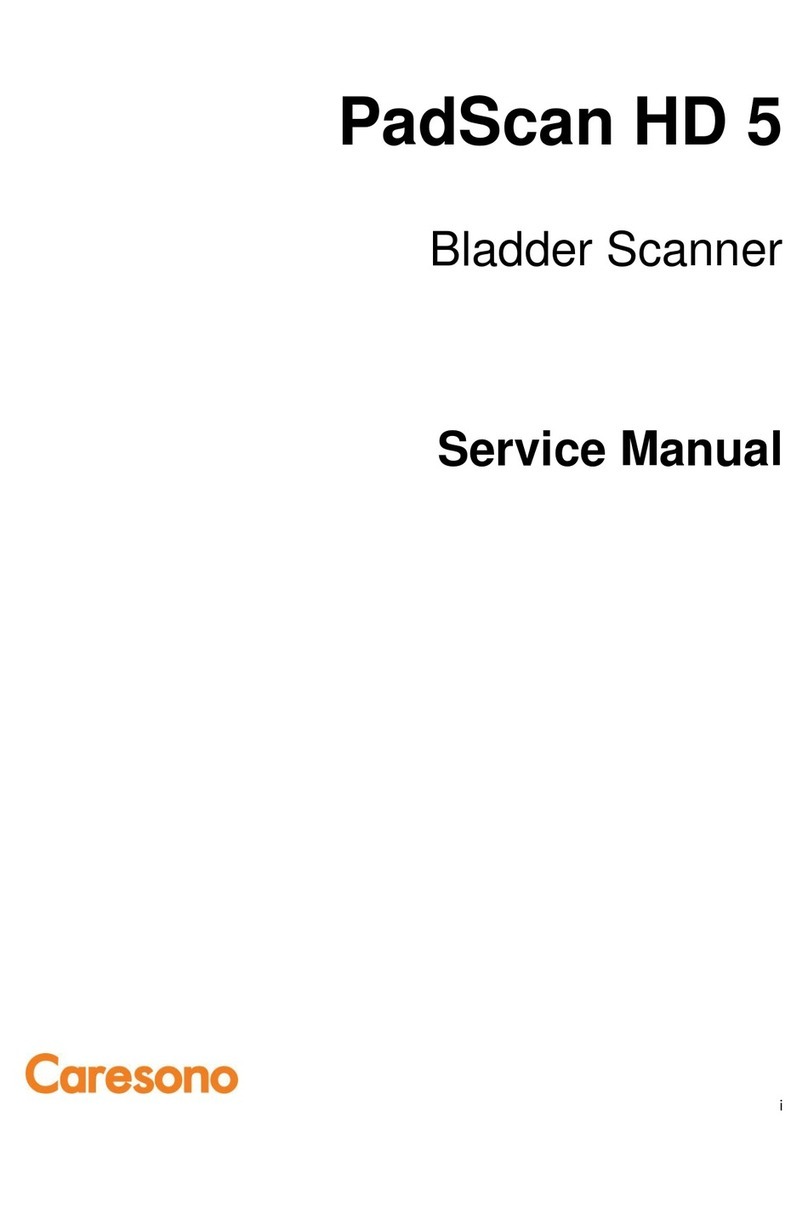

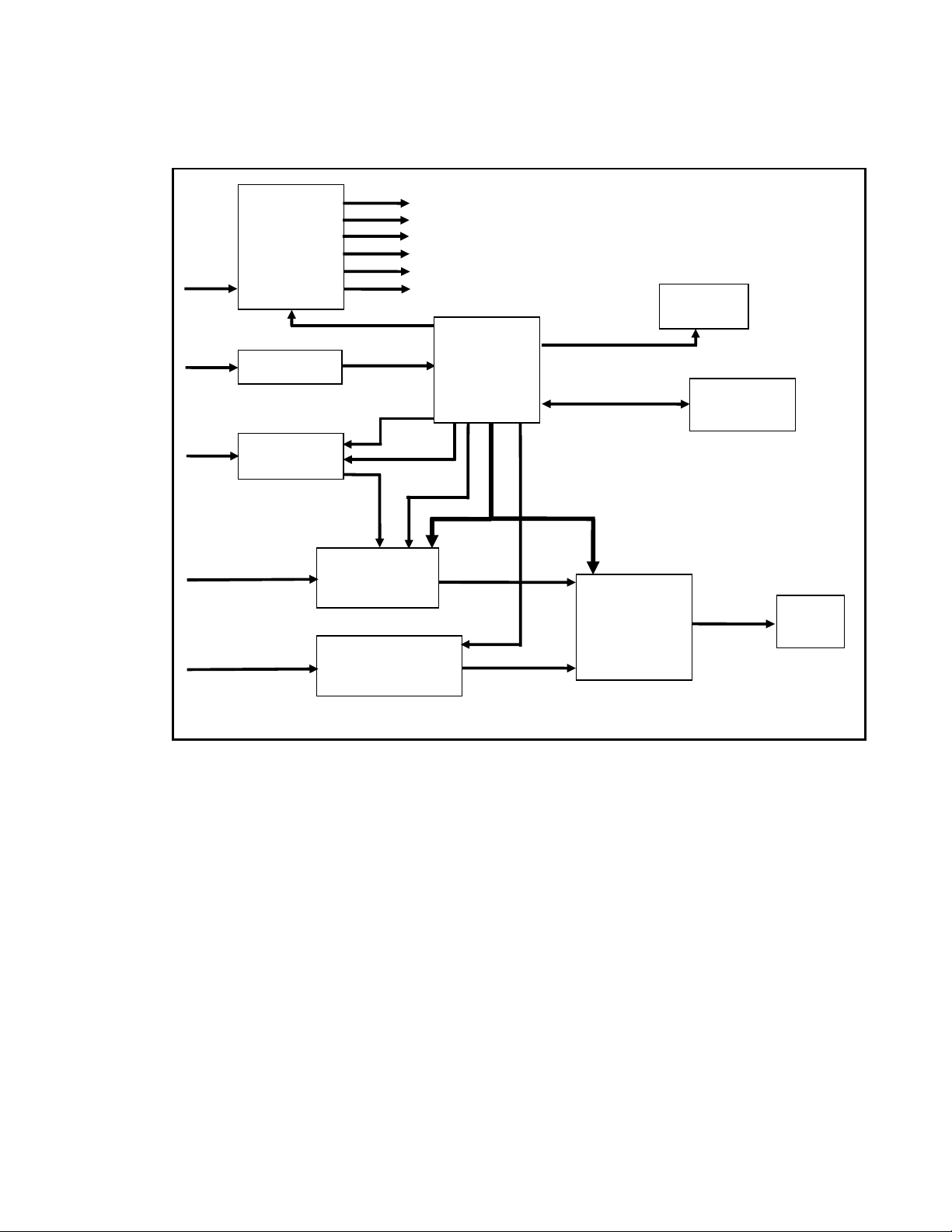

CIRCUIT DESCRIPTION : Console PCB

The Console PCB provides tally inputs, drafting outputs, communication with the Duo-Scan

module, video decoding and display signals and power. The 68HC processor (U2) is in overall

control of the operation of the Console PCB with the ability to disable parts of the circuit, as well

as shutting off power to all components except the tally pullups and RS232 transceiver (U7).

The processor reads the tally data, switches the drafting gate outputs, provides serial

communications with the Duo-Scan and the RFID reader and selects which of the 3 video inputs

is to be decoded and displayed.

POWER SUPPLY

The power supply section of the Console PCB provides power to all of the devices on the PCB

and to the inverter board for the LCD display.

The following supplies are generated:

Parallel

Video Data

Parallel

Video Data

Serial Links

Duo-Scan & RFID

Enable

I

2

C

Received Video

Drafting Outputs

Channel Select

Enable

Enable

Tally Inputs

Power On

Power Supply

Tally Pullups

RF Video Rx

U3

Video Decoder

U1

LVDS De-serialiser

Drafting

Output

RS232

Interfaces

U6

EP1C3T100C6

FPGA

12Vdc

Tally

Input

Aerial

Video In

Digital Video In

SK2

Display

1.5Vdc

1.8Vdc

3.3Vdc Standby

3.3Vdc (a)

3.3Vdc (d)

5Vdc

Block Diagram

U2

68HC908AP8

Processor

Page - 10

3.3Vdc Standby – Supplied by linear regulator, U13, to the processor, U2, RS232 transceiver, U7,

and tally inputs pull ups (RN1 & RN2). This supply is permanent and cannot be switched off, so

that the processor remains powered in standby mode and can detect tally inputs or serial data.

12Vdc – Supplied by switching regulator, U5, to the LCD Display inverter board and to the other

voltage regulators (except the 3.3Vdc standby). This supply is under processor control via the

‘Power on’ line (U2 pin 42 to U5 pin 6, active high). Disabling this supply also disables the other

supplies, placing the Console in Standby mode. U5 is a Buck/Boost switching regulator which

will generate regulated 12Vdc from a supply voltage of 9-18Vdc. External switching components

M5-M8 are used in pairs according to whether the input voltage is above or below 12V; in step up

mode, M5 is on, M6 is off and M7 & M8 are switched. In step down mode, M7 is on, M8 is off

and M5 & M6 are switched. R26 provides current feedback to the device.

5Vdc – Supplied by switching regulator, U10, to the Airwave RF video receiver (RX2) and the

video amplifier U11 via the linear regulator (U14).

The switching regulator steps down the 12 supply from U5 to 5.35Vdc, this is fed to linear

regulator U14 which supplies a regulated 5Vdc supply to the RF video receiver. The output from

U14 may be disabled by the processor via the ‘Vid RX On” line (U2 pin 37 to U14 pin 7

Enable=High).

3.3Vdc – Supplied by switching regulator, U9, split into 2 supplies, 3.3VD and 3.3VA (digital

and analogue) separated by filters. This regulator also supplies power to the 1.8 & 1.5V supplies.

The 3.3VD supplies the analogue video converter and LVDS De-serialiser (U3 & U1), the crystal

for the dgital video converter (X2) and the FPGA (U6).

The 3.3VA supplies the digital video converter (U1).

1.8Vdc – Supplied by linear regulator, U12, this regulator is powered by the 3.3Vdc supply.

The 1.8Vdc supplies the analogue video decoder (U3).

1.5Vdc - Supplied by linear regulator, U4, this regulator is powered by the 3.3Vdc supply.

The 1.5Vdc supplies the FPGA (U6).

Video Processing

Analogue video inputs:

The Console PCB accepts analogue video from 2 sources; RF, via the Airwave receiver and

composite via the Molex connector J11.

RF Video: The Airwave receiver (RX2) receives RF video via the aerial connected to PCB, the

receiver has 4 input selection lines (RF_SEL_0 to RF_SEL_3 all active low) which are controlled

by the processor, U2, to select the desired channel. The power supply to the receiver (5Vdc) can

be disabled by the processor, switching off the receiver.

The selected channel is fed to the External Video Out connector (J10) via the video amplifier U11

and to Input A (pin 1) of the Analogue Video Decoder.

External Video: The external video input is fed to connector J11 and from there to input B (pin

2) of the Analogue Video Decoder.

Analogue video decoding:

The Analogue Video Decoder (U3) has 2 video inputs (A & B) which are connected to the RF

Page - 11

video receiver output and the external video input respectively. Control over which input is

decoded is via the I

2

C bus from the processor. The decoder also has a single output (under I

2

C

control) which is used to drive an LED (LD2), illuminated by the processor when the decoder is

active.

The selected input is converted to a digital video signal to ITU-R BT.656 standards and fed to the

FPGA (U6) via 8 data lines and 1 clock line.

The analogue decoder is powered by the 3.3V power supply and as such is shut down when the

processor disables supplies in standby mode, the device also has a separate enable line

(Vid_Comp_On) which is under direct processor control (U3 pin 28 to U2 pin 41 active high).

When the device is active there should be data on all 8 lines and a clock on the clock line.

Digital video input and decoding:

The Console PCB accepts a single serial digital video source via the blind mate connectors in the

console to Molex connector J4.

This signal is a differential serial signal using a proprietary video format, the LVDS De-Serialiser

converts this signal into a 10-bit parallel signal, this is fed to the FPGA over 10 data lines and 1

clock line.

The de-serialiser is powered by the 3.3V power supply and as such is shut down when the

processor is in standby mode, the device also has a separate enable line (LVDS_On) which is

under direct processor control (U1 pin 7 to U2 pin 17 active high).

The ‘Lock’ output of the device is connect to an LED (LD4), this illuminates when the device has

locked onto a valid serial data stream.

Video Conversion and display driver.

The parallel digital video signals from the analogue video decoder and the deserialiser are fed to

the FPGA, in addition, the FPGA has its own internal video source which is used to display the

various system text messages. The appropriate source is selected by the processor via the I

2

C bus.

The output is a 18 bit RGB digital video signal (6 bits per channel) with separate horiziontal and

vertical syncs and clock. In operation, there should be data present on the data lines (R0-R5, G0-

G5 & B0-B5) as well as on the sync and clock lines.

When the FPGA is displaying its internal source (text messages), LED LD1 is illuminated.

Interfacing and processing

The processor (U2) controls the overall operation of the console, controlling the power supply to

the other devices and display and handling the serial interfaces, tally input and drafting output

switching.

The processor is attached to an LED (LD3) which is illuminated following processor

configuration.

Serial Interfaces:

The processor provides 2 serial interfaces, both are configured at 9600 baud, 8bits, 1 stop bit, no

parity. Both interfaces are routed from the processor to an RS232 Transceiver (U7) and from

there to connectors J6 & J7. Connector J6 connects to the blind mate connectors on the console

to provide communications with the Duo-Scan, J7 connects to the rear panel 9 way D-type

connector for communications with the RFID reader.

Tally input:

Page - 12

The front panel tally connector on the console connects to J5 on the PCB, providing 4 discrete

input lines for the tally input. Each line is pulled high by resistor RN2 and is pulled low when the

appropriate tally button is pressed. These 4 lines are read by the processor (on pins 19-22) which

then transfers the tally data to the Duo-Scan over the serial link.

If the processor receives the correct response from the Duo-Scan, it then switches the appropriate

drafting outputs, if not or if an incorrect response is received from the Duo-scan, the console

switches into Video Monitor Mode.

Drafting Output:

The console provides 4 drafting outputs and a 12Vdc supply line via the 5 pin Binder connector

on the rear panel connected to J8 on the Console PCB. The 12Vdc output is unregulated 12

supply (9-18Vdc) fused with a 2.5A polyfuse.

Each output line is switched via a FET (M1 – M4 for Draft-1 to Draft-4 respectively). To switch

the output on, the processor applies a logic 1 to its output, switching on the appropriate FET, this

pulls the drafting output to 0vdc, completing the circuit.

Page - 13

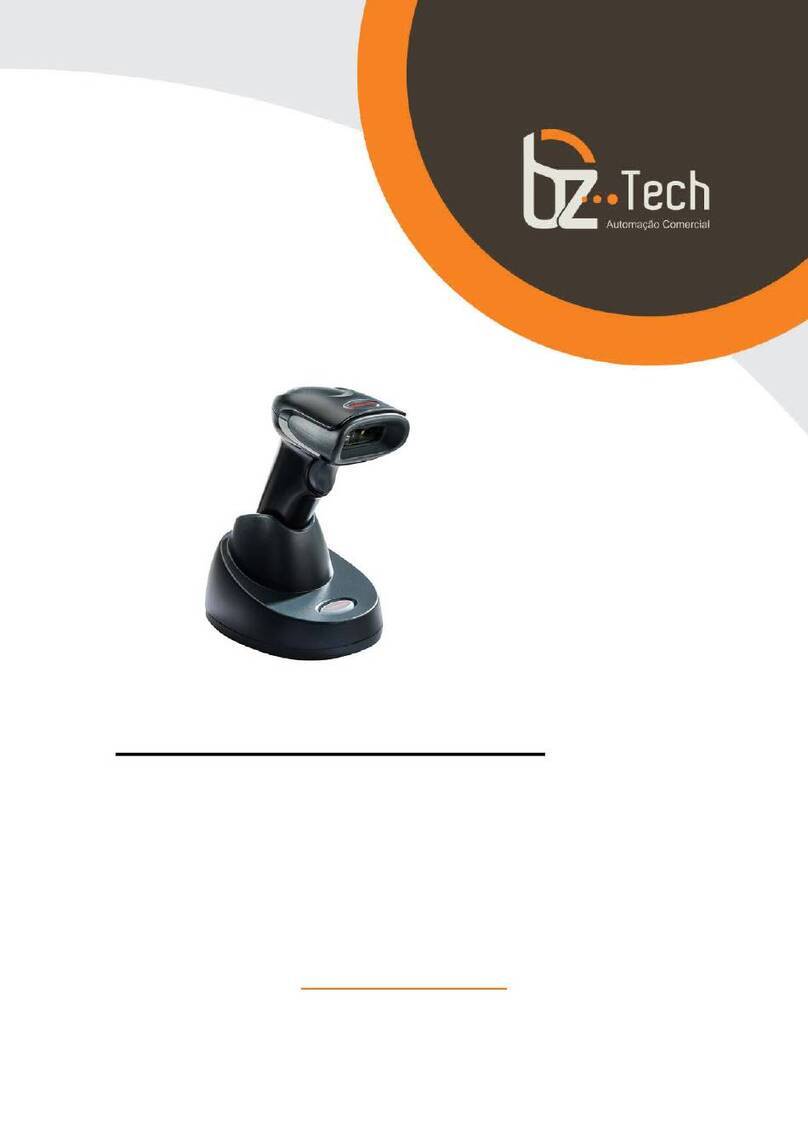

Module

The module forms a self

contained scanner with basic

functions and preset controls.

Connections for probe and

display are on the front panel. DC

Power is supplied to the module

through its latches.

Mounting in the Oviscan console

connects I/O through the blind

mate connector on the rear panel,

providing further controls and

video output.

POWER

The DC power in from the latches is protected from reverse polarity and overcurrent by Diode

and polyfuse. A High-Side switch IC (U105) Passes power to the Supply PCB under control of a

logic level input. This power-on control line can be driven by one of three sources; the System

PCB under Microprocessor control, the front panel ‘POWER’ key, or shorting link (J100) on

Supply PCB.

Pressing the keypanel power switch powers up the system; once the System Board Core is loaded

successfully the power switch control line is latched on and the front panel indicator is lit (Key

can be released after a few 100uS). The ‘POWER’ key is also read as an input to the System

Core, enabling detection of a long press (>2sec) to toggle power off.

The Power switch IC provides current limiting and is overload protected.

DISPLAY

Output connector provides +6.5V, +12V supplies and Video composite greyscale signal (with

NTSC timing).

PROBE

15 Way mixed coaxial and pin connector carries co-axial signals to/from the four transducers,

probe resolver and index signals, motor drive and identifier resistor.

Single pins are used for image wobble correction potentiometer connections and grounding.

KEYPANEL

The five keys are read by the System core and used to control all settings through a menu system.

CIRCUIT BOARDS

The module consists three PCBs:

•The Supply Board switches the incoming DC supply and provides all DC supplies for the

display connector and PCBs including variable high voltage supply for the TX transmitter. In

INTERFACE PCB

SUPPLY PCB

SYSTEM BOARD

PROBE

DISPLAY

12V DC

2 x 20 way ribbon cable

20 way ribbon cable

Transducers

Wobbles

Identifier

Motor

Index

Resolver

KEYPANEL

BLIND MATE

CONNECTOR

Video + Serial

Page - 14

addition there is an A-to-D converter reading DC input voltage, and drive to front panel

LED.

•The System board combines Analogue Ultrasound functions (Crystal selection, Ultrasound

transmit, Ultrasound receive processing and sampling) with scanner control and digital

processing functions (Ultrasound digital processing, Scan conversion, Graphics generation

and serial Digital video output, Probe control, scanner setup through control menu.

•The Interface board reads keypanel inputs, digitizes probe index, resolver, wobbles and

identifier, sending digital values to the System Board. Video data from the System board is

converted to composite video analogue signal to front panel and to PCB-mounted video

transmitter module. The Interface board also generates the motor drive voltage under System

board control.

SERVICE MENU

A service mode can be entered on the Duoscan enabling test routines and other data display. It

can be used to display Index and resolver waveforms, and a total of all Tally batches that have

been cleared.

To enter service mode, with the Duoscan connected to a console, press keypanel button 1 to scroll

through to the ‘foetal age’ menu. With foetal age selection ‘OFF’ Press and hold buttons 3&4

until ‘service’ menu appears. Press button 4 to scroll through the series of tests or press button 3

to toggle between Total tally display and live display of digitized values of probe identifier and

wobble correction pots. To exit service mode, remove power from the scanner.

INDEX, RESOLVER DISPLAY

Index and resolver waveforms may be displayed on-screen when the Duoscan is connected to a

Console and a probe connected. Enter service mode and press button 4 to scroll through to test 1

or 2 (1 or 2 displayed in TALLY LATE column) for Index or Resolver display. In either of these

two tests, an analogue version of the on-screen displayed values is provided on the video out

connector in place of NTSC video signal.

Page - 15

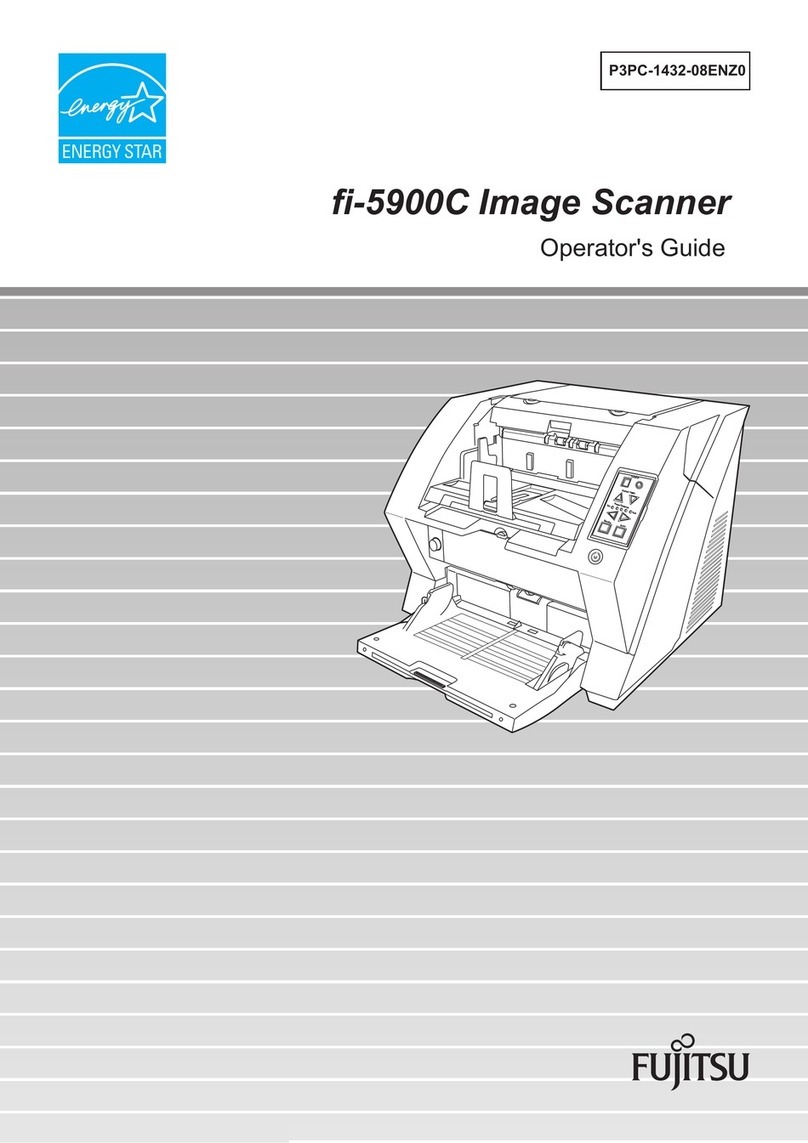

CIRCUIT DESCRIPTION : System PCB

TRANSDUCER SELECTION

The ultrasound is generated by pulsing the transducers in the probe. There may be either two or

four transducers fitted to the probe; only one pair of transducers is used for any one imaging

mode. From the selected pair of transducers only one is used at a time, with alternate transducers

used on consecutive image frames . When a mode is selected the desired pair of transducers is

connected to two separate transmit\input selection circuits selected by latching relay RL100

(DPCO). The relay has two coils, one to switch into each state. The coil is energized by a short

pulse (few 100mS) when a change of selection is required, generated by core IC, buffered by U9

and driven by high side switch (M103 or M106) from the 6.5V supply. As alternate ultrasound

frames are displayed, the appropriate transmitter is used and only one of the two input selection

circuits is enabled.

TRANSMITTER

The Transmit pulse timing is generated digitally (Core IC) and fed through buffer U9 to one of

two transmitters. Capacitatively coupled transistor Q100 acts as a current source to drive the gate

of power FET M1. Transistor Q101 provides gate voltage clamping for M1 and gate discharge for

fast turnoff of M1. The Large negative transmit pulse is coupled to the selected transducer

through diode D8. When not transmitting, D8 is biased off to isolate transmitter noise from the

received signal path.

PROTECTION\SELECTION

Each of the two active transducers connects to a protection\selection circuit. Only one of the two

TRANSDUCER

SELECTION

RL100

INPUT SELECT

+PROTECTION

D5,D6,M100

VGA

U2

ANTI-

ALIAS

FILTER

L2,L3,C6

A

TO

D

U5

SYSTEM CORE CPLD U4

GAIN CONTROL

U11

P

R

O

B

E

I

N

T

E

R

F

A

C

E

TRANSMITTER

PULSER M1

INPUT SELECT

+PROTECTION

D1,D2,M101

TRANSMITTER

PULSER M2

S

U

P

P

L

Y

SERIALIZER

GRAPHICS

CONTROL

PROCESSOR

PROCESS

U

-

SOUND

MEMORY

(SRAM)

U8

BOOT

MEMORY

(FLASH)

U10

SCAN

CONVERT

TX VOLTS+

V DC SAMP

IIC BUS

DC

SUPPLIES

DIGITAL

VIDEO

POWER

CONTROL

TIMING

INDEX,

RESOLVER

IIC BUS

MOTOR

IDENTIFIER

WOBBLES

IIC BUS

CRYSTAL

OSCILLATOR

Page - 16

selection circuits is enabled by biasing the diode protection circuit on; Core IC, Level translate

M105,M107, high side switch M100,M101. The unbiased circuit does not pass any small signal;

D6, D5 do not conduct while the signal is less than +/- 0.5V. The selected diode protection circuit

which is biased on passes small signals through D1,D2 but blocks any large (transmit) pulses.

RECEIVE PROCESSING

The small received echoes from the selected input are passed through lowpass filter L6, C13 and

are amplified by U2. U2 is a variable gain amplifier with low noise preamplifier. The gain of the

preamplifier and input impedance are set by feedback resistors R7, R8. The variable gain stage

provides from -12dB to +36dB with a differential output. A ramp voltage between 0 and 1V

generated by digital potentiometer U11 under core IC control varies the gain setting. L2, L3, C6

form a 2-pole anti-alias filter before coupling to the analogue-to-digital converter U5 through TF1

which provides dc level isolation between U2 output bias level of 2.5V and U5 input bias below

1V.

SAMPLING

U5 is a high-speed sigma-delta A-to-D converter with onboard DSP and clock generation

providing a 14-bit output at 30 MHz and 80dB anti-alias filtering with a 2V p-p differential input.

U5 is reset following power up and configured over SPI bus by the core IC. Parallel data is passed

directly to the core IC. U5 requires a 1.2V supply filtered separately for analogue and digital

internal functions, and a 2.1V supply for its output pin drive.

CORE FUNCTIONS

Internal to the Core IC, the digitized ultrasound is operated on by means of digital signal

processing to provide filtering, compression, automatic Gain Control, and brightness mapping.

The internal scan converter writes the processed ultrasound value and its corresponding screen

location address to the graphics memory. The graphics generator reads the data back to produce

both encoded VGA and composite NTSC timed digital video outputs. The encoded VGA digital

video signal is passed to an on-board parallel to serial LVDS driver chip. Digital NTSC video

data is passed to the interface PCB.

The probe index and resolver pulses are digitized on the Interface PCB along with Wobble

correction pot settings and processed in the System core using a digital PLL to generate the digital

frame and vector pulses related to precise crystal position with wobble correction, and used for

the scan converter timing within the core. The drum position is decoded to select between the two

transducers currently being used for imaging, appropriate input source and transmitter being

selected. U4 runs on a 1.2V supply (with separate filtered feeds to internal PLLs), a 2.1V supply

is used for interface to A\D converter connected (all pins 56 to 104) and a 3.3V supply is used for

all other input\output pins.

CONTROL

Within the core IC is a processor which is responsible for system configuration and user interface

(information display and menu) with access to display memory, probe identifier digital value and

keypanel data fed from the interface PCB. The resolver period is also monitored by the processor

Page - 17

to adjust the probe rotation motor speed, controlled over IIC Control bus to the Interface board

which generates the motor drive DC voltage. The transmitter supply voltage on the supply PCB

can be varied and the incoming 12V supply voltage can be monitored over the supply IIC bus.

Control can be switched over to an alternate pair of crystals by a latching relay, for example if a

dual-frequency probe is used.

MEMORY

All non-volatile data is stored in U10 serial Flash device. The three main sections are Firmware

configuration data, Software, and System stored values (Running tally, overall tally, preferred

startup mode, duoscan modes) System storage area can be read and re-written by the processor

within the core IC.

IC U8 is 2Mx8bit SRAM. It is used as display memory for the 640x480 display area which can

be written to by firmware and read or written by core processor. The remaining area is used for

software storage.

FIRMWARE STARTUP

These steps are followed during system initialization on power-up:

core CPLD senses power-up and loads configuration data from serial flash Boot ROM device

U10 to configure the CPLD firmware including the processor.

Successfully configured processor within CPLD logic transfers software program from boot ROM

to SRAM.

Processor resets and runs from SRAM program and initializes the system as follows;

SOFTWARE STARTUP

Short delay (prevents accidental switch on) followed by core driving power enable line.

Sets up SPI for comms with flash memory.

First beep.

Sends ASCII data at low baud rate to wake up console.

Sends ASCII ‘H’ character at 9600 baud to establish console comms.

Sets motor speed to the lowest value.

Reads ‘Total Tally’ configuration byte from Flash, if the value is incorrect, the flash is then

initialised. If the value is correct, the system calculates the total tally.

Reads ‘Running Tally’ configuration byte from Flash, if the value is incorrect, the flash is then

initialised. If the value is correct, the system calculates the running tally.

Switches front panel LED on.

Reads Duo_Mode 1 and configures Range, Frequency etc.

Writes menu data to display.

Configures Index /Resolver A/D.

Sets output power.

Sets motor speed.

Enable Index/Resolver sampling.

Enable Ultrasound scan.

Second Beep.

Enters mains loop.

Page - 18

N.B. Once in the main loop, the Duo-Scan will poll the RS232, if it receives an ‘H’ character

from the console, it undergoes the following process:

Read Drafting Data from console.

Read Brightness & Contrast values from Console.

Read Ovi-Scan mode data from flash.

Setup Range, Frequency etc.

Write Ovi-Mode menu to display.

Once the system has initialized, the controller continually monitors the probe identifier for

change, interrupted only by a keypress.

Page - 19

CIRCUIT DESCRIPTION : Supply PCB

SUPPLY

BOARD

The Supply board accepts an input voltage range of 9 to 18 V and generates all system supplies

required, passing them to the SYSTEM board through a 20 Way ribbon cable

Input protection

The input supply is connected to the supply board through flying lead to CN1. Reverse polarity

and overcurrent protection is provided by polyfuse F1 with trip current of approx. 2.5A. This

device automatically resets following removal of fault condition, when it cools down. Diode

D101 shorts a wrong polarity supply through F1, causing it to trip and limiting reversed circuit

supply to less than 1V.

Soft Switch

The incoming supply is switched by U101 which is a high-side FET with internal overcurrent and

overvoltage protection. When power is first applied the ‘POWER ON’control line is biased to

3.3V by pullup resistor R121, switching M100 on and pulling pin2 of U101 low (switch is OFF).

The ‘POWER ON’ control line can be pulled low by the system board or by link J100. M100 is

switched off and pin2 of U101 is pulled high by R127 (switch is ON). Switched, fused input

voltage is routed to the rest of the supply board and to the front panel display connector

Supply Bus; 6.5V

Switched, fused input supply feeds a high efficiency ISRs Integrated Switching Regulator SR1.

Similar to a DC-DC converter, except the output supply is not isolated from the input. The

converter has overload protection and can supply up to 2A.

The 6.5V bus feeds the two IC based converters which step down to 2.1V and 3.3V and is passed

to the supply board for further distribution and regulation. It also supplies the front panel display

connector via filter based around L103 and J101.

INPUT

PROTECTION

6.5V BUS

CONVERTE

2.1V

SWITCHE

3.3V

SWITCHE

- HT SUPPLY

GENERATION

1.8V TO SYSTEM

6.5V TO DISPLAY CONN

3.3V TO SYSTEM

-

HT TO SYSTEM

LED DRIVE

Vin ROUTED TO

DISPLAY CONN

SOFT

SWITCH

CONTROL

FROM

SYSTEM

BOARD

ANALOGUE

SAMPLING

CONVERTER

IIC CONTROL BUS

Page - 20

Low Voltage switchers

Based around switching regulator chips MAX887 (U3, U12) with integrated switching FET, the

inductor and diode on the output are used to provide smoothed voltage across the output

capacitor. A resistor network from the output feeds back to the chip to provide regulation. Output

is short circuit protected. Further filtering is provided by inductors L104, L106 used to feed the

System board.

- HT Generation

A variable high voltage supply is generated by step-up switching regulator controller U102.

Current in the primary of the planar transformer flows from the 12V supply through M101 until

peak primary current is reached (U102 senses voltage rise across R118). M101 is switched off

and the collapsing magnetic field generates a high (negative) voltage across the secondary (1:10

turns ratio). D102,D104 rectify the high voltage which is then stored on C5. R1, R2,C114 provide

low pass filtering and limit the discharge current if the HT supply output pin is suddenly shorted.

The HT voltage is regulated by U102 which alters the transformer pulse frequency to maintain a

voltage of 1.2V at pin 3 (feedback) input. The negative high voltage output draws a small

feedback current through R136+ R138 proportional to the output voltage. This small current is

mirrored by transistor pair Q100, Q102, with R112 setting mirrored current 10x current in R111.

The voltage at the controller feedback pin is a function of this mirrored current (proportional to

output voltage) and the resistance from this pin to ground. The digitally controlled resistor U101

has a range from 0-10Kohm, giving an output voltage range from -25V to -200V. Q101 is wired

as a diode to limit possible high negative voltage across the current mirror. The switching

controller limits current in the transformer primary every cycle to prevent transformer saturation.

The limited switching frequency ensures output supply is current limited at about 7mA at -200V

with short circuit protection. Oscillations in the Switching circuit which could potentially

interfere at ultrasound frequencies are minimized by snubber components L101,C108. Variable

resistor U101 is controlled over the IIC bus from the system board.

DC input voltage sensing

The incoming DC supply voltage can be measured, and any step rise in the supply voltage due to

the input switch being briefly switched off can be measured. These voltage readings taken over

the IIC bus are used to calculate as accurately as possible the battery voltage while eliminating the

effect of voltage drop over the varying resistance of the battery connection latches. U103 is a 4-

channel 10bit A-to-D converter with an internal 2V reference. Ch1 reads any positive step

increase in the DC input voltage up to 2V (readings taken after the power switch IC is briefly

switched off), Channel 2 senses the switched input voltage scaled to read 0V to 22V, Channel 3 is

used to read a scaled version of the unswitched DC input voltage (0-22V), Channel 4 input is not

used.

This manual suits for next models

1

Table of contents

Other BCF Technology Scanner manuals