BD Diesel Performance 1037135 User manual

8 February 2021 BD Universal Remote Mount Vacuum Brake (I-00102) 1

BD Engine Brake Inc.

Plant Address: 33541 MacLure Rd. Abbotsford, BC, Canada V2S 7W2

U.S. Shipping Address: 1124 Fir Avenue, Blaine, WA 98230 U.S. Mailing Address: P.O. Box 231, Sumas, WA 98295

Phone: 604-853-6096 | Fax: 604-853-8749 | Internet: www.bddiesel.com

DOWNLOAD THE LATEST

INSTALL MANUALS AT

www.bddiesel.com

BD Remote Mount Vacuum Exhaust Brake

Part Number

Application

1037135

*1989-1998 Dodge Cummins 12V (Micro Switch) 4” Exhaust

1037136

1998-2002 Dodge Cummins 24V (DFIV) 4” Exhaust

1037143

1994-1997 Ford 7.3L Power Stroke 3.5” Exhaust

1037144

1994-1997 Ford 7.3L Power Stroke 4” Exhaust

*1989-1993 Dodge trucks must purchase a separate throttle switch bracket (BD PN 1300535)

Serial #

Date Purchased

Purchased from

Installed by

OWNER’S MANUAL – LEAVE IN GLOVE BOX

8 February 2021 BD Universal Remote Mount Vacuum Brake 2

BD Engine Brake Inc.

1-800-887-5030 | https://www.bddiesel.com

TABLE OF CONTENTS

Generic Vacuum Brake Parts....................................................................................2

STANDARD REQUIRED PARTS –40/60................................................................3

Welcome...................................................................................................................3

Options.....................................................................................................................4

Additional Required Parts .........................................................................................4

Valve Assembly Installation ......................................................................................5

Control Valve Assembly............................................................................................6

Throttle Switch/DFIV Installation...............................................................................7

Ford Power Strokes (1994-97).........................................................................7

DFIV Wiring Diagram.....................................................................7

Dodge 1994-1998............................................................................................9

Dodge 1988-1993..........................................................................................10

Dodge 1998-2002 (24 valve engines)............................................................10

Dodge DFIV Wiring Diagram (1998½ - 2002)..............................10

CRUISE CONTROL WIRING 2000-2002 6-speed MANUAL ONLY........................12

DFIV Calibration (Only for kits using a DFIV module) .............................................13

Power and Toggle Switch .......................................................................................13

Exhaust Brake Routing Diagram.............................................................................14

Optional Manual Shifter (Push-Pull Style)...............................................................15

Testing....................................................................................................................15

Vacuum Brake Troubleshooting Guide ...................................................................16

Operating Guidelines..............................................................................................17

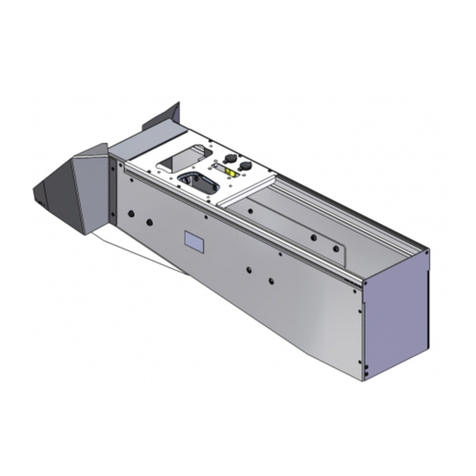

Generic Vacuum Brake Parts

8 February 2021 BD Universal Remote Mount Vacuum Brake 3

BD Engine Brake Inc.

1-800-887-5030 | https://www.bddiesel.com

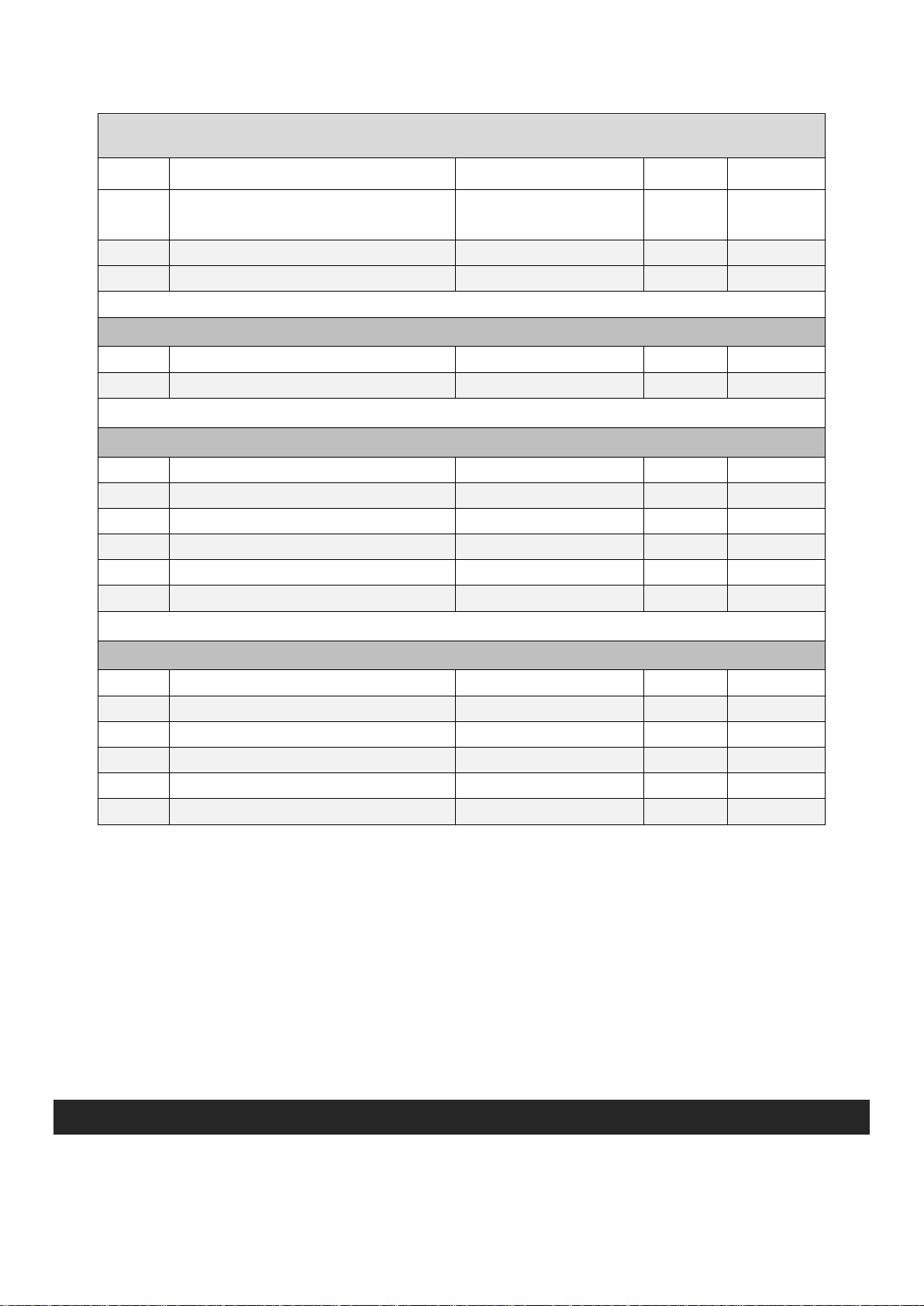

STANDARD REQUIRED PARTS –40/60

Description

Part Number

Qty

1

Brake Valve

1137000 or

1137005

1

REQ’D

2

Spool Valve

1230001

1

REQ’D

3

Marmon Clamps

1100404

2

REQ’D

STEP #2 –THROTTLE SWITCH SELECTION

4

DFIV module

1321039

1

5

Micro Switch

1300420

1

STEP #3 –EXHAUST PIPE SIZE

6

Pipe Adapter 3”

1100300

2

7

Exhaust Seal Clamp 3”

1100730

2

8

Pipe Adapter 3.5”

1100350

2

9

Exhaust Seal Clamp 3.5”

1100735

2

10

Pipe Adapter 4”

1100400

2

11

Exhaust Seal Clamp 4”

1100740

2

STEP #4 –MAIN SWITCH SELECTION

12

Toggle Switch

1300201

1

13

Push / Pull Switch 5/8”

1300210

1

14

Push / Pull Switch 3/4”

1300211

1

15

Rocker Switch 5/8”

1030900

1

16

Rocker Switch 3/4”

1030910

1

17

Switch Cover (toggle only)

1302250

1

1137005 brake kit uses actuator 1133065 (65 pound spring)

1137000 brake kit uses actuator 1133060 (60 pound spring)

Welcome

Thank you for purchasing a BD Engine Exhaust Brake. This manual is to aid you with

your installation and operation of your braking unit. We strongly suggest that you fill

out the information on the front page and retain this manual for any future reference.

8 February 2021 BD Universal Remote Mount Vacuum Brake 4

BD Engine Brake Inc.

1-800-887-5030 | https://www.bddiesel.com

Options

Description

Part #

Manual Transmission Shifter Switch Kit

1300210 / 1030900

AutoLoc Convertor Lock-up Kit

1030390

Torqloc Convertor Lock-up Kit

1030395

Brake Pressure Gauge Kit

1030050

HD Exhaust Valve Springs

1030060

Additional Required Parts

To install the microswitch on 1989-1993 Dodge trucks requires a microswitch bracket

that is not supplied in this kit. BD part number 1300535.

8 February 2021 BD Universal Remote Mount Vacuum Brake 5

BD Engine Brake Inc.

1-800-887-5030 | https://www.bddiesel.com

Valve Assembly Installation

Inspect the vehicles exhaust system between the engine and the muffler. A straight

section of pipe will have to be cut to accommodate the exhaust brake assembly -

approximately 7 to 8 inches long. On 1994 or newer Dodges, the valve is mounted

before the Catalytic Converter, on Ford and Chev/GM vehicles with Catalytic

Converters, the valve is mounted between the Cat and muffler.

There should be no exhaust-flex pipe between the engine and exhaust brake valve,

however, flex pipe is okay after the valve. Cut the exhaust pipe in a straight section of

the system, you will need to weld one of the supplied adapters to the section of pipe

coming from the front of the vehicle’s engine.

Weld

Here Use SS

Band Clamp

Use V

Clamp

Rear of Truck

Temporarily mount the exhaust valve assembly on the adapter, with the supplied V

clamp on the valve sliding. From here, cut off as much of the remaining exhaust

needed to accommodate thevalve andremaining adapter. Remove the exhaust valve

assembly and clamp, or weld the rear adapter to the other section of exhaust pipe.

Mount the exhaust valve assembly using the two supplied V-clamps, with the vacuum

cylinder pointing away from the engine, and tighten the nuts and bolts.

NOTE: The arrow on the Exhaust Valve casting indicates exhaust flow, which

should be pointed towards the rear of the vehicle (Figure 1).

Plastic button must

be facing down.

8 February 2021 BD Universal Remote Mount Vacuum Brake 6

BD Engine Brake Inc.

1-800-887-5030 | https://www.bddiesel.com

Control Valve Assembly

The control valve assembly has two hoses

attached to it. Push the shorter piece onto

the barbed fitting on the front cap of the

vacuum cylinder on the exhaust valve

assembly (see Diagram 1) and push the

longer piece onto the barb fitting on the

back cap (Red).

With the hoses now attached, locate or drill

a new hole on the inner frame rail to mount

the control valve assembly within reach of

the hoses.

Existing holes or new holes will have to be drilled out to 5/16”. Mount the control valve

assembly to the frame using the long bolt, spacer and nut provided (Dia. 2). A good

ground must be made when bolting bracket to frame rail.

There is a loose section of plastic hose that came included with the spool valve kit

with a yellow plastic vent filter on it. Attach this to the spool valve (#3) and run to a dry

location inside your cab. This vent prevents moisture from entering inside the control

(spool) valve.

NOTE: If the vehicle has a vacuum assisted hydraulic brake booster or the vacuum

pump is located on the driver side, then run the hose and wire along a cross member

and up the driver’s side frame rail.

In the engine compartment, locate the hose coming from the vacuum pump on the

engine or to the vacuum assisted hydraulic Brake Booster. (On newer Chevrolets,

the Air Conditioner Pump will have to be unbolted from its bracket and pushed off to

one side.) Push the plastic tee (supplied in Application Kit) onto the hose coming from

the Control Valve Assembly, and run hose to Vacuum Pump or Brake Booster.

Cut the outlet hose of the vacuum pump or brake booster, no closer than 1” from the

outlet fitting. Push both ends of the hose onto the plastic tee. Secure the hose with

tie wraps and keep it clear of moving or heated parts.

Run the wire coming from the Control Valve Assembly though the fire wall (except

Dodge and Cummins Trucks & Motorhomes) and to the Throttle Switch; using an

electrical connector, hook up wire to the top screw on switch, or on Ford Power

Strokes, free terminal (#87a) on relay.

For Dodge and Cummins Trucks & Motorhomes, run wire over to Throttle Switch, cut

wire and connect to the top terminal with an electrical connector.

See microswitch/DFIV wiring diagrams in this manual for more information.

8 February 2021 BD Universal Remote Mount Vacuum Brake 7

BD Engine Brake Inc.

1-800-887-5030 | https://www.bddiesel.com

Throttle Switch/DFIV Installation

Ford Power Strokes (1994-97)

DFIV Wiring Diagram

CAUTION Disconnect the batteries before installation.

NOTE: If the vehicle does not have Cruise Control, remove the green and blue wire

from the install and discard.

Remove the lower section of the drivers side dash, under the steering column, and

mount the DFIV module to the structural brace. Connect the black wire from the DFIV

module to a good ground.

Locate one of the ignition switched red/black tracer wires under the steering column

(one is 10/12ga and the other is 14/16ga) and connect an appropriate Posi-Tap

connector to it (green for 10/12ga and black for the 14/16ga wire). Connect the fused

red wire from the toggle switch to this Posi-Tap and mount the switch in a convenient

spot on the dash.

Locate the Throttle Position Sensor (TPS) at the throttle pedal. Use a Posi-Tap

connector to attach the yellow wire from the DFIV module to the red wire w/gray tracer

wire (1994-1997 trucks) to the TPS.

Ensure the green wire is connected to the ‘COM’ terminal of the DFIV module, the

blue wire is connected to the ‘FORD’ terminal of the DFIV module, and the pink wire

is connected to the ‘BRAKE’ terminal of the DFIV module. Also check to ensure all

other wires at the DFIV module are secure.

8 February 2021 BD Universal Remote Mount Vacuum Brake 8

BD Engine Brake Inc.

1-800-887-5030 | https://www.bddiesel.com

Run the pink, green and blue wires through a grommet on the firewall making sure all

wires are secure and away from moving objects and heat sources. Go to page 11 and

follow the instructions to calibrate the DFIV module.

Cruise Control Disable Wiring

Locate the factory black w/yellow tracer wire at the cruise control disable (Brake

Applied) switch located on the brake master cylinder and expose the wiring

approximately 4-6 inches from the switch to allow for a good length to work with. This

wire may be a different color in various applications. If there is no black w/yellow wire

going to this switch, then use a test light to check which wire changes state (power to

no power) when the brake pedal is applied.

Cut the black w/yellow tracer wire (BK/Y), then strip both ends and attach a separate

blue Posi-Lock connector on each end of the cut wire. Run the green and blue wires

that were brought through the firewall to the Brake Applied Switch at the brake booster

and cut off any excess. Attach these wires to the two blue Posi-Lock connectors that

you have just installed to the Black wire w/Yellow tracer.

8 February 2021 BD Universal Remote Mount Vacuum Brake 9

BD Engine Brake Inc.

1-800-887-5030 | https://www.bddiesel.com

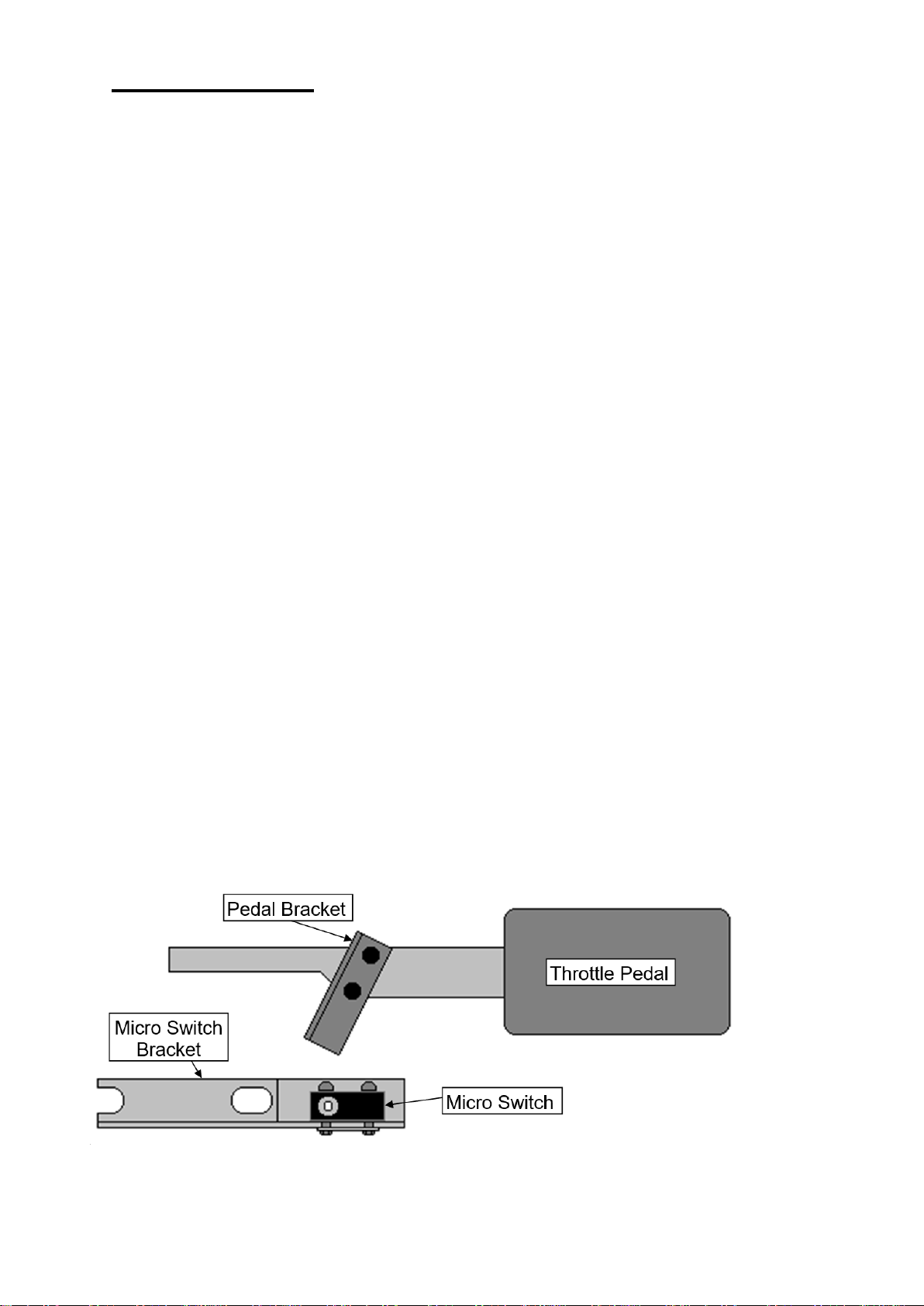

Dodge 1994-1998

At the throttle pedal, locate the nuts on the large aluminum bracket just up from and

to the left of the pedal. Remove the lower nut and loosen off the top nut. Locate the

larger microswitch bracket (1300533) included in the control kit. Slide the top of the

bracket under the upper loosened nut and the lower stud through the hole. Reinstall

the lower nut but don’t tighten them yet.

Loosely install the microswitch into the microswitch bracket if not already done. Do

not tighten yet as it will need to be adjusted.

Locate the small pedal bracket (1300532). Position this bracket over the throttle pedal

arm so that it will line up with the microswitch button as shown in the diagram below.

Ensure sufficient clearance between the long Micro Switch Bracket and the throttle

pedal by sliding the bracket as far to the left as possible, to eliminate any possibility

of pedal catching on bracket. Adjust both brackets so that the small bracket on the

pedal arm will depress the button on the Micro Switch when the pedal is in the idle

position.

When satisfied, mark and drill the two holes on the pedal arm and screw or pop rivet

pedal bracket to arm. Tighten the nuts for the aluminum bracket and do final

adjustments to Micro Switch bracket on the aluminum bracket. Periodic adjustment to

the Throttle Switchmight be needed to maintain proper contact with bracket on throttle

pedal.

Connect a length of the supplied wire from the “com” terminal on the micro switch to

the red wire on the spool valve. Run another length of wire from the “NO” (Normally

Open) terminal through the firewall. This will be connected later.

NOTE: If the throttle return springs are weak, they may not be strong enough

to depress the button on the micro switch. In this case the springs will have to

be replaced or additional springs added. Also, worn throttle linkage can make

it difficult to get the micro switch to activate consistently.

8 February 2021 BD Universal Remote Mount Vacuum Brake 10

BD Engine Brake Inc.

1-800-887-5030 | https://www.bddiesel.com

Dodge 1988-1993

The Throttle Switch Bracket mounts behind

the throttle linkage using the two bolts used

for mounting the throttle linkage to the

engine (Diagram 6). On all years, if throttle

return spring(s) are weak, another spring

may have to be installed.

This bracket is not included in this kit. Order

BD #1300535.

On all microswitch installations, adjustment of the microswitch is needed.

Manually move the linkage back and forth to make sure the proper activation to the

throttle switch is occurring. The throttle switch may have to be adjusted on occasion.

NOTE: With mechanical injection pump systems, the linkage is moved during cruise

control and/or fast idle operations, so the brake will not be activated during these

occurrences.

Dodge 1998-2002 (24 valve engines)

Dodge DFIV Wiring Diagram (1998½ - 2002)

Mount the DFIV module in a secure location under the dash using the cable ties

provided. Route the pink and yellow wires through the firewall into the engine bay,

8 February 2021 BD Universal Remote Mount Vacuum Brake 11

BD Engine Brake Inc.

1-800-887-5030 | https://www.bddiesel.com

there is usually an existing grommet in the firewall behind the brake pedal which can

be used for this. Attach the black ground wire to the “Gnd” terminal on the DFIV and

attach the ring terminal to a good ground.

Route the Yellow wire from the DFIV

module along the driver side of the

engine to the throttle linkage and APPS

Sensor.

Remove the cover of the throttle linkage

then locate and disconnect the wiring

connector for the APPS.

NOTE: This connector is located on

the underside of the throttle linkage

assembly and is in a difficult

position.

Open the loom and

locate the Light Blue

w/Black wire and install a

supplied Posi-Tap™to it.

Connect the Yellow wire

from the DFIV Module to

this Posi-Tap™and

reconnect the APPS

connector then reinstall

the throttle linkage cover.

8 February 2021 BD Universal Remote Mount Vacuum Brake 12

BD Engine Brake Inc.

1-800-887-5030 | https://www.bddiesel.com

CRUISE CONTROL WIRING 2000-2002 6-speed MANUAL ONLY

This step is only for 2000-2002 manual transmission trucks with cruise control. All

other vehicles do not need the cruise control wires connected as they use a vacuum

servo for cruise control rather than an internal program in the ECM.

If your vehicle does not have cruise control you can remove the blue and green wires

from the DFIV and discard them. Skip this step and proceed to Switch Installation.

To obtain access to the Cruise

Control wiring harness remove the

lower steering column panel by

removing the mounting screws

and unsnapping the panel from the

instrument panel.

Under the dash running vertical by

the left of the steering column,

locate the smaller wiring harness

that runs out of the main harness.

Remove some of the black electrical tape to gain access to the smaller wire bundle.

***DANGER***

THERE IS A BLACK WIRE WITH A TWISTED LIGHT BLUE/GREEN TRACER DO

NOT CONNECT OR TEST THIS WIRE AS IT IS CONNECTED TO THE AIR BAG

AND THE BAG MAY DEPLOY CAUSING DAMAGE AND/OR INJURY

***DANGER***

Remove some of the black electrical tape from the small bundle to gain access to the

small Black wire with Light Blue tracer and install a Posi-Tap™ to it. Insert the Blue

wire from the DFIV module into this connector.

In this same wiring harness, locate the Red wire with Light Green tracer and install

another Posi-Tap™. Insert the Green wire from the DFIV module into this connector.

8 February 2021 BD Universal Remote Mount Vacuum Brake 13

BD Engine Brake Inc.

1-800-887-5030 | https://www.bddiesel.com

DFIV Calibration (Only for kits using a DFIV module)

Ensure the connections of the corresponding wires to the DFIV Control Module are

correct as shown in the wiring diagram.

To achieve the correct setting for the activation

of the exhaust brake in relation to the throttle

pedal the DFIV Module must be calibrated for

your vehicle.

Connect one end of a test light to the “BRAKE”

terminal of the DFIV module and the other end

to a good ground. With the throttle at idle, start

the engine and turn on brake switch. Then, using a small flat bladed screwdriver, turn

the small adjusting screw in the DFIV Module counterclockwise or clockwise until the

test light JUST turns on.

CAUTION: THE ADJUSTING SCREW IS A MICRO-SWITCH THAT IS VERY

DELICATE, SO TURN USING SMALL ADJUSTMENTS.

Test by revving up the engine to approximately 1200 RPM and releasing the throttle.

As the accelerator pedal is applied the test light should turn off just before the engine

starts to rev, indicating proper calibration of the DFIV Module with the APPS.

Then the test light should activate again when the throttle pedal returned to idle. If

not, readjust the DFIV Module so that it does. Reinstall lower dash cover.

Power and Toggle Switch

Mount the toggle switch in a convenient and

secure location on the dash. Locate a 12v

ignition switched source (fuse panel or wire),

then connect the in-line fuse holder to the

source line or use the fuse tapper (Diagram

7).

This power wire should be connected to the

middle terminal of the toggle switch. Ground

the black wire from the upper switch terminal

marked amber. Connect the lower switch

output terminal to the middle position on the

throttle micro switch or to the DFIV “Switch”

terminal. Connect the remaining terminal on

the micro switch to the exhaust brake control

valve you mounted earlier. Route this wire away from any heat sources or moving

parts.

8 February 2021 BD Universal Remote Mount Vacuum Brake 14

BD Engine Brake Inc.

1-800-887-5030 | https://www.bddiesel.com

Exhaust Brake Routing Diagram

Factory vacuum line

Vent line filter

(Mount in dry location)

Direction of exhaust flow

Test button faces down

Brake activation wire

(To DFIV or microswitch)

Ground

Spool valve flows crisscross when not energized,

and flows directly across when energized.

Applying vacuum to the red end of the cylinder will

release the brake. Applying vacuum to the blue end

will apply the brake.

8 February 2021 BD Universal Remote Mount Vacuum Brake 15

BD Engine Brake Inc.

1-800-887-5030 | https://www.bddiesel.com

Optional Manual Shifter (Push-Pull Style)

Mount the push/pull switch on the shifter lever

(Diagram 10), using the switch clamp, and

secure the cable on to the lever.

NOTE: Keep cable away from spots where it

could get pinched during shifting. Strip the ends

of the wires and attach male blade connectors

to each.

Slip off the Red wire from Toggle Switch and

attach to Black wire of Manual Shifter Switch

cable, and, slip off the Yellow wire from Toggle

Switch and attach to White wire of cable. Discard Toggle Switch and its black wire.

Attach the Yellow wire to the middle terminal of Throttle pedal Switch or the 12V

Switched input of the DFIV.

Testing

Start up the engine and turn the toggle switch on to make sure the brake activates.

Depress the throttle pedal and let up on it to check that operation of the throttle switch,

allowing the brake to engage when the throttle is in the resting/idle position.

Using a standard pressure gauge, follow the list below for proper setting, with the

engine running at idle and brake turned on. Install the pressure gauge into the NPT

port on the side of the exhaust brake casting to measure exhaust pressure.

Vehicle

Lbs.

Pressure @ Idle

Chevy 6.2/6.5L & Ford 6.9/7.3L

32lbs.

8-10 lbs.

Ford Powerstroke & Dodge Cummins

40lbs.

10-12 lbs.

Dodge Cummins w/ 60lb. exhaust springs

60lbs.

18-20 lbs.

If the brake pressure does not fall within these limits, please call the BD

Engine Brake technical hotline at (800) 887-5030.

Be sure to test the cruise control disconnect system (where applicable) while test-

driving. Set the cruise at a safe speed and then turn the exhaust brake on, which

should turn the Cruise Control off right away.

If the cruise control does not disengage right away, then turn the exhaust brake off

immediately.

If the cruise control did disengage, then turn the exhaust brake off and hit the resume

function on the cruise control switch to see if the cruise will re-engage.

8 February 2021 BD Universal Remote Mount Vacuum Brake 16

BD Engine Brake Inc.

1-800-887-5030 | https://www.bddiesel.com

Vacuum Brake Troubleshooting Guide

This guide assumes that your exhaust brake system is using a DFIV. If you system uses a microswitch for throttle

activation, the operation of the spool valve is the same as with the DFIV. Always check to make sure the vehicles

vacuum system is operating correctly and is free of leaks. Most systems will produce approximately 15in/Hg (inches

of mercury), or 7.5psi absolute, at sea level.

When I let off the throttle

nothing happens.

No

Yes

Check vacuum supply to the spool

valve.

Is the DFIV powering the “brake”

output wire when the throttle is at

idle and brake switch and ignition

are both on?

Check that DFIV has good power,

ground and throttle signal.

Check DFIV adjustment.

If all these things check out, but the

DFIV won’t power the “brake” wire, the

DFIV is likely faulty.

Also check for a good ground at the

spool valve.

Check that when spool valve is

powered it switches vacuum output

from the hose going to the rear of the

vacuum cylinder to the hose going to

the front of the cylinder (the end that

the rod comes out of).

The brake comes on but

there’s little or no holdback

No

Yes

Check that torque converter is

staying locked up. If it is not, the

engine RPM will fall to idle when the

throttle is released.

Check off-idle brake backpressure.

Are you getting maximum allowable

backpressure?

(See backpressure chart)

Check for exhaust leaks. A small leak

can result in a significant decrease in

brake backpressure. Check for

vacuum leaks.

Try down shifting more aggressively.

More RPM will give more holdback.

Vacuum systems will decrease in

effectiveness with an increase in

altitude. For example at 5000ft a

60psi brake will only make about

50psi exhaust backpressure.

Transmission or torque converter

could be slipping internally.

Everything seems to work,

but the brake valve won’t

close.

No

Yes

Check that vacuum is reaching the

front hose (near where the rod

comes out) of the brake cylinder.

Spool valve stuck, plugged or faulty.

Clean or replace as required.

Cylinder or brake valve are seized.

Remove the clevis pin on the end of

the cylinder rod & see if the valve

lever can be moved freely.

The valve lever can be moved

freely.

Try dismounting the brake & cleaning

the carbon out of it. If this does not

work the brake valve will need to be

replaced.

The cylinder is stuck and will need to

be replaced.

Problem

Solution

Air compressor runs in short bursts

and brake is slow to apply.

There is a restriction in the air system, normally in the regulator or air solenoid.

Remove the fittings from the regulator and air solenoid, you will likely find some

corrosion or debris caught in them. Clean this out with a pick, small brush,

compressed air and WD40 or similar lubricant.

Air compressor runs continually.

Pump relay is likely stuck on. Check operation of relay & replace as required.

Brake is slow to release.

Debris or corrosion is restricting the quick release valve or air solenoid. Clean

as required. Air solenoid could be too far from brake.

8 February 2021 BD Universal Remote Mount Vacuum Brake 17

BD Engine Brake Inc.

1-800-887-5030 | https://www.bddiesel.com

Operating Guidelines

Thank you for taking interest in the BD Engine Exhaust Brake. As a driver, you

probably already know the need for extra braking power that your vehicle requires on

the hills and long grades. With loads being towed behind you, the extra push when

slowing down or maintaining speed on downward grades can prove to be a great

strain on your vehicles chassis’s braking system, even to the point of “burn-up”. These

guidelines were designed to offer you a better understanding of the benefits of

exhaust brakes and are partly based upon material developed by the U.S. Department

of Transportation National Highway Traffic Safety Administration.

The emphasis on today’s vehicles is to give the consumer a product that can give

them usable power with fuel efficiency. But, in the transition, the vehicles have lost

their natural braking power, making it easier for the vehicle to continue to roll and

harder to stop. Of course, this gets more noticeable with the increase of weight, on

or behind the vehicle. This is where an exhaust brake becomes a useful tool for

increasing the driveline drag of the vehicle without the use of the chassis’s brakes. A

tool, which with maximum or even occasional use can reduce wear on chassis’

braking parts and at the same time increase safety.

The BD Exhaust Brake can be used to help maintain a controlled vehicle speed on a

downward grade, as well as slowing the vehicle down for such times as turns or exit

ramps, without you using your chassis’s brakes. The exhaust brake cannot be used

as a parking brake or will not bring your vehicle to a complete stop.

By using a BD Exhaust Brake, the life and effectiveness of your chassis’s brakes will

increase. This is because of the decreased use of the chassis’s brakes in situations

like hills, the wear factor is reduced and there is less opportunity for your chassis’s

brakes to heat up which would reduce the efficiency.

When you ride your chassis’s brakes, make hard stops or have poorly adjusted

brakes, this creates high temperatures and as your brakes get hotter, the more

chance there is for fade or failure.

When the toggle switch is turned to the “On” position, the valve is activated every time

the driver takes their foot off of the throttle pedal. When the driver puts pressure back

on the throttle pedal, the throttle switch is deactivated and the valve opens again.

Exhaust brakes are designed to operate with the throttle at idle, not to be used in

conjunction with cruise controls, and not designed to aid in gear shifting. Such cases

could cause damage to engine and/or the exhaust brake.

Incorporated with the BD Exhaust Brake, there is a pressure regulating system that

will control the created backpressure. If the backpressure reaches the set limit, the

exhaust valve will open slightly to relieve the excess pressure.

8 February 2021 BD Universal Remote Mount Vacuum Brake 18

BD Engine Brake Inc.

1-800-887-5030 | https://www.bddiesel.com

The brake pressure at idle is required to be checked and adjusted at time of installed,

two weeks after installed, and on a regular twice a year interval.

For Ford IDI and Chevy vehicles adjust the brake pressure to

8-10lb at idle; and Ford PowerStrokes, adjust to 10-12lb at idle.

On Dodge 6BTA (1989-98) with the stock exhaust valve springs, adjust the idle

pressure to 10-12lb at idle, and if the heavy duty valve springs have been installed,

adjust idle pressure to 18-20lb at idle. Dodge ISB (1998-up), adjust idle pressure to

18-20lb at idle.

Never adjust the brake to the 60 lb. setting on an engine that has not had the heavy-

duty engine exhaust valve springs installed first.

With the normal mounting position of the Control Valve Assembly being on the frame

rail, it would make it exposed to water if driven through rivers, creeks, or deep bodies

of water. If the Exhaust Brake is being used during these situations, water could be

sucked through the venting filter and eventually into the Vacuum Cylinder, damaging

booth. For the best prevention of this damage, do not operate the brake during these

occurrences.

The best scenario for exhaust braking is when going down hill, select a gear that lets

you maintain a constant speed with little or no use of the chassis’s brakes, or the

same gear that would be used to go up the same grade of hill. This also depends on

the weight, load or road conditions that the vehicle will come upon.

So, in summary, by using the BD Exhaust Brake, you reduce the need for use of your

chassis’s brakes in situations where you need to slow down or maintain (i.e. hills, off

ramps, approaching speed changes or traffic lights). By reducing the use of your

chassis’ brakes, in these situations, the heat build up is reduced, as well as wear and

damage to linings and drums. And, when you reduce these factors, you save your

chassis’s brakes for when you really need them (i.e. for stopping or emergencies).

The BD Exhaust Brake is not a substitute for your chassis’s brakes and, cannot correct

or compensate for poorly maintained or misadjusted brakes. But, when you need to

slow down or maintain a constant speed, the BD Exhaust Brake will be a valuable and

effective tool. Exhaust Brakes are more efficient at preventing than correcting an over

speed condition.

To increase the life of your exhaust brake we recommend daily operation. This could

simply be switching it on and off a couple times a day. This will prevent the butterfly

from sticking due to carboning up.

Thank you and happy motoring,

BD Engine Brake, Inc.

This manual suits for next models

3

Table of contents

Other BD Diesel Performance Automobile Accessories manuals

Popular Automobile Accessories manuals by other brands

Powrwheel

Powrwheel POWRTOUCH CLASSIC Installation, use and maintenance

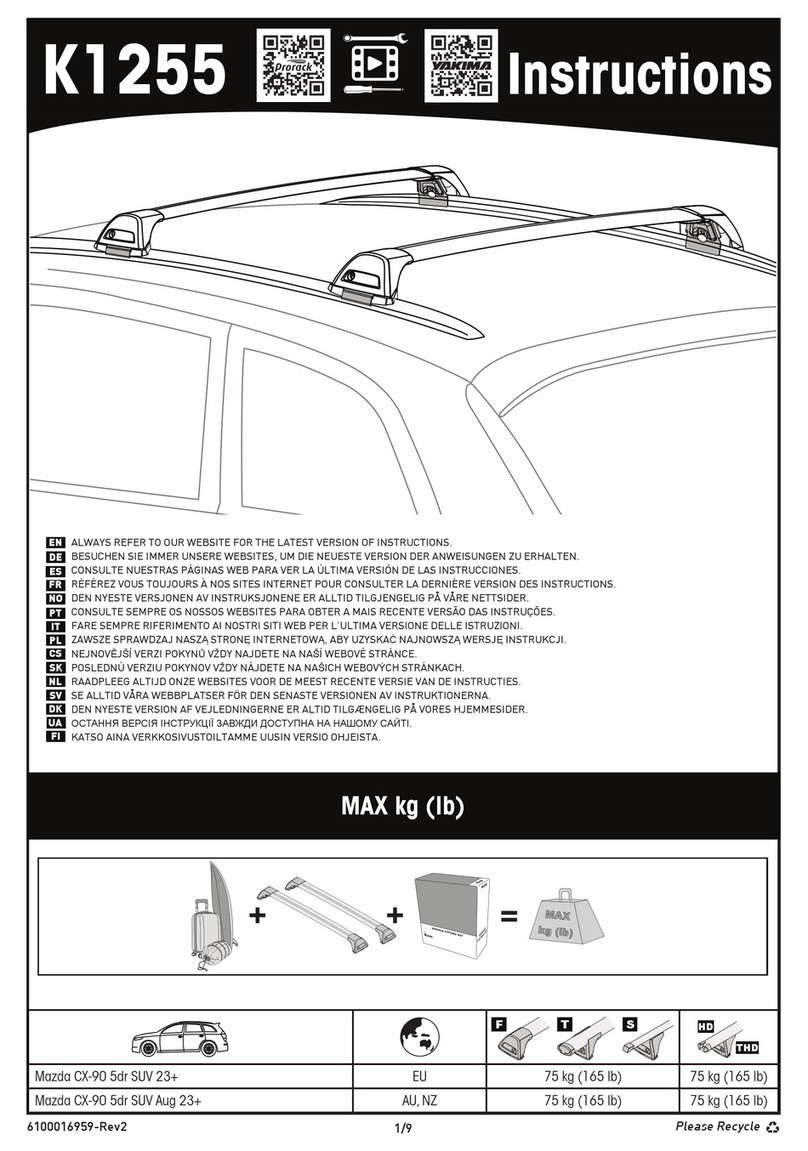

Prorack

Prorack K1255 instructions

TAUBENREUTHER

TAUBENREUTHER 50-5212100-RCP58-BK manual

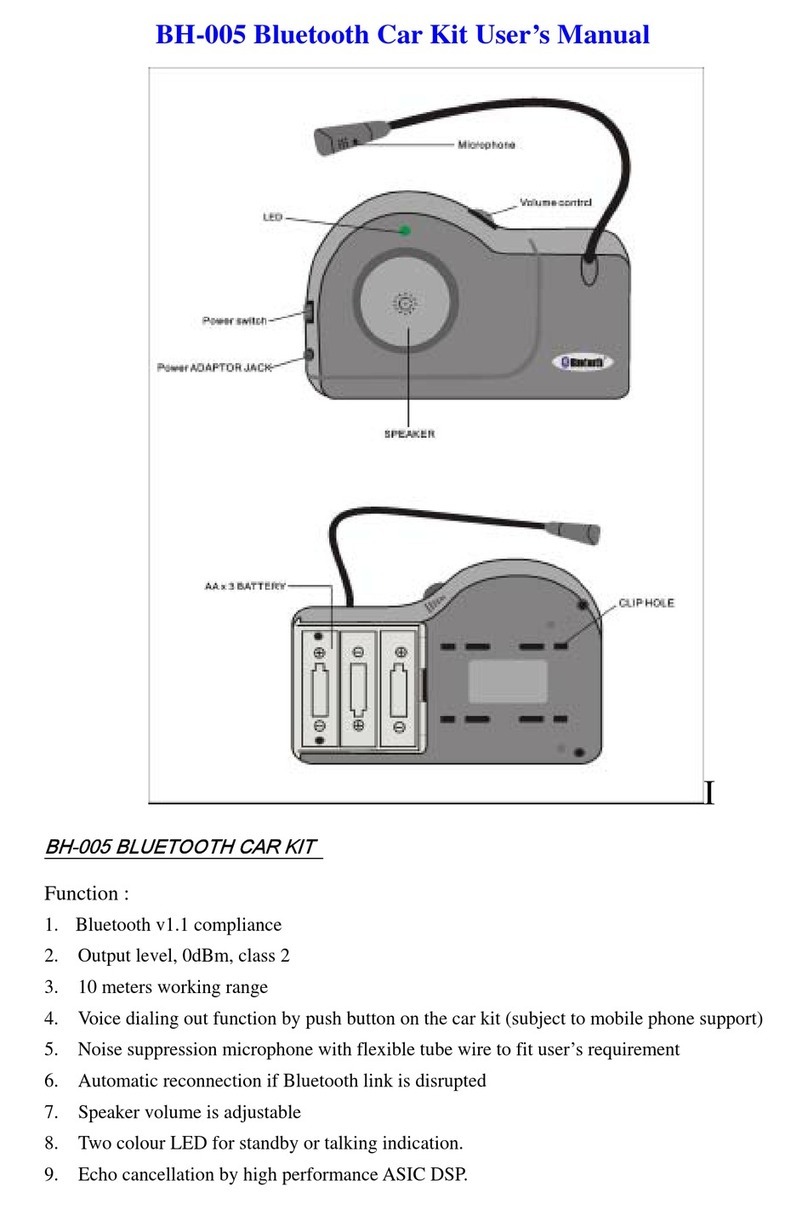

Archer Wireless

Archer Wireless BH-005 user manual

Steinhof

Steinhof S-463 FITTING AND OPERATION MANUAL

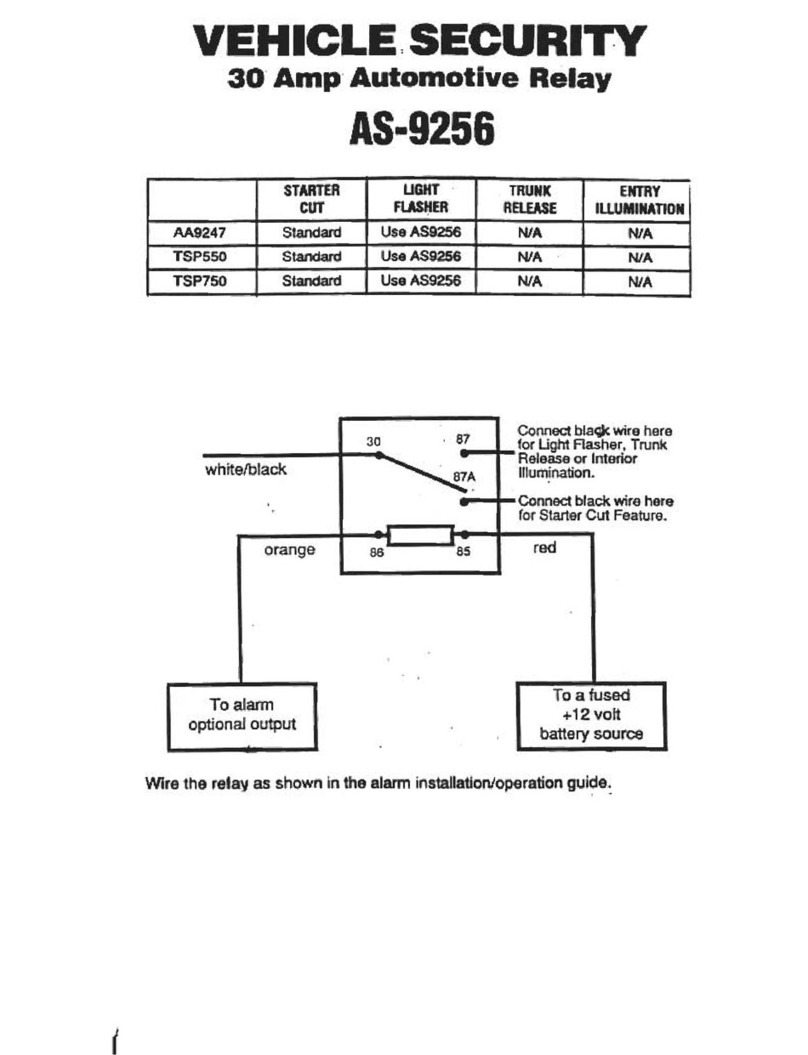

Omega Vehicle Security

Omega Vehicle Security AS-9256 Schematic diagram