BD Diesel Performance BD-Power X-MONITOR User manual

12 May 2005 1086210 GMC/Chevy Duramax X-Monitor 1

BD X-MONITOR

2001-2006 GMC/Chevy 6.6L Duramax

Installation Manual

Date Purchased

Purchased from

Installed by

READ THIS MANUAL COMPLETELY BEFORE INSTALLING THIS PRODUCT.

OWNER’S MANUAL - LEAVE IN GLOVE BOX

Installation Manual Part # I1086210

Printed in Canada

BD Engine Brake Inc.

Plant Address: Unit A10, 33733 King Rd, Abbotsford, BC, Canada V2S 7M9

U.S. Shipping Address: 88-446 Harrison St, Sumas, WA 98295 U.S. Mailing Address: P.O. Box 231, Sumas, WA 98295

Phone: 604-853-6096 Fax: 604-853-8749 Internet: www.bd-power.com

12 May 2005 1086210 GMC/Chevy Duramax X-Monitor 2

Table Of Contents

Kit Contents................................................................................................................3

Welcome ....................................................................................................................4

Pre-Installation ...........................................................................................................4

Installation..................................................................................................................5

Pyrometer Sending Unit (Thermocouple)..........................................................5

Thermocouple Wiring...............................................................................6

Boost Pressure Sender Installation...................................................................6

LB7 Motor................................................................................................6

LLY & LBZ motor .....................................................................................7

Manual Transmission / Diff Temperature Sensor..............................................8

Wiring Diagram - w/Remote Temp Sensor..............................................9

Exhaust Brake Pressure Sensor.....................................................................10

Wiring Diagram – Back Pressure...........................................................11

Engine Oil Pressure Sensor............................................................................12

2001-02 Duramax..................................................................................12

2001-02 Duramax Oil Pressure Wiring Diagram ..........................13

2003+ Duramax.....................................................................................14

2003+ Duramax Oil Pressure Wiring Diagram .............................15

Auxiliary Fuel Tank Level................................................................................16

Auxiliary Fuel Tank Level Wiring Diagram.............................................16

Power and Ground..........................................................................................17

Display Assembly Installation..........................................................................17

Programming and Set Up.........................................................................................18

Programming Chart..................................................................................................19

Operation..................................................................................................................20

X-Monitor Display Settings Flowchart ......................................................................21

Maintenance & Troubleshooting...............................................................................22

LIMITED WARRANTY STATEMENT.......................................................................23

BD Engine Brake Inc.

Plant Address: Unit A10, 33733 King Rd, Abbotsford, BC, Canada V2S 7M9

U.S. Shipping Address: 88-446 Harrison St, Sumas, WA 98295 U.S. Mailing Address: P.O. Box 231, Sumas, WA 98295

Phone: 604-853-6096 Fax: 604-853-8749 Internet: www.bd-power.com

12 May 2005 1086210 GMC/Chevy Duramax X-Monitor 3

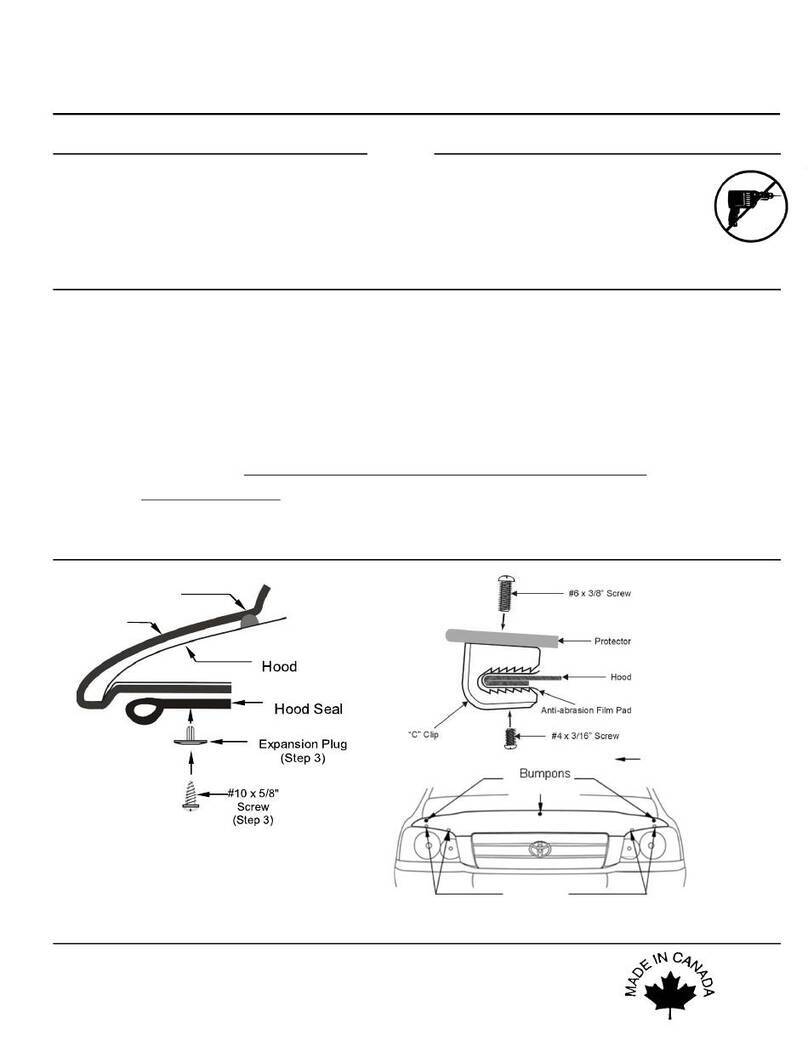

Kit Contents

1830030 Universal Installation Kit

(Includes thermocouple, bushing, control module vacuum tube boost

connection, 6ft of 1/8” air tubing, & fused power wire with ground wire)

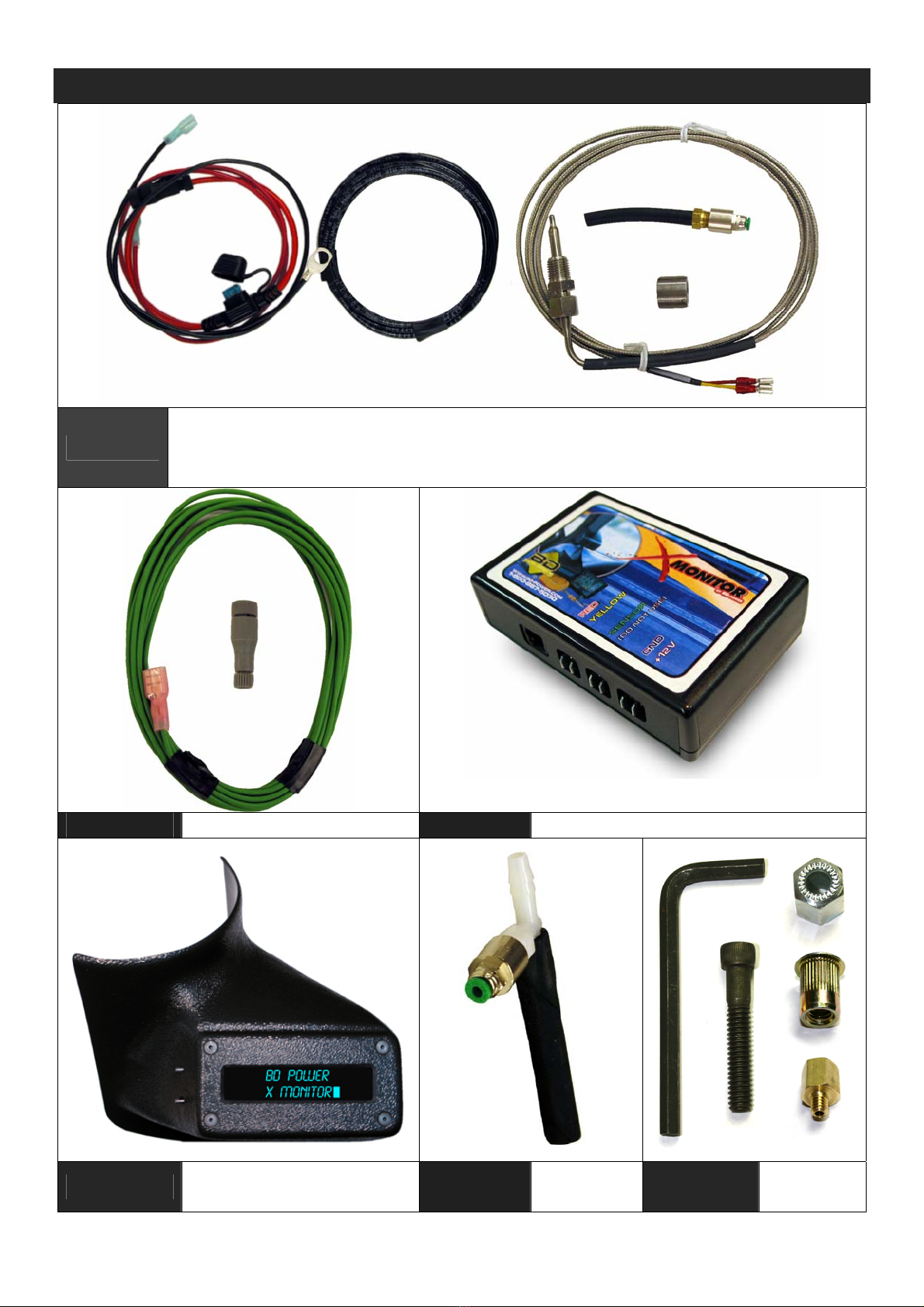

1830010 Sensor Wire Kit 1820210 Control Module

1806200 Display Kit (Side) 1300838 LB7

Boost Kit 1300835 LLY-LBZ

Boost Kit

BD Engine Brake Inc.

Plant Address: Unit A10, 33733 King Rd, Abbotsford, BC, Canada V2S 7M9

U.S. Shipping Address: 88-446 Harrison St, Sumas, WA 98295 U.S. Mailing Address: P.O. Box 231, Sumas, WA 98295

Phone: 604-853-6096 Fax: 604-853-8749 Internet: www.bd-power.com

12 May 2005 1086210 GMC/Chevy Duramax X-Monitor 4

Welcome

Thank you for purchasing the BD X-Monitor. Your kit should have the items

mentioned on the previous page for your installation. This manual is divided into

different areas to assist you with your installation and operation of your unit.

Pre-Installation

If you have existing gauges installed, you may have to determine where to

reposition them to accommodate the X-Monitor. The X-Monitor mounts on the

driver’s side A-pillar panel, or, a custom dash-top universal kit can be purchased as

well.

This X-Monitor comes with all the programming to measure exhaust temperature

and boost pressure, plus, the option of adding one of the following: automatic

transmission temperature (using the OEM sensor), remote temperature sender (for

use with differentials for example), exhaust brake backpressure, and aftermarket

fuel tank levels.

Here are the standard list measurements:

Exhaust Gas Temperature (PYRO)

Turbo Boost Pressure (TURBO)

The above two measurements can be displayed by themselves or you can add one

of these options along with them:

Description Value BD P/N#

Transmission Temperature (TRANS) INCLUDED

Remote Oil Temp (OIL) 1080126

Exhaust Brake Back Pressure (B-PSI) 1080136

Auxiliary Tank Level (FUEL) 1080160 *

The standard kit comes with all the components and wiring to hook up the exhaust

temperature, turbo boost pressure and automatic transmission temperature (using

the trucks OEM sensor); all other applications will require one of the accessories

above to install.

* The fuel tank level accessory kit interfaces with an aftermarket level sender with a

range of 240ohms (Empty) to 33ohms (Full). Sender not included.

Once the components have been installed, the X-Monitor will have to be

programmed to match the application and the measurements being monitored. This

will be done via the buttons on the display and will be explained further in this

manual. If you wish to change from one optional measurement to another, the X

BD Engine Brake Inc.

Plant Address: Unit A10, 33733 King Rd, Abbotsford, BC, Canada V2S 7M9

U.S. Shipping Address: 88-446 Harrison St, Sumas, WA 98295 U.S. Mailing Address: P.O. Box 231, Sumas, WA 98295

Phone: 604-853-6096 Fax: 604-853-8749 Internet: www.bd-power.com

12 May 2005 1086210 GMC/Chevy Duramax X-Monitor 5

Monitor can be reprogrammed to that application but an additional accessory kit

may be required.

The following sections will give detail on the install of each measurement available

but not all will apply to your installation.

Installation

NOTE: The ground terminals of the vehicle’s batteries should be disconnected

before performing any welding or taping onto any ECM/PCM wire.

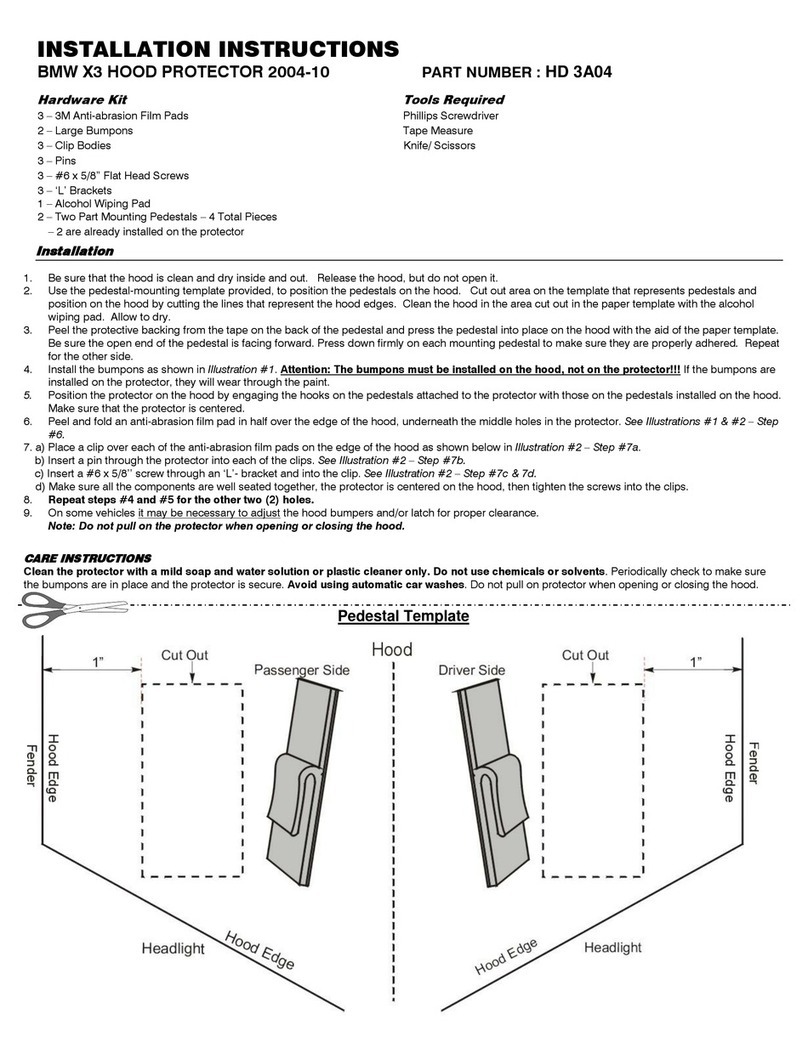

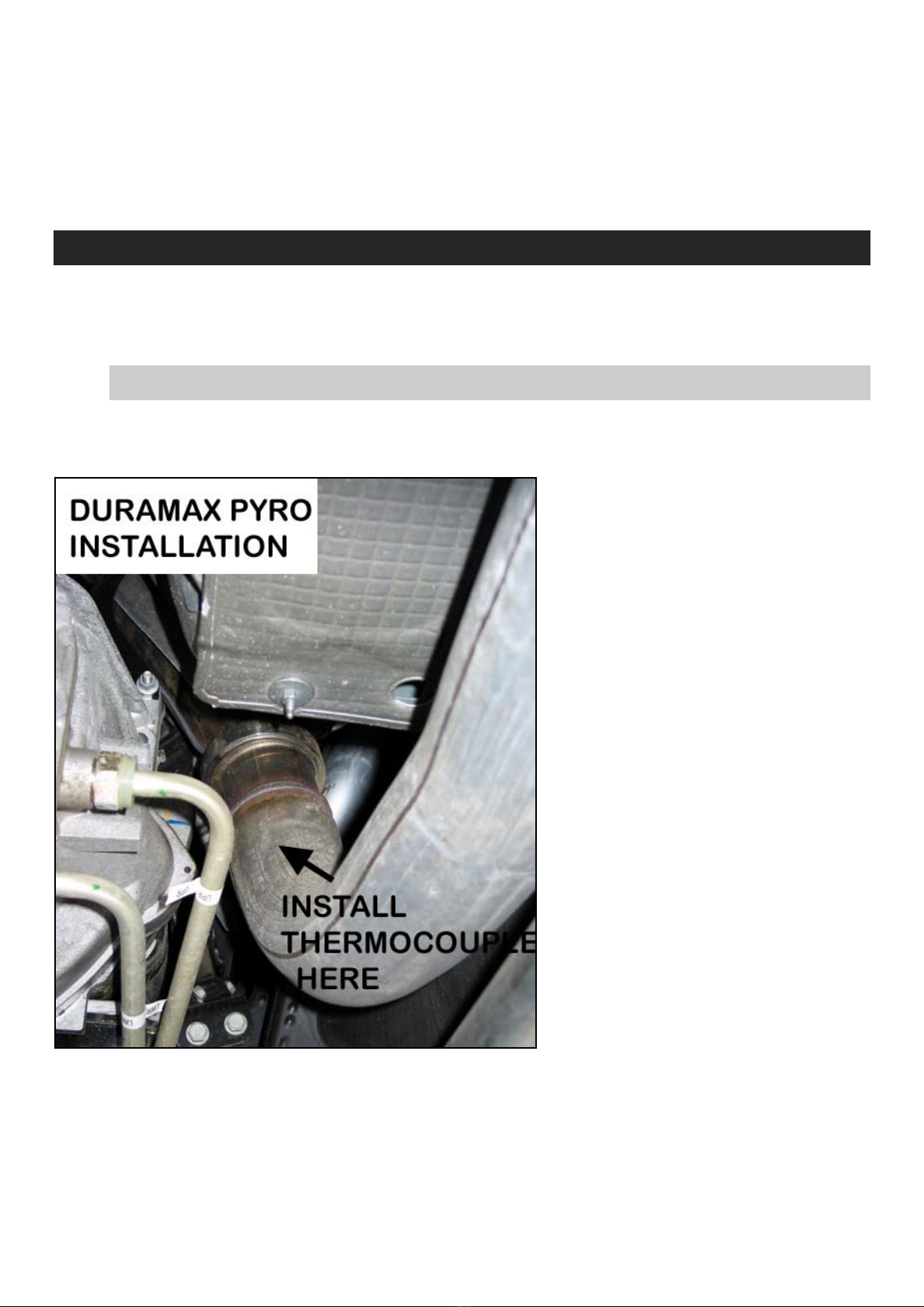

Pyrometer Sending Unit (Thermocouple)

If your existing exhaust does not have a fitting to install a pyrometer sender unit

(thermocouple), you will have to install the bushing supplied in this kit. The best

place to locate the thermocouple is in the turbo charger down pipe.

If you have a TURBO-MOUNT

EXHAUST BRAKE or an after

market down pipe installed there

may be a ¼” NPT plug already

in the system. Remove this plug

and install thermocouple into the

¼” NPT hole and tighten with an

open-end wrench.

If you have an OEM or stock

down pipe you will have to drill a

hole and then weld the bushing

that is supplied with this kit in

place. It is recommended that

you remove the existing down

pipe for ease of drilling and

welding but it is possible to

install with pipe in place. Install

thermocouple into the 1/4 pipe

tap hole and tighten with an

open-end wrench.

For advanced users, the thermocouple can be directly installed into the manifold

before the turbo. This is a more difficult installation and should only be attempted by

an experienced mechanic. When drilling and tapping the ¼” hole, be sure not to drill

into any webbing or critical areas of the exhaust manifold. When monitoring the

exhaust temperature before the turbo the critical temperature is ~1250-1300°F.

BD Engine Brake Inc.

Plant Address: Unit A10, 33733 King Rd, Abbotsford, BC, Canada V2S 7M9

U.S. Shipping Address: 88-446 Harrison St, Sumas, WA 98295 U.S. Mailing Address: P.O. Box 231, Sumas, WA 98295

Phone: 604-853-6096 Fax: 604-853-8749 Internet: www.bd-power.com

12 May 2005 1086210 GMC/Chevy Duramax X-Monitor 6

Thermocouple Wiring

Route the wire toward the firewall taking precaution to keep it away from hot and

moving parts, and then run it through the firewall by piercing a large rubber grommet

in the firewall beside the brake booster canister.

Do NOT cut or splice the thermocouple lead wire as it is special wire that

provides correct reading to the gauge. Simply coil any excess wire out of the

way.

From under the dash, retrieve the thermocouple wire and route it to the X-Monitor

Control Module. Install the wires onto the Control Module as shown in the diagram.

DO NOT MIX UP THESE WIRES, ENSURE YELLOW TO YELLOW AND RED TO

RED OR DAMAGE WILL RESULT AND WARRANTY WILL BE VOIDED.

Boost Pressure Sender Installation

LB7 Motor

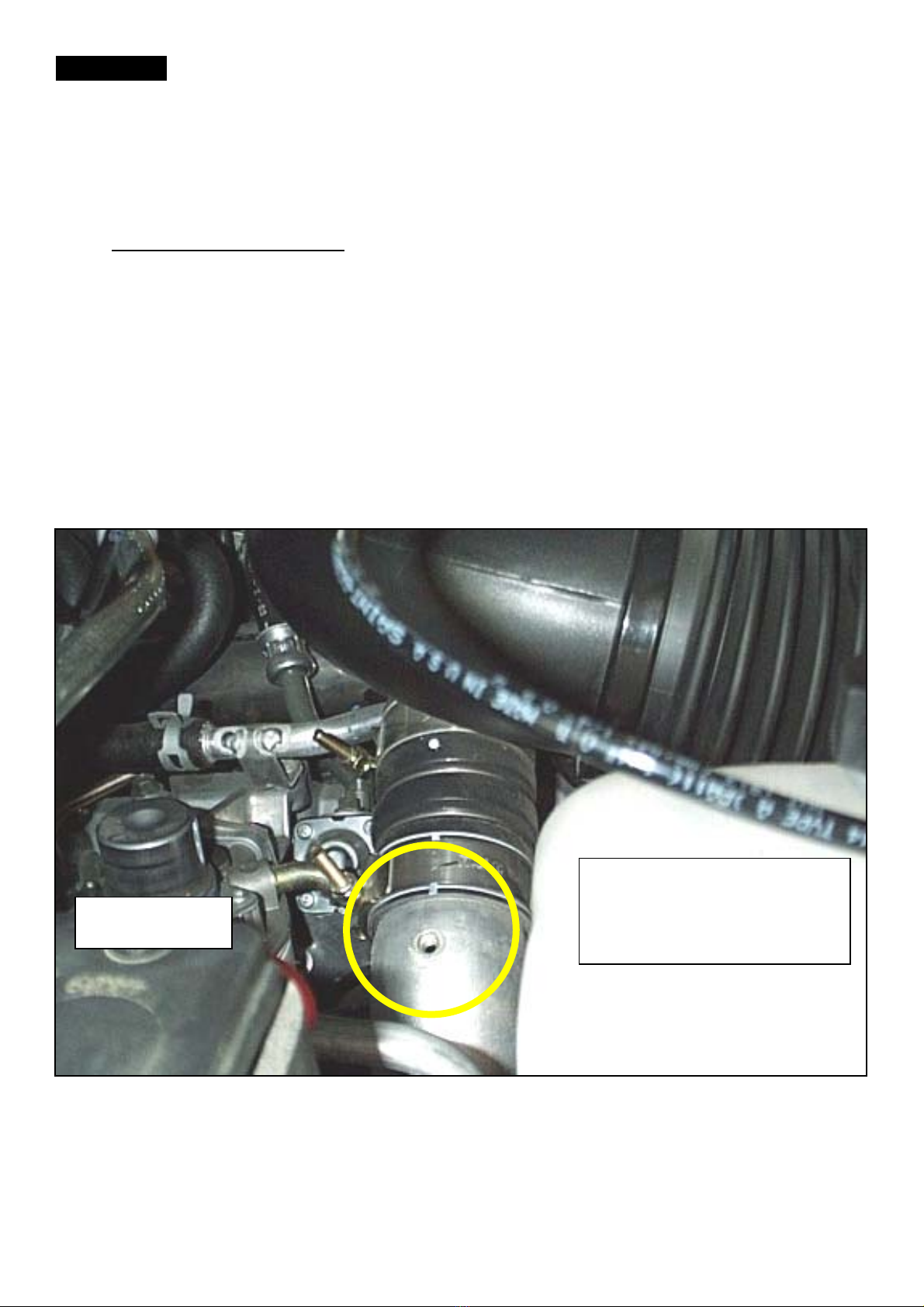

Locate the Turbo Wastegate hose

and follow it along to the Plenum.

Install the other end of the fitting

with the 3” hose onto the fitting of

the plenum as shown in the

photos.

Connect the supplied tubing to the

fitting and route to the inside the

cab. Push this end into the

supplied fitting (see diagram

above) and connect the short

section of rubber hose (with the

female quick-connect fitting) to the

pressure sensor on the back of

control box.

BD Engine Brake Inc.

Plant Address: Unit A10, 33733 King Rd, Abbotsford, BC, Canada V2S 7M9

U.S. Shipping Address: 88-446 Harrison St, Sumas, WA 98295 U.S. Mailing Address: P.O. Box 231, Sumas, WA 98295

Phone: 604-853-6096 Fax: 604-853-8749 Internet: www.bd-power.com

12 May 2005 1086210 GMC/Chevy Duramax X-Monitor 7

WARNING: BE SURE TO USE THE RUBBER HOSE AND NOT THE PLASTIC

TUBING WHEN MAKING THE CONNECTION TO THE CONTROL BOX.

NOTE: The module should be mounted with the boost fitting pointed down to avoid

condensation from collecting inside the module.

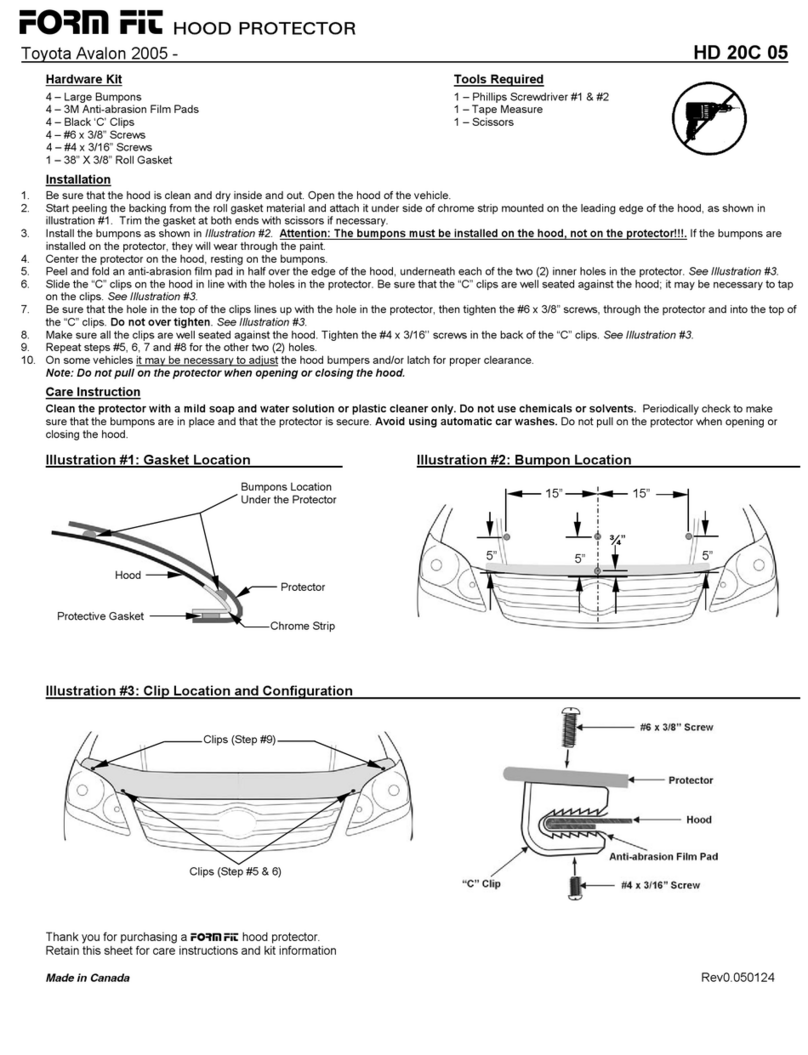

LLY & LBZ motor

Using a 7/16 deep socket, remove the ‘T’ clamps at either end of the intercooler

tube on the passenger side of the engine. Once this pipe is removed, drill a 3/8”

hole on the top of the pipe closest to the turbo. Use a file or de-burring wheel to

clean to hole. Coat the nutsert or rivnut with a moderate temperature silicon or

gasket maker. Insert the coated nutsert or rivnut into the 3/8” hole in the pipe. Insert

the Allen head screw through the install nut with the serrated end facing towards the

nutsert or rivnut. Use a wrench to hold the nut in place while tightening the Allen

screw with the provided Allen key. Continue to tighten the Allen key until the force

needed to turn it drastically increases. Reinstall the tube into place on the truck,

making sure the all the intercooler boots are clean of oil and the clamps are tight.

Install the 90° quick connect swivel fitting into the small brass adapter and tighten it

before installing the assembly into the nutsert. When installing the adapter assembly

into the nutsert use a small amount of silicone sealer/gasket maker around the base

of the brass adapter being careful not to obstruct the hole in the end. When

tightening the assembly into the nutsert, do not over torque or breakage will result!

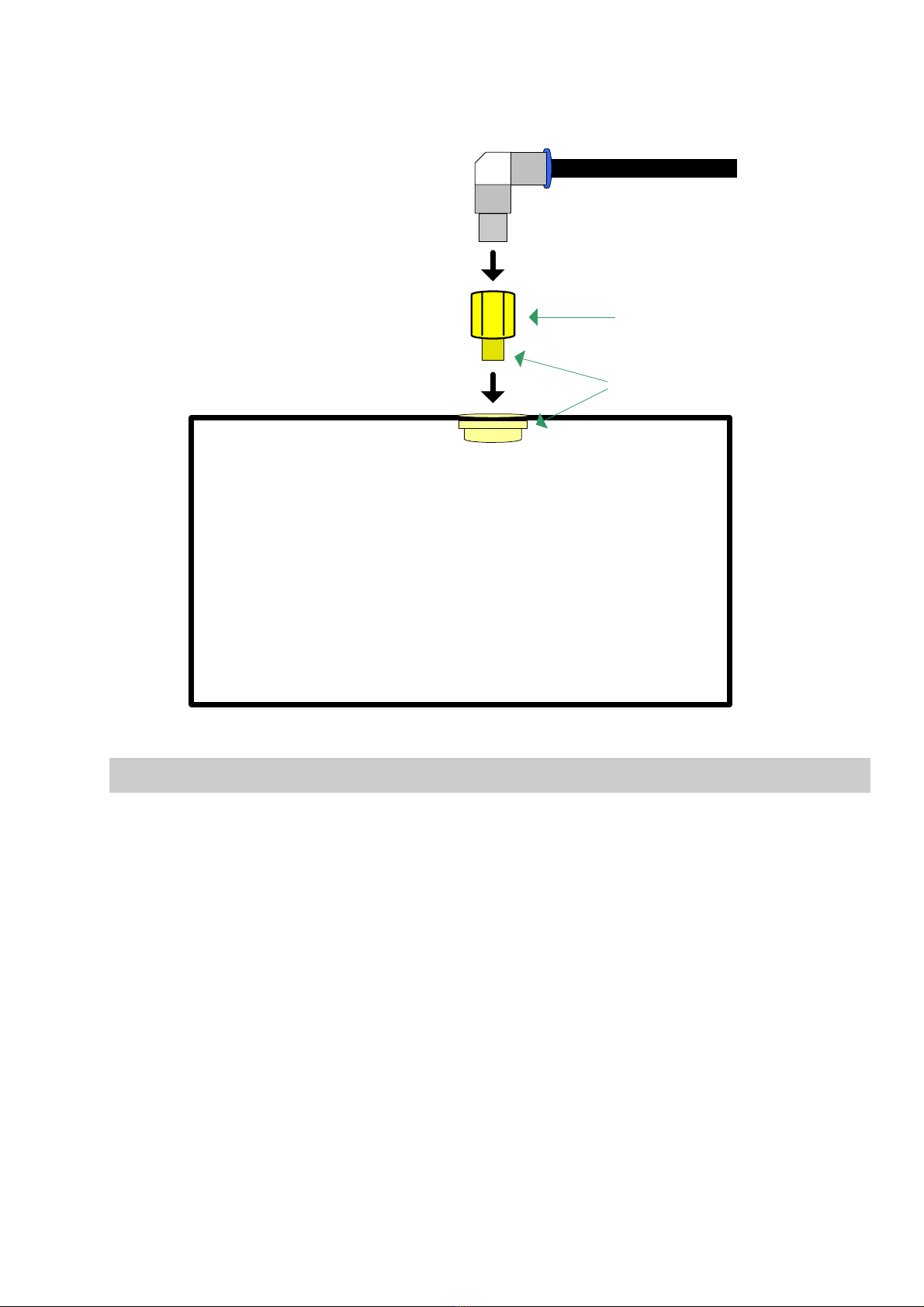

Insert and tighten the

rivnut.

Fuel Filter

BD Engine Brake Inc.

Plant Address: Unit A10, 33733 King Rd, Abbotsford, BC, Canada V2S 7M9

U.S. Shipping Address: 88-446 Harrison St, Sumas, WA 98295 U.S. Mailing Address: P.O. Box 231, Sumas, WA 98295

Phone: 604-853-6096 Fax: 604-853-8749 Internet: www.bd-power.com

12 May 2005 1086210 GMC/Chevy Duramax X-Monitor 8

You can now route the nylon tubing from the quick connect nutsert assembly to the

boost input on the X-monitor. Black Nylon hose To X Monitor

Nutsert

Brass Adapter

Quick Connect

Swivel Elbow

To Intake Manifold

Use sealant here

From Intercooler

DO NOT OVER

TORQUE!

Manual Transmission / Diff Temperature Sensor

Using parts supplied in X-Monitor kit, insert the Temperature Sender into the large

bushing. This will replace the rear differential housing fill plug on the back cover. For

manual transmission temperature, locate the appropriate location for sender to fit.

NOTE: Not all locations will accommodate the size of the sender or the bushings

supplied in the kit. An alternative location may need to be found, or a sender or

bushing may have to be purchased to be installed in the desired location.

BD Engine Brake Inc.

Plant Address: Unit A10, 33733 King Rd, Abbotsford, BC, Canada V2S 7M9

U.S. Shipping Address: 88-446 Harrison St, Sumas, WA 98295 U.S. Mailing Address: P.O. Box 231, Sumas, WA 98295

Phone: 604-853-6096 Fax: 604-853-8749 Internet: www.bd-power.com

12 May 2005 1086210 GMC/Chevy Duramax X-Monitor 9

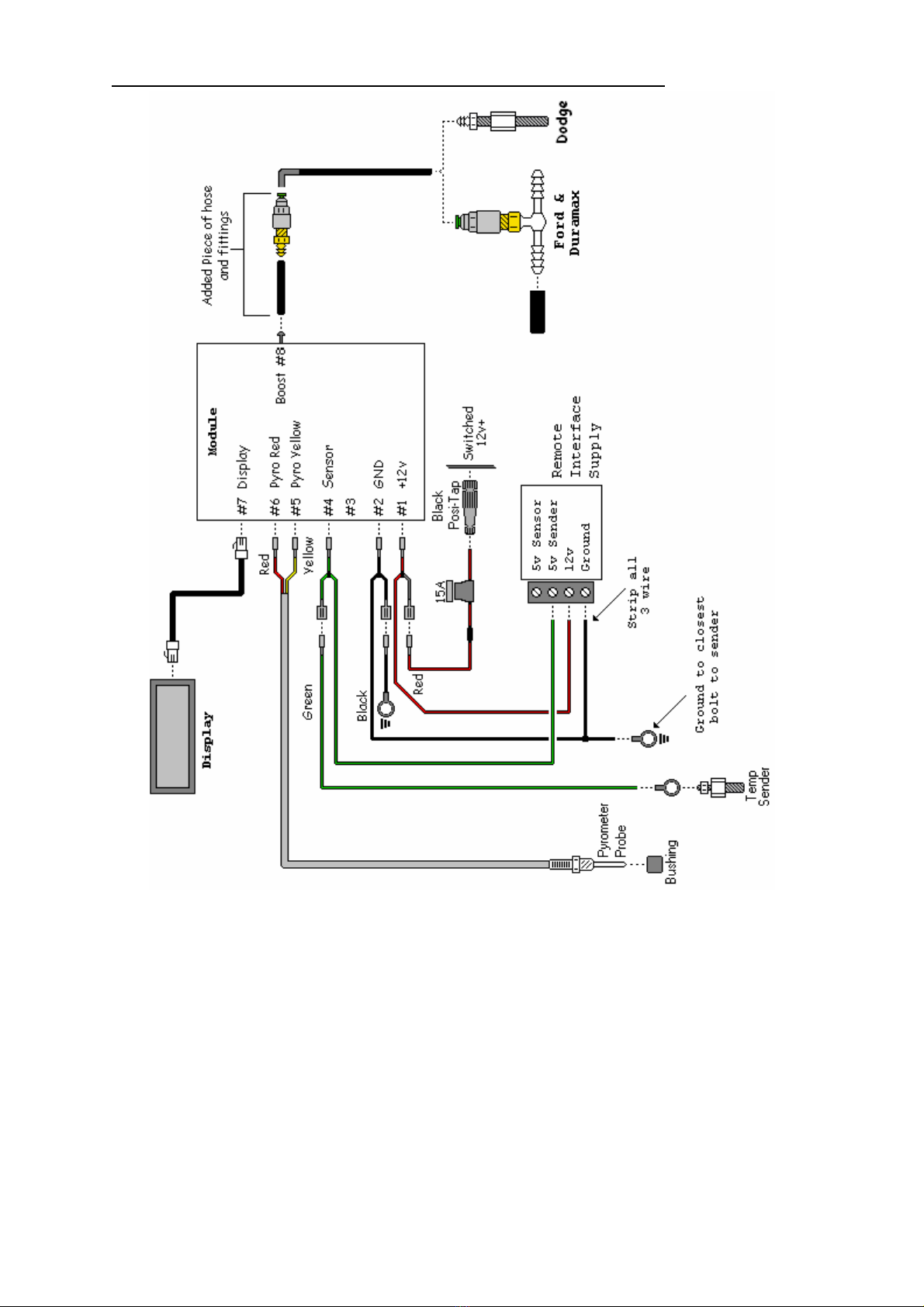

Wiring Diagram - w/Remote Temp Sensor

BD Engine Brake Inc.

Plant Address: Unit A10, 33733 King Rd, Abbotsford, BC, Canada V2S 7M9

U.S. Shipping Address: 88-446 Harrison St, Sumas, WA 98295 U.S. Mailing Address: P.O. Box 231, Sumas, WA 98295

Phone: 604-853-6096 Fax: 604-853-8749 Internet: www.bd-power.com

12 May 2005 1086210 GMC/Chevy Duramax X-Monitor 10

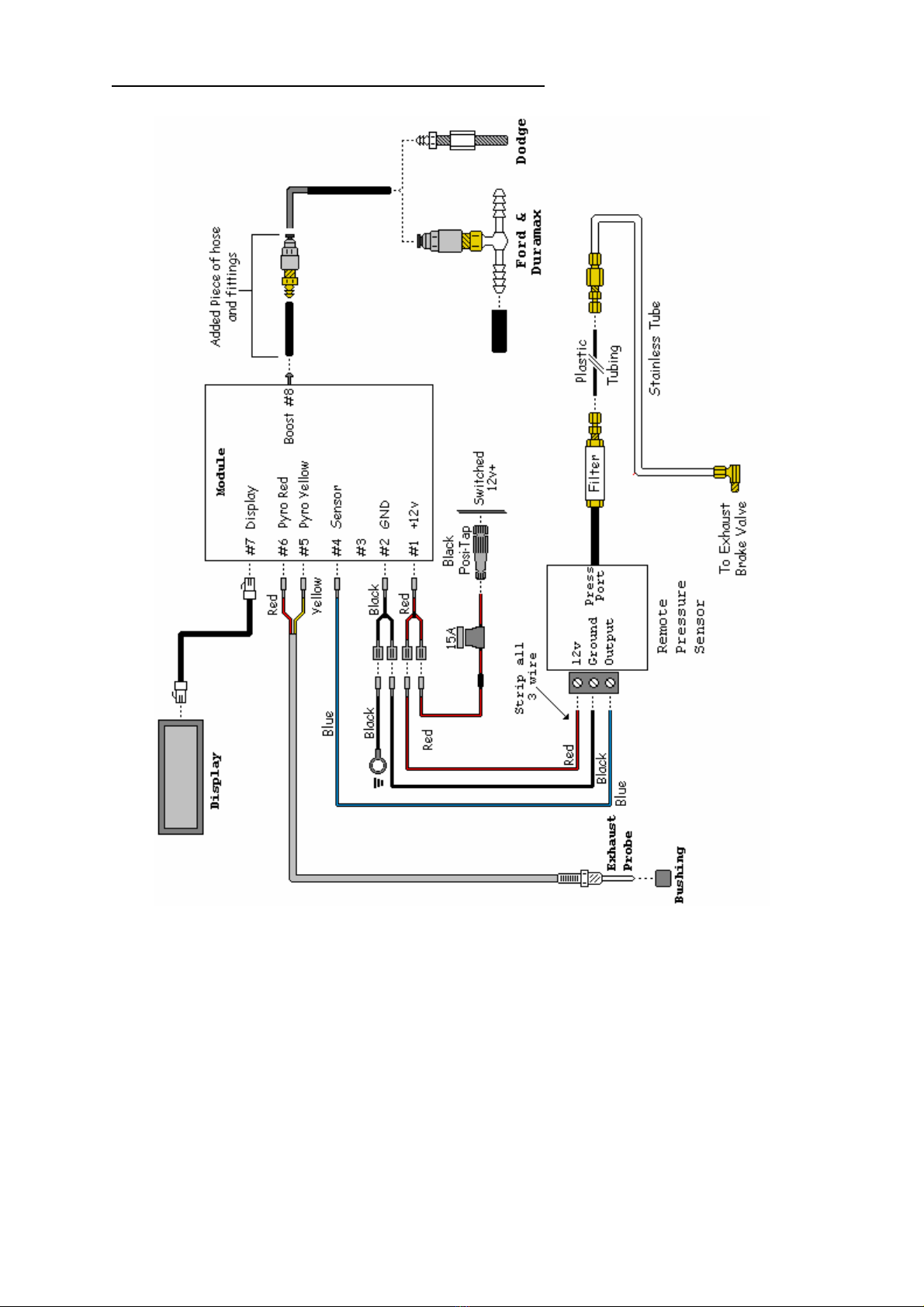

Exhaust Brake Pressure Sensor

Install the supplied stainless steel line and fitting into the test port of the exhaust

brake. Secure the line and attach the plastic hose.

Route the hose up along the vehicle frame and into the cab then attach the hose to

the interface filter and connect the wires as per the “Back Pressure” diagram that will

follow after this section.

Use the following diagram/photo as a guide. Install the filter and tubing together and

insert onto the inlet of the RPS Module.

The plastic filter housing will need to be changed out after 6-12 months of use. This

time is dependant on air humidity and the amount moisture trapped in the actual

filter. The replacement filter part number is 1800135. This filter should be mounted

in an easy to access, visible location.

Because of the moisture accumulating in the line and filter, it is highly recommended

that the RPS unit be mounted at the highest point of the air line causing all the

moisture to run back down the line into the exhaust.

BD Engine Brake Inc.

Plant Address: Unit A10, 33733 King Rd, Abbotsford, BC, Canada V2S 7M9

U.S. Shipping Address: 88-446 Harrison St, Sumas, WA 98295 U.S. Mailing Address: P.O. Box 231, Sumas, WA 98295

Phone: 604-853-6096 Fax: 604-853-8749 Internet: www.bd-power.com

12 May 2005 1086210 GMC/Chevy Duramax X-Monitor 11

Wiring Diagram – Back Pressure

BD Engine Brake Inc.

Plant Address: Unit A10, 33733 King Rd, Abbotsford, BC, Canada V2S 7M9

U.S. Shipping Address: 88-446 Harrison St, Sumas, WA 98295 U.S. Mailing Address: P.O. Box 231, Sumas, WA 98295

Phone: 604-853-6096 Fax: 604-853-8749 Internet: www.bd-power.com

12 May 2005 1086210 GMC/Chevy Duramax X-Monitor 12

Engine Oil Pressure Sensor

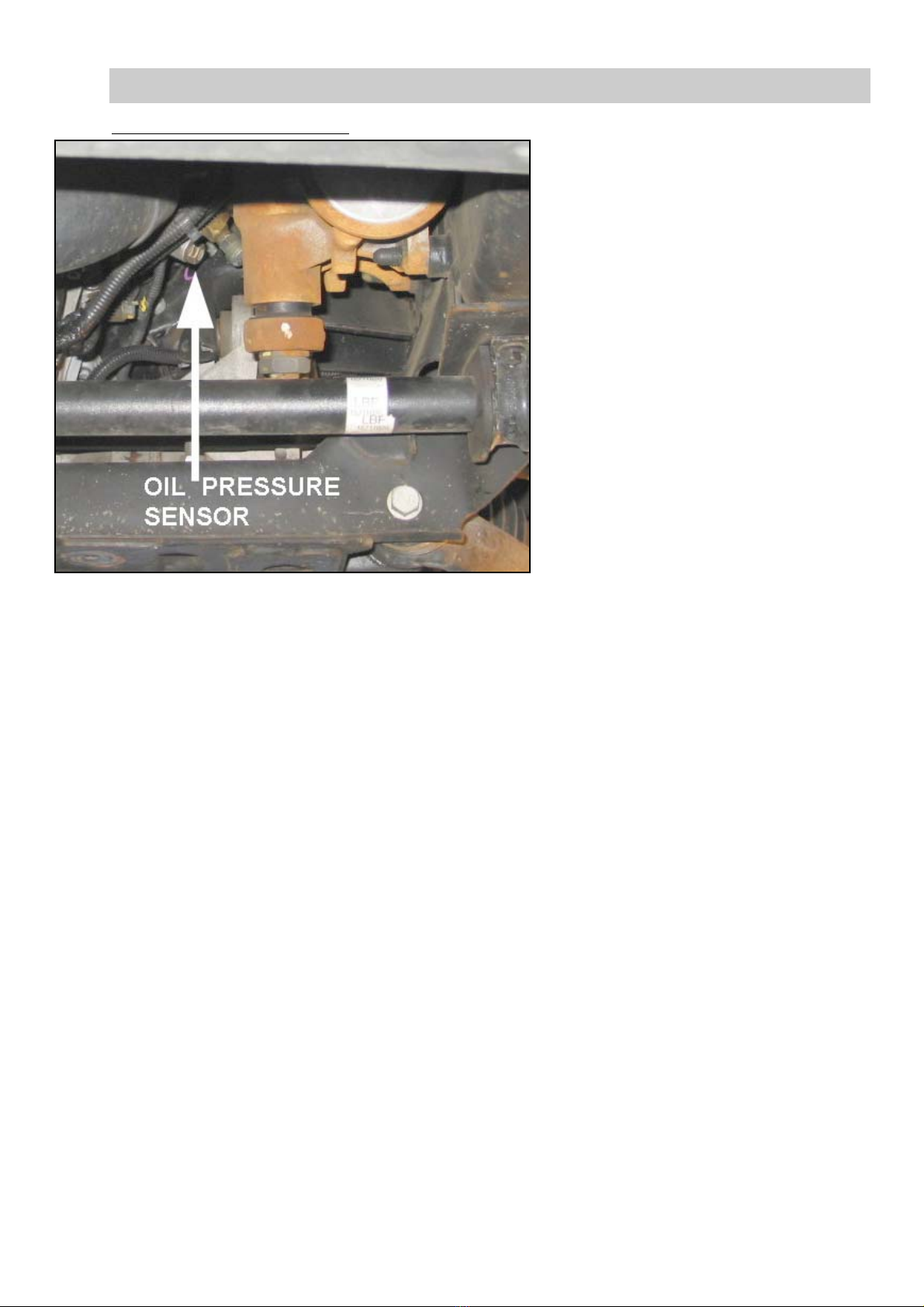

2001-02 Duramax Remove the front skid plate from

the bottom of engine and locate

the oil pressure-sending unit on

left side of engine block by the

steering box.

BD Engine Brake Inc.

Plant Address: Unit A10, 33733 King Rd, Abbotsford, BC, Canada V2S 7M9

U.S. Shipping Address: 88-446 Harrison St, Sumas, WA 98295 U.S. Mailing Address: P.O. Box 231, Sumas, WA 98295

This sensor has only one (1)

wire attached.

Install a gray Posi-Tap onto the

tan w/white tracer wire of the

sensor then insert one end of the

green wire from the oil pressure

sensor kit to the gray Posi-Tap

and run the wire up into the cab.

Attach the other end of green

wire to the ‘DO NOT USE’ terminal on the control box. That’s right, this wire goes to

the ‘DO NOT USE’ terminal (this should have been labeled 'Future Expansion').

Secure the green wire in place away from any moving and/or hot parts and install

the skid plate that was removed in the first step. Tighten all fastening bolts. See

page 13 for the wiring diagram.

Phone: 604-853-6096 Fax: 604-853-8749 Internet: www.bd-power.com

12 May 2005 1086210 GMC/Chevy Duramax X-Monitor 13

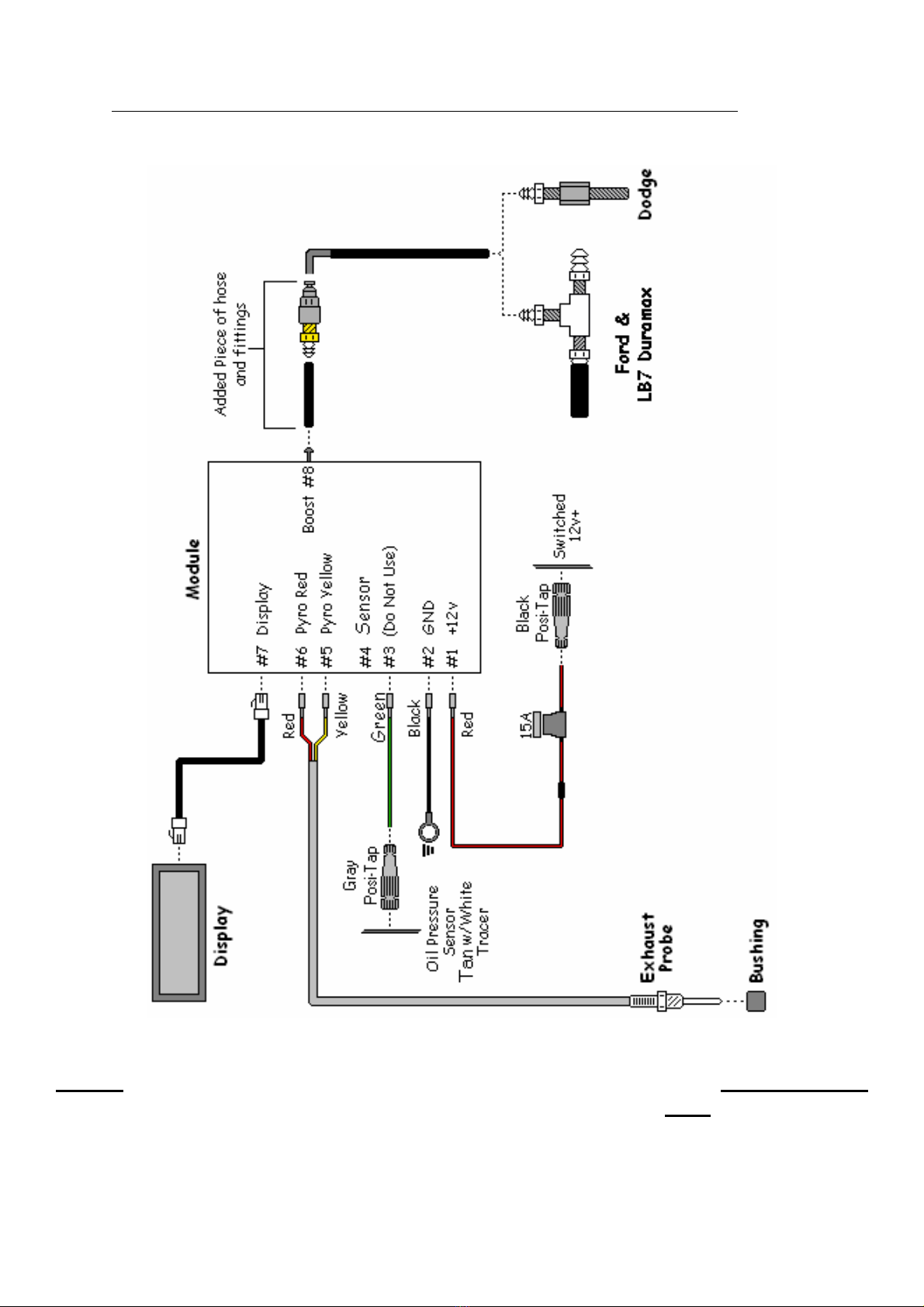

2001-02 Duramax Oil Pressure Wiring Diagram

NOTE: THE GREEN WIRE FROM THE OIL PRESSURE SENSOR IS ATTACHED

TO THE ‘DO NOT USE’ TERMINAL OF THE CONTROL BOX NOT ‘SENSOR’.

BD Engine Brake Inc.

Plant Address: Unit A10, 33733 King Rd, Abbotsford, BC, Canada V2S 7M9

U.S. Shipping Address: 88-446 Harrison St, Sumas, WA 98295 U.S. Mailing Address: P.O. Box 231, Sumas, WA 98295

Phone: 604-853-6096 Fax: 604-853-8749 Internet: www.bd-power.com

12 May 2005 1086210 GMC/Chevy Duramax X-Monitor 14

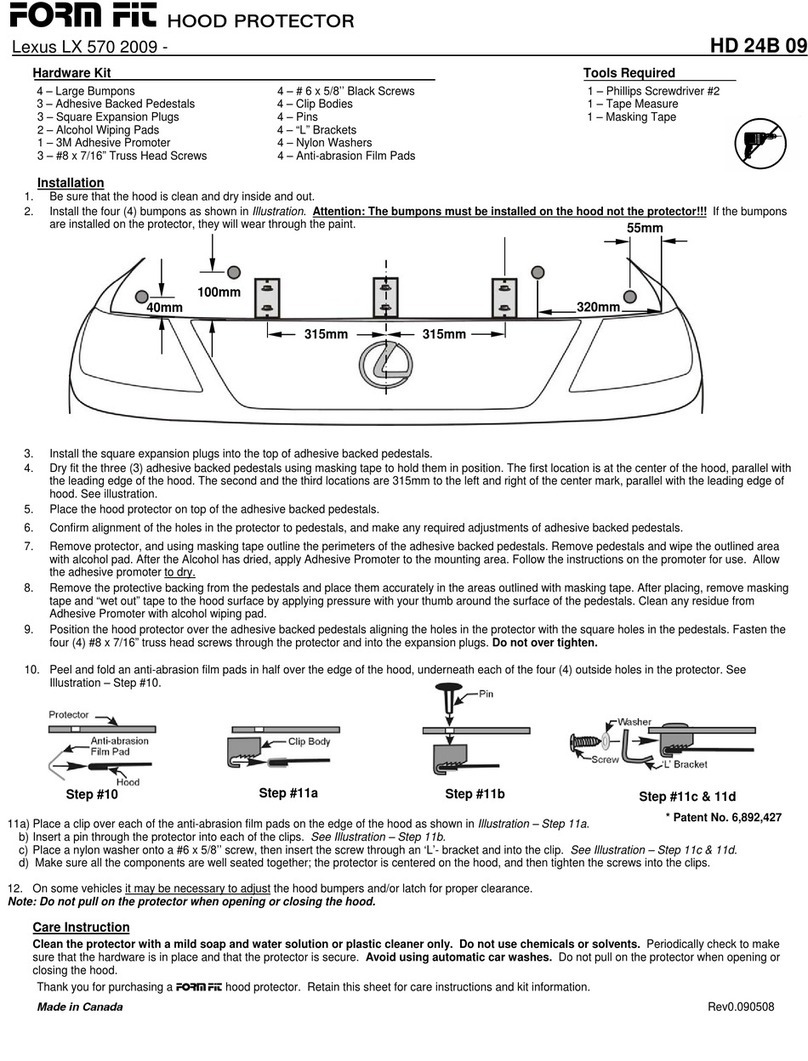

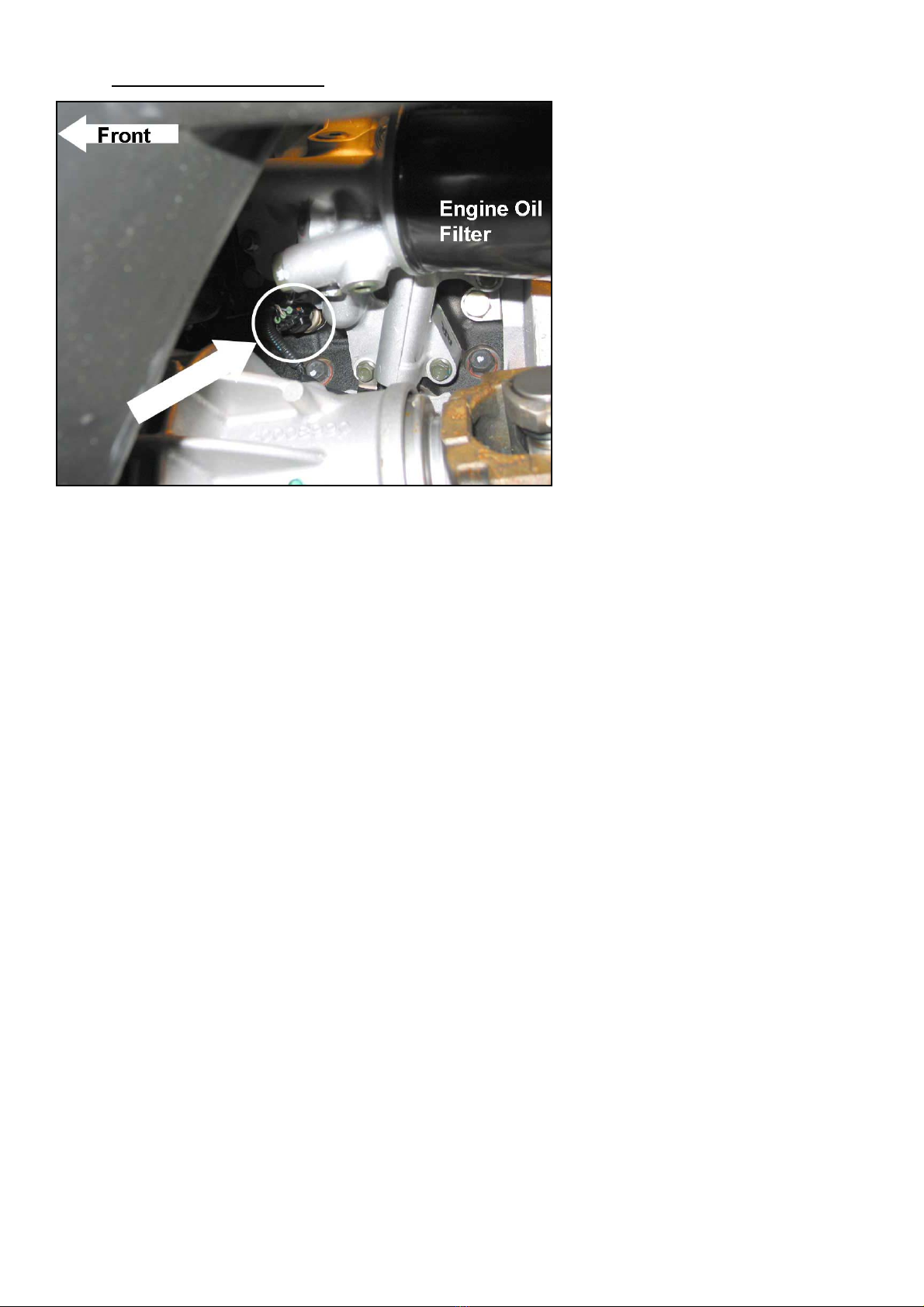

2003+ Duramax The engine oil pressure sensor

is located just in front of the

engine oil filter and housing.

This sensor has 3 wires

attached.

BD Engine Brake Inc.

Plant Address: Unit A10, 33733 King Rd, Abbotsford, BC, Canada V2S 7M9

U.S. Shipping Address: 88-446 Harrison St, Sumas, WA 98295 U.S. Mailing Address: P.O. Box 231, Sumas, WA 98295

Install a gray Posi-Tap onto the

tan w/white tracer wire of the

sensor harness then insert one

end of the green wire from the

oil pressure kit to the gray

Posi-Tap and then run the wire

up into the cab.

Attach the other end of the

green wire to the #4 ‘Sensor’

terminal on the control box.

Secure the green wire in place away from any moving and/or hot parts and install

the skid plate that was removed in the first step. Tighten all fastening bolts. See

page 15 for the wiring diagram for reference.

Phone: 604-853-6096 Fax: 604-853-8749 Internet: www.bd-power.com

12 May 2005 1086210 GMC/Chevy Duramax X-Monitor 15

2003+ Duramax Oil Pressure Wiring Diagram

BD Engine Brake Inc.

Plant Address: Unit A10, 33733 King Rd, Abbotsford, BC, Canada V2S 7M9

U.S. Shipping Address: 88-446 Harrison St, Sumas, WA 98295 U.S. Mailing Address: P.O. Box 231, Sumas, WA 98295

Phone: 604-853-6096 Fax: 604-853-8749 Internet: www.bd-power.com

12 May 2005 1086210 GMC/Chevy Duramax X-Monitor 16

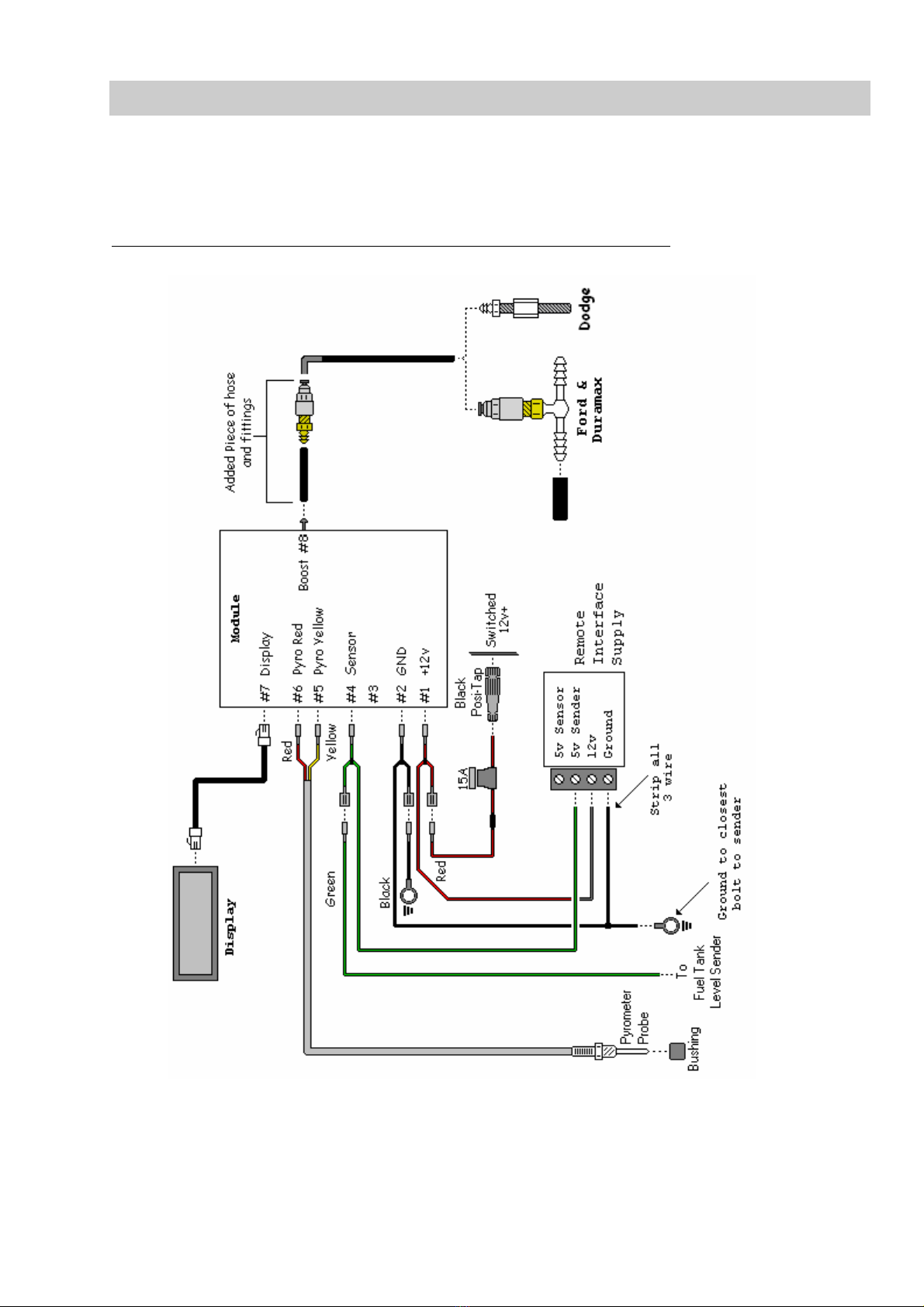

Auxiliary Fuel Tank Level

This wiring for the auxiliary fuel tank level is virtually similar to the remote

temperature installation. Consult the literature for the sender for the correct terminal

or wire for the output.

Auxiliary Fuel Tank Level Wiring Diagram

BD Engine Brake Inc.

Plant Address: Unit A10, 33733 King Rd, Abbotsford, BC, Canada V2S 7M9

U.S. Shipping Address: 88-446 Harrison St, Sumas, WA 98295 U.S. Mailing Address: P.O. Box 231, Sumas, WA 98295

Phone: 604-853-6096 Fax: 604-853-8749 Internet: www.bd-power.com

12 May 2005 1086210 GMC/Chevy Duramax X-Monitor 17

Power and Ground

Locate a switched 12-volt power source under the dash and install the Red wire to it.

Install the other end to the Power connector of the control box.

Install the Black ground loop to a good ground and install the other end to the

Ground connector of the control box.

Display Assembly Installation

* * * E X T R E M E C A U T I O N * * *

THE DISPLAY IS VERY FRAGILE AND IS INSTALLED AND

TESTED AT THE MANUFACTURER. IF YOU MUST REMOVE

THE DISPLAY IN ORDER TO PAINT THE PILLAR MOUNT

TAKE EXTREME CARE WHEN REINSTALLING. DO NOT

OVERTIGHTEN MOUNTING SCREWS OR DISPLAY WILL BE

DAMAGED AND WARRANTY WILL BE VOIDED. ***

Place the display assembly on the A-pillar to determine the best mounting location

and mark this location on the pillar. Remove the A-pillar for ease of installation.

Hold the display assembly in place on the A-pillar. Drill 3/16” holes into the corners

of the display assembly mount and also through the pillar.

Drill a hole through the A-pillar large enough for the display control wiring connector

to pass through. This hole is NOT required if you decide to run wiring along the

outside of the A-pillar.

Install the telephone-type communication cable into the back of the display circuit

board and route the wiring through the drilled hole or along the outside of the pillar

as preferred.

Insert the supplied ratchet fasteners through the drilled holes and into the A-pillar,

securing the X-Monitor display assembly to the A-pillar. Install the A-pillar into place

and route the control wiring down to the control box.

Insert the other end of the communications cable into the socket of the control box.

Once all connections are made, secure the box in place under the dash and away

from moving parts.

BD Engine Brake Inc.

Plant Address: Unit A10, 33733 King Rd, Abbotsford, BC, Canada V2S 7M9

U.S. Shipping Address: 88-446 Harrison St, Sumas, WA 98295 U.S. Mailing Address: P.O. Box 231, Sumas, WA 98295

Phone: 604-853-6096 Fax: 604-853-8749 Internet: www.bd-power.com

12 May 2005 1086210 GMC/Chevy Duramax X-Monitor 18

Programming and Set Up

Press both buttons in on the X-Monitor display

and turn on the ignition. You will get a screen

that the first line on the display will read “SIDE

OR TOP BTN?” and the bottom line reads

“SIDE”. Let go of both buttons. Press the

bottom button to go to the next screen.

BD Engine Brake Inc.

Plant Address: Unit A10, 33733 King Rd, Abbotsford, BC, Canada V2S 7M9

U.S. Shipping Address: 88-446 Harrison St, Sumas, WA 98295 U.S. Mailing Address: P.O. Box 231, Sumas, WA 98295

You will now get a screen that will read

“PART:” on the top line and “1080000” on the bottom line. Using the programming

chart located on the next page, find the program number that matches the

application and measurements you are going to program the X Monitor for. Press

the upper button until the program number appears, then press the bottom button to

activate that program. The display will now cycle through the normal start-up

screens that will appear every time the ignition is started.

It should display the following:

Phone: 604-853-6096 Fax: 604-853-8749 Internet: www.bd-power.com

12 May 2005 1086210 GMC/Chevy Duramax X-Monitor 19

Programming Chart

BD Engine Brake Inc.

Plant Address: Unit A10, 33733 King Rd, Abbotsford, BC, Canada V2S 7M9

U.S. Shipping Address: 88-446 Harrison St, Sumas, WA 98295 U.S. Mailing Address: P.O. Box 231, Sumas, WA 98295

Phone: 604-853-6096 Fax: 604-853-8749 Internet: www.bd-power.com

12 May 2005 1086210 GMC/Chevy Duramax X-Monitor 20

Operation

Once the display has gone through the startup cycle it should end up with the

following, default display.

To change the settings and set

alarm values there are 2 buttons

on the side of the display, the

bottom (MENU) button cycles

through the different modes and

the upper (MODIFY) button

controls the setting of the values.

RECOMMENDED ALARM SETTINGS:

PYRO * 900°F *

TURBO 25

TRANS 200

OIL Dependant On Location of Sender

B-PSI User Defined – Consult Exhaust Brake

Manual for safe ranges

F-PSI 3

FUEL 25

* This value based on a pyrometer probe mounted post-turbo.

These are only suggested settings and will vary depending on vehicle condition,

performance enhancements and driving techniques.

NOTES: All temperature readings are in Fahrenheit (°F), pressures are in pounds-

per-square-inch (PSI) and fuel level is displayed in percentages. All readings are

approximate and may vary due to characteristics of sensor, sender or probe, and,

certain conditions can cause interference or sway reading.

The alarm settings for fuel pressure (F-PSI), oil pressure (O-PSI) and fuel level

(FUEL) are for will display an alarm with the measurement drops below the set

value; all other measurements will alarm when the value is above the setting. The

history value also works the same where it records the lowest achieved value on F-

PSI, O-PSI and FUEL and the highest value on all others.

BD Engine Brake Inc.

Plant Address: Unit A10, 33733 King Rd, Abbotsford, BC, Canada V2S 7M9

U.S. Shipping Address: 88-446 Harrison St, Sumas, WA 98295 U.S. Mailing Address: P.O. Box 231, Sumas, WA 98295

Phone: 604-853-6096 Fax: 604-853-8749 Internet: www.bd-power.com

Table of contents

Other BD Diesel Performance Automobile Accessories manuals

Popular Automobile Accessories manuals by other brands

Weather Guard

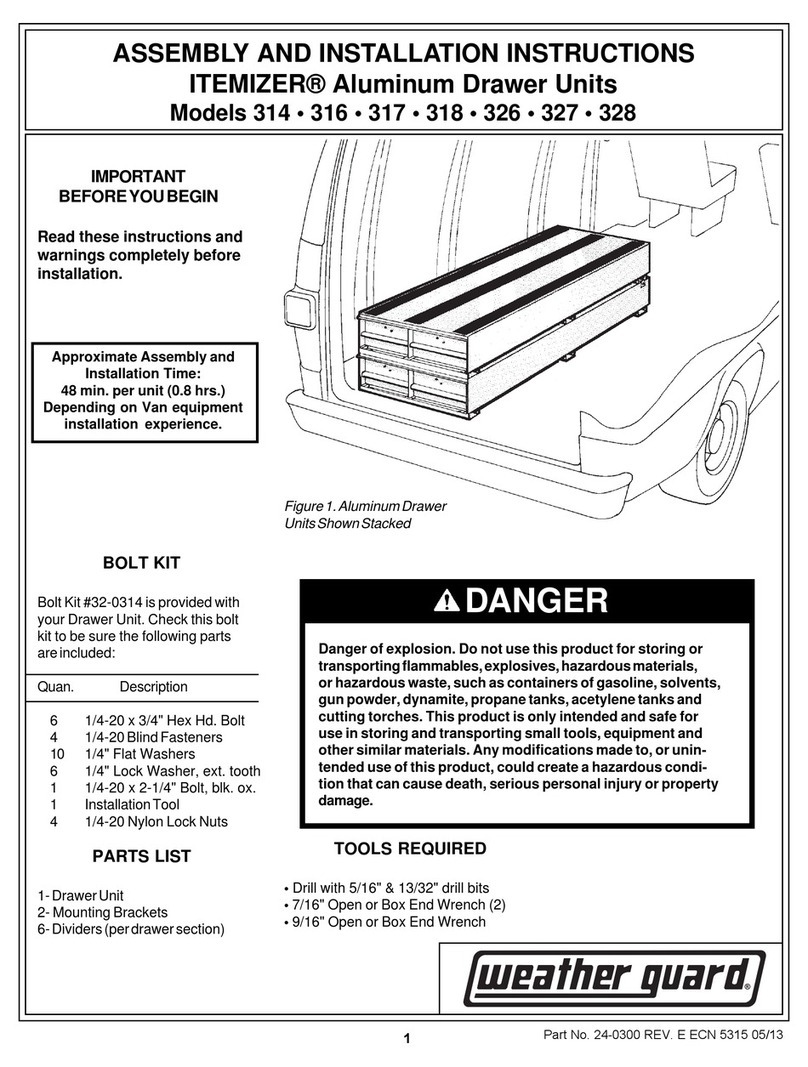

Weather Guard ITEMIZER 314 Assembly and installation instructions

FormFit

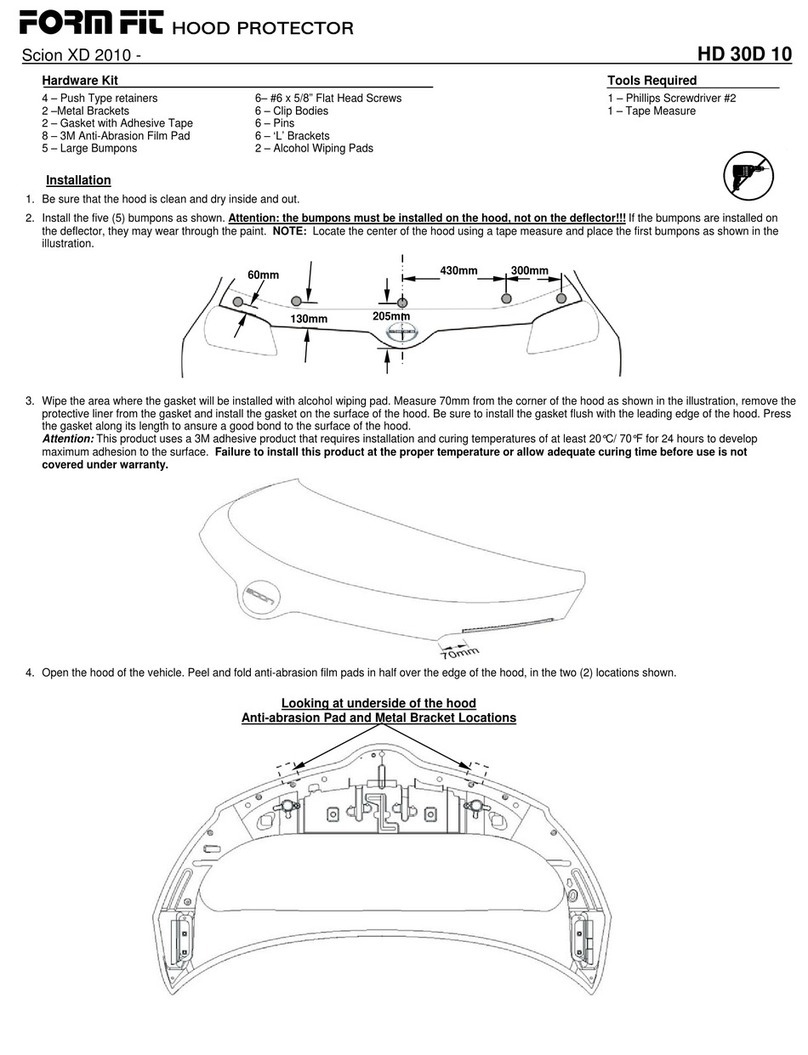

FormFit HD 30D 10 manual

AutoWatch

AutoWatch CHOST-II owner's manual

Proseries

Proseries 1040200 quick start guide

THB Bury

THB Bury COMFORT Installation and operating manual

ICON

ICON 58990 Owner's manual & safety instructions