BD Laser MAX User manual

ENGLISH

Class C Solutions Group BD LASER MAX Man. cod. B409652FG 1

INDEX

0Index

1. General Information and Safety instructions .......................2

1.1.0 Scope and contents of the manual . . . . . . . . . . . . 2

1.1.1 How to store the manual . . . . . . . . . . . . . . . . . . . . . 2

1.2.0 Manufacturer's address . . . . . . . . . . . . . . . . . . . . . 2

1.3.0 Working conditions . . . . . . . . . . . . . . . . . . . . . . . . . . 2

1.3.1 Intended use . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

1.3.2 Improper Use . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

1.4.0 Safety legislation . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

1.4.1 General safety requirements . . . . . . . . . . . . . . . . . 2

1.5.0 Protection devices . . . . . . . . . . . . . . . . . . . . . . . . . . 3

1.5.1 Personal protective equipment . . . . . . . . . . . . . . . 3

1.5.2 Safety signs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

1.6.0 Residual risks . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

2. Machine description .............................................................4

2.1.0 Technical features . . . . . . . . . . . . . . . . . . . . . . . . . . 4

2.2.0 BD LASER MAX main features . . . . . . . . . . . . . . . . 4

2.2.1 Machine accessories . . . . . . . . . . . . . . . . . . . . . . . . 4

2.2.2 Parts- Machine . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

2.3.0 Jaws supplied with the machine . . . . . . . . . . . . . . 5

3. Transport and installation ....................................................6

3.1.0 Packaging . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

3.1.1 Opening the package . . . . . . . . . . . . . . . . . . . . . . . . 6

3.2.0 Transport . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

3.2.1 Unloading and handling the machine . . . . . . . . . . 6

3.3.0 Temporary storing . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

3.3.1 Characteristics of the place of installation . . . . . 6

3.3.2 Temperature and humidity . . . . . . . . . . . . . . . . . . . 6

3.3.3 Working environment . . . . . . . . . . . . . . . . . . . . . . . . 6

3.3.4 Lighting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

3.4.0 Connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

3.4.1 Grounding . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

4. Start up ................................................................................7

4.1.0 Notice for machine use . . . . . . . . . . . . . . . . . . . . . . 7

4.1.1 Preliminary controls and setup . . . . . . . . . . . . . . . 7

4.2.0 Starting the consolle . . . . . . . . . . . . . . . . . . . . . . . . 7

4.3.0 Language setting . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

5. Setup ....................................................................................8

5.1.0 Main Menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

5.1.1 Search by car brand . . . . . . . . . . . . . . . . . . . . . . . . . 8

5.1.2 Search by code . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

5.1.3 Search by article . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

5.2.0 Setup Menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

5.3.0 Calibrations Menu . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

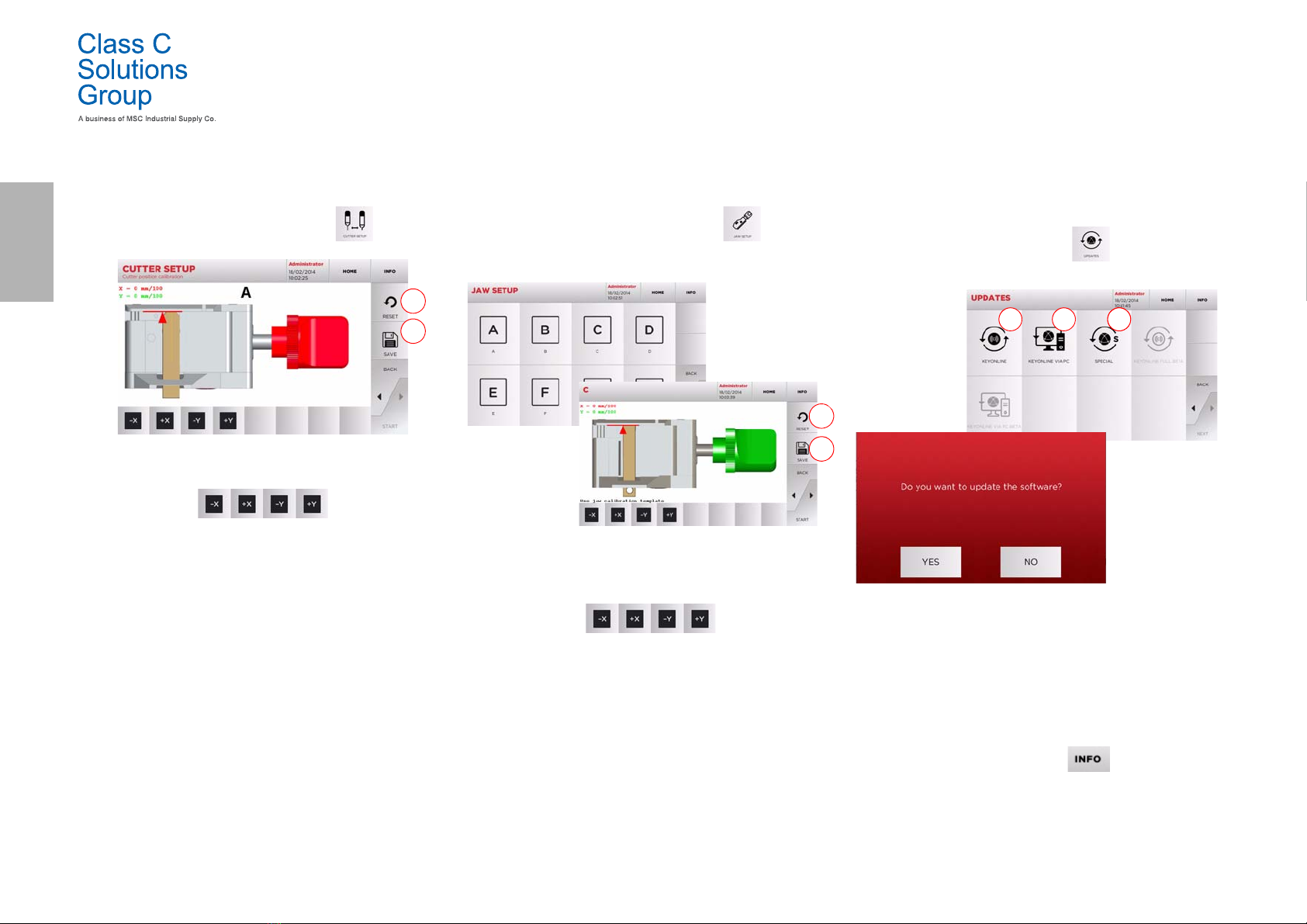

5.3.1 Cutter Setup . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

5.3.2 Jaw Setup . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .10

5.4.0 Update . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .10

5.4.1 Keyonline Update . . . . . . . . . . . . . . . . . . . . . . . . . .11

5.4.2 Keyonline via PC Update . . . . . . . . . . . . . . . . . . . . .11

5.4.3 Special . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .12

6. Key search ......................................................................... 13

6.1.0 Search menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .13

6.1.1 Search by record number . . . . . . . . . . . . . . . . . . . .13

6.1.2 Search by code . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

6.1.3 Search by card . . . . . . . . . . . . . . . . . . . . . . . . . . . . .13

6.1.4 Search by cylinder brand . . . . . . . . . . . . . . . . . . . .14

6.1.5 Search by motorbike brand . . . . . . . . . . . . . . . . . .14

6.1.6 Search by car brand . . . . . . . . . . . . . . . . . . . . . . . .14

6.1.7 Search by article . . . . . . . . . . . . . . . . . . . . . . . . . . .14

6.2.0 Bookmarks list . . . . . . . . . . . . . . . . . . . . . . . . . . . . .14

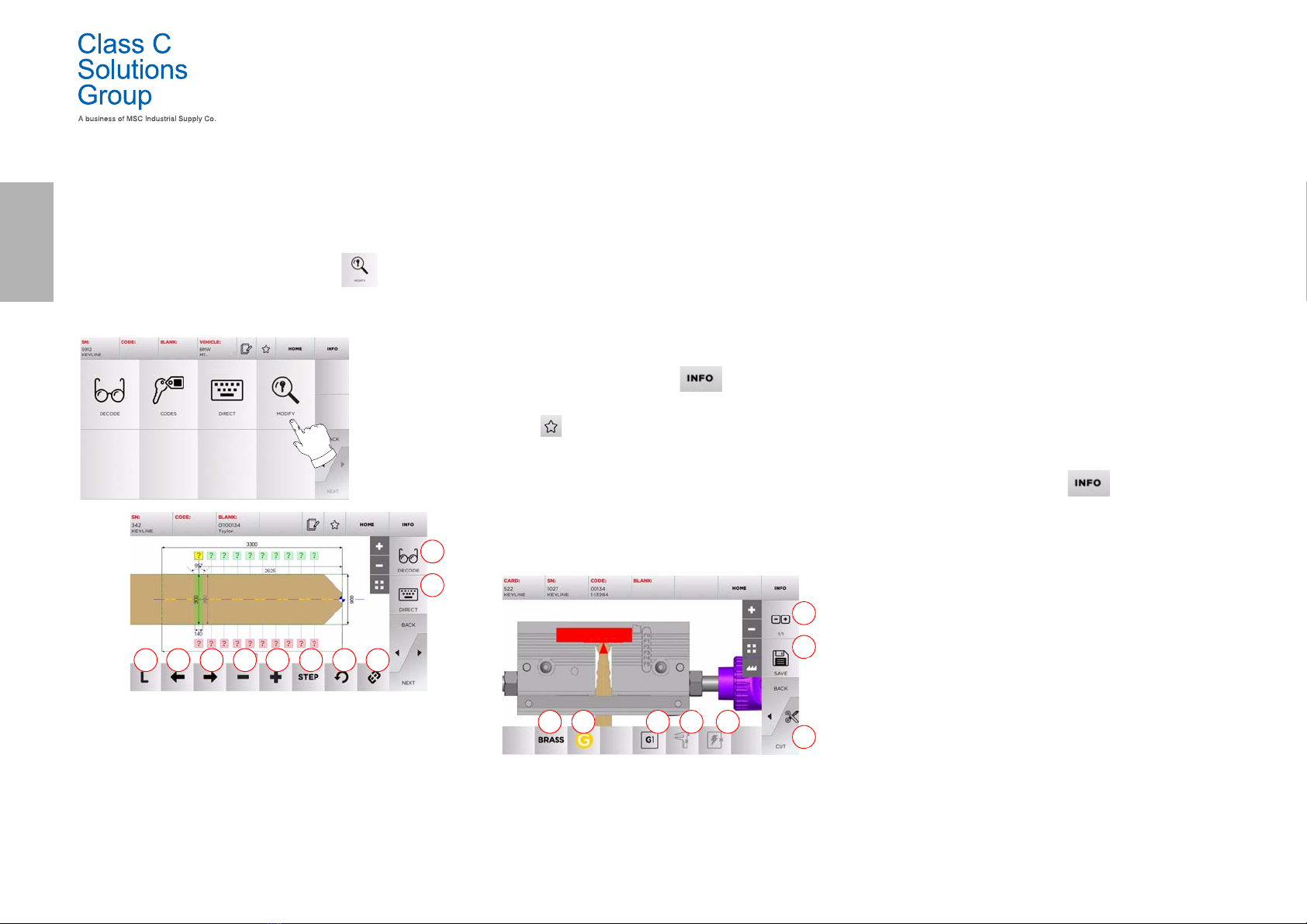

7. Modify and cut ................................................................... 15

7.1.0 Decode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .15

7.2.0 Code . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .15

7.3.0 Direct . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .15

7.4.0 Key modify menu . . . . . . . . . . . . . . . . . . . . . . . . . . .16

7.5.0 Key cut menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .16

8. Archive, PC and user menu ................................................. 17

8.1.0 Archive Menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .17

8.2.0 PC Menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .17

8.3.0 User Menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .17

9. Maintenance, Dismantling and disposal ............................ 18

9.1.0 General information . . . . . . . . . . . . . . . . . . . . . . . . 18

9.1.1 Skills of maintenance personnel . . . . . . . . . . . . . . 18

9.1.2 Type of Maintenance . . . . . . . . . . . . . . . . . . . . . . . .18

9.2.0 Ordinary maintenance . . . . . . . . . . . . . . . . . . . . . . 18

9.2.1 Checking and cleaning the fan . . . . . . . . . . . . . . .18

9.2.2 Cleaning the working area . . . . . . . . . . . . . . . . . . . 18

9.2.3 Cleaning the display . . . . . . . . . . . . . . . . . . . . . . . .18

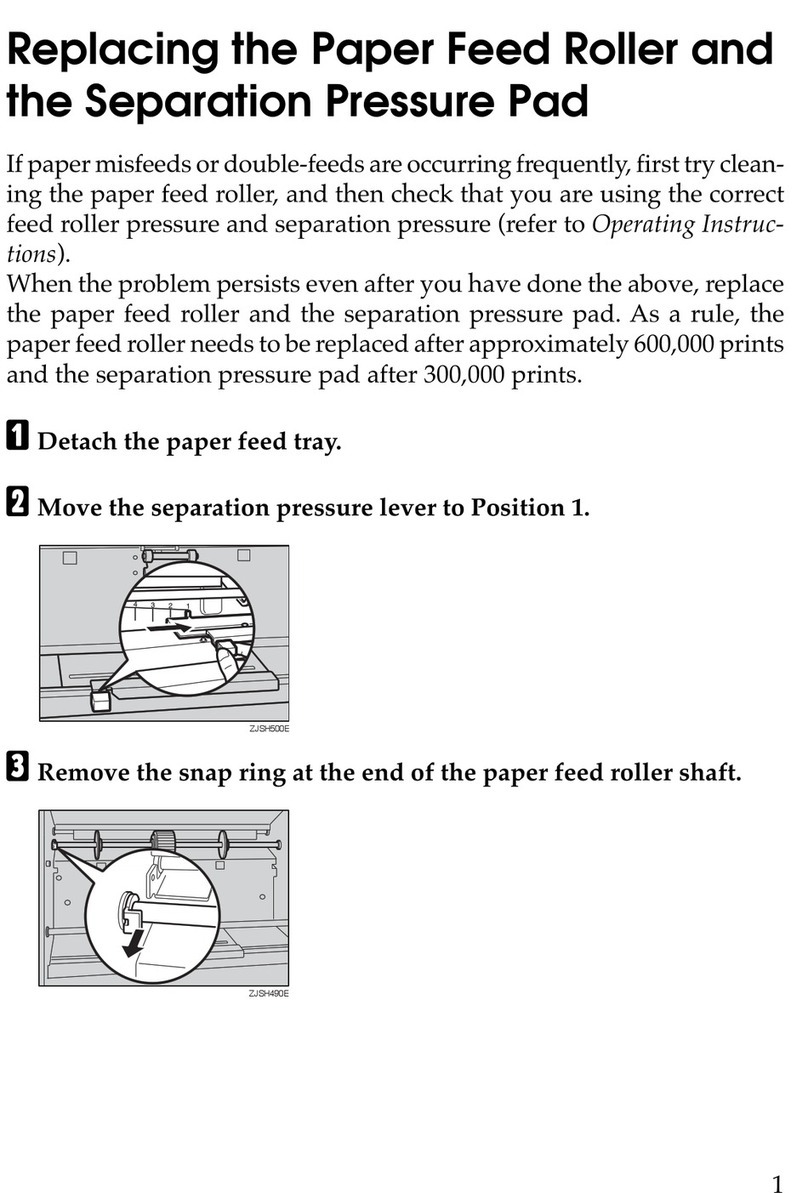

9.2.4 Replacing the milling cutter . . . . . . . . . . . . . . . . . 18

9.2.5 Replacing the fan . . . . . . . . . . . . . . . . . . . . . . . . . .19

9.2.6 Replacing the startup unit . . . . . . . . . . . . . . . . . . . 19

9.2.7 Inspecting and replacing the fuses . . . . . . . . . . .20

9.2.8 Replacing the motor belt . . . . . . . . . . . . . . . . . . . .20

9.2.9 Replacing the X axis sensor . . . . . . . . . . . . . . . . . 20

9.2.10 Replacing the Y axis sensor . . . . . . . . . . . . . . . . . 21

9.2.11 Replacing jaw parts . . . . . . . . . . . . . . . . . . . . . . . . 22

9.3.0 Waste disposal . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

9.4.0 The WEEE directive . . . . . . . . . . . . . . . . . . . . . . . . 22

9.4.1 Disposal of the packing material . . . . . . . . . . . . . 22

ENGLISH

2BD LASER MAX Man. cod. B409652FG Class C Solutions Group

GENERAL INFORMATION AND SAFETY

INSTRUCTIONS

1General Information and Safety instructions

Glossary

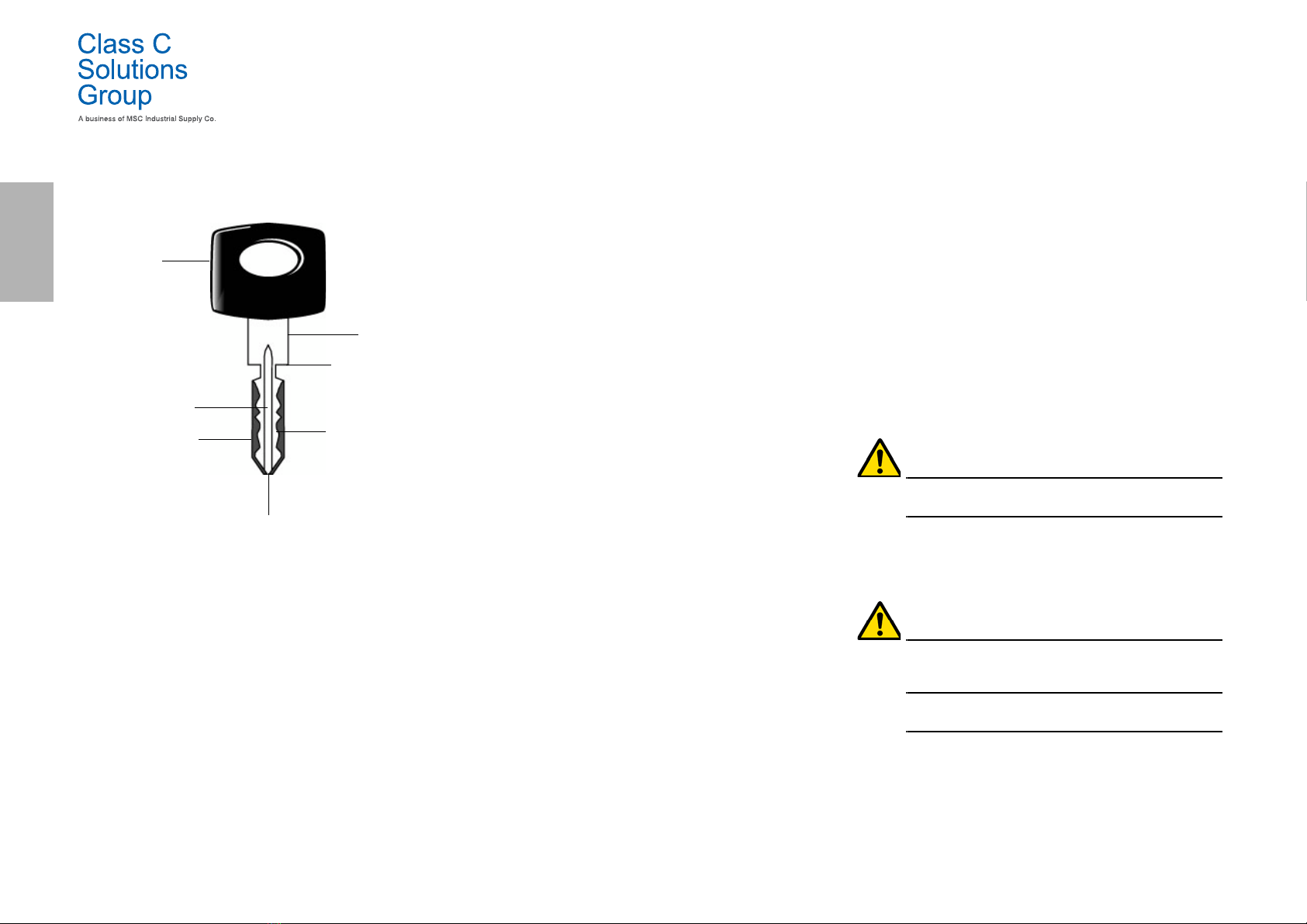

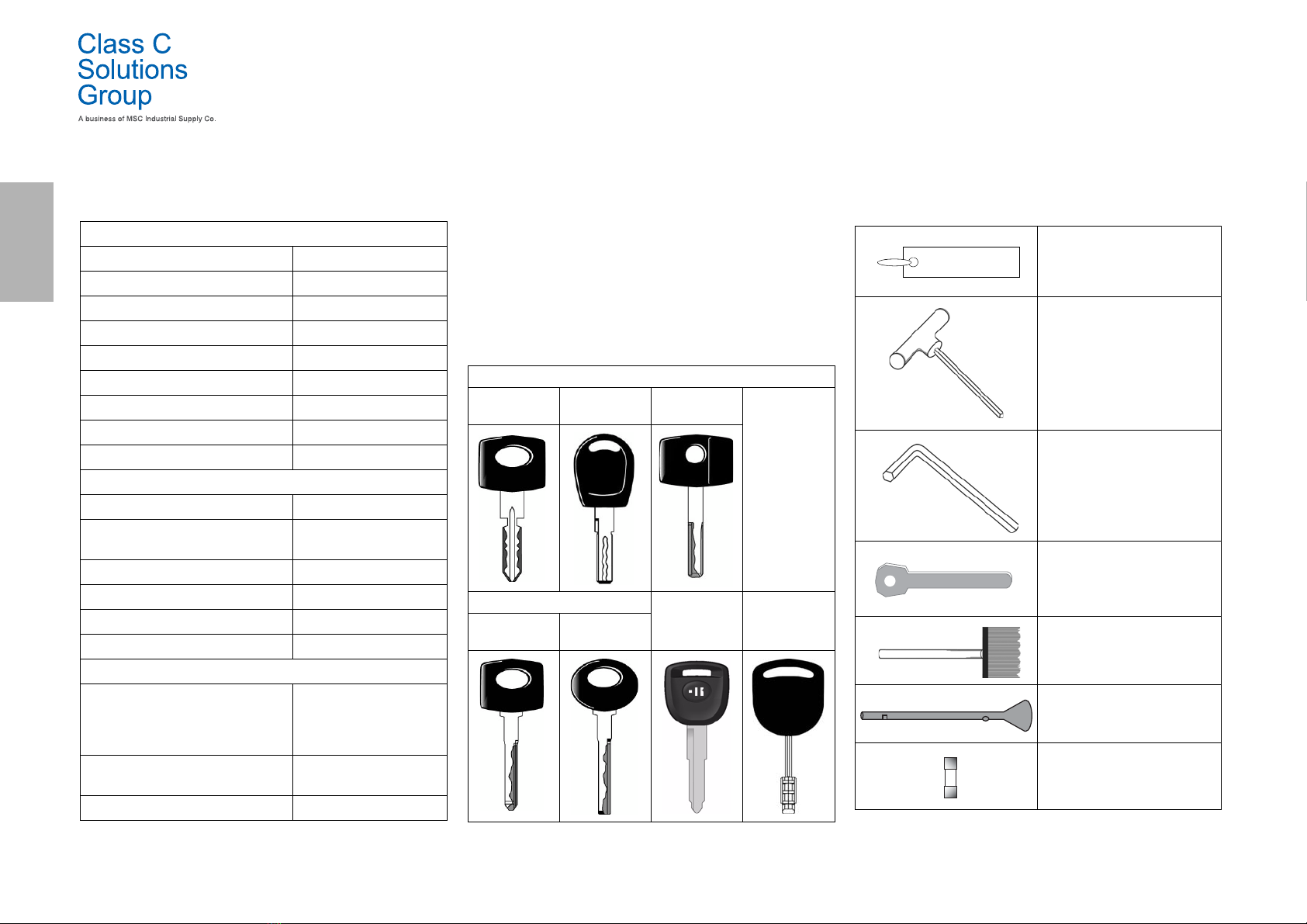

01. Head

02. Neck

03. Shoulder

04. Blade

05. Tip

06. Back

07. Bitting

Laser-Style keys Such keys are called “Laser” on account of

their special bitting style across the profile.

Key sample The “original” key from which, through bit-

ting, a duplicate key is obtained.

Key blank A key with no engraving that is cut following

the profile of the key sample.

The user's and maintenance manual of the “BD LASER MAX” for the

duplication of Laser keys, contains all operation instructions on the

best way to use the machine while guaranteeing the safety of opera-

tors.

1.1.0 Scope and contents of the manual

This manual provides basic information on the installation, operation

and maintenance of the key duplicating machine.

Users must follow the instructions contained in this manual scrupu-

lously, especially those concerning safety norms and ordinary main-

tenance.

1.1.1 How to store the manual

The manual must always be kept with the machine it refers to.

The manual must be stored in a safe place, away from dust and moi-

sture and it must be accessible to all users who shall consult it any

time they are in doubt on how to operate the machine.

1.2.0 Manufacturer's address

Class C Solutions Group

CLEVELAND, OH

1-866-267-6776

OPTION #2

Website: www.mscdirect.com/ClassCSolutions

E-mail: [email protected]ect.com

To facilitate communication please state:

- the name of the customer;

- the name of the customer.

1.3.0 Working conditions

1.3.1 Intended use

The key cutting machine described in this manual has been designed

for the electronic code cutting and duplication of Laser-type keys,

using special adaptors.

1.3.2 Improper Use

The improper use of the machine includesusing the tool to perform an

operation that it was not intended for. Should this occur the manufac-

turer shall take no responsibility for damage to materials or persons

and shall consider all warranties on the machine void.

1.4.0 Safety legislation

The key duplicating machine and its safety devices comply with mac-

chine Council Directive 2006/42/EEC known as “Machine Directive“.

When employed for their intended use all machines marked CE com-

ply with EU 'machine' directive 2006/42/EEC known as “Machine Di-

rective“ and directives 2006/95/EEC, 2004/108/EEC.

Warning: Important!

Users must be informed about the instructions contai-

ned in the following screens.

Users must carefully follow the instructions contained

in this manual.

1.4.1 General safety requirements

Warning: Important!

Make sure that the grounding system is well

connected.

Always unplug the machine (turn off the main switch)

before servicing mobile parts that are electrically

operated.

Do not pour water or other liquids onto electrical cables

and connections.

1

2

4

7

5

3

6

ENGLISH

Class C Solutions Group BD LASER MAX Man. cod. B409652FG 3

GENERAL INFORMATION AND SAFETY

INSTRUCTIONS

1.5.0 Protection devices

a. Ground Connection

b. Protective eye guard

c. Emergency Button

1.5.1 Personal protective equipment

When operating and maintaining the key cutting machine users must

wear the following personal protective equipment:

Protective clothing Maintainers and key cutting machine operators

must wear protective clothing that complies

with the basic safety requirements currently in

force.

In case of slippery floors users must wear sa-

fety shoes with anti-slip soles.

Safety glasses During key cutting operations operators must

wear eye protection (glasses or goggles).

Gloves If milling cutters are present, operators must

wear protective gloves to avoid injuries.

1.5.2 Safety signs

The key cutting machine bears the following safety signs.

- Wear safety glasses.

- Wear safety gloves.

1.6.0 Residual risks

When operating the machine the following residual risks - as well as

those connected with its use - must be taken into due consideration:

• Electrical hazard (A)

Since the machine is equipped with electrical devi-

ces, in case of faults there might be a risk of

electrocution. The power line must be fitted with

the appropriate control and protection devices (cir-

cuit breaker, thermal overload switch and differen-

tial switch).

• Mechanical hazard (D)

The machine is fitted with milling cutters used in

key cutting operations. Operators must watch out

to avoid cutting their hands when they are cutting

keys or changing tools.

D

C

A

B

ENGLISH

4BD LASER MAX Man. cod. B409652FG Class C Solutions Group

MACHINE DESCRIPTION

2Machine description

2.1.0 Technical features 2.2.0 BD LASER MAX main features

Professional

BD LASER MAX

key cutting machines are electronic devi-

ces able to facilitate the duplication of a variety of keys that require the

use of fixed adaptors.

The BD LASER MAX has an aluminum body that reduces vibration

while guaranteeing noiseless operation and a longer cutter life.

The key cutting machine BD LASER MAX is used to duplicate the

following types of keys:

2.2.1 Machine accessories

Dimensions

Width 300 mm

Height 360 mm

Depth (Length) 360 mm

Weight 16,5 Kg

Dimensions Console

Width 200 mm

Height 150 mm

Depth (Length) 50 mm

Weight 0,8 Kg

Technical features

Power voltage 110/250 V 50/60 Hz

Absorption 125 W (machine) - 35W

(Stand By)

Motor Brushless 6000 rpm

Type of cutter Ing carbide

Operating temperature 0° / + 40°C

Acoustic pressure level Lp(A) 78,5 dB(A)

User Interface

Type 7” industrial colour touch

screen, 16:10, resolution

800x480 px, incorporated

CPU

Input / Output 2 USB 2.0 ports; 2 RS232

serial ports; 1 LAN port

CPU ARM Cortex A8

Laser-type keys

4 External

cuts

Double inter-

nal bitting

Double exter-

nal bitting

Laser-type keys with thin stem Double bit-

ting flat keys

Tibbe-Ford

keys

Double exter-

nal bitting

Double exter-

nal bitting

Jaw calibrating templates -994

Code RIC03444B

T- Handle hexagon wrench (long)

2,5mm

Code RIC03442B

T- Handle hexagon wrench (long)

3mm

Code RIC03440B

Hexagonal keys

Code RIC03438B

Setup blanks

Code RIC03448B

Brush

Code RIC03446B

Cutter insertion tool-994

Code RIC03436B

1 pc. - Rapid fuse 4A 5x20

Code RIC02592B

ENGLISH

Class C Solutions Group BD LASER MAX Man. cod. B409652FG 5

MACHINE DESCRIPTION

2.2.2 Parts- Machine 2.3.0 Jaws supplied with the machine

12

8

4

16

11

5

10

9

76

17

1314 15 2

1

3

1. Main switch

2. Power connection

3. Fuses holder

4. Tracer holder

5. Cutter

6. Jaw

7. L e v e r s t o l o c k j a w

8. Levers to clamp jaw

9. Jaw support carriage

10. Container to collect waste

11. Protective eye guard

12. Emergency button

13. Serial port (RS232)

14. Input / Output

15. Fan filter

16. Patent pending

17. Console

Jaw Car brands Key-system

Honda 4 External Track

Gm - Pontiac - GTO 2 External Track

Mercedes 4 External Track

Volvo 4 External Track

Volvo (V50 2004) 2 External Track

Saab 2 External Track

Vauxhall (U.K.) 2 External Track

Ford (U.K.) 2 External Track

Subaru - Outback 4 External Track

BMW 4 External Track

Volvo 2 External Track

Peugeot 4 External Track

Volkswagen 2 Inside Track

Audi 2 Inside Track

Lexus 4 Inside Track

Kia (Amanti: US +

Oprius: UK) 4 Inside Track

BMW 2 Inside Track

Saab 4 Inside Track

Porsche 2 Inside Track

Scoda (U.K.) 2 Inside Track

Seat (U.K.) 2 Inside Track

Vauxhall (U.K.) 2 Inside Track

Ford (U.K.) 2 Inside Track

Mazda - Millennia 4 Inside Track

Chrysler - Crossfire External Track

Mercedes External Track

A

B

C

D

ENGLISH

6BD LASER MAX Man. cod. B409652FG Class C Solutions Group

TRANSPORT AND INSTALLATION

3Transport and installation

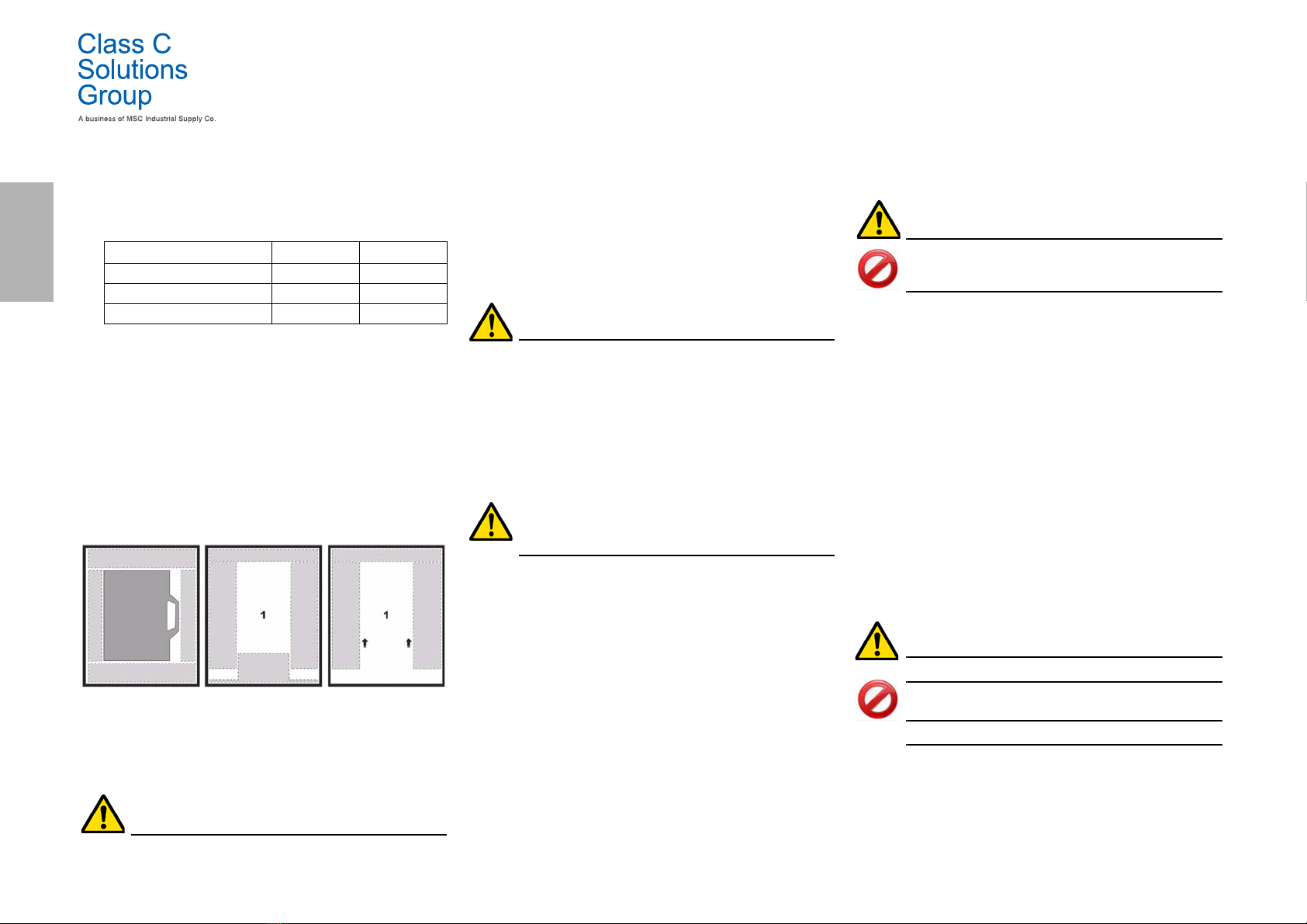

3.1.0 Packaging

Packaging includes a cardboard box with the following dimensions:

3.1.1 Opening the package

Remove the machine and the console from the packing materials fol-

lowing the instructions below:

Key-cutting machine

1. Remove the seals or the tape to open the package.

2. Open the box that contains the key duplicating machine.

3. Remove carton “6” that contains the case with the kit of

accessories.

4. Remove carton “5” from the box.

5. Remove carton “2” and “4” from the box.

6. Free the machine from the packaging material.

Console

1. Remove the seals or the tape to open the package.

2. Open the box that contains the console.

3. Free the console from the packaging material.

IMPORTANT!

We recommend you to keep the packaging during the

warranty period.

3.2.0 Transport

The markings on the packing materials indicate how to handle the

machine during transport.

3.2.1 Unloading and handling the machine

The machine can be unloaded manually by 2 or 3 persons, or by using

a handling equipment (for example a lift truck).

Avoid dropping the machine, even a small damage

could impair its correct functioning.

3.3.0 Temporary storing

If the installation of the machine does not occur immediately, store

the machine in a dry and properly ventilated place.

• Apply an appropriate coating .

• Rubber parts must be protected against too low

temperatures. Never store them outdoors, not even for

short periods.

If the machine is stored or remains unused for long pe-

riods or if it is started a long time after delivery, gaskets

or retaining rings may undergo hardening thus causing

leaks or seizures.

3.3.1 Characteristics of the place of installation

The key cutting machine must be placed on a smooth level bench

about 90 - 110 cm (35 - 43 Inches) high, suitable for bearing the weight

of the machine and keep it horizontal, thus avoiding vibrations and

stress.

Allow a 30 cm (12 Inches) clearance around and above the key cutting

machine for correct functioning and maintenance.

3.3.2 Temperature and humidity

The tool should be used in rooms with a temperature range of 0 and 40

°C (273 K - 313 K) and a relative humidity lower than 50 - 60%.

3.3.3 Working environment

The machine must be used in a place protected from bad weather

(rain, hail, snow etc.).

If the machine is used in places exposed to corrosion,

maintenance shall be scheduled in such a way as to

prevent extreme wear of the components.

Do not use the machine in explosive or partially explo-

sive atmospheres or in the presence of inflammable

liquids of gases.

3.3.4 Lighting

In the place of installation lighting must be appropriate, in order to al-

low the correct use and maintenance of the machine.

3.4.0 Connections

3.4.1 Grounding

Key cutting machines BD LASER MAX have been designed in

compliance with the safety legislation in force and feature appro-

priate safety devices to prevent work accidents. In particular the

machine was built with materials that:

•areself-extinguishing;

• protect against electrocution.

The machine must be grounded through the centralized circuit of the

place of installation.

Warning:

Make sure that the main voltage is compatible with the

machine voltage.

Make sure that the active power outlets are grounded.

Do not touch the machine when your hands and/or feet

are wet or humid.

Avoid any contact with grounded plates.

Dimensions Macchina Console

Width 460 mm 460 mm

Height 460 mm 200 mm

Depth (Length) 435 mm 435 mm

65

22

3344

ENGLISH

Class C Solutions Group BD LASER MAX Man. cod. B409652FG 7

START UP

4Start up

4.1.0 Notice for machine use

In order for the machine to function under optimum conditions and in

complete safety at all times:

• Keep the power cable away from sources of heat, humidity,

oil, water and sharp objects.

• Keep cutting tools sharpened and clean at all times to

ensure better and safer performance.

• Do not expose the machine to inclement weather.

• Disconnect the machines power cable before any

maintenance, repairs and whenever the machine is not

used for a lengthy period of time.

•Useonlyoriginalspareparts.

4.1.1 Preliminary controls and setup

Before proceeding with the start up of the machine the operator must:

• Check to make sure the power cable is correctly connected

to the machine.

• Perform a general visual inspection of the machine to

ensure that no components have been removed or

modified.

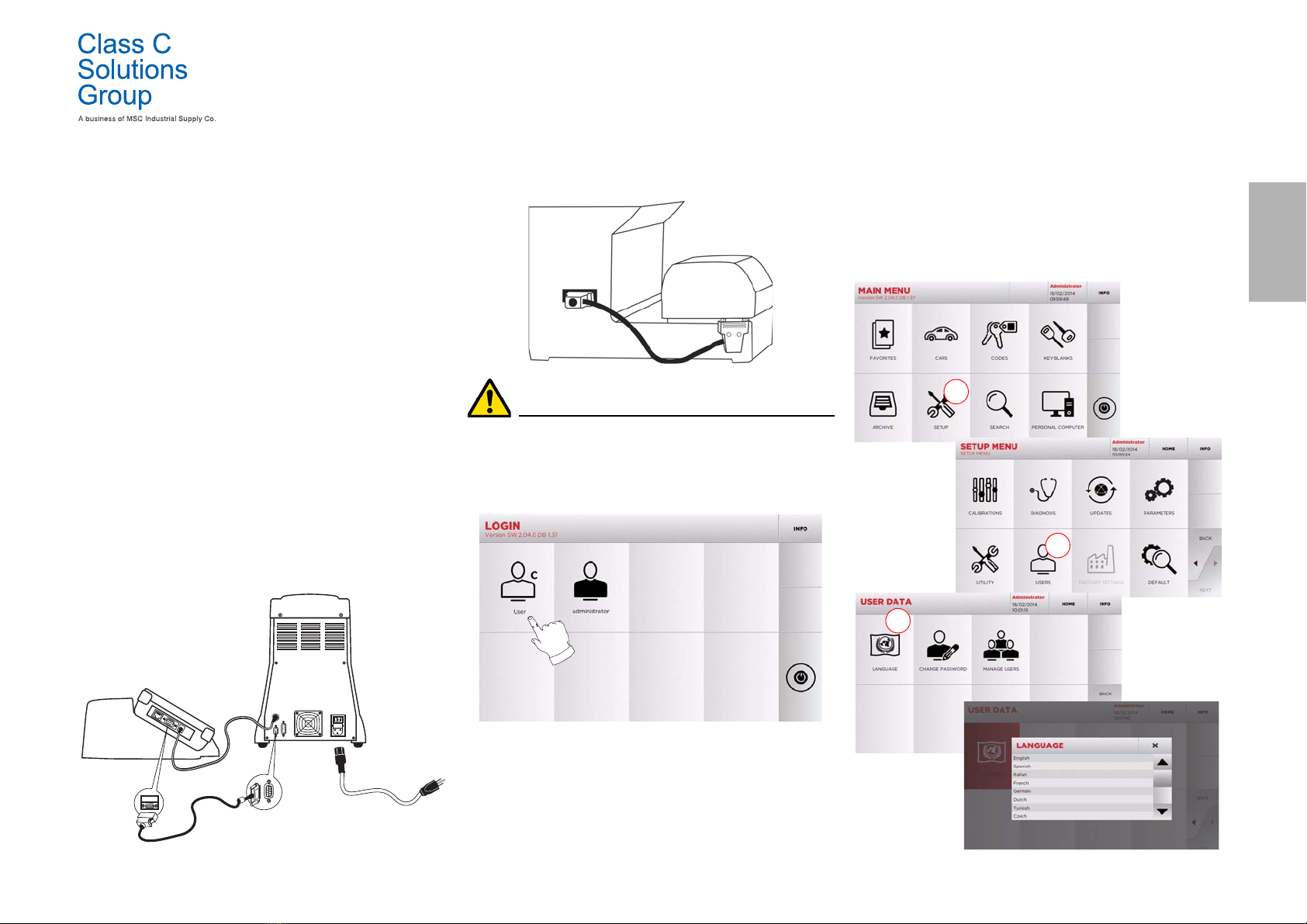

4.2.0 Starting the consolle

After checking that the emergency button has been pressed, connect the

consolle serial cable and the power cable to the duplicating machine.

Connect the cable when the machine is turned off.

Within a few minutes of switching on, the Touch-Screen will display

the “LOGIN” page.

• Select the user for operating with the machine (e.g. USER).

• With the admin user is possible to enter the Setup Menu for

managing calibrations and settings .

• In the following page enter the password to access the

MAIN MENU.

Note: No password is required for the first start of the

machine.

4.3.0 Language setting

How to proceed:

•FromtheMAINMENU,select:“A”.

• From the SETUP MENU, select: “B”.

• Select “C” and chose the interested language.

A

B

C

ENGLISH

8BD LASER MAX Man. cod. B409652FG Class C Solutions Group

SETUP

5Setup

5.1.0 Main Menu

Options displayed:

1. This function gives access to a collection of "Bookmarks"

previously saved by the user, for faster access to the

most frequently saved keys/systems.

2. This allows you to search and select data via the car

brand and model.

3. This allows you to search and select data via the original

indirect code (profile and series).

4. This allows you to search and select data via the Class C

Solutions Group key article and similar blank keys made

by other manufacturers.

5. This function makes it possible to access the archive

containing the keys identified during the search and

decoding processes, so that they can be retrieved quickly

every time the user needs them.

6. To access the menu for adjusting the cutting and

decoding process, updating and diagnostics of the

machine and calibrating the operating parameters.

7. This function allows access to the database on the

machine to search for coded processing data or

deciphering.

8. Set of functions used to connect the machine to

programmes being executed on remote PCs and import

DAT files.

9. Back to login page.

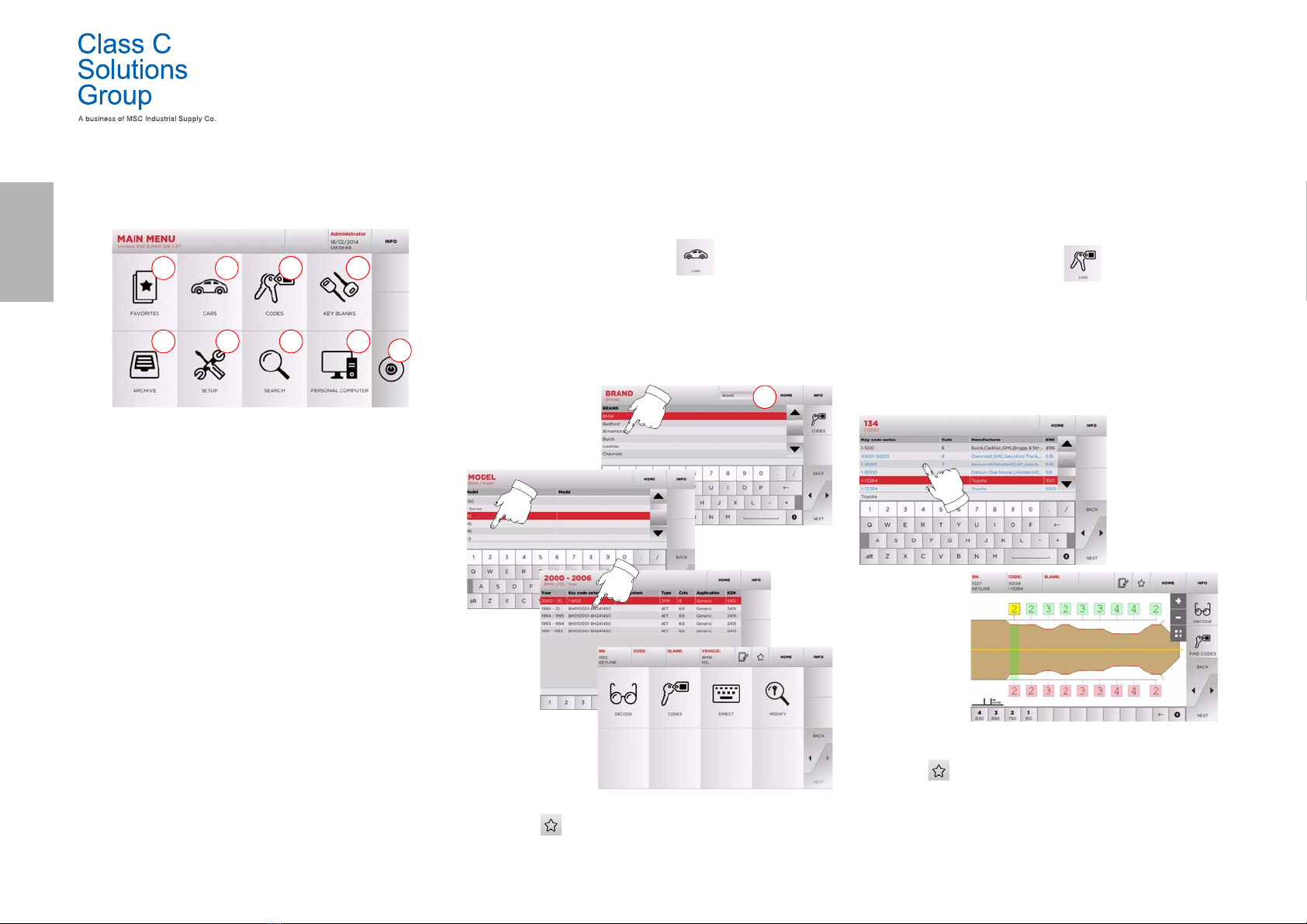

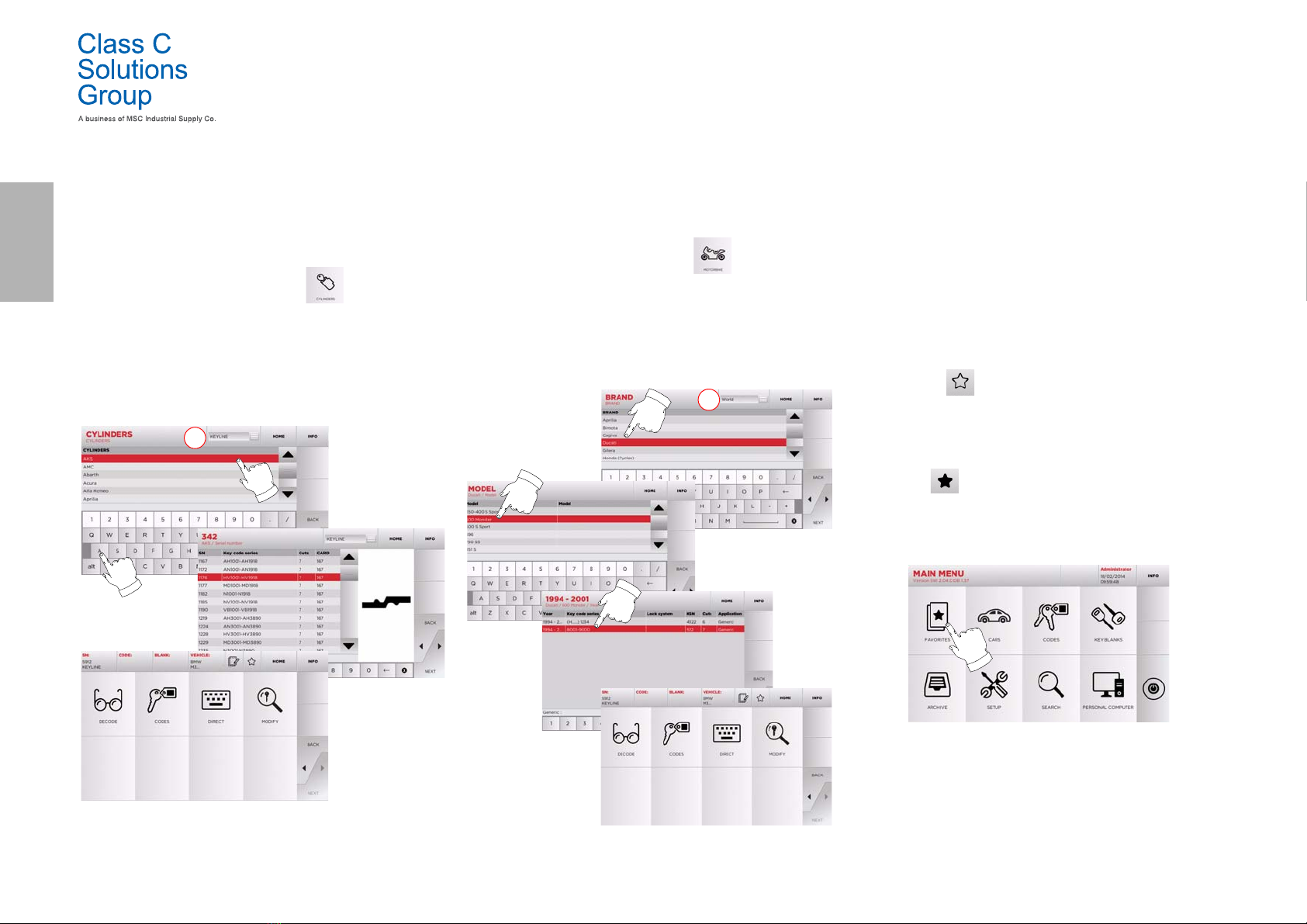

5.1.1 Search by car brand

The “CAR” menu makes it possible to search and duplicate a key

through a list of car brands included in the database.

How to proceed:

• From the MAIN MENU, select “ ”.

• Select one of the options in the top drop-down menu (A).

• Input the brand or scroll the menu and select the desired

brand (e.g., BMW), then press “►”.

• Choose the car model first, then the year of production, and

press “►”.

• From the operating menu, choose one of the search or key

modification options: DECODE, CODE, DIRECT and MODIFY.

Note: From now on, please refer to chapter 7 on page15.

Note: The “ ” symbol makes it possible to save the selected

key in the list of bookmarks. See paragraph6.2.0.

5.1.2 Search by code

The search by code is made when one wishes to search for a key using

the indirect code pertaining to the key's series, as provided by the ma-

nufacturer.

How to proceed:

•FromtheMAINMENU,select“ ”.

•Inputthecompleteoriginalcode (or part of the same)

through the keypad and scroll the list of articles to choose

the desired one.

Note: All the series and the records that may contain the

inserted code are displayed in ascending order, with

attached application / brand of use.

•Press“►” to access the key modify menu.

Note: From now on, please refer to chapter 7 on page15.

Note: The “ ” symbol makes it possible to save the selected

key in the list of bookmarks. See paragraph6.2.0.

• To go back to the previous page, press the “◄” key.

131 2

5 76

14

89

A

ENGLISH

Class C Solutions Group BD LASER MAX Man. cod. B409652FG 9

SETUP

5.1.3 Search by article

Selecting the search by article function allows quick access to the in-

formation that refers to a Class C Solutions Group key article or to

other well known brands.

How to proceed:

•FromtheMAINMENU,select:

• Select one of the options in the top drop-down menu (A).

• Input the article code for the Class C Solutions Group key

or other key, then press “►”.

• Choose the desired code, or press the “B” button to select

the manufacturer of the blank key (e.g. Keyline) then enter

it with

“

►

”.

• From the operating menu, choose one of the search or key

modification options: DECODE, CODE, DIRECT and MODIFY.

Note: From now on, please refer to chapter 7 on page15.

5.2.0 Setup Menu

The main menu allows access to the set-up menu to regulate the cut-

ting and reading devices, to update the machine and use the diagno-

stic function.

How to access the page:

• From the MAIN MENU, select:

Options displayed:

1. For the calibration of the devices on the machine.

2. To access the status check menus of the main devices of

the machine.

3. To access the software and database updating procedure

of the machine.

4. To consult and set the operating parameters of the

machine.

5. To access the following functions:

•NetworkStatus:displaysthe status of the connection.

• Keys History: to access the database of duplicated keys.

• Cutter change: guided procedure for cutter change.

• Tracer point change: guided procedure for tracer point change.

• Statistics: keeps track of the total number of cut keys

and of other useful counters.

• Format USB drive: to format the USB drive.

• Date and Time: to set current date and time.

• Restart: restarts the program automatically.

• Reboot: restarts the whole system automatically.

• Machine data: displays some useful pieces of information,

such as the machine serial number or the software version.

6. To access the user data management menu described in

paragraph8.1.0 on page17.

7. To access all predefined settings for some viewing

parameters, such as the unit of measure, the preferred

vehicle brand, the preset region and numbering system.

• For further information select “ ” from the display .

5.3.0 Calibrations Menu

Through the CALIBRATIONS menu it is possible to access the calibra-

tion functions of the machine's devices, in order to obtain the correct

execution of the duplication process.

How to access the page:

•FromtheSETUPMENU,select:

Options displayed:

1. Used to calibrate the cutter manualy and to adjust its

position in respect to the X and Y axes.

2. To select the jaw to be installed and to calibrate it

according to the type of key to be cut.

3. To regulate the Touch Screen settings.

4. To access the menu that allows the operator to reset the

tracer point and jaws.

• For further information select “ ” from the display .

A

B

131 2 4

56 7

1234

ENGLISH

10 BD LASER MAX Man. cod. B409652FG Class C Solutions Group

SETUP

5.3.1 Cutter Setup

How to proceed:

•FromtheCALIBRATIONSMENU,select:

• Change the position of the X-Y axes with the buttons:

• On the top left of the display it is possible to view the

height to be modified.

• Save your changes by pressing “1”.

Note: If you leave the page without pressing the "1" key , all

changes shall be lost.

• To reset the changes and go back to the previous setting,

press “2”.

5.3.2 Jaw Setup

How to proceed:

•FromtheCALIBRATIONSMENU,select:

• Install the required jaw and select the corresponding code

from the JAW SETUP MENU.

• Insert the calibration template as requested.

• Then press “1” to launch the jaw self-calibration process.

• Change the position of the X-Y axes with the buttons:

• On the top left of the display it is possible to view the

height to be modified.

• Save your changes by pressing “1”.

Note: If you leave the page without pressing the "1" key , all

changes shall be lost.

• To reset the changes and go back to the previous setting,

press “2”.

•Press“►” and follow the instructions on screen to

calibrate the jaw correctly.

5.4.0 Update

It is possible to update the machine through the graphic interface.

How to access the page:

•FromtheSETUPMENU,select:

Options displayed:

1. To proceed with the online software and database

update, through the "Keyonline" service.

2. The update package is downloaded through a normal PC

connected to the internet and saved on a USB flash drive,

so as to be able to install it later on in the machine.

3. To proceed with the software and database update,

taking the data from a USB flash drive.

• For further information select “ ” from the display.

2

1

1

2

131 2

ENGLISH

Class C Solutions Group BD LASER MAX Man. cod. B409652FG 11

SETUP

5.4.1 Keyonline Update

Note: Before updating, check that the console is connected to

a LAN Network.

Pressing the "KEYONLINE" key, the programme proceeds to send the

necessary information to the Keyonline service and later to download

the update package.

According to the quantity of the data to be downloaded,

the process might require a waiting time.

Note: During this phase, some error messages might appear,

stating that the machine is not registered or that it is

impossible to download the updates. In such cases,

please check that all the preliminary operations have

been concluded and that all the network parameters are

configured correctly. For further help, please contact the

Class C Solutions Group Service Centre.

How to proceed:

• From the UPDATES menu select:

• Disconnect any USB flash drives connected to the machine

and press the "YES" key.

• The programme shall reboot and the update software

executed; the user might be required to turn off and reboot

the machine.

• Follow the instructions and wait until the end of the

procedure, whereupon the most recent versions of the

software and database shall be available.

• To annul the operation, press NO.

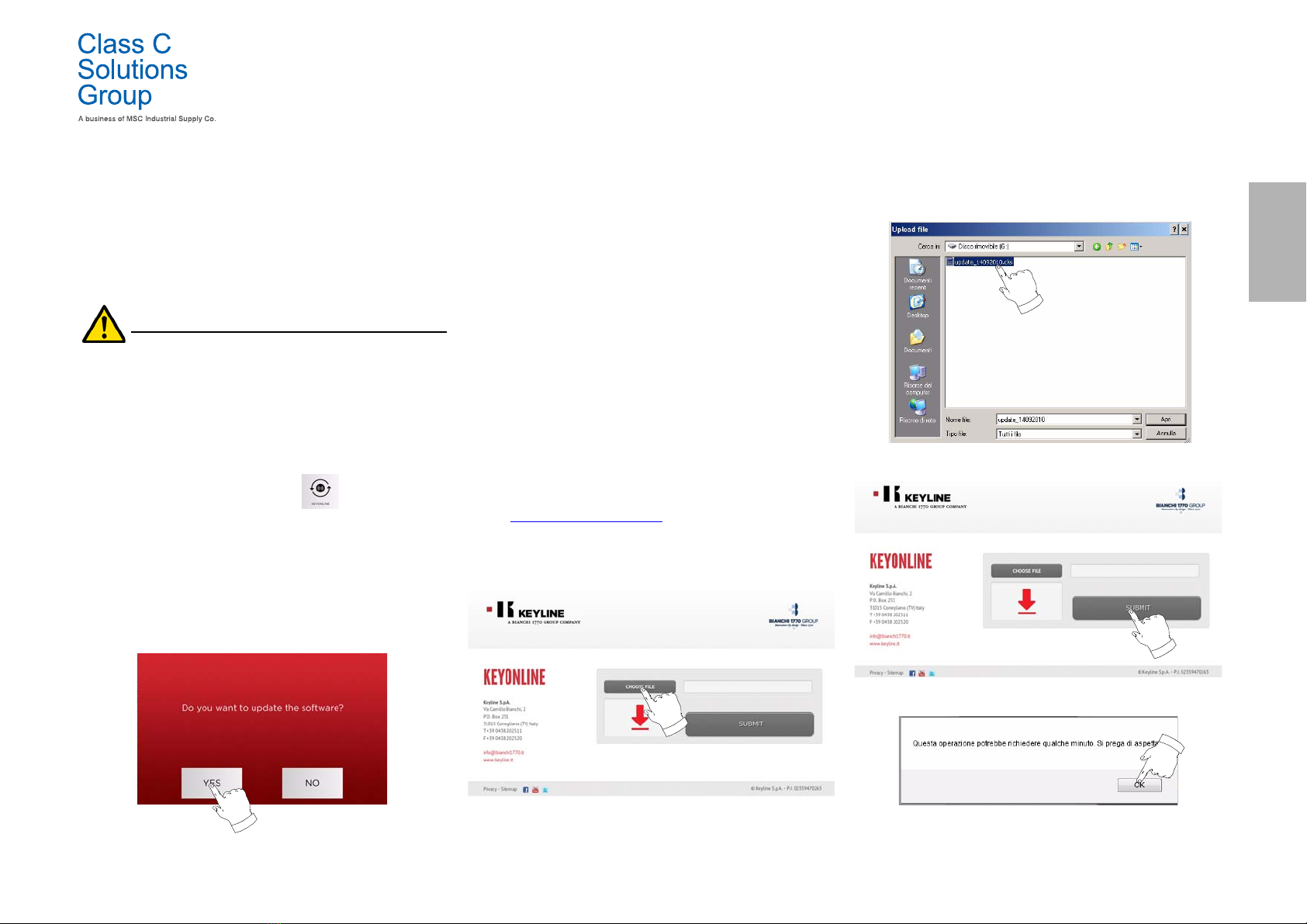

5.4.2 Keyonline via PC Update

If it is not possible to configure the machine to connect to the internet,

this procedure makes it possible to update it by connecting to

Keyonline through a PC with internet connection.

How to proceed:

• Press the "VIA PC" button; a message asking to connect a

USB flash drive to the machine shall appear.

• Then, press the "NEXT" button to proceed, or the

"CANCEL" one to cancel the operation.

• The programme shall copy a file with a .csk extension on

the USB flash drive, containing the information to be sent

to Keyonline to update the machine.

• After a few seconds a message stating that the operation

is finished shall appear and the user will be asked to

download the update from Keyonline.

• Interrupt the operation by pressing "CANCEL" or proceed

with the following instructions:

1. disconnect the USB flash drive and connect it to a PC

with an internet connection.

2. Using the browser, connect to the following web page:

http://keyonline.keyline.it/

3. Select the "CHOOSE FILE" button to access the file

selection dialogue box.

4. Search and select the .csk file previously saved in the flash drive,

then press "OPEN".

5. Press the "SUBMIT" button.

6. The following message shall appear:

7. Press "OK" to start downloading the file and when the

browser asks where to save it, choose the USB flash drive.

ENGLISH

12 BD LASER MAX Man. cod. B409652FG Class C Solutions Group

SETUP

Note: The download may require some minutes, it is necessary

to wait for the process to end.

8. At the end, remove the flash drive and connect it again to

the machine.

Note: The downloaded package can be used only by the

machine with which the update procedure was started.

9. After connecting the USB flash drive to the machine, press

NEXT. The updates shall be analysed and loaded in the

machine's memory.

During this phase, messages may appear stating the

presence of errors in the package, the absence or invali-

dity of the licence. In these cases, check that you have

used the same USB flash drive that you connected to the

machine at the beginning of the update process. Contact

the Class C Solutions Group Service Centre to solve any

problems.

10. At the end of the download a message confirms that the

data have been received and can now be installed.

11. Disconnect the USB flash drive connected to the machine

and press the "INSTALL" button. To annul the operation,

press CANCEL.

12. The programme shall reboot and the update software

executed; the user might be required to turn off and

reboot the machine.

13. Follow the instructions and wait until the end of the

procedure, whereupon the most recent versions of the

software and database shall be available.

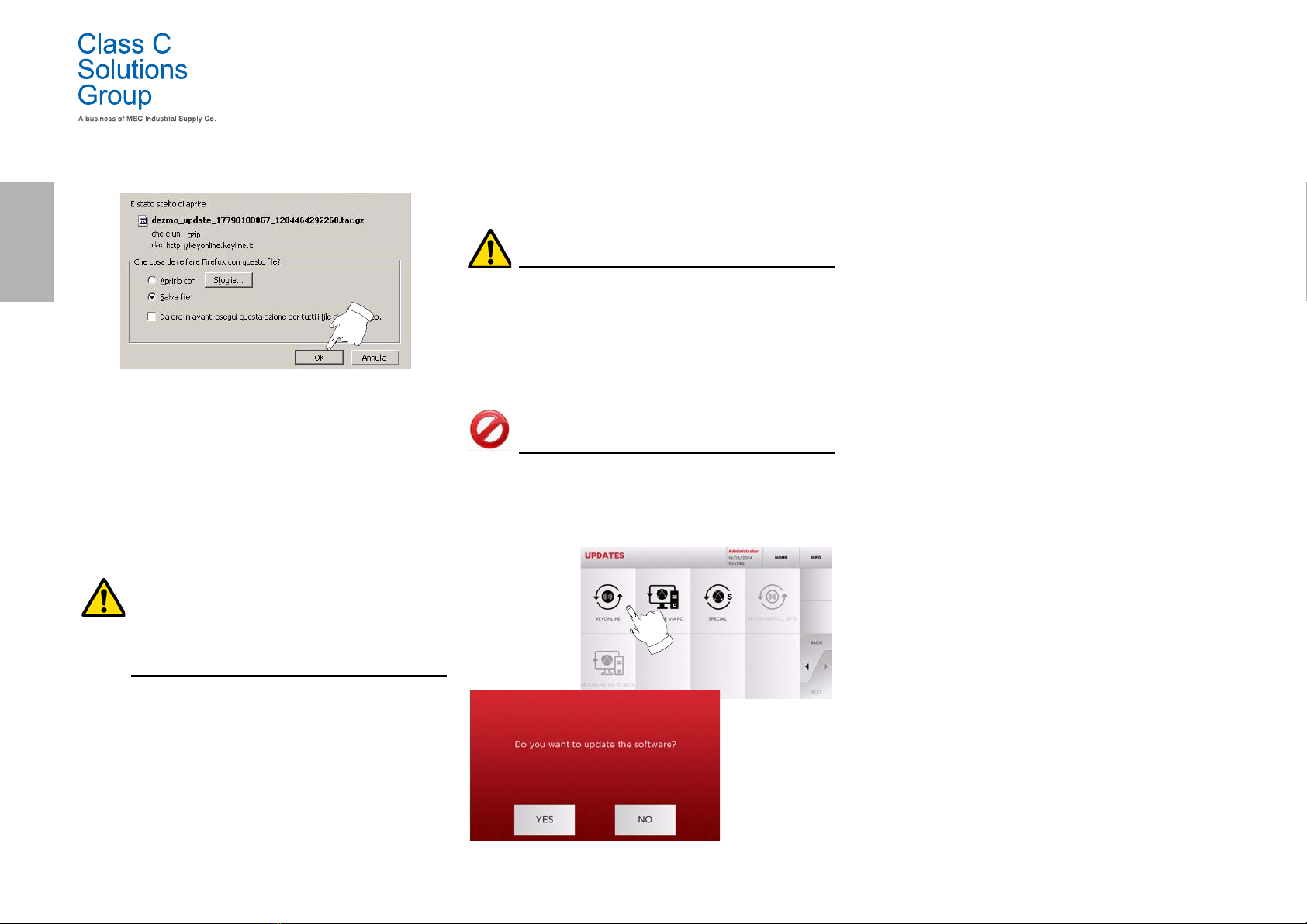

5.4.3 Special

Warning:

This update procedure may be carried out only upon re-

quest by Class C Solutions Group.

How to proceed:

• Pressing the USB button, the programme will ask you to

insert a USB flash drive containing the data for the update.

Note: The data for this kind of update can be provided

EXCLUSIVELY by Class C Solutions Group.

It is not possible to update the machine with packages

downloaded from "Keyonline" of from the Class C

Solutions Group server.

• After inserting the flash drive, press YES to update the

machine.

• To annul the operation, press NO.

• Follow the instructions to the end of the procedure.

ENGLISH

Class C Solutions Group BD LASER MAX Man. cod. B409652FG 13

KEY SEARCH

6Keysearch

6.1.0 Search menu

This function is used when some details of the key to be duplica-

ted are known, such as the manufacturer of the rough piece, the

cylinder, the car or motorcycle brand, the indirect code or the

card number. Once the machine's database has been searched, it

is possible to input the key code manually, or obtain it through

the decoding process.

How to access the page:

•FromtheMAINMENU,select:

Options displayed:

1. This allows you to search and quickly select data via the

RECORD number attributed by Class C Solutions Group to

a specific series, key and card.

2. This allows you to search and select data via the original

code (profile and series).

3. This allows you to search and quickly select data through

the card number, according to the Class C Solutions

Group and other manufacturers numbering system.

4. This allows you to search and select data via the lock

and/or cylinder manufacturer’s brand.

5. This allows you to search and select data via the car

brand, model and year of manufacture.

6. This allows you to search and select data via the

motorcycle brand, model and year of manufacture.

7. This allows you to search and select data via the Class C

Solutions Group key article and similar blank keys made

by other manufacturers.

6.1.1 Search by record number

The “RECORD NUMBER” page makes it possible to search for the type

of key to be duplicated by inputting the key's system number.

How to proceed:

•Fromthe"SEARCH"page,select“ ”.

• Select one of the options in the top drop-down menu (A).

• Input the Record number for the make / model / year / series

/ profile to be duplicated, then press “►”.

• From the operating menu, choose one of the search or key

modification options: DECODE, CODE, DIRECT and MODIFY.

Note: From now on, please refer to chapter 7 on page15.

Note: The “ ” symbol makes it possible to save the selected

key in the list of bookmarks. See paragraph6.2.0.

• To go back to the previous page, press the “◄” key.

6.1.2 Search by code

Note: This procedure is described in paragraph5.1.2 on page8

6.1.3 Search by card

This function makes it possible to obtain quick access toa specific lock

system, by choosing the memorised key manufacturer's card.

How to proceed:

• From the "SEARCH" page, select “ ” button.

• Select one of the options in the top drop-down menu (A).

• Input the Record number for the make / model / year / series /

profile to be duplicated, then press “►”.

• From the operating menu, choose one of the search or key

modification options: DECODE, CODE, DIRECT and MODIFY.

Note: From now on, please refer to chapter 7 on page15.

Note: The “ ” symbol makes it possible to save the selected

key in the list of bookmarks. See paragraph6.2.0.

• To go back to the previous page, press the “◄” key.

131 2 4

175 6

A

A

ENGLISH

14 BD LASER MAX Man. cod. B409652FG Class C Solutions Group

KEY SEARCH

6.1.4 Search by cylinder brand

This function is used when you know the bitting code of the key to be

copied or if you wish to search for it using the decoding process. The

menu makes it possible to search through the system’s database as

described below.

How to proceed:

•Fromthe"SEARCH"page,select: .

• Select one of the options in the top drop-down menu (A).

• Scroll the menu of available brands or enter the name and

choose the required one (e.g.: ACURA).

•Press“►” to go to the list of blank keys and choose the

one most appropriate for the selected brand (e.g. 342),

then press “►”.

• From the operating menu, choose one of the search or key

modification options: DECODE, CODE, DIRECT and MODIFY.

Note: From now on, please refer to chapter 7 on page15.

• To go back to the previous page, press the “◄” key.

6.1.5 Search by motorbike brand

The “MOTORBIKE” menu makes it possible to search and duplicate a

key through a list of brands included in the database.

How to proceed:

•Fromthe"SEARCH"page,select:

• Select one of the options in the top drop-down menu (A).

• Enter the brand or scroll the menu and select the required

one (e.g.: DUCATI), then press “►”.

• Choose the car model first, then the year of production, and

press “►”.

• From the operating menu, choose one of the search or key

modification options: DECODE, CODE, DIRECT and MODIFY.

Note: From now on, please refer to chapter 7 on page15.

6.1.6 Search by car brand

Note: This procedure is described in paragraph5.1.1 on page8.

6.1.7 Search by article

Note: This procedure is described in paragraph5.1.3 on page9

6.2.0 Bookmarks list

Every time a key is modified, irrespective of which database it comes

from, it is possible to save the changes in a specific "favourite keys"

database.

How to proceed:

• Press the button from “MODIFY” page after making

the necessary changes.

• Input the name for the subsequent searches, then press

“OK”.

• Confirm that you want to save by pressing "YES" and go

back to the "MODIFY" page.

The black icon shows that the key has been saved in the “FAVORI-

TES” database.

Later, the user shall be able to look for the key by accessing the “FA-

VORITES” menu from the main menu:

Note: This function must not be confused with the saving of a

key in the archive. The saving concerns all the

information that characterise a key (bitting, cutting

parameters, material, number of copies, etc.) for both

keys found in a database (coded) and read keys. This list,

instead, leads directly to a RN, that is to say, a technical

card for cutting a key (and so the bitting and other data

are not memorised).

A

A

ENGLISH

Class C Solutions Group BD LASER MAX Man. cod. B409652FG 15

MODIFY AND CUT

7Modify and cut

7.1. 0 D e c o d e

This function makes it possible to decode the key using the selected

key system.

How to proceed:

• From the key search sub-menu, select “ ”.

• Insert the original key in the jaws and lock it in place.

• Then follow the instructions on screen until the end of the

decoding process.

7. 2 . 0 C o d e

This function makes it possible to search for a specific code

contained in the data base and obtain the relevant coding.

How to proceed:

• From the key search sub-menu, select “ ”.

• Input the blind code.

•Thenpress►” to go to the following screen, the key

“CUTTING” one (for additional information, please refer to

paragraph7.5.0 on page16).

7. 3 . 0 D i r e c t

This function makes it possible to insert the bitting code for the key

directly.

How to proceed:

• From the key search sub-menu, select “ ”.

• Input a value for each cut that shall correspond to the

bitting code.

•Thenpress►” to go to the following screen, the key

“CUTTING” one (for additional information, please refer to

paragraph7.5.0 on page16).

ENGLISH

16 BD LASER MAX Man. cod. B409652FG Class C Solutions Group

MODIFY AND CUT

7.4.0 Modify menu

The MODIFY MENU is used to modify the cut parameters for a key and

it also makes it possible to personalise some characteristics of the

key, according to the client's specific requirements.

How to proceed:

• From the key search sub-menu, select “ ”.

• This displays the technical sheet for the selected article and

makes it possible to change some of the key characteristics.

Options displayed:

1. With this button is possible to decode the key using the

selected key system.

2. With this button is possible to insert the cuts directly.

3. With the Cut Type button is possible to select between

the possible cut types for the selected key. For Flat keys

cut types are: Normal, Laser and Plane.

4. With the left arrow button is possible to scroll the spaces

moving to left direction.

5. With the right arrow button is possible to scroll the

spaces moving to right direction.

6. With the minus button is possible to decrement the depth

of the highlithed tooth.

7. With the plus button is possible to increment the depth of

the highlithed tooth.

8. This makes it possible to select the depth increase or

decrease rate when the + or - buttons are pressed. The

available options are: one STEP is either 0.1 mm or 0.01 mm.

9. With this button is possible to reset the modifications

made on the selected tooth.

10. With this button is possible to modify simultaneously all

the teeth.

• For further information select “ ” from the display .

Note: The “ ” symbol makes it possible to save the selected

key in the list of bookmarks. See paragraph6.2.0.

7. 5 . 0 K e y c u t m e n u

Once the key to be copied has been searched using the relevant func-

tions in the Database menu, the programme will direct the user to the

CUT screen, that makes it possible to duplicate the desired key.

Options displayed:

1. With this button is possible to set the amount of copies

that need to be cut.

2. With this button is possible to save the key.

3. Starts the key cutting process.

4. With this button is possible to change the default

material. The selectable material are: BRASS,

ALUMINUM, STEEL, NIKEL SILVER, CUSTOM. Each

material has a dedicated set of parameters for the

movement speed and cutter speed for optimizing the

quality of the cut and ensure the life of the cutter. The

custom material can be customized on the Parameters

Panel of the Setup Menu.

5. With this button is possible to select the Jaw that has to

be used to cut the key, only compatible Jaws will be

selectable.

6. Displays the type of stop to be used to cut the key.

7. With this button is possible to enable or disable the

measure of the dimension of the key.

8. With this button is possible to enable or disable the

measure of the width of the key, this measure is faster

respect of the complete measure and is useful to

optimize the cut procedure but when using blank keys

with precuts the complete measure is preferred .

• For further information select “ ” from the display .

3 4 5 6 7 8 9 10

1

2

3

1

2

4 5 6 7 8

ENGLISH

Class C Solutions Group BD LASER MAX Man. cod. B409652FG 17

ARCHIVE, PC AND USER MENU

8Archive, PC and user menu

8.1.0 Archive Menu

The ARCHIVE menu makes it possible to manage the user data and

the database saved by the user during the key reading, decoding and

modification phases. It is also possible to access the import and

export functions from and to external supports (USB flash drive).

How to access the page:

•FromtheMAINMENU,select: .

Options displayed:

1. This function makes it possible to access the archive

containing the keys identified during the search and

decoding processes, so that they can be retrieved quickly

every time the user needs them.

2. This function makes it possible to export a file from the

machine's database to a USB flash drive. The export and

import functions allow the customer to exchange

customised data between machines or create backup

copies of the exported archive.

3. This function makes it possible to import a file from a USB

flash drive to the machine's database. Data imported from

the USB flash drive shall be saved in the archive.

• For further information select “ ” from the display .

8.2.0 Personal Computer Menu

Through this menu it is possible to access the functions to interface

BD LASER MAX with queuing software that might reside in a remote

PC or USB flash drive.

It is possible to import job queues containing several processes

(JOBS).The JOBS, in turn, contain information for each key to be cut,

such as: type of key, type of bitting, and number of copies to be cut.

The programme makes it possible to select and execute only one JOB

at a time, until the queue is exhausted.

How to access the page:

• From the MAIN MENU, select: .

Options displayed:

1. These menus manage and process job queues created

with Instacode and Promaster key processing software

and sent to the machine.

2. This menu makes it possible to import, manage and

process job queues saved in DAT format files.

• For further information select “ ” from the display.

8.3.0 User Menu

The USER menu makes it possible to manage the user data and the

database saved by the user during the key reading, decoding and mo-

dification phases.

How to access the page:

•FromtheSETUPMENU,select:

Options displayed:

1. This allows you to change displayed language (refer to

paragraph4.3.0 on page7).

2. Thisallows you to change password to existing users.

3. This allows you to manage users, add a new user, remove

exixting users and change information.

• For further information select “ ” from the display.

1 2 3

1

2

1 2 3

ENGLISH

18 BD LASER MAX Man. cod. B409652FG Class C Solutions Group

MAINTENANCE, DISMANTLING AND DISPOSAL

9Maintenance, Dismantlingand di sposal

Warning: IMPORTANT!

Before carrying out any maintenance operation you

must turn OFF the power and disconnect the power cord.

Maintenance must be carried out only by qualified per-

sonnel equipped with appropriate protective devices

for safe work.

Always use original Class C Solutions Group spare parts.

9.1.0 General information

9.1.1 Skills of maintenance personnel

The machine operator must be knowledgeable about machine opera-

tion.

9.1.2 Type of Maintenance

Ordinary Maintenance

• Servicing operations that must be carried out periodically

by the machine operator.

• The purpose of ordinary maintenance is guarantee regular

functioning of the machine and a consistent quality of the

product.

• The maintenance schedule may vary in relation to work or

environmental conditions in the place of installation.

Complex Maintenance

• Complex maintenance consists of actions to be taken only

when given conditions occur (break downs, failures,

replacement of parts).

• Due to the complex nature of such actions and the special

tools required, we recommend you should contact

qualified personnel from or authorized by Class C

Solutions Group.

9.2.0 Ordinary maintenance

We recommend inspecting the machine periodically and replace worn

parts.

9.2.1 Checking and cleaning the fan

It is suggested to periodically check the cleaning level of the air grids

and make sure that there is no accumulated dust that could obstruct

the air passage.

Poor ventilation could cause a machine overheating

and damage the components.

9.2.2 Cleaning the working area

At the end of each working day clean the machine removing scrap and

burrs to ensure proper functioning of the machine and to prevent any

damage to its parts.

Empty the shaving collection drawer every time that the work surface

is cleaned or whenever it is full of shavings.

Do not clean the machine with compressed air.

9.2.3 Cleaning the display

To clean the Touch Screen display we recommend using a micro-fibre

cloth; avoid using substances that contain alcohol or solvents.

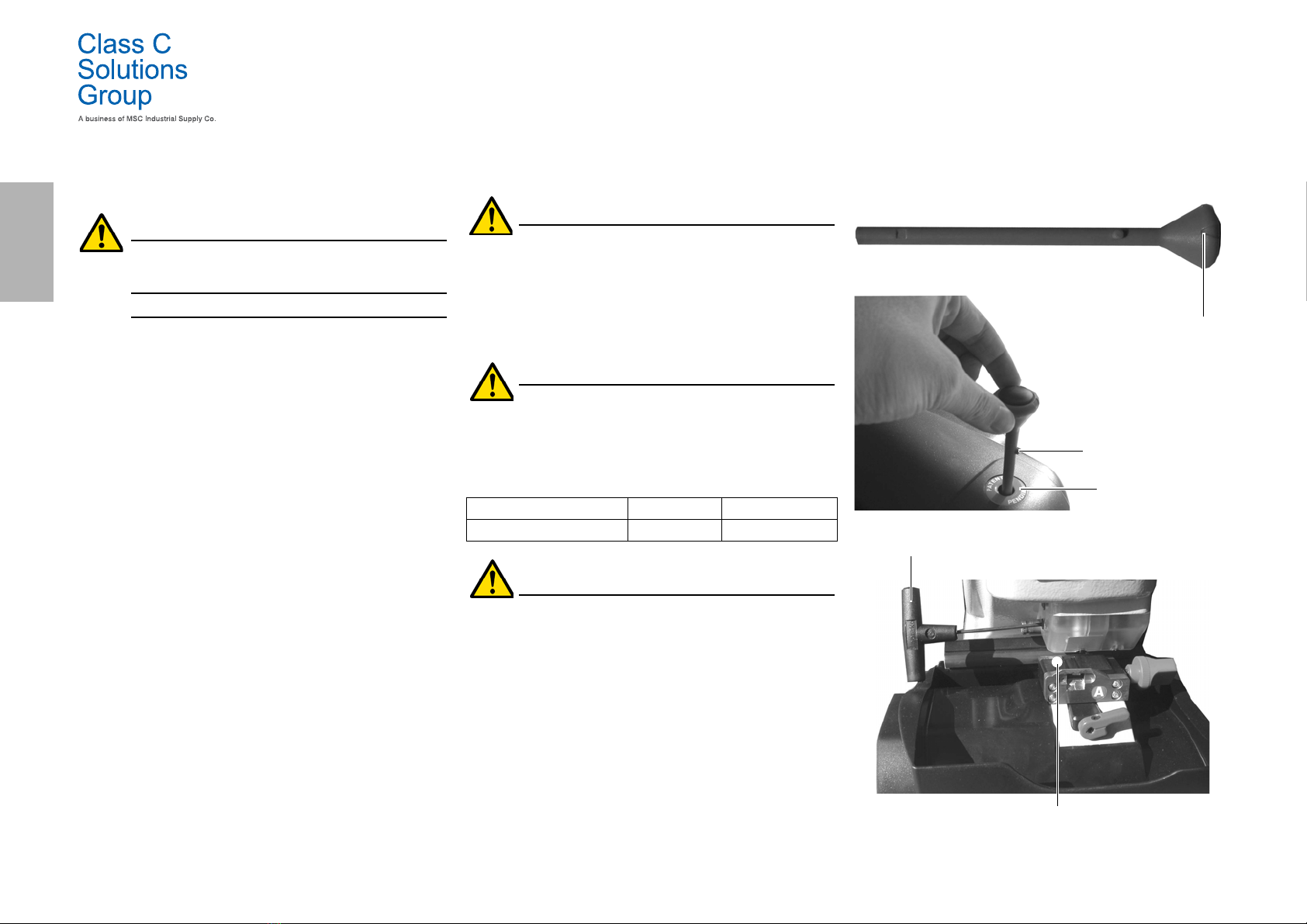

9.2.4 Replacing the milling cutter

Before carrying out this operation disconnect the

power cable from the mains.

Required tools when replacing the fuses

•Patentpending.

• 1 T- Handle hexagon wrench (long) 3mm.

How to proceed:

• insert the bar to remove the cutter into the “Patent

pending” seat;

• rotate the bar slowly until the bar ‘tooth’ fits into the slot

located inside the “Patent pending” seat;

• rotate the bar: the triangular mark on top of the bar will

point to the left;

• insert the T-shaped 3 mm hexagon wrench in the hole to

unlock the cutter (see picture in the next screen);

• loosen the nut that fastens the cutter;

• pull out the bar from the “patent pending” seat and remove

the cutter.

Spare part description Code Frequency

Milling cutter 2,5mm RIC03304B When required

Bar ‘tooth’ to

Patent pending

Triangular mark

replace the cutter

T- Handle hexagon wrench (long) 3mm

Cutter calibration cut out

Table of contents

Popular Disc Duplicator manuals by other brands

U-Reach

U-Reach Super1 Series user manual

U-Reach

U-Reach Mini Series user manual

MF DIGITAL

MF DIGITAL 5500 Series Operator's guide

MicroBoards Technology

MicroBoards Technology LightScribe Series user manual

Rimage

Rimage Producer III 7100 user guide

Addonics Technologies

Addonics Technologies HDUSAS user guide