CCP-1100SFCCP-1100SF

!WARNING

This manual is intended for qualified service personnel only.

To reduce the risk of electric shock, fire or injury, do not perform any servicing other than that

contained in the operating instructions unless you are qualified to do so. Refer all servicing to

qualified service personnel.

!WARNUNG

Die Anleitung ist nur für qualifiziertes Fachpersonal bestimmt.

Alle Wartungsarbeiten dürfen nur von qualifiziertem Fachpersonal ausgeführt werden. Um die

Gefahr eines elektrischen Schlages, Feuergefahr und Verletzungen zu vermeiden, sind bei

Wartungsarbeiten strikt die Angaben in der Anleitung zu befolgen.Andere als die angegeben

Wartungsarbeiten dürfen nur von Personen ausgeführt werden, die eine spezielle Befähigung

dazu besitzen.

!AVERTISSEMENT

Ce manual est destiné uniquement aux personnes compétentes en charge de l’entretien.Afin

de réduire les risques de décharge électrique, d’incendie ou de blessure n’effectuer que les

réparations indiquées dans le mode d’emploi à moins d’être qualifié pour en effectuer d’autres.

Pour toute réparation faire appel à une personne compétente uniquement.

After correcting the original service problem, perform

the following safety checks before releasing the set to

the customer.

Check that the set does not have leakage current in

excess of 0.5 mA when measured as described below.

All exposed conductive surfaces are to be tested for

leakage currents. The leakage currents from these

surfaces are to be measured to the grounded supply

conductor individually as well as collectively where

simultaneously accessible, and from one surface to

another where simultaneously accessible. These

measurements do not apply to terminals operating at

voltages that are less than 30 volts.

The measurement circuit for the leakage current test is

as described below. The measurement instruments

defined in the following (a)-(d).

a) The meter is to have an input impedance of 1500

ohms resistive shunted by a capacitance of 0.15

microfarad.

b) The meter is indicate 1.11 times the average of the

full wave rectified composite waveform of voltage

across the resistor or current through the resistor.

c) Over a frequency range of 0-100 kilohertz the

measurement circuitry is to have a frequency

response (ratio of indicated to actual value of

current) that is equal to the ratio of the impedance

of a 1500 ohm resistor shunted by a 0.15 microfarad

capacitor to 1500 ohms. At an indication of 0.5

milliampere, the measurement is to have an error of

not more than 5 percent at 60 Hz.

d) Unless the meter is being used to measure current

from one part of the equipment to another, the

meter is to be connected between the accessible

parts and the grounded supply conductor.

The test sequence is as follows:

a) With switch S1 open, the equipment is to be

connected to measuring circuit. Leakage current is

to be measured using both positions of switch S2,

and with the equipment switching devices in all of

their intended operating positions.

b) Switch S1 is then to be closed, energizing the

equipment, and within 5 seconds the leakage

current is to be measured using both positions of

switch S2, and with the equipment switching

devices in all their intended operating position.

c) Leakage current is to be monitored until thermal

stabilization. Both positions of S2 are to be used in

determining this measurement.

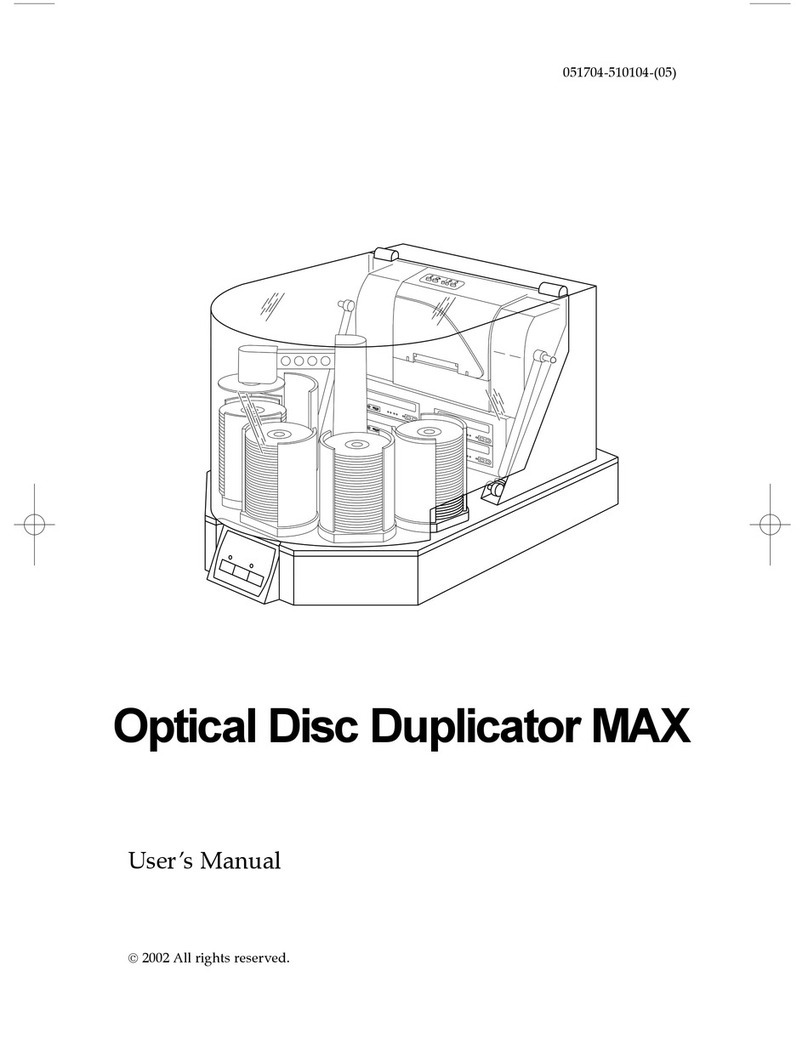

Leakage current measurement circuits

Equipment intended for connection to a 120 volt power supply.

Equipment intended for connection to a 3-wire, grounded

neutral power supply, as illustrated above.

Equipment intended for connection to a 3-wire, grounded

neutral power supply, as illustrated above.

A. Probe with shielded lead.

B. Separated and used as clip when measuring currents

from one part of equipment to another.

SAFETY CHECK-OUT