BE Ag & Industrial Agri Ease BE-SGG Series Application guide

PURCHASE DATE MODEL NO. SERIAL NUMBER

DEALER

STUMP GRINDER

BE-SGGXX

OPERATIONS & PARTS MANUAL

MANUAL CODE: 101.102B

FOR MODELS:

• BE-SGGR15

• BE-SGGH13

2 BE-SGGxxx USER MANUAL

WARNING

READ and UNDERSTAND THIS MANUAL COMPLETELY BEFORE USING THE GRINDER! Failure to

properly operate, and maintain this grinder could result in serious injury or death to the operator or

bystanders.

All machines have hazards associated with their operation. This stump grinder has certain special

hazards, which you must aware of. As an operator or owner you have a duty to be aware of these

hazards and know preventive measures to take to avoid them. When reading this manual pay particular

attention to avoiding these hazards.

In particular, be aware of the following:

• Know location of buried electrical and other utility lines.

• Do not allow children or untrained adults to operate.

• Wear eye protection and other personal protection against flying rocks and debris.

• Check that cutter wheel teeth are secured, sharp and not missing.

• Do not operate if operator presence bar fails to stop engine upon release.

• Make sure no children or bystanders are within 75 feet (25m) of stump grinding operation.

• Protect cars, windows and other objects within 75 feet (25m) from flying debris.

• Be prepared for machine “kickback” when initially contacting the stump.

• Be aware of potential for carbon monoxide (CO) poisoning.

• Prevent fires/explosions from fueling.

• Do not attempt to perform adjustments, clean unit while engine is running.

• Avoid bumps from engine or hot exhaust.

• Avoid using in wet or icy conditions where falls may occur.

Details about these hazards are found throughout the manual and are summarized at the end of the

manual under “Important Safety Information”

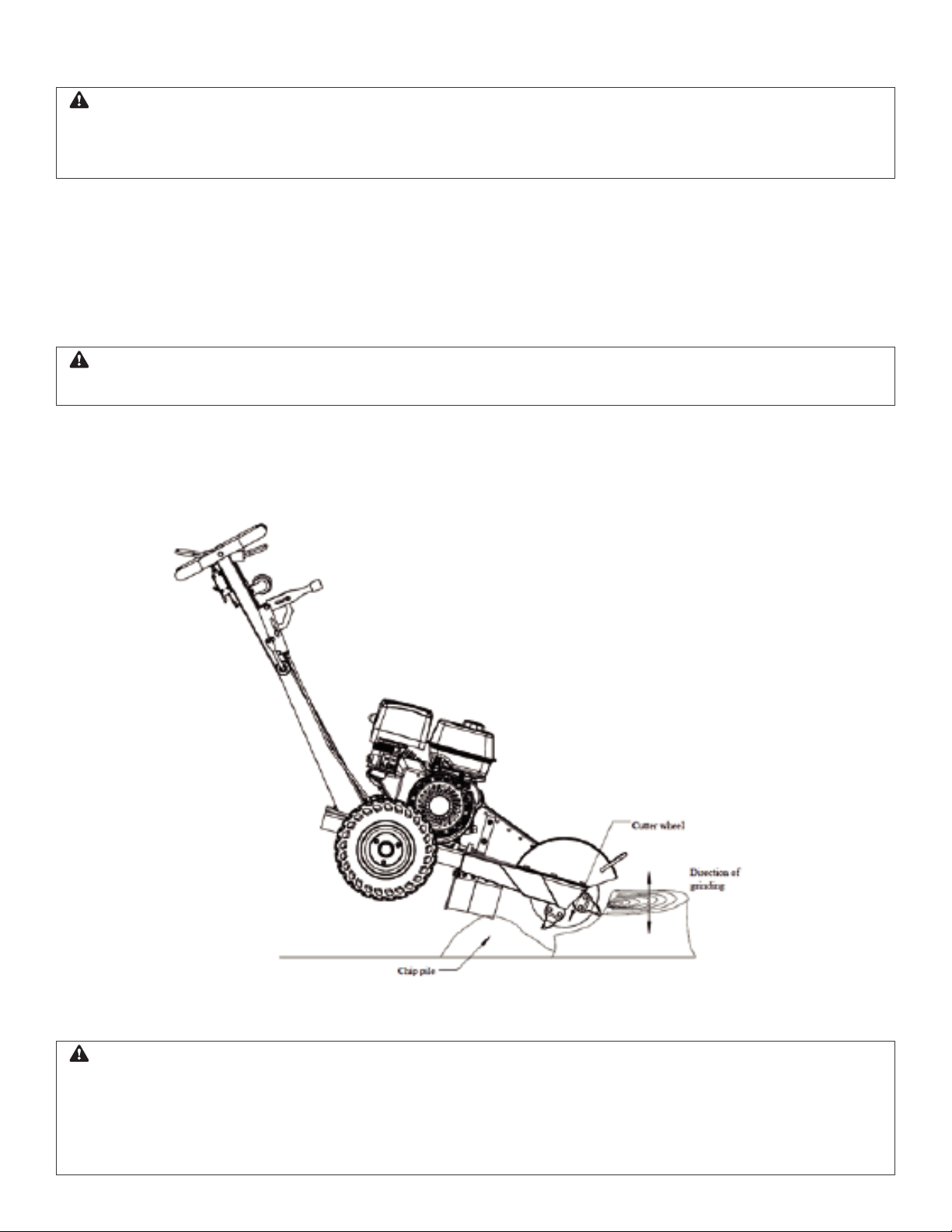

COMPACT STUMP AND ROOT GRINDER

Your stump grinder is intended for outdoor-use only and can be used to remove many trees stumps and

exposed root systems close to ground level. By moving the blade in sweeping movements laterally over the

top and front of the stump, you can gradually grind it away. Make sure you completely read and understand

this manual before using the grinder for the first time.

BE-SGGxxx USER MANUAL 3

STOP

ADD ENGINE OIL: Your stump grinder comes fully assembled and requires only that you add engine oil to

crankcase and fuel to tank.

INSPECT COMPONENTS: Closely inspect to make sure no components are missing or damaged. See the

“Receiving Your Unit” section for instructions on whom to contact to report missing or damaged parts.

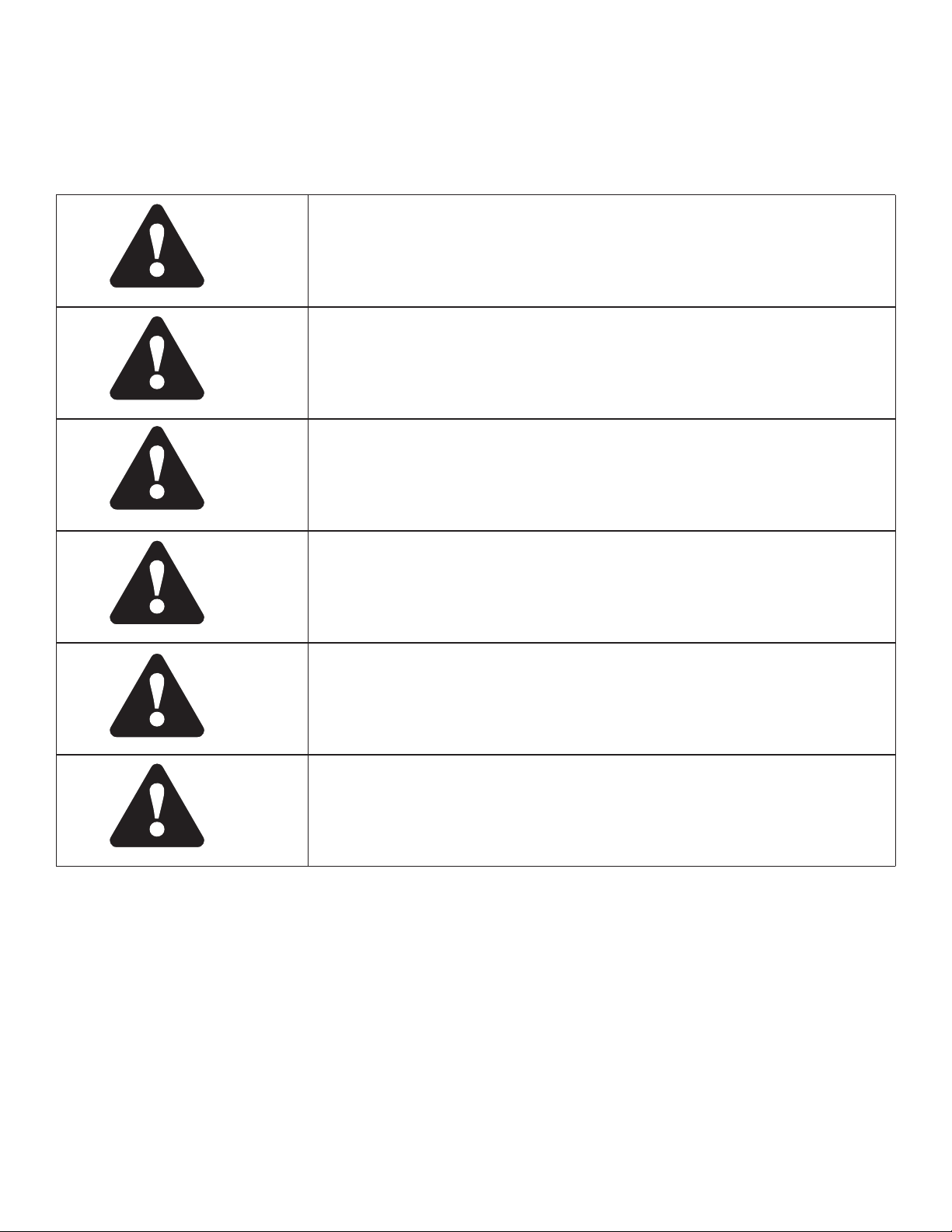

HAZARD SIGNAL WORD DEFINITIONS

This is the safety alert symbol. It is used to alert you to potential per-

sonal injury hazards. Obey all safety messages that follow this symbol to

avoid possible injury or death.

DAN-

GER

DANGER indicates an imminently hazardous situation which, if not avoid-

ed, will result in death or serious injury.

WARN-

ING

WARNING indicates a potentially hazardous situation which, if not avoid,

could result in death or serious injury.

CAU-

TION

CAUTION indicates a potentially hazardous situation which, if not avoid,

may result in minor or moderate injury.

CAU-

TION

CAUTION used without the safety alert symbol indicates a potentially

hazardous situation which, if not avoided, may result in property damage.

CAU-

TION

Neither the machine as a whole nor its internal components are intended

for use in potential explosive atmospheres.

4 BE-SGGxxx USER MANUAL

TABLE OF CONTENTS

PART I. INTRODUCTION

5About Your Grinder

6Safety Decal Locations

7Safety Decals

8Machine Component Identification

PART II. OPERATION

91. Pre-Start Check List & Procedures

10 2. Starting the Grinder

11 3. Stopping the Engine

12 4. Grinding the Stump

13 5. Refueling

14 6. Storing the Machine

PART III. MAINTENANCE AND REPAIR

15 Maintenance (To be done by owner or Rental Dealer)

16 Belt Tension Adjustment

17 Stop-Switch Adjustment

18 Installing Teeth

18 Schedule

19 Engine Specifications

PART IV: IMPORTANT SAFETY INFORMATION

20 Summary of Important Safety Information

23 Special Safety Information on Static Electricity

26 Exploded View & Parts List

27 Warranty

BE-SGGxxx USER MANUAL 5

ABOUT YOUR GRINDER

Owner/Operator/Renter Training

Read and follow all instructions and safety precautions presented throughout this manual. A summary of

important safety information can be found at the end of the manual. Keep this manual for reference and

review. If the owner of this unit is dierent than the operator, give a copy of this manual to any operator to

read.

Rental Companies

All persons to whom you rent/loan this grinder must have access to this manual and read it. Check the tube

on the side of the unit to make sure a manual is inside. Advise all persons who will operate the machine to

read it. You should also provide personal instruction on how to safely operate the grinder and remain

available to answer any questions a renter/borrower might have. If videos are available, have renter watch

training video.

Engine Instructions

For detailed engine operation and maintenance information, always refer to the engine4 Owner’s Manual

furnished with the grinder.

Product Suitability

Before using, the user shall determine the suitability of this product for this intended use and assumes

liability therein.

Your stump grinder can be used to remove many tree stumps and exposed root systems close to ground

level. By moving the blade in sweeping movements laterally over the top and front of the stump, you can

gradually grind it away. Make sure you completely read and understand this manual before using the grinder

for the first time. If you have any question, contact your retail or rental dealer or manufacturer.

WARNING: NEVER ATTEMPT TO CUT AN A SLOPE EXCEEDING 15°

Exercise caution when cutting stumps on an incline, as the machine may shift or slide unpredictably.

Never attempt to cut with the machine uphill or downhill from you as it may slide toward you or you

may fall toward the machine. Cut only on a slope from the side.

The supplier is constantly improving its products. The specifications outlined herein are subject to change

without prior notice or obligation. The purchaser and/or user shall assume liability for any modification and/

or alterations of this equipment from original design and manufacturer.

Warranty Registration

Please fill out and submit the warranty registration card so that we have your contact information for any

future product literature or replacement parts you may need.

6 BE-SGGxxx USER MANUAL

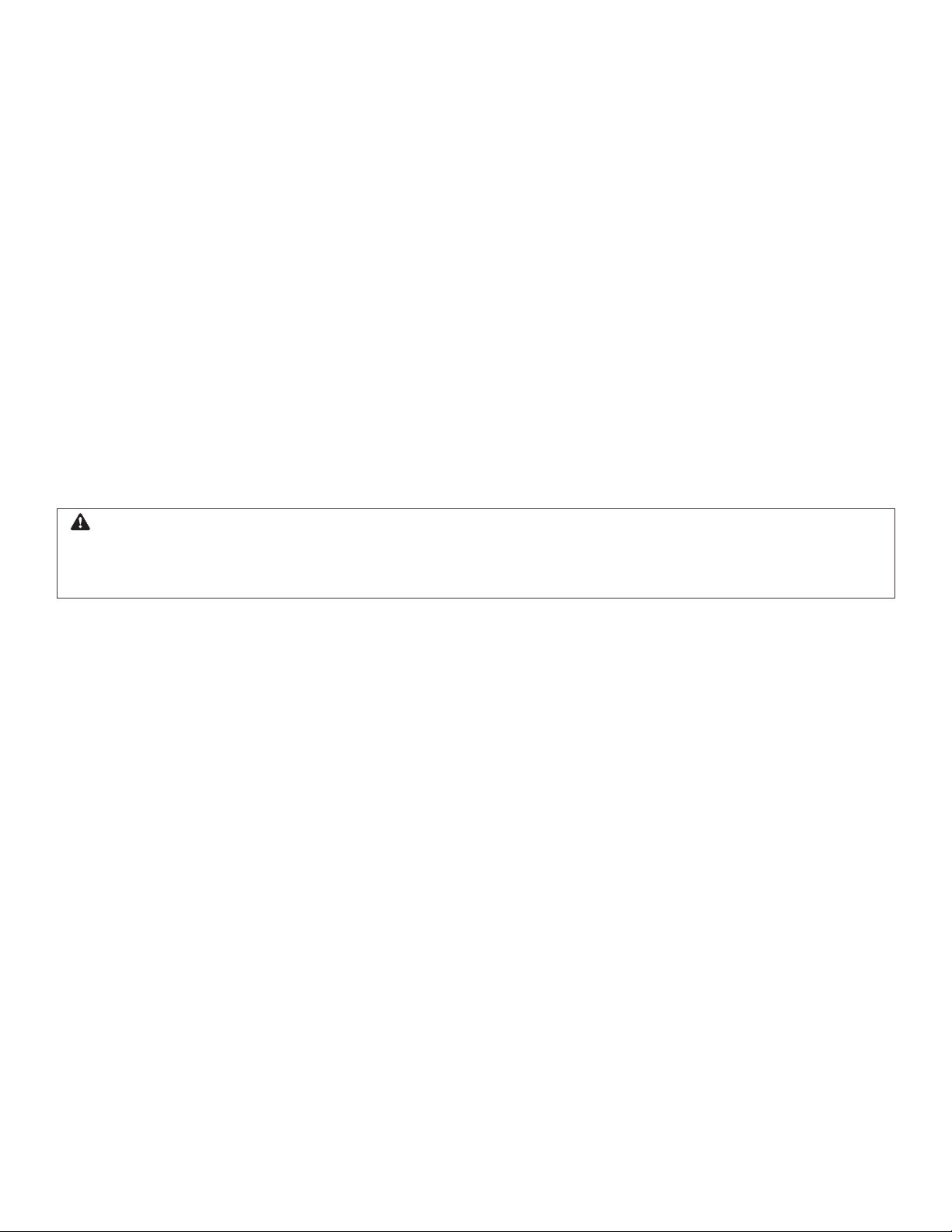

SAFETY DECAL LOCATIONS

REFERENCE # DESCRIPTION

1 Control Panel Operator Hazard

2 Brake Identification

3 Poisonous Gas Hazard

4 Flying Debris Hazard

5 Flying Debris Hazard

6 Amputation & Entanglement Hazard

WARNING

ALWAYS make sure safety labels are in place and in good condition, if a safety label is missing or not

legible, order new labels.

BE-SGGxxx USER MANUAL 7

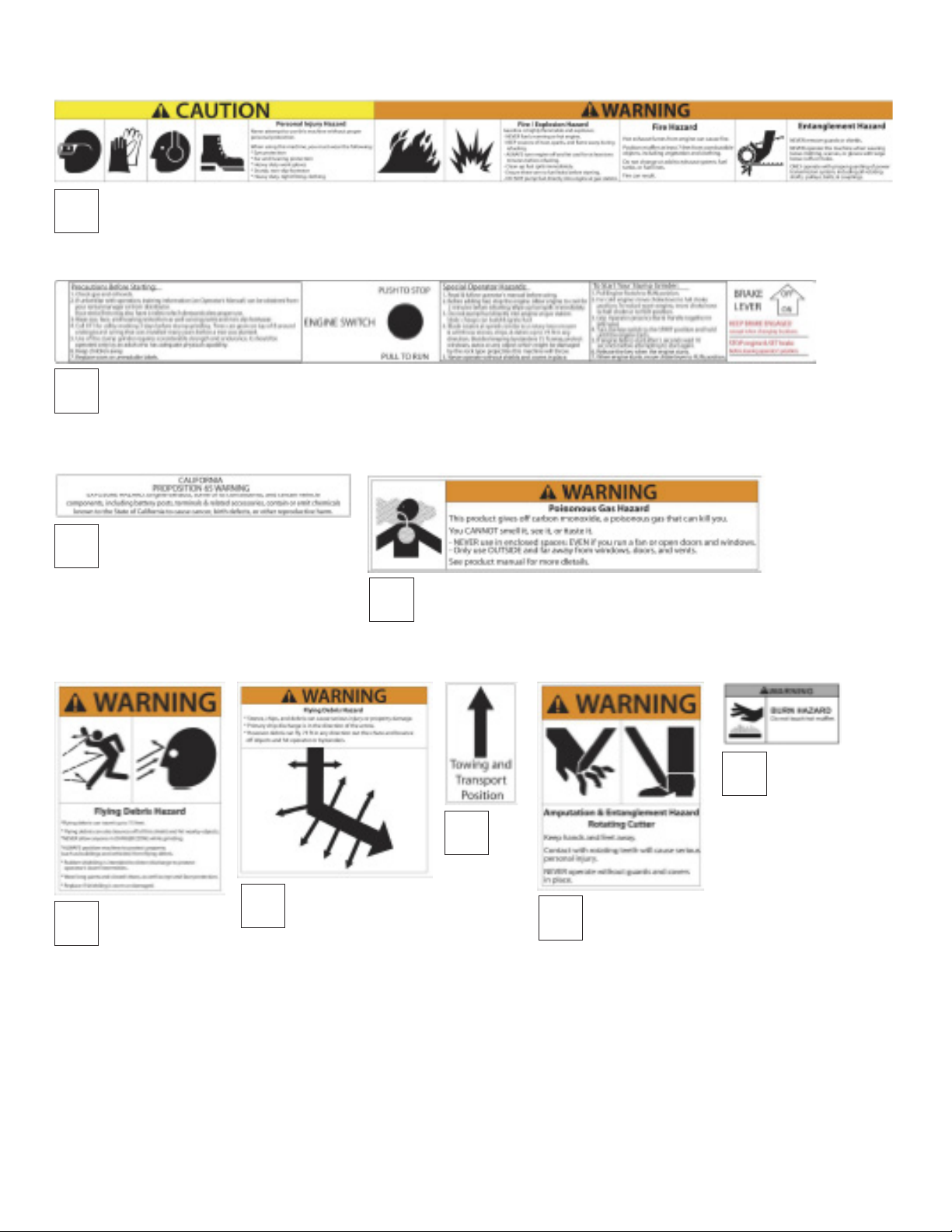

SAFETY DECALS

8

7

5

1

2

3

4

9

6

8 BE-SGGxxx USER MANUAL

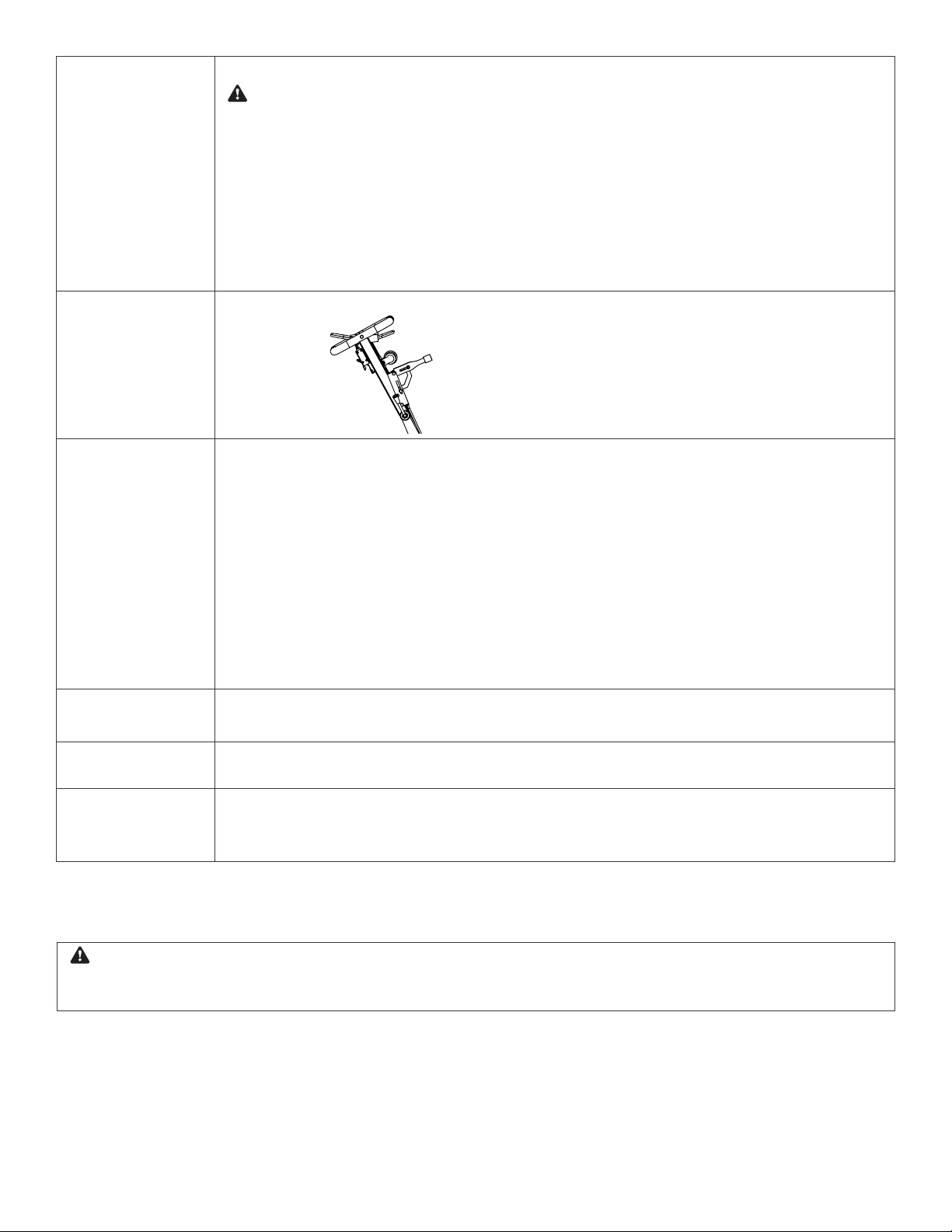

MACHINE COMPONENT IDENTIFICATION

REFERENCE # DESCRIPTION

1 Operator Presence Handle Bar

2 Handle Bar

3 Throttle Control Lever

4 Manual Holder

5 Adjustable Brake Lever

6 Clamp Handle

7 Engine

8 Starter Grip

9 Wheel

10 Engine On/O Switch

11 Rubber Bae

12 Cutter Guard

13 Cutter Wheel

14 Cutter Teeth

15 Front Handle

16 Belt Cover

BE-SGGxxx USER MANUAL 9

CAUTION

Add engine crankcase oil. A new engine is shipped without oil. You must add the correct amount of oil to

engine crankcase or engine will be damaged beyond repair.

Note: #92 gasoline fuel and 5w30 engine oil.

OPERATION

1. PRE-START CHECK LIST & PROCEDURES

Before starting the engine you will want to make sure you have completed the following:

1. Marking Underground Utilities.

2. Checking Controls.

3. Checking Cutting Teeth.

4. Checking/Adding Oil.

5. Filling Stump Grinder Gasoline Tank.

6. Inspecting Fuel System for Leaks.

7. Locking Handle Bar.

8. Wearing Personal Protection.

9. Trimming Stump with Saw.

10.Clearing Area of People and Objects.

11. Working During Daylight.

Each of these procedures is discussed in detail below.

Check

Controls

All guards are in place and tight.

Operator presence bar switch is free moving.

Inspect tires and rims for looseness, damage, and tire inflation.

Check

cutting teeth

Inspect cutting teeth for tightness and sharpness. Only use factory-ap-proved parts for

repair.

Check/Add oil Check the oil level using the dipstick and add oil as needed.

Using a funnel, add oil up to the FULL mark on the dipstick with the recommended oil

type for your engine and expected ambient conditions.(See engine Owner’s Manual for

oil type and capacity, and more detailed oil check/fill instructions).

WARNING: BURN HAZARD

Never open oil fill port while engine is running. Hot oil can spray over face and body.

Fill stump grinder

gasoline tank

Check the gasoline level in the engine’s fuel tank. If needed, fill tank with fresh

unleaded gasoline from a portable container, after first reading the warnings &

instruction below.

• DO NOT fill the gas tank to the top. Gasoline may spill when operating on a slope.

• DO NOT overfill the gasoline tank. Allow at least 1” of empty space below the fill neck

to allow for fuel expansion. #92 gasoline fuel and 5w30 engine oil

WARNING: GASOLINE FIRE/EXPLOSION HAZARD

Gasoline is highly flammable and explosive. Heat, sparks and flames can ignite

gasoline vapors, which can become widespread during fueling. A flash fire ignition

and/or explosion could result and cause serious injury or death.

The following conditions could result in gasoline ignition/explosion:

• Gas vapor collection inside enclosures.

• Static electric sparks.

• Sparks from electric wiring, batteries, or running engines.

• Sources of heat (such as a hot engine or exhaust).

• Open flames, including pilot lights.

10 BE-SGGxxx USER MANUAL

Inspect Fuel

SystemCheck for

Leaks

Inspect fuel system & check for leaks BEFORE starting grinder.

WARNING: FUEL LEAK HAZARD

A leaking fuel line no matter how small can be the source of a fire or explosion when

starting or operating the engine.

• Inspect the entire fuel system. Look for: Signs of leaks or deteriora-tion, chafed or

spongy fuel hose, loose connections, loose or missing fuel hose clamps, damaged

gasoline tank, or defective gasoline shut-o valve.

• If grinder is in an enclosed area and you smell gas, DO NOT start engine! DO NOT

light a match. DO NOT flip on an electrical switch. Exit area immediately leaving

doors open and call fire department.

Locking

Handle Bar

Handle is capable of folding when not in use.

Personal

Protection

Use approved protective clothing and approved protective equipment when using the

machine.

• Always wear safety glasses with side shields and a full-face shield.

• The use of ear plugs or other hearing protection device is also recom-mended for

persons working within 15-20 feet (5-6.5m) of the running grinder for longer than a

few minutes. Hearing can be damaged from prolonged, close- range exposure to the

type of noise produced by this grinder.

• Wear long pants to protect legs from sparks, hot engine and flying debris.

• Never wear jewelry or loose-fitting clothing when starting or operating the grinder or

any mechanical device. Loose or dangling apparel, jewelry or hair can become entan-

gled in moving parts.

• Neither the machine as a whole nor its internal

components are intend-ed for use in potential explosive atmospheres.

Trim Stump

with Saw

Cut or trim the stump preferably to ground level using a power saw.

Clear Area Dig away the earth and remove any stones near the tree stump or roots that may

interfere with your work.

Working During

Daylight Hours

Only use the machine in daylight or in well-lit conditions. Never operate the grinder

after dark.

2. STARTING THE GRINDER

After you have completed the pre-start checking list and procedures, you are ready to start the grinder.

The following directions details how to start the engine of your grinder.

To start the grinder:

Note: For additional engine starting instructions see your gasoline engine manual.

• Lock handle in the upright position.

• Place stump grinder into position with cutting wheel near the front-top edge of the stump.

• Use brake lever on handle to lock the wheel brake.

Note: For tighter brake adjustment, turn knob on top of brake lever. (See Maintenance & Repair sections for

instructions).

WARNING

Never attempt to use the grinder without proper protective equipment, particularly eye protection and

a full-face shield.

BE-SGGxxx USER MANUAL 11

• For cold engine, mover choke lever to the CLOSED position. To restart a warm engine, leave choke lever in

OPEN position.

• Turn engine switch to the ON position.

• Grip operator presence bar and handle bar together in left hand.

WARNING

Stay in the OPERATOR POSITION (Behind the machine) while actuating controls. Never leave grinder

unattended.

WARNING

A rotating cutting wheel is very dangerous. Stay at the controls and keep others away until you are sure

the blades has come to a complete stop.

• Pull the starter grip lightly until you feel resistance, then pull briskly. Return the starter grip gently. If the

choke lever was moved to the CLOSED position to start the engine, gradually move it to the OPEN position

as the engine warms up.

• If engine does not start, repeat steps 5-7.

• Press down on handle bar to lift cutter wheel o the ground.

• Grip throttle control lever and handle bar together in right hand. Centrifugal clutch will engage and cutter

wheel will begin to rotate.

3. STOPPING THE ENGINE

Stop the engine using the following steps:

• While holding blade o ground, release the operator presence bar. The engine will stop. Wait until the

blade completely stops. Lower the blade so it is resting against the ground.

• Make sure brake is set before leaving the controls, particularly if you are on an incline.

• Turn engine switch to OFF position.

• Allow the engine to cool for at least 30 minutes before releasing brake and moving to storage or

transporting. A hot engine can be a fire hazard.

12 BE-SGGxxx USER MANUAL

WARNING FLYING DEBRIS HAZARD

Stones, chips, and debris can cause serious injury or property damage. Debris can fly 75 ft (25m) in any

direction out of the chute. They can bounce o any fixed objects as well and hit operator, bystanders or

breakable objects.

• Set/engage the brake.

• Pivot the grinder toward the side of the stump, with a fairly light touch feed straight into the stump. As

soon as you feed in, start to swing to the side until you feel the wheel drop o the edge of the stump.

• Change direction and swing back the other way until you feel it reach the other edge of the stump. As you

swing to the side listen to the engine. Provide enough feed to give it a moderate load. If you hear any belt

or clutch squealing you are pushing to hard. If you can not swing it to the side, raise the grinder up. You can

cut roots o by plunging straight through them.

WARNING ROTATING CUTTER WHEEL

Keep hands and feet away. Contact with wheel rotating teeth will cause serious personal injury.

WARNING: FLYING DEBRIS HAZARD

Stones, chips, and debris can cause serious injury or property damage.

Debris can fly 75 ft (25m) in any direction out of the chute. They can bounce o any fixed objects as

well and hit operator, bystanders or breakable objects.

• On these large stumps, DO NOT allow grinder wheels to drop into stump hole. If a hole is in the way of

your progress, fill it with chips or change position.

• When grinding larger stumps, chips may begin to build up under the wheel.

• Release brake and pull machine towards you so that the “chip pile” is directly under the cutting wheel.

• Drop cutter wheel down on “Chip pile”, material will be discharged from machine area.

4. GRINDING THE STUMP

BE-SGGxxx USER MANUAL 13

WARNING

Stop engine and set brake before leaving operator’s position. KEEP BRAKE ENGAGED except when

changing locations.

• When finished, stop the engine.

• Pull machine away from stump, and rack chips away from stump.

WARNING: STATIC ELECTRIC SPARK HAZARD

A static electric spark can explosively ignite gasoline vapor, resulting in a flash fire that could cause

serious injury or death. See “Special Safety Information on Static Electricity” at end of this manual.

5. REFUELING

Stop the engine using the following steps:

• Before removing gas cap, turn engine o and allow to cool for at least two minutes.

• Note: A running or hot engine can ignite fuel.

• Remove grinder gasoline cap.

• Add gasoline through the fill opening

• Use only an portable gasoline container to transfer the gasoline to the grinder’s tank.

• Be aware of safety warning and instructions below for avoiding static electric caused fires.

• Do not overfill.

• Clean up gasoline spills / splashes immediately.

• If possible, move the grinder away from spilled gasoline on the ground.

• Wipe up spilled gasoline, and wait 5 minutes for excess gasoline to evaporate before starting engine.

• Gasoline soaked rags are flammable and should be disposed of

properly.

• If gasoline is spilled on your skin or clothes, change clothes and wash skin immediately.

14 BE-SGGxxx USER MANUAL

5. REFUELING (CON’T)

• Replace gasoline cap securely before starting engine.

• Store extra gasoline in a cool, dry place in an tightly sealed container.

• Filling towable units or portable containers at service stations:

• Even if you have a towable unit, avoid static electric sparking while filling the gasoline tank:

• Never fill the grinder’s gas tank directly from the fuel pump. The grinder’s tank is not grounded and high

velocity flow from the pump can cause static electricity build-up. Use an portable container to transfer

gas to the grinder’s tank.

• Use a portable container made of metal or conductive plastic. This is preferred because it dissipates

static charge to ground more readily.

• Never fill a portable gas container while it is sitting inside a vehicle, trailer, trunk, or pick-up truck bed.

ALWAYS place container on the ground to be filled.

• Keep nozzle in contact with container while filing. Do not use a nozzle lock-open device.

6. STORING THE MACHINE

When you are finished using the grinder and it has cooled, you must:

• Cool engine before storage.

• Clean the grinder.

• Inspect for worn or damaged parts.

• Choose covered storage location.

• Prevent accidental starting.

• Plan on exercising the engine at least monthly unless the grinder is prepared for long term storage.

Detailed instructions are provided below.

Cool Engine Let engine cool for at least 30 minutes before storing.

A hot engine can be a fire hazard.

Clean Grinder Clean all grease, dirt, mud and other foreign matter from the machine. Touch up paint

damage to prevent rust.

Inspect Grinder Inspect the machine for worn or damaged parts and tighten any nuts or screws that

may have become loose. Pay particular attention to the cutting teeth.

Choose a Storage

Location

Store the grinder in a location that is:

• Clean and dry

• Away from sources of heat, open flames, sparks, or pilot lights, even if the grinder’s

gas tank is empty. Residual gasoline could ignite.

• Away from extreme high or low temperatures.

• Cover it for extra protection.

Remove Spark

Plug

Remove spark plug, in order to ensure the grinder cannot be started in a storage

location or any untrained persons or children.

Start

Grinder Every 4

Weeks

The grinder should be started regularly. At least every 4 weeks, start the engine and

let it run for 10 to 15 minutes.

Monthly exercising of the grinder will dry out any moisture that has accumulated,

lubricate cylinders, and clean out old gas in the carburetor. Moisture, old gas, and dry

mechanical parts cause deterioration in stored engines.

BE-SGGxxx USER MANUAL 15

Prepare Engine for

Long Term

(Seasonal)

Storage if needed

If you will not be able to start the grinder regularly, you must prepare the engine for

long term storage to prevent gum deposits from forming and causing malfunction of

the engine.

Prepare engine for long term storage by:

• Removing all gasoline from the tank and carburetor

OR

• Adding fuel stabilizer to the gasoline (following manufacturer’s instructions)

Fuel stabilizer steps:

1. Ensure gas tank is full.

2. Add fuel stabilizer to fuel tank.

3. Run engine at least 10 minutes after adding stabilizer to allow it to enter the fuel

system.

4. Shut o engine.

5. Disconnect spark plug wire and remove spark plug.

6. Add one teaspoon oil through spark plug hole.

7. Place rag over spark plug hole and turn starter (or pull the recoil) a few times to

lubricate the combustion chamber.

8. Replace spark plug, but do not reconnect the spark plug wire.

WARNING: GASOLINE FIRE / EXPLOSION HAZARD

Gasoline is highly flammable and explosive. Drain the fuel into an approved container OUTDOORS and

far away from open flame. NEVER store an engine with fuel in the tank indoors or in poorly ventilated

spaces where fuel vapor can come in contact with

• Static electric sparks.

• Sparks from electric wiring, batteries, or running engines.

• Sources of heat (such as a hot engine or exhaust).

• Open flames, including pilot lights.

WARNING

ALWAYS shut o the engine, make sure the engine is cool, and disconnect the spark plug before

cleaning, adjusting, or servicing the grinder. Make sure all guards and shields are replaced before using.

MAINTENANCE

Perform

regular

Maintenance

Perform periodic maintenance as directed in this

manual to keep the grinder in safe working condition.

Follow Safety

Rules

Read and follow these safety rules whenever you will be servicing the grinder:

• Turn o grinder. Always turn o grinder and remove spark plug or spark plug wire

before working on the engine or grinder to prevent accidental starting.

• Replace guards/shields. Make sure all guards and shields are replaced after servicing

the grinder.

• Burns. Muer will be hot even after unit is stopped. Allow unit to cool before

servicing.

• Repair. Major service, including the installation or replacement of parts, should be

performed only by a qualified electrical service technician.

• Replacement parts. If a part needs replacement, only use factory approved repair

parts. Replacement parts that do not meet specifications may result in a safety

hazard or poor operation of the grinder and will void the warranty.

16 BE-SGGxxx USER MANUAL

Perform

Engine

Maintenance

Perform engine maintenance as specified in the

engine owner’s manual.

Engine maintenance items include:

• Oil and oil filter changing

• Air filter check/replacement

• Spark plug cleaning and replacement

• Fuel filter check/replacement

• Fuel tank cleaning.

Inspect Fuel Sys-

tem / Check for

Leaks

Inspect the fuel system and check for leaks on a

regular basis.

Look for: signs of leaks or deterioration, chafed or spongy fuel hose, loose

connections, loose or missing fuel hose clamps, damaged gasoline tank, or defective

gasoline shut-o valve.

Lubricate Cutter shaft bearings should be greased.

The cutter shaft bearing is greased by pumping grease into zerks located on the hous-

ing of the bearing. Lubricate after every 20 hours of use.

Grease Specifications

Soap Type Lithium Complex

NLGI Grade #2

Dropping Point 230°C (446°F)

Additives Corrosion and Oxidation inhibitors, EP optional

Viscosity Index 80 Minimum

Check and Adjust

Brake

Check that the brake is functioning properly.

• Lock the brake, push down on handle bar so that

cutter wheel is o the ground.

• Push or pull the grinder- if the brake is loose, the wheel will rotate.

To adjust braking tension:

• Unscrew set screw.

• Turn knob clockwise to increase tension or

counter-clockwise to decrease tension.

• Once you have set the brake to the proper tension, tighten set screw to lock

adjustment knob.

BELT TENSION ADJUSTMENT

Note: Belt tension and alignment are inter-related. Do not adjust one without checking the other.

• Remove belt guard.

• Loosen (4) engine base (mount) bolts.

• Loosen lock nuts on tension bolt and alignment bolt.

• Turn tension bolt clockwise to increase belt tension and

counterclockwise to decrease belt tension.

• Check that the pulleys are aligned using a straight edge. To achieve proper pulley alignment you may need

to adjust the alignment bolt. This bolt will serve as an adjustment point to counter the tension in the belts,

which may cause the engine pulley to be misaligned with the cutter wheel pulley. Note: Set screws in pulley

have a torque

specification of 25.3kg/m.

• Belt tension is proper when a 2.27kg to 3.18kg force will deflect the belt 2/5” (1cm) at the midpoint.

• Retighten all loosened nuts and bolts.

• Reassemble belt guard.

BE-SGGxxx USER MANUAL 17

STOP-SWITCH ADJUSTMENT

WARNING

Never attempt to alter, modify or override this switch.

If stop-switch ever needs to be replaced or adjusted follow the below directions.

Loosen Hex Nut.

1. Turn the Linkage Bolt clockwise to lower or counter-clockwise to raise the point of interaction with

Stop Switch. To set the proper interaction distance, grip the Operator Presence Bar & Handle Bar

together and lower the Linkage Bolt onto the Switch Button until the switch button cannot be

depressed any further.

Then raise the linkage bolt one turn (counterclockwise).

2.Tighten Hex Nut.

3.Verify operability of stop switch before operating machine by releasing the operator presence bar

next to the handle bar. You should hear a “CLICK”, signifying that the Linkage Bolt has been adjusted

properly.

18 BE-SGGxxx USER MANUAL

INSTALLING TEETH

Among the most critical elements of the stump grinder is the cutting wheel. It is also the most subject to

damage and wear. In the course of grinding stumps it not only makes contact with the wood, but also

encounters numerous abrasives and objects in the stump’s environment, such as dirt, stones, large rocks and

buried scrap.

The loss and wear of cutting teeth can significantly impair the eciency and performance of the stump

grinder. Therefore, it is important to make frequent inspections of the condition of all the cutting teeth and

to replace any damaged or worn teeth

Thread in the bolt through the cutter wheel and into the teeth as shown, then tighten. Bolt should be torque

to 60ft/lbs.

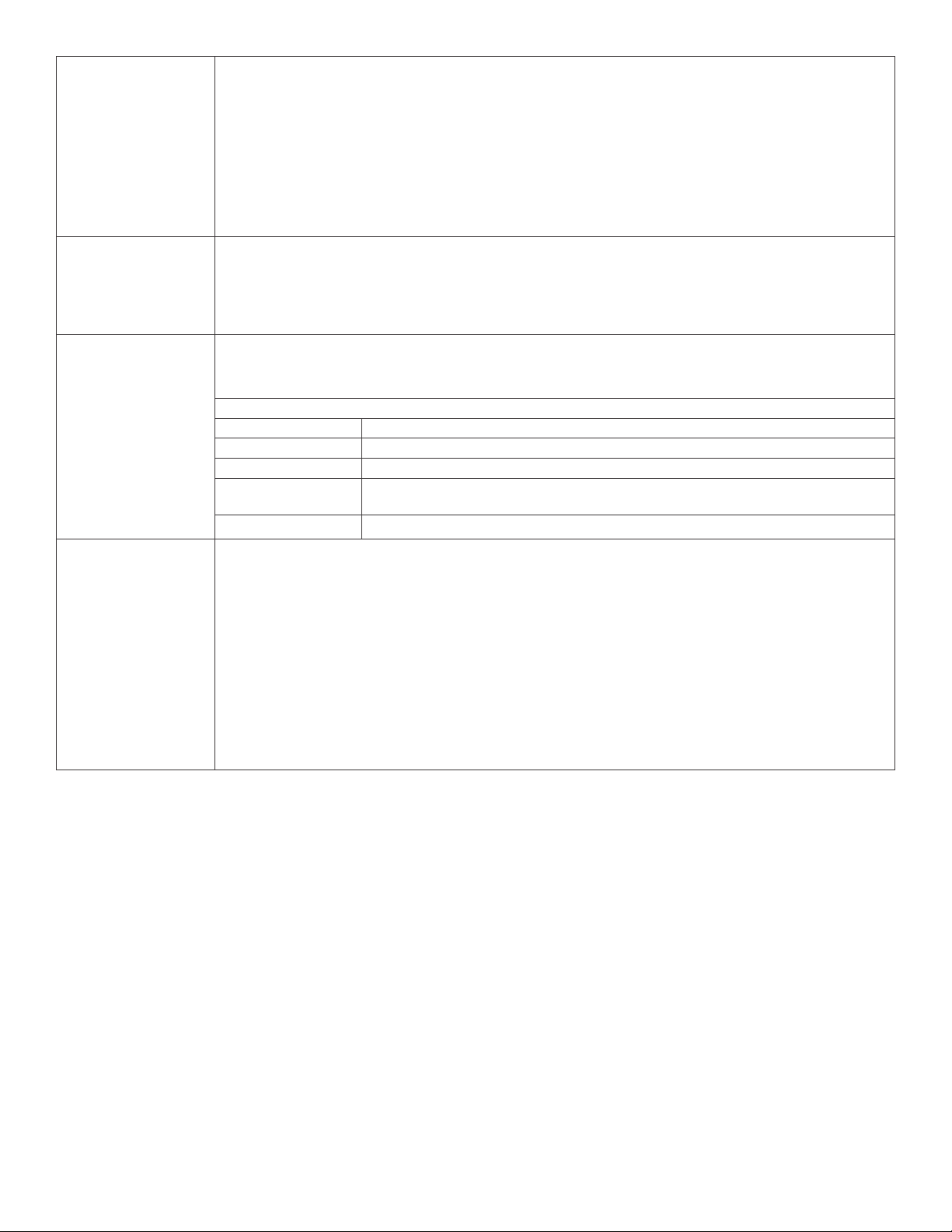

MAINTENANCE SCHEDULE

CAUTION

Before attempting any maintenance, be sure that the engine is shut o, the spark plug wire is removed,

and the engine is cool to the touch!

IMPORTANT:

If a part needs replacement, only use parts that meet the manufacturer’s specifications. Replacement parts

that do not meet specifications may result in a safety hazard or poor operation of the grinder.

Item -What to check or

action req’d

Daily Each Use 10 hours 20 hours 40 hours

Bearing, Shaft-Grease

X

Belt Tension-Tension

X

Bolts-Tightness

X

Engine See Manual

Gasoline-Amount

X

Safety Switch-Operation

X

Warning Decals-Legible

X

Tires, Flaps-Condition

X

Wires, Cables-Condition

X

Cutter Teeth-Sharpness

X

BE-SGGxxx USER MANUAL 19

ENGINE SPECIFICATIONS

Maker LONCIN G200F

Model G200F

CC Rating 200cc

GENERAL

Weight 90kg

Length 1605mm

Width 680mm

Height 1200mm

RPM Operating 3600 rpm

Type of Fuel Gasoline

Starting Recoil

Oil Sensor Yes

Wheel Tire 140/70-6

CUTTER WHEEL

Diameter 8.66” (220mm)

Thickness 4.72” (12mm)

Bearing UCP205

Cutter Wheel RPM 2200 rpm/min

Drive Direct Belt Drive

Centrifugal Clutch

CUTTING CAPACITY

Above Grade 9” (230mm)

Below Grade 8” (203mm)

Stump Diameter 20cm

TEETH, CARBIDE TIPS

Cutter Type Wood

Steel Type 42CrMo

Steel Harness HRC40-42

Weight 1.59 lbs (0.72kg)

Length 4-1/4” (10.8cm)

Width 2-13/16” (7.1cm)

Tip Length 1-1/2” (3.8cm)

20 BE-SGGxxx USER MANUAL

A-weighted sound power level emitted by the machine: 100.6dB for model SGR650; 103.8dB for model

SGR1500.

A-weighted emission sound pressure level at the operator’s station: 86.8dB for model SGR650; 90.8dB for

model SGR1500.

The vibration total value to which the hand-arm system is subjected, less than 7.4 m/s2 for model SGR650;

6.9 m/s2 for model SGR1500

The range of temperature in which the machine is intended to operate and be stored is 5-40°C;

SUMMARY OF IMPORTANT SAFETY INFORMATION

This section provides a summary of the various safety procedures and measures that have been presented

throughout the manual. Keep this summary handy and refer to it to refresh your memory about how to

safely use your grinder.

WARNING

Carefully read and make sure you understand the following safety information before using the grind-

er. Improper use or maintenance of the grinder can result in serious injury or death from fire/explosion,

carbon monoxide poisoning, lacerations, entanglement or burns. Damage can also occur to windows,

siding, vehicles, and bystanders from chips and debris which can become projectiles.

GENERAL

• Read manual. Read this Owner’s Manual and the engine Owner’s

Manual completely before attempting to use and service the grinder. Serious injury or death can result if

safety instructions are not

followed.

• Instruct operators. The grinder owner or rental company must instruct all operators in safe grinder set-up

and operation. Do not allow anyone to operate the grinder who has not read the Owner’s Manual and been

instructed on its safe use. Make sure Owner’s manual is within the attached storage tube on the grinder.

• Adults only. Only trained adults should operate and service the grinder. Do not let children operate.

• Under the influence. Never operate, or let anyone else operate, the grinder while under the influence of

alcohol, drugs, or medication.

• Intended use. Carefully read about and understand the intended use of this grinder. Do not use for other

purposes, as unforeseen hazards or equipment damage may result.

• Controls and safety labels. Learn how to use the machine and it’s controls safely. Understand and follow all

safety labels.

• Weather. Never use in foul, bad or questionable weather, which causes a slippery ground condition.

PROHIBITION AGAINST MODIFICATIONS

Never modify or alter the grinder in any way. Modifications can create serious safety hazards and will also

void the warranty.

• Fuel/exhaust system. Never modify the exhaust system, fuel tanks, or fuel lines. Carbon monoxide

poisoning, fire, or explosion could result.

• Guards. Do not operate grinder unless all guards and cover shields, which prevent access to moving parts

and pinch points, are in place. Failure to guard the power transmission mechanisms may result in serious

injury or death.

SAFETY - BEFORE USE

Know how to operate

• Review safety rules. Before use of this grinder, review the “Rules for Safe Operation.”

• Know how to operate. Be thoroughly familiar with all controls and with the proper use of the equipment.

Know how to stop the grinder quickly if needed.

Getting Ready

• Flying debris. Clear area of objects such as stones, toys, steel wire, etc. that could become caught in

moving machine parts and ejected as a projectile.

• Operate OUTSIDE only – dangerous carbon monoxide exhaust!

Grinders give o carbon monoxide exhaust, a poisonous gas that can kill. You CANNOT smell it, see it, or

This manual suits for next models

5

Table of contents

Other BE Ag & Industrial Grinder manuals