FOLD ON DOTTED LINE

(1/8")

DRILL 3.2mm HOLE

(2 PLACES)

PLACE AGAINST DOOR

(11/16")

DRILL 16mm HOLE

TEMPLATE

PLACE AGAINST JAMB

OPPOSITE HINGES FOR

L.H.R. DOOR INSTALLATION

PLACE AGAINST HEADER

185mm ARMATURE PLATE GUIDE PIN HOLE

[6mm(1/4") DIA, 12.5mm(1/2") DEEP]

185mm ARMATURE PLATE

[6mm(1/4") DIA, 12.5mm(1/2") DEEP]

PLACE AGAINST JAMB

OPPOSITE HINGES FOR

R.H.R. DOOR INSTALLATION

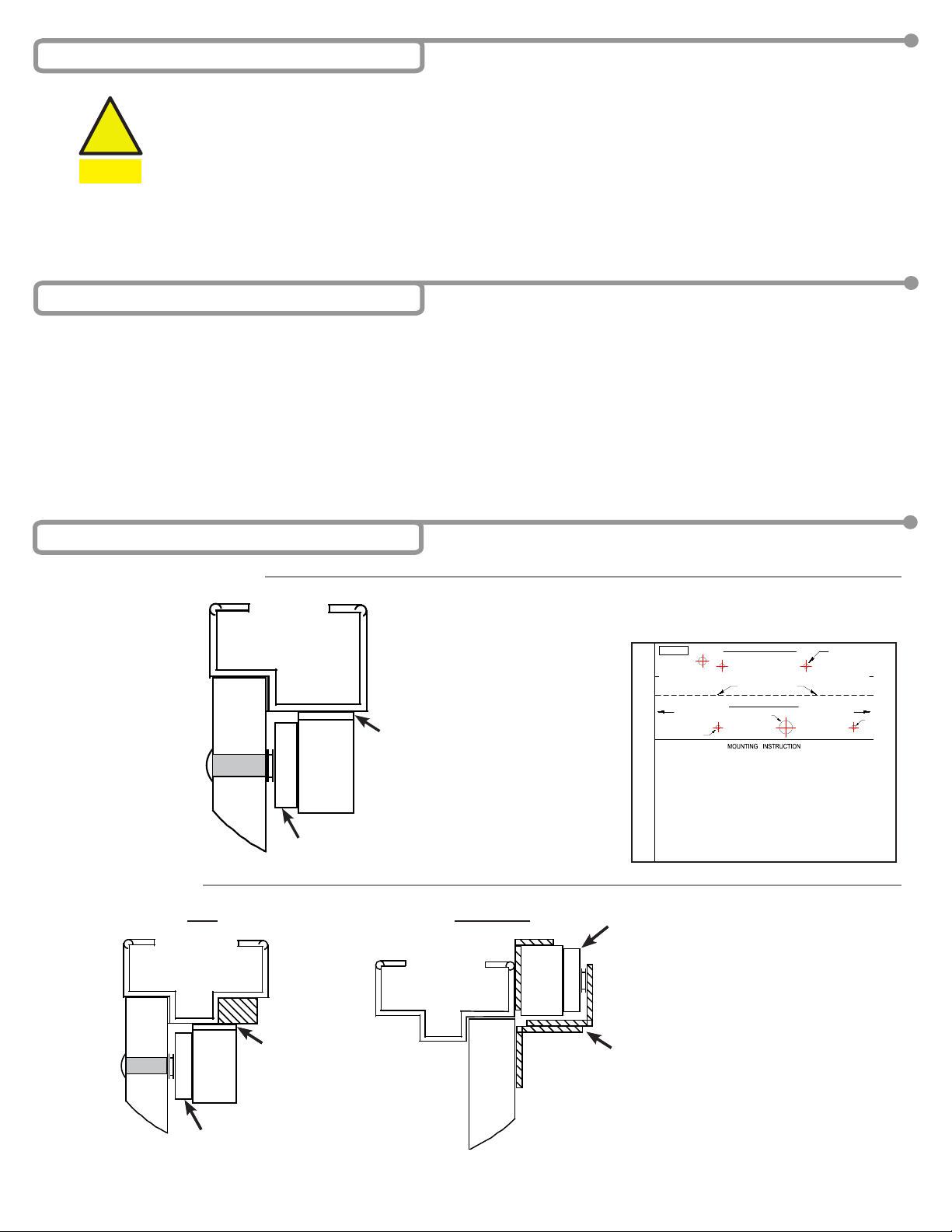

STEP 1

FOLD TEMPLATE ALONG DOTTED LINE.

PLACE TEMPLATE AGAINST DOOR AND HEAD FRAME.

DRILL HOLES AS INDICATED ON TEMPLATE.

STEP 2

MOUNT THE ARMATURE PLATE TO DOOR USING

1 RUBBER WASHER SANDWICHED BETWEEN 2 STEEL

WASHER (THE RUBBER WASHER AND 2 STEEL

WASHER ARE INSTALLED ON THE THROUGH SEXNUT

BETWEEN THE ARMATURE PLATE AND DOOR).

●

●

●

●

STEP 3

DETACH MOUNTING PLATE FROM MAGNET BY REMOVING

2 SOCKET CAP SCREWS. SCREWS COULD BE ACCESSED

THROUGH BOTTOM OF MAGNET.

●

●INSTALL THE MOUNTING PLATE WITH 2 FLAT HEAD

SCREWS (THE 2 M5x15 FLAT HEAD SCREWS ARE

INSTALLED IN THE SLOTTED HOLES FOR ADJUSTMENT).

ADJUST MOUNTING PLATE SO THAT IT FORMS A RIGHT

ANGLE WITH THE ARMATURE PLATE.

●

●USING THE MOUNTING PLATE AS A TEMPLATE,DRILL

THE WIRE HOLE.

●DRILL AND INSTALL THE REMAINING MOUNTING SCREWS.

STEP 4

INSTALL MAGNET TO MOUNTING PLATE WITH

2 M6 SCREWS SUPPLIED.

●

INSTALL ELECTRICAL WIRING PER

INSTRUCTION SHEET.

●

STEP 5

TEST ALL FUNCTIONS OF THIS MODEL (SEE

WIRING INSTRUCTION).

●

STEP 6

INSERT 2 LOCKING STOPPERS IN TWO END

PLATES,AND COVER WITH 4 mm SCREWS.

●

STEP 7

INSERT 2 ALUMINUM CAPS TO COVER THE

TWO M6 SCREW HOLES.

●

STEP 8

NOTE: IF NEEDED, USE SMALL MAGNET TO

REMOVE LOCKING STOPPERS FROM HOLES.

●

DWG. NO. 820001

Page 2 of 4 75.5366.08 UL MAGLOCKS 600lb 20210806

5Handle the equipment with care. Damaging the mating surfaces of the magnet and armature plate may reduce locking efciency.

5The maglock mounts rigidly to the door frame. The armature plate mounts to the door with the hardware provided. This allows

the armature plate to pivot about its center to compensate for door wear and misalignment.

5Template use must take place with the door in its normally closed position.

5Add threadlocker to all screws before installing, and rmly tighten screws.

5Install only for indoor, dry applications.

5Installation and wiring must be performed in compliance with ANSI/NFPA70 regulations.

5The Maglock shall be installed within the same room as other equipment and circuitry connecting to the Maglock (per UL 864).

5Shut off all power going to door or header before attempting any wiring procedures.

5Maintain a clean and safe environment when working in public areas.

5Constantly be aware of pedestrian trafc around the door area.

5Always stop pedestrian trafc through the doorway when performing tests that may result in unexpected reactions

by the door.

5Always check placement of all wiring before powering up to ensure that moving door parts will not catch any wires

and cause damage to equipment or cable insulation.

5Ensure compliance with all applicable safety standards (i.e. ANSI A156.10) upon completion of installation.

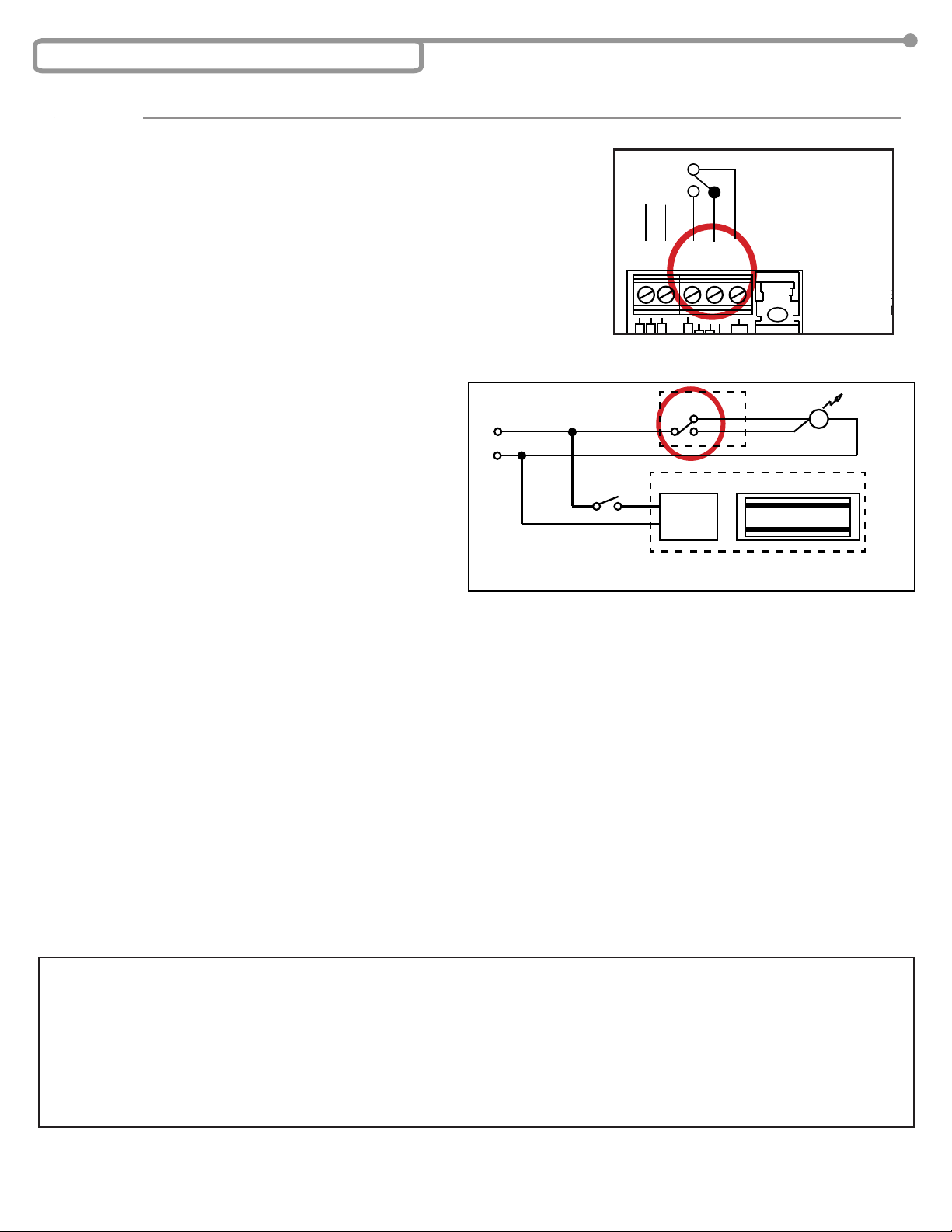

DO NOT over-tighten the armature plate.

The rubber washer is designed to allow the armature plate to automatically adjust position for best mating position between the magnet and armature plate.

DOOR FRAME

DOOR FRAME

DOOR FRAME

MAGNET

MAGNET

MAGNET

DOOR

DOOR

DOOR

MOUNTING PLATE

Use the applicable mounting template.

See image of template below.

See User’s Guide 75.5643 for U-bracket

installation (to be used with glass doors).

MOUNTING PLATE L&Z BRACKET

FILLER

ARMATURE PLATE

ARMATURE PLATE

ARMATURE PLATE

Filler L&Z bracket

3 Precautions

4 Installation Notes

5 Installation – Mechanical

Mounting Options

TYPICAL INSTALLATION

!

CAUTION