51120-G 10/2008

4

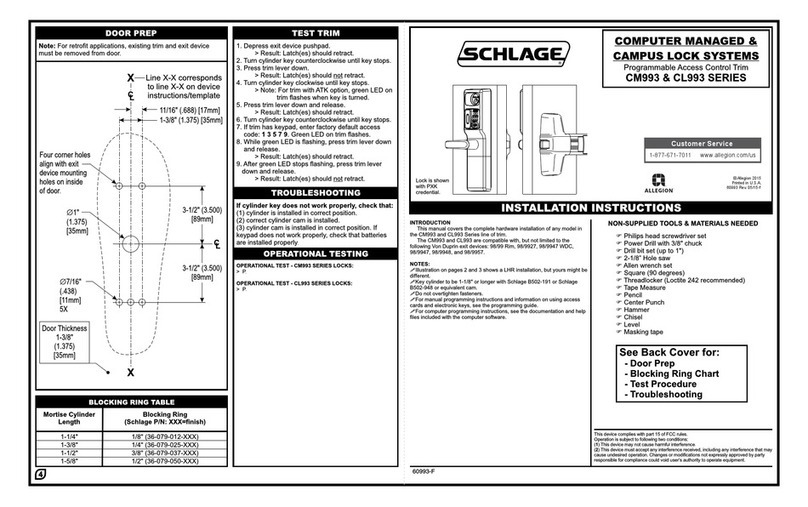

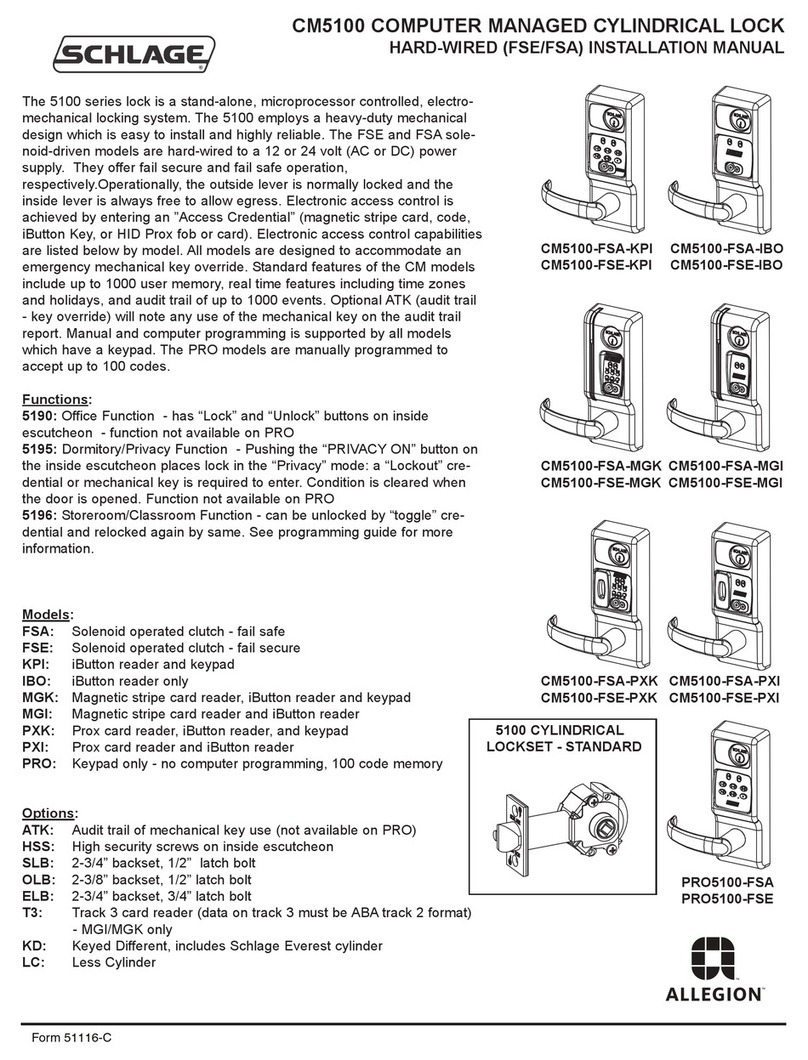

INTRODUCTION:

This manual covers the complete hardware installation of all models in

the WA5200 & AUWA5200 Cylindrical Series line of Wireless Access

Modular Locks.

NOTES:

!Illustration on pages 2 and 3 shows a LH installation, but yours might be

different.

!When mounting Reader and Transceiver:

- Wear some form of ESD protection.

- Do not use power tools to tighten mount screws. Hand tools only.

- Turn in each mount screw a little bit at a time.

- Do not over tighten mount screws.

If cylinder key does not work properly, check that cylinder and appropriate

cylinder cam are installed in correct position.

NON-SUPPLIED TOOLS & MATERIALS NEEDED:

F Philips head screwdriver set

F Power Drill with 3/8"[10mm] chuck

F Drill bit set (up to 1"[25mm])

F 2-1/8"[54mm] hole saw w/mandrel

F Allen wrench set

F Square (90 degrees)

F Threadlocker (Loctite 242 recommended)

F Tape Measure

F Pencil

F Center Punch

F Hammer

F Chisel

F Masking tape

F Level

F Fire rated putty (recommend-Metacaulk Putty from Rectorseal Corp.)

4

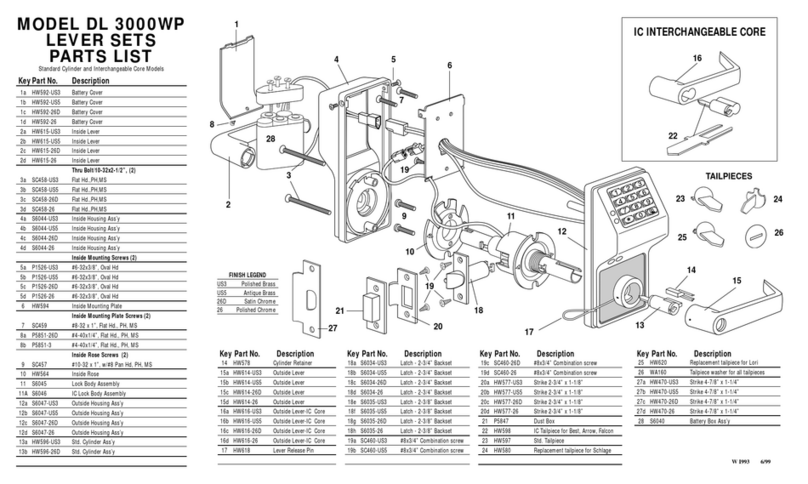

INSTALLATION INSTRUCTIONS

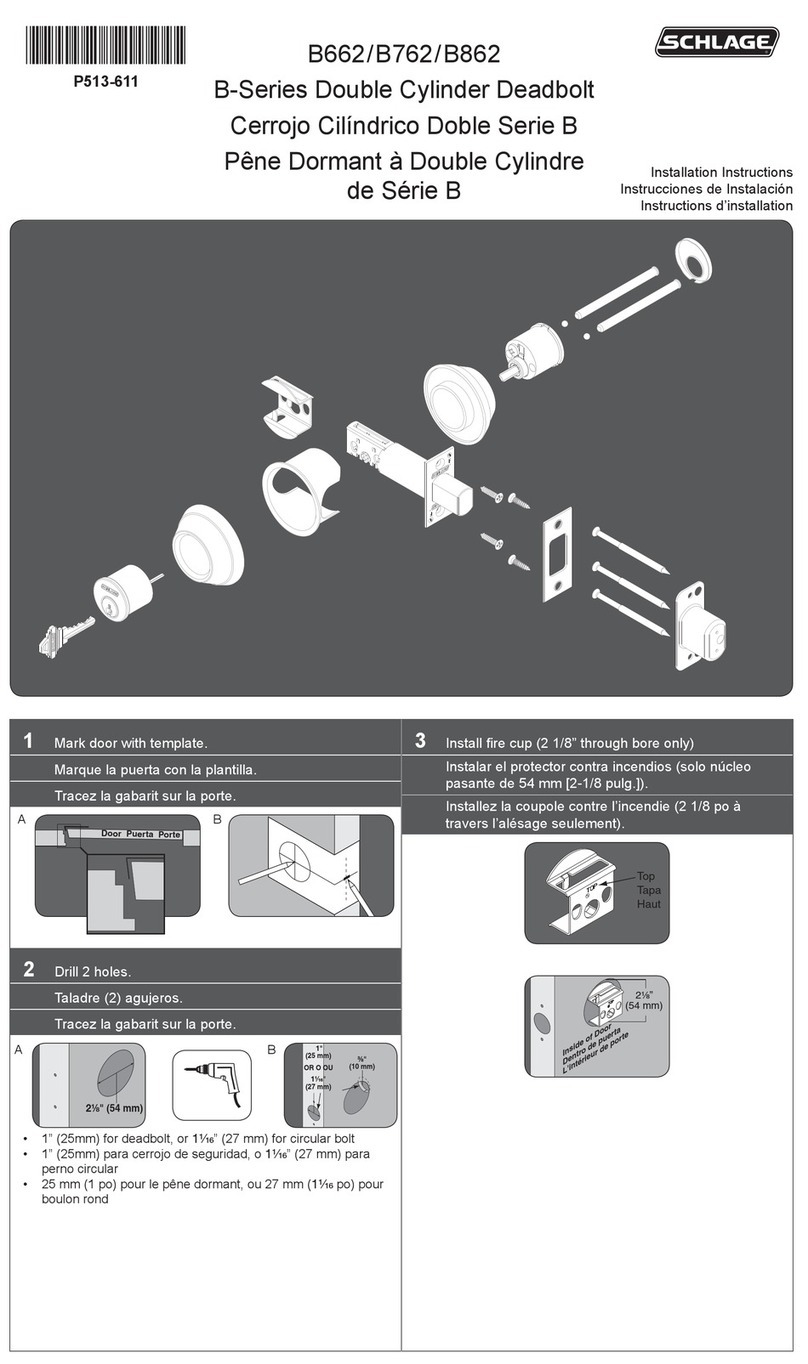

See Back Cover for:

- Door & Frame Prep

- Interchangeable Core Installation

- Tailpiece Installation

- Lock Timing: SFIC, Standard, & LFIC

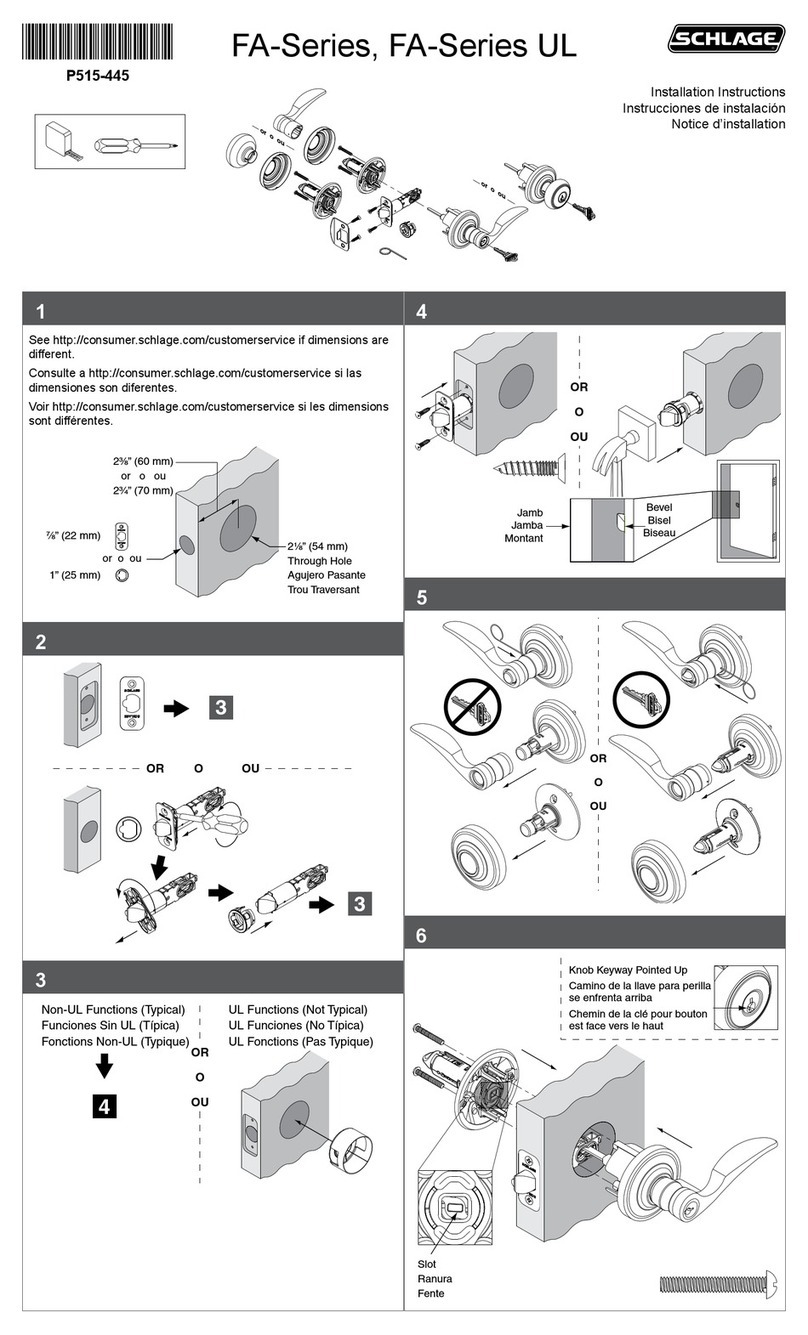

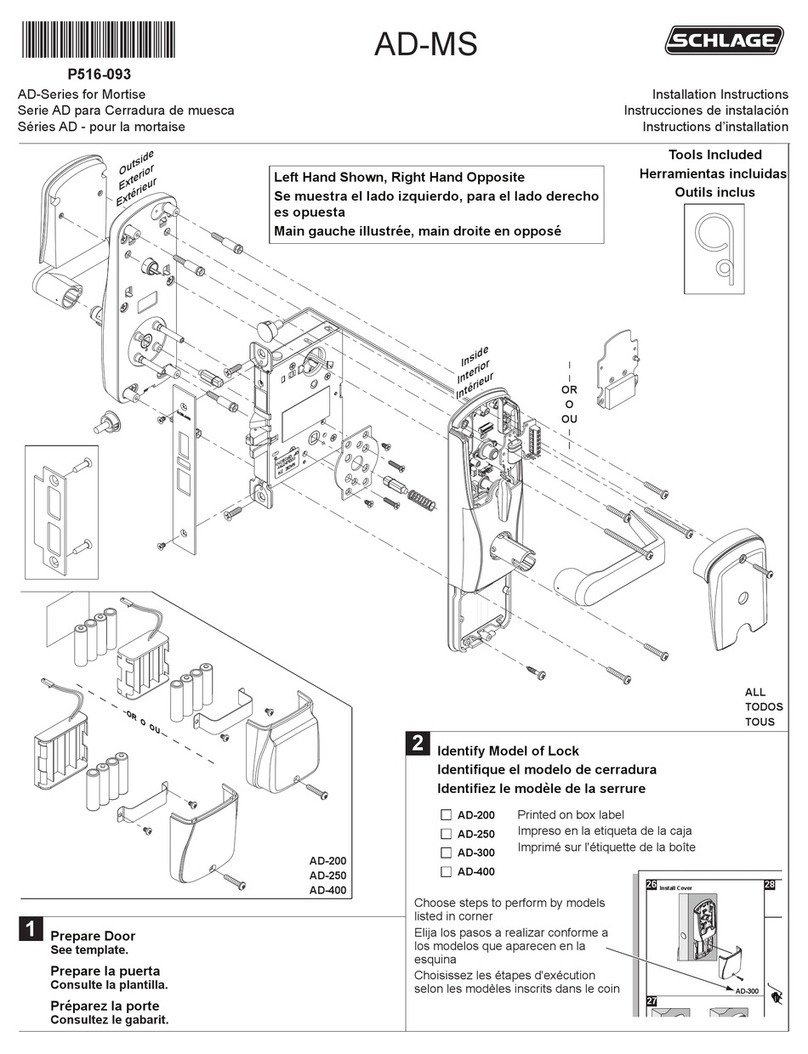

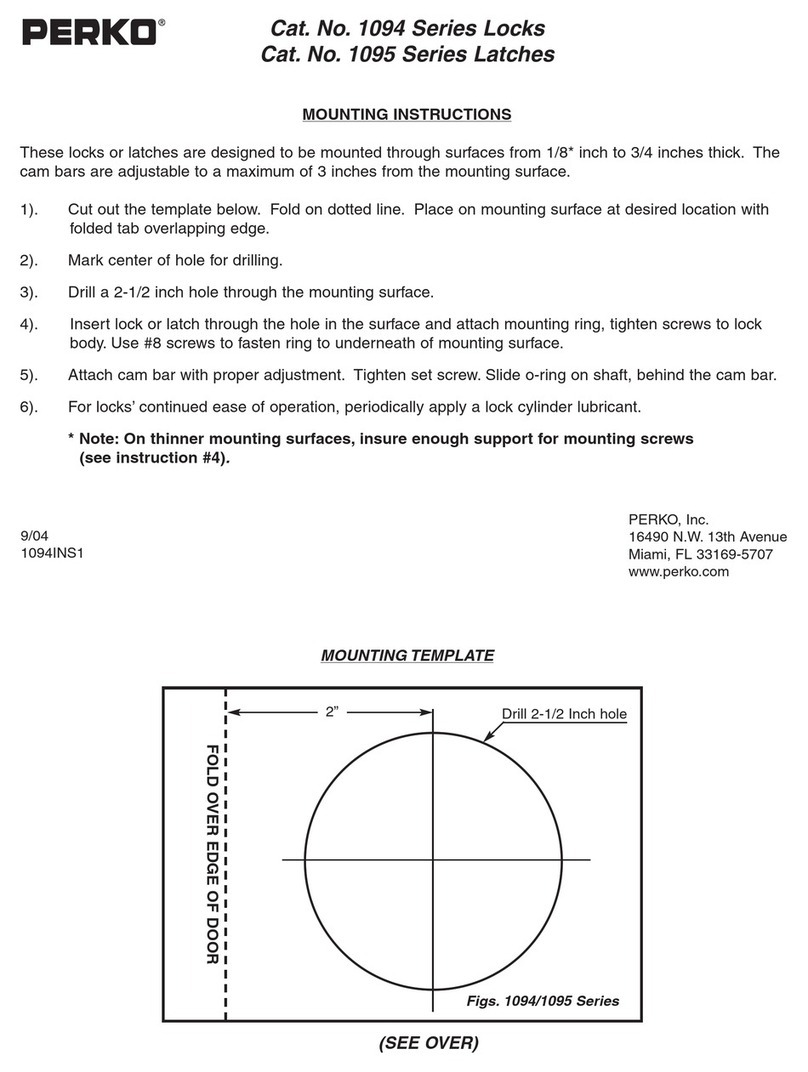

DOOR & FRAME PREP

WIRELESS ACCESS

MODULAR LOCKS

WA5200 & AUWA5200

CYLINDRICAL SERIES

OUTSIDE FRAMEDOOR EDGE

2-5/8"

(2.625")

[67mm]

INSIDE

C

LLever

5-3/4"

(5.750")

[146mm]

ø1/8"

(0.125")

[3mm]

1" Deep

[25mm]

6X

LH / LHR RH / RHR

C

L

2-3/4"

(2.750")

[70mm]

3"

(3.00")

[76mm]

2"

(2.00")

[51mm]

ø2-1/8"

(2.125")

[54mm]

THRU

ø5/16"

(0.313")

[8mm]

THRU

2X

C

LDoor

Contact

1-3/8"

(1.375")

[35mm]

1-5/8"

(1.625")

[41mm]

13/16"

(0.813")

[21mm]

2-3/4"

(2.750")

[70mm]

3/8"

(0.375")

[10mm]

3/4"

(.750")

[19mm]

1-5/16"

(1.313")

[33mm]

Top hole: For metal doors. Drill this side only.

Bottom hole: For wood doors. Drill thru.

13/16"

(0.813")

[21mm]

1-5/8"

(1.625")

[41mm]

#8-32

FH

Comb.

2X

ø1"

(1.000")

[25mm]

To intersect

2-1/8" hole.

ø3/4"

(0.750")

[19mm]

ø3/4"

(0.750")

[19mm]

To Intersect

Wire Hole

1-1/8 x 2-1/4"

(1.125 x 2.250")

[29mm x 57mm]

Depth = 3/16" (0.188") [5mm]

5-11/16"

(5.688")

[144mm]

1-1/4 x 4-7/8"

(1.250 x 4.875")

[32mm x 124mm]

Depth = 3/16" (0.188") [5mm]

15/16 x 3-5/8"

(.940 x 3.625")

[24mm x 92mm]

Depth =1- 1/8" (1.125") [29mm]

4-1/8"

(4.125")

[105mm]

#12-24

FHMS

2X

ø3/4"

(0.750")

[19mm]

Depth=2"

(2.000") [51mm]

1-1/4"

(1.250")

[32mm]

ø3/4"

(0.750")

[19mm]

11/16"

(0.688")

[17mm]

5/8"

(0.625")

[16mm]

LH / LHR RH / RHR

C

L

4"

(4.000")

[102mm]

5"

(5.000")

[127mm]

1-7/16"

(1.438")

[37mm]

ø1/8"

(0.125")

[3mm]

Depth=1" [25mm]

4X

Measure

backset

from center

of bevel.

2-3/4"

(2.750")

[70mm]

2-3/8"

(2.375")

[60mm]

C

LC

L

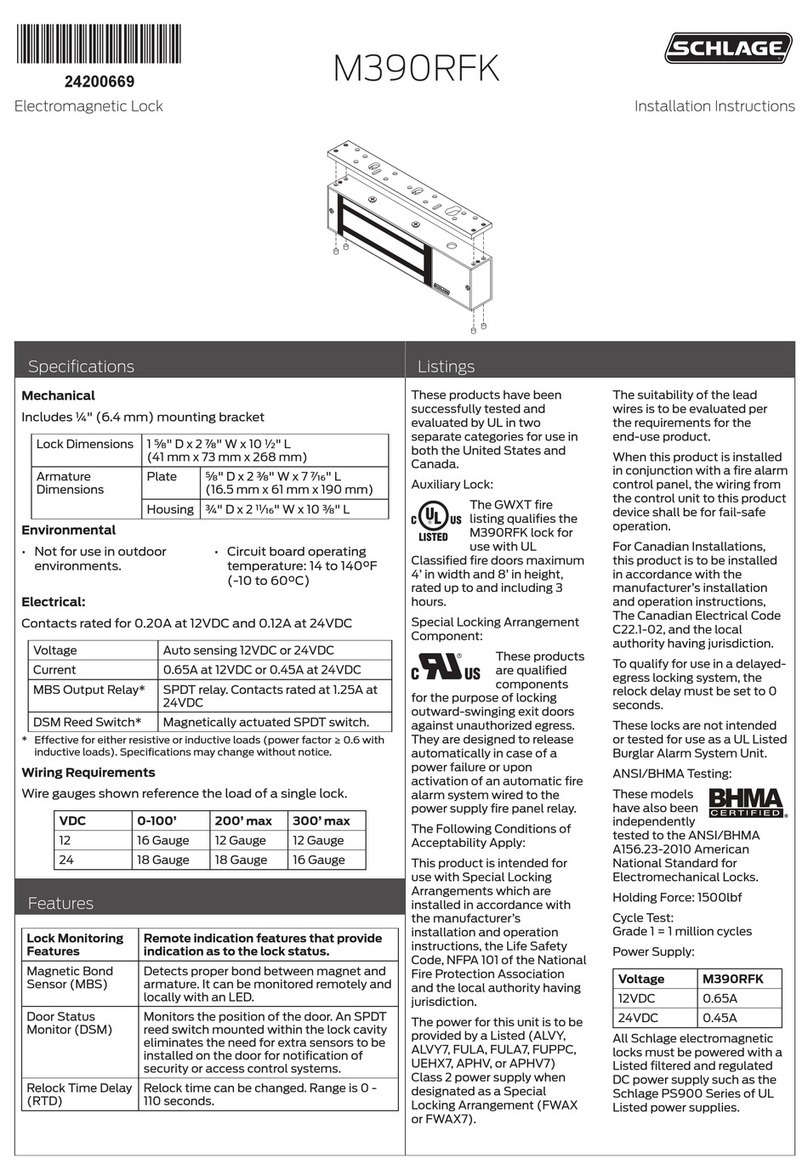

SFIC

(Small Format IC)

Install Interchangeable Core

FSIC: Insert key into core. Turn key 15° CW and

hold. Insert core into lever.

SFIC: Insert driver into back of core. Insert key

into core. Turn key 15° CW and hold.

Insert core into lever.

----

Install Tailpiece

(a) Remove Cyl. Cap. Depress

cap pin. Rotate cap CCW until off.

(b) Select Tailpiece. See below.

(c) Install Tailpiece. Place tailpiece

against back of cyl. Place cap over

tailpiece. Depress cap pin. Rotate

cap CW until tight.

FSIC

(Full Size IC)

b

a

a

b

c

Lock Timing- SFIC & Standard

(a) Insert key into cylinder. Rotate key

90 CW & hold.

(b) Insert push pin into lever hole.

Depress lever catch. Pull off lever.

(c) Rotate key 180 CCW. Slide lever

onto spindle.

°

°

Lock Timing - LFIC

(a) Remove core. Remove lever assembly

(refer to illustration on pages 2 and 3).

(b) Using provided driver tool, rotate driver

180° CW. Reinstall lock.

core

driver

core

15°

15°

N523-022

N523-023

a

b

c

Classic

Everest or Primus

cap pin cap

push

pin

cap

core

driver tool

(provided)

180°

90°

lever

catch

180°

FCC Compliance

s This device has been authorized by the FCC Rules and Industry Canada.

s This device complies with the limits for a Class B digital device and a

Class B intentional radiator, pursuant to Part 15 of the FCC Rules and with

RSS-210 of Industry Canada. Operation is subject to the following two

conditions: (1) This device may not cause harmful interference, and (2) this

device must accept any interference received, including interference that

may cause undesired operation.

s The Wireless Access System Component must be installed by qualified

professionals or contractors in accordance with FCC part 15.203, Antenna

Requirements.

s Do not use any antenna other than the one provided with the unit.

UL Compliance

w The WA5200 & AUWA5200 Wireless Access Cylindrical Locks are listed

under UL294 as an access control system accessory.

w The WA5200 & AUWA5200 Wireless Access Cylindrical Locks are listed

under UL10C.

w Access equipment manufactured and/or sold by Ingersoll Rand Security

Technologies is not rated for, or intended for use in life safety installations.

w For UL installations that use a Door Position Switch, use a UL listed

door/window contact. Door contacts for door position monitoring are not for

intrusion protection.

w No standby power provided.

w The WA5200's & AUWA5200's maximum current at 12 VDC is 250 mA.

Warnings

s RF Exposure - To comply with FCC RF exposure requirements for mobile

transmitting devices, this transmitter should only be used or installed at

locations where there is normally at least a 20 cm separation between the

antenna and all persons.

s Do not co-locate and operate in conjunction with any other antenna or

transmitter.

s Use only the Battery Pack specified in this instruction manual.

s Do not subject Battery Pack to fire or high temperatures.

s Do not attempt to recharge, short out or disassemble Battery Pack.

s Follow local regulations for alkaline battery disposal.

s Immediately remove the batteries and discontinue use if: the product is

impacted after which the interior is exposed, or the product emits a strange

smell, heat, or smoke.

s Changes or modifications not expressly approved by Ingersoll Rand

Security Technologies could void the user's authority to operate the

equipment.

Schlage Lock Company

575 Birch Street

Forrestville, CT 06010

technical support: 866-322-1237

web: www.irsupport.net