Becker FEP-1000/1500-CH Series Pilot Instruction Manual | 1

© 2021 Baker Hughes Company. All rights reserved.

Table of Contents

Page

Introduction ..........................................................................................................................1

Description...................................................................................................................1

Scope of Manual..........................................................................................................1

Model Number Explanation .........................................................................................1

Technical Assistance....................................................................................................1

Technical Information..........................................................................................................2

Advantages of the Combination Chamber FEP-CH Pilot............................................2

Technical Specifications...............................................................................................2

Materials of Construction.............................................................................................2

Applications .................................................................................................................2

Ordering Information...........................................................................................................3

FEP-CH Stock Numbers and Spring Ranges..............................................................3

Accessories..........................................................................................................................4

FSP Series Setpoint Change Pump ............................................................................4

RSM Series Remote Setpoint Module.........................................................................4

REM Remote Setpoint Module....................................................................................4

Setpoint Change Indicator ...........................................................................................4

NBV Series No Bleed Valve ........................................................................................4

Principles of Operation .......................................................................................................5

Pressure Reducing Regulator Mode ...........................................................................5

Backpressure Regulator Mode ....................................................................................5

Explanation of Droop ...................................................................................................7

Piping Schematics..........................................................................................................9-10

Downstream Pressure Control ....................................................................................9

Backpressure Control ................................................................................................10

Drawings........................................................................................................................11-12

FEP-1000/1500-CH Pilot Spring Chamber................................................................ 11

FEP-1000/1500-CH Sensing Chamber ..................................................................... 11

FEP-1000/1500-CH Body..........................................................................................12

FEP-1000/1500-CH Bottom Cartridge.......................................................................12

Assembly Procedures .................................................................................................13-19

List of Recommended Tools.............................................................................................20

Parts Silhouettes................................................................................................................20

Introduction

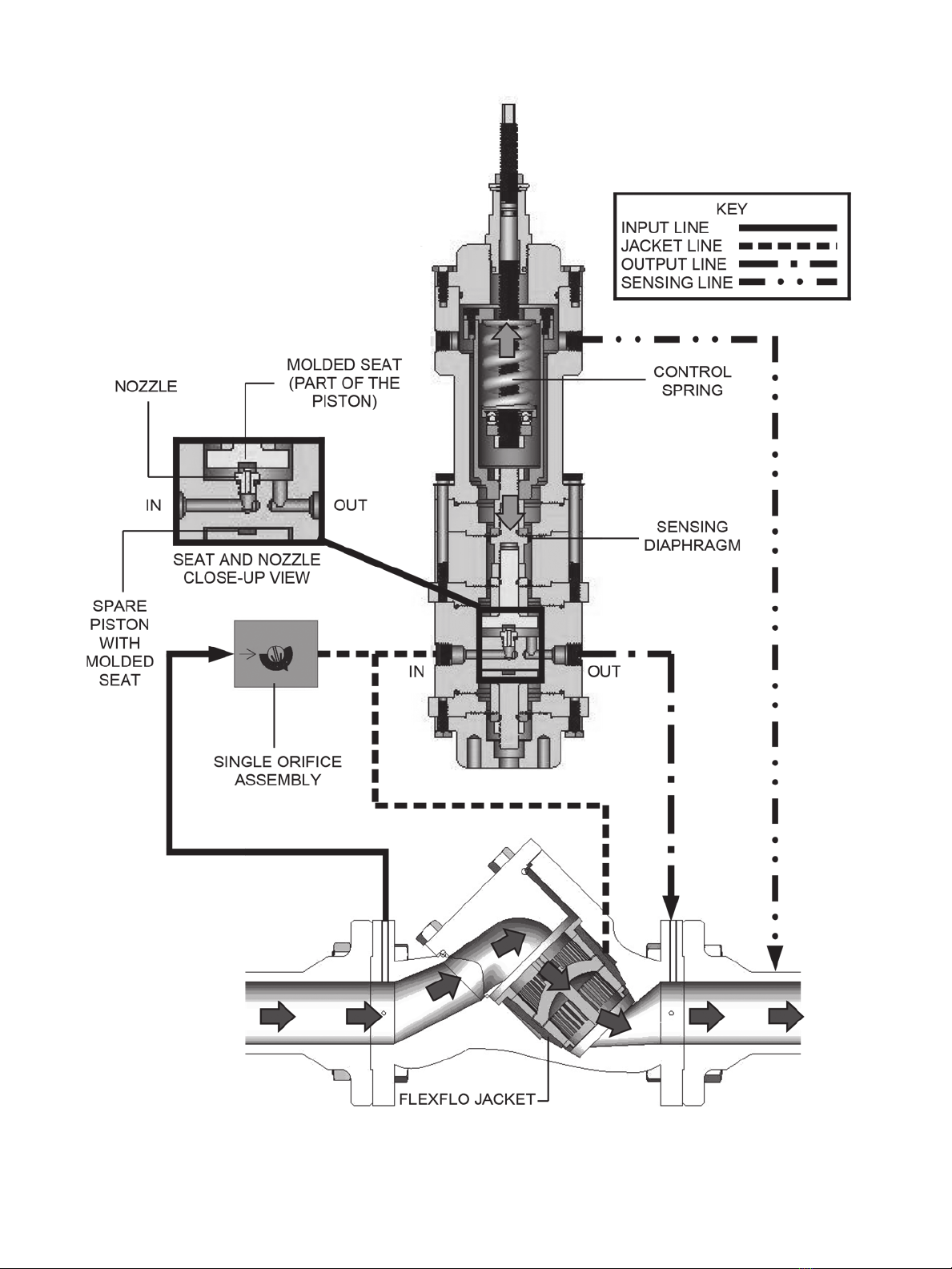

The Becker FEP-CH series single-acting pilot represents a

breakthrough in valve control technology for the natural gas

industry. Built to exacting specications, this easily maintained

unit offers highly accurate control characteristics over a wide

range of operating environments.

Description

The Becker FEP-CH single-acting pilot provides pressure

control when used with a boot or diaphragm style regulator. The

FEP-CH measures downstream sensing pressure and positions

the control element of the regulator to maintain the desired

downstream pressure. The FEP-1000/1500-CH pilot may be

used for pressure control applications with setpoints ranging

from 550 psig to 1500 psig. The FEP-CH design pilot represents

our commitment to continually develop new products and update

existing ones to increase their performance while retaining

simple operation and low maintenance.

Scope of Manual

This manual provides information on the installation, operation,

adjustment, and maintenance of the Becker FEP-1000/1500-

CH single acting pilot. For information concerning valves and

accessories, refer to the instruction manuals provided with the

specic product.

Model Number Explanation

The FEP-CH pilot is available in two different models to cover

sensing pressures from 550 psig to 1500 psig. The number

expressed in the FEP model designation is the maximum

sensing pressure; for example, a FEP-1500-CH has a maximum

sensing pressure of 1500 psig.

To nd your FEP model number, refer to the stainless steel tag

attached to your pilot by the 7/16 hex head cap screws.

Note: Only those qualied through training or experience

should install, operate, or maintain Becker positioners.

If there are any questions concerning these instructions,

contact your Baker Hughes sales representative, sales

ofce, or manufacturer before proceeding.

Technical Assistance

Should you have any questions, you may contact your local

Baker Hughes sales representative or technical assistance

at e-mail address appearing on the back cover page of this

Manual.