After contouring, attach the upper bar(s) and

stirrup(s) to the fabrication tool and insert into the

positive model. Create the orthotic shell using the

desired fabrication technique. If thermoforming,

or fabricating open pocket laminated shells (with

the bars under the PVA bag), back-ll the bars with

plaster where they contact the positive model. If

integrating the bars into a laminated shell, remove

the adapter plate from the tool. Slide the inner PVA

bag over the mold and apply vacuum. Place the

adapter plate on the tool, over the PVA bag, and

attach with screws going through the bag.

Step 4

After fabricating, remove the bars from the fabrication tool and wipe clean using a rag

with solvent. DO NOT grind or blast the bars where they attach to the component.

Protect the areas shown in red using tape before nishing the bars (Figure 1).

Step 5

Final Assembly

a. The upper bar must be t to

the component. Use a le, or ne

sanding cone to t the upper bar. The

upper bar should require moderate

pressure from a vise, or arbor press

to seat the bar into the bar pocket.

Failure to properly t the upper bar

may result in screw loosening. Apply a

small drop of thread locking adhesive

to the bar attachment screws

(included) and tighten. Use a torque

wrench to torque the bar attachment

screws to the value shown in Table 1.

Step 6

(continued)

DO NOT bend or

mar bars inside

the red boxes

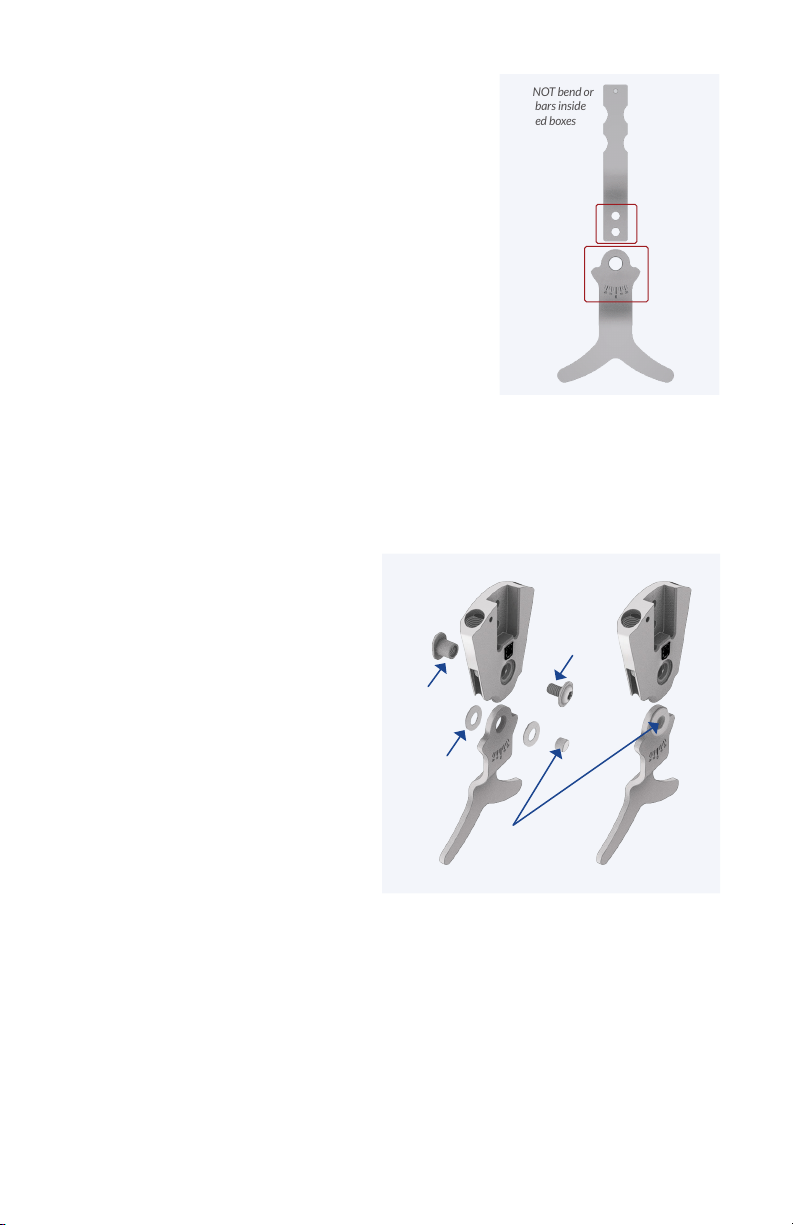

b. Install the MILINE stirrup with the selected thrust washers (included) to adjust

the mediolateral play of the component to the desired stability. Refer to Table 2

for thrust washers included by component size. After selecting the desired washer

thickness, use the thrust washer installation tool to hold the thrust washers in

alignment with the stirrup as it is pushed into the component body (Figure 2). When

the thrust washer installation tool is aligned with the pivot hole, install the pivot

bushing, pushing the thrust washer installation tool out of the pivot hole. Apply a

small drop of thread locking adhesive to the pivot screw and tighten. Use a torque

wrench to torque the pivot screw to the value shown in Table 1.

Figure 1

Figure 2

Pivot Screw

Pivot

Bushing

Thrust

Washer

Thrust Washer

Installation Tool