Becker VASF 1.120/1 User manual

Other Becker Water Pump manuals

Becker

Becker KVX 3.80 User manual

Becker

Becker VT 4.10 User manual

Becker

Becker Variair VASF 2.50/2-0.DC024 User manual

Becker

Becker VariAir VASF 2.50/1-0.AC115 User manual

Becker

Becker U 5.71 User manual

Becker

Becker KVT 3.140 User manual

Becker

Becker KVT 3.140 User manual

Becker

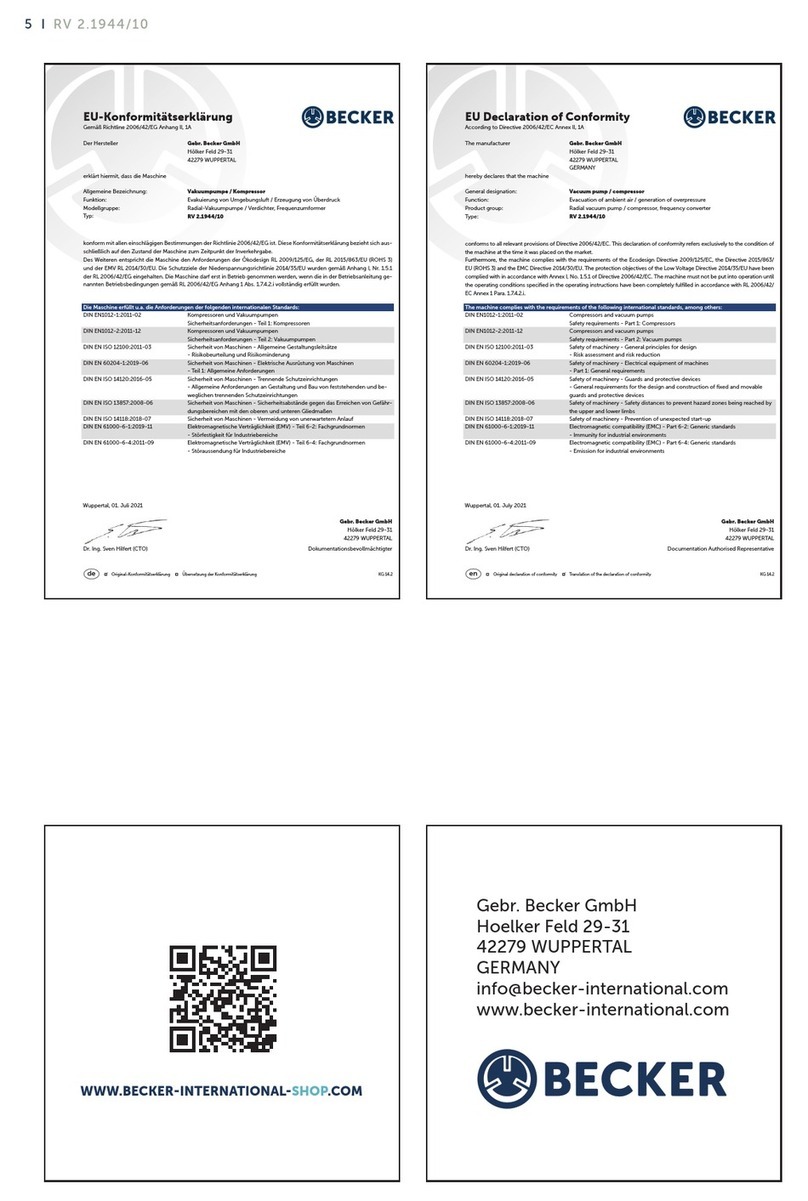

Becker RV 2.1944/10 User manual

Becker

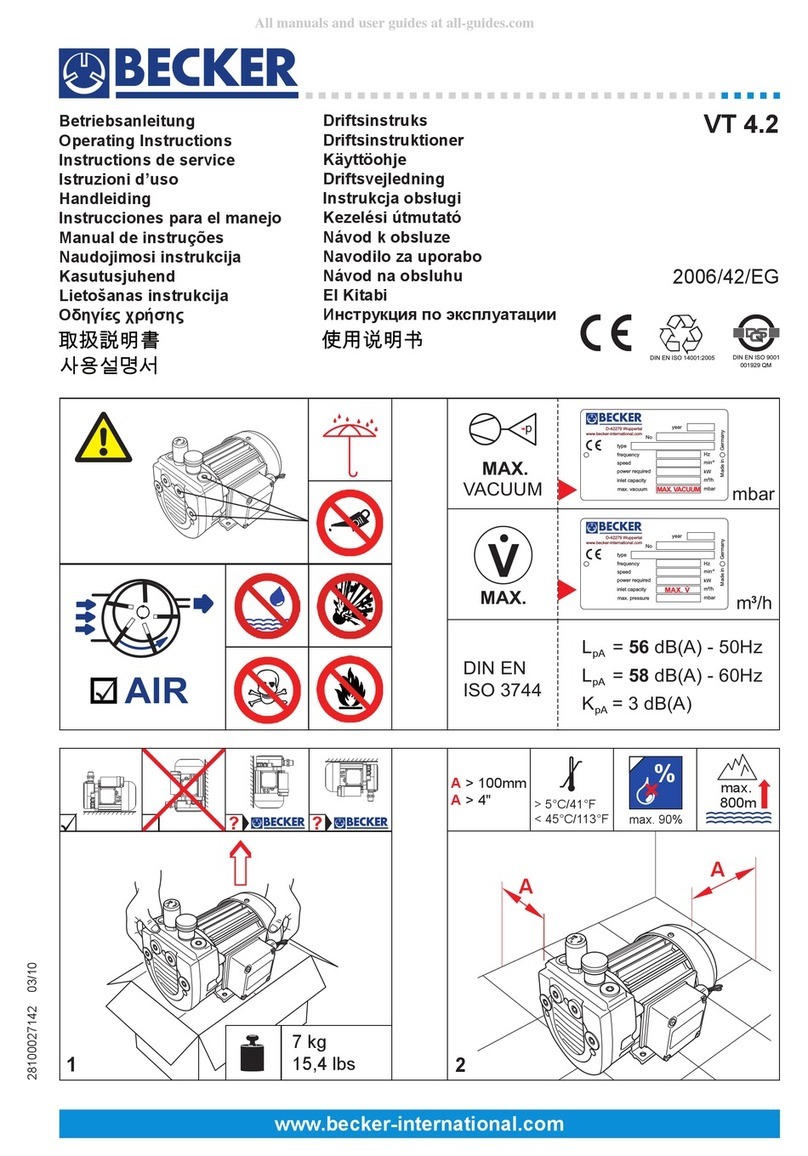

Becker VT 4.2 User manual

Becker

Becker KVT 3.100 User manual

Becker

Becker KVX 3.80 User manual

Becker

Becker VT4.25 User manual

Becker

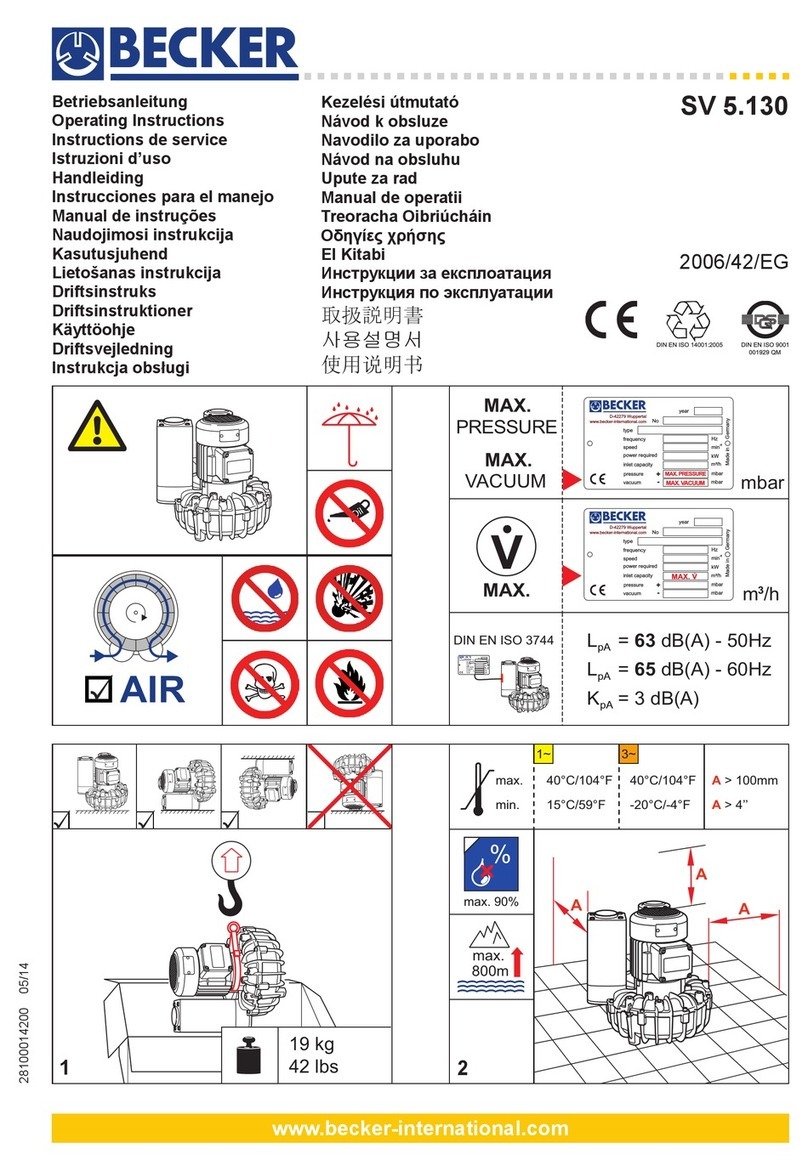

Becker SV 5.130 User manual

Becker

Becker VT4.25 User manual

Becker

Becker VT 4.40 User manual

Becker

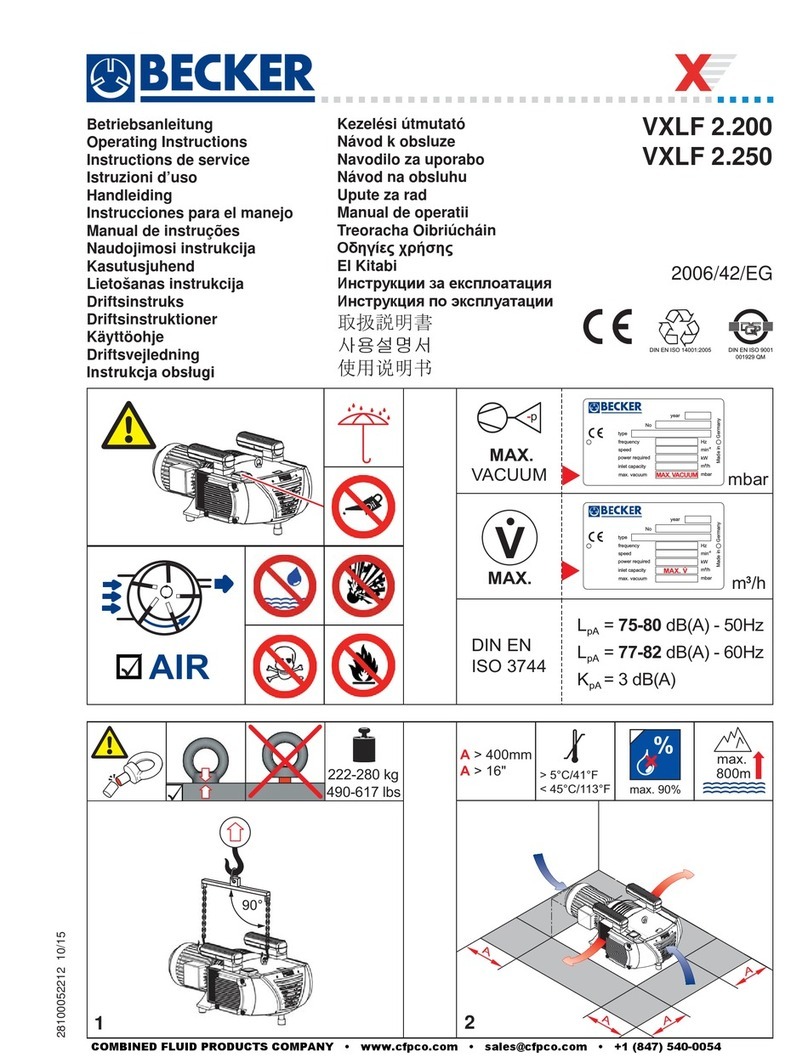

Becker VXLF 2.200 User manual

Becker

Becker Variair KVT 3.100 4 Series User manual

Becker

Becker U 5.201 User manual

Becker

Becker KDX 3.140 User manual

Becker

Becker VARIAIR VASF 2.50/1-0.DC024 BASIC User manual

Popular Water Pump manuals by other brands

BRINKMANN PUMPS

BRINKMANN PUMPS SBF550 operating instructions

Franklin Electric

Franklin Electric IPS Installation & operation manual

Xylem

Xylem e-1532 Series instruction manual

Milton Roy

Milton Roy PRIMEROYAL instruction manual

STA-RITE

STA-RITE ST33APP owner's manual

GÜDE

GÜDE HWW 900 GC Translation of the original instructions