16

Start the Burner

Burner start procedure

(Before proceeding, turn off and lock out electrical

power and close the main leak test cock to shut off gas

to the burner.)

With the power and main gas supply to the burner

turned off, make sure gas has not accumulated in the

boiler or flues.

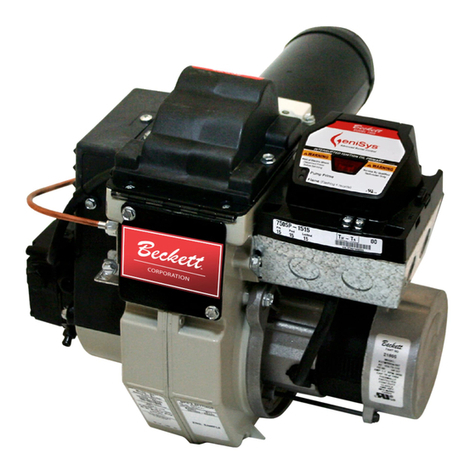

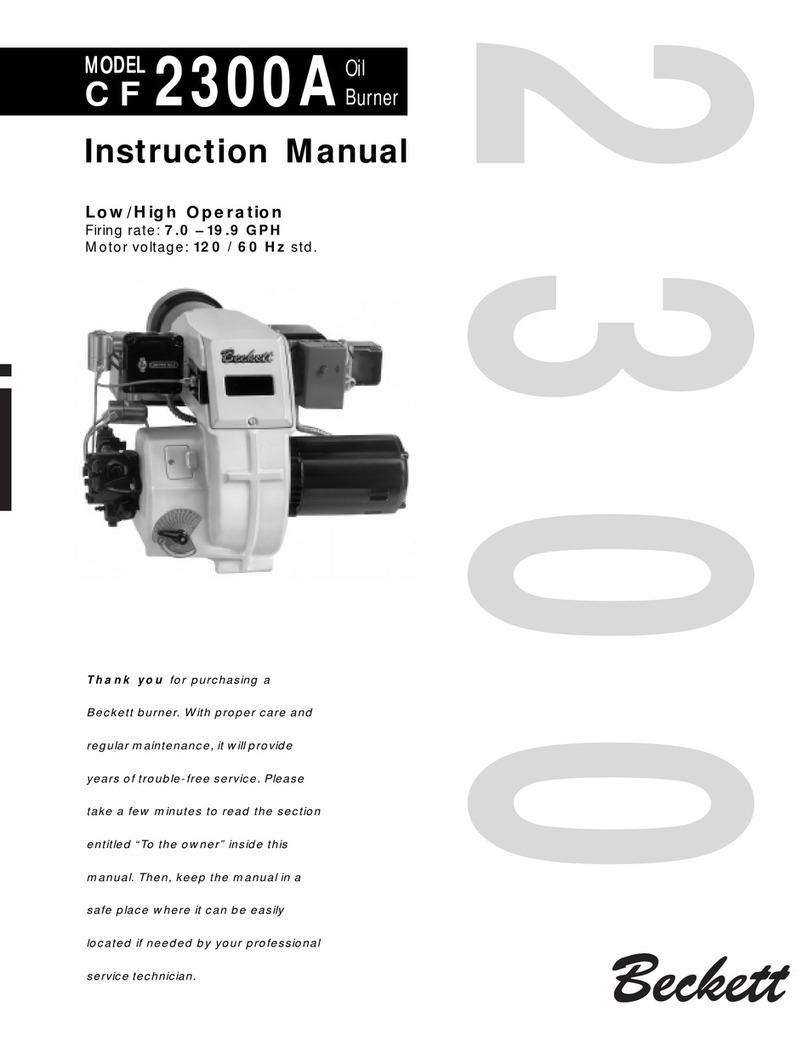

Check the initial air settings (shutter & band) for input

firing rate. Check the manufacturer’s settings either on

the nameplate shown in Figure 1 or listed in Table 2. If

adjustment is necessary refer to Figure 11 and loosen

the adjustment screws then twist the shutter and/or air

band until the indicators point to the values shown on

the nameplate or listed in Table 2.

With the main gas supply valve closed. Set the limit or

controller to call for heat then apply power to start the

burner. Reset the high and low gas pressure switches

if necessary.

In order to check the function of each component

(i.e: flame safeguard sequence, airflow proving

switch, ignition transformer, gas valves, safety lockout

timing, etc.), with the gas supply closed off, monitor

a complete burner run sequence. Note that the flame

safeguard control will lock out since the fuel supply has

been closed off.

If component operation sequence and function is

correct, reset the flame safeguard and initiate a new

cycle. Monitor the start-up cycle and manually open

1.

2.

3.

4.

5.

the main leak test cock as soon as the flame safeguard

powers the safety shutoff valves. If the boiler room is

quiet you may be able to hear the valve open, if not

you can generally place your hand on the valve and

feel it open. After you have observed main flame for

a brief time, trip any of the switches in the limit string

to shut the burner down. Monitor the flame and safety

shutoff valves to assure that shutdown is controlled by

the valves and that they operate properly. With this

test passed you may safely initiate automatic start-ups

on subsequent cycles.

Verify input firing rate

Clock the meter for CFH and calculate the

input firing rate. Compare the calculated rate to

the specified input for the boiler found on the

specification sheets and on the rating plates for

the burner and boiler. Do not exceed the specified

maximum input for the boiler.

Attach a manometer to the manifold test port, clock

the meter, and adjust the regulated pressure until the

specified input level is achieved. Refer to Table 2.

Be sure to set the breech or furnace pressure to the

correct value, since this will have an effect on the

manifold pressure.

1.

2.

3.

Section: Start the Burner

Professional Installation

and Service Required

Incorrect installation and mishandling

of start-up could lead to equipment

malfunction and result in asphyxiation,

explosion or fire.

This burner must be installed and prepared for start-

up by a qualified service technician who is trained

and experienced in commercial gas burner system

installation and operation.

Do not attempt to start the burner unless you are

fully qualified.

Do not continue with this procedure until all items in

the ‘Prepare the Burner for Start-up’ section have

been verified.

Carefully follow the wiring diagrams, control

instruction sheets, flame safeguard sequence

of operation, test procedures and all appliance

manufacturer’s directions that pertain to this

installation.

If any of these items are not clear or are unavailable,

call Beckett at 1-800-645-2876 for assistance.

y

y

y

y

y

Figure 11. Shutter and Band

ADJUSTMENT SCALE

(FOR SHUTTER AND BAND)

BAND INDICATOR MARK

SHUTTER INDICATOR

SHUTTER

(for low rate adjustments)

adjust this with band fully

CLOSED AIR BAND

(for high rate adjustments)

adjust this with shutter fully

OPEN

=

Tighten locking screws securely after adjustments have been made

◄

◄

◄

◄

The shutter and band both control

the amount of flow area available for

air inlet to the burner. The greater their combined flow area,

the higher the firing rate. The primary differences between

the two are their ease of adjustment and their total airflow

area. The shutter turns more easily and has a smaller net

flow area. As a result we have found the shutter to be better

suited for low rate adjustments, and the band better suited

for high rate adjustments. We recommend that at low rates

the band be left completely closed until the shutter has been

fully opened, and that for higher rates the shutter is left

completely open as the band is opened.