f

GENERAL IN FORMATION

FUEL UNITS & TUBING INSTALLATION

Burners are most commonly installed with a single stage fuel

unit. This fuel unit, when connected with a supply line only,

is satisfactory where the fuel supply is on a 'Ievel with, or

above the burner permitting gravity flow of oil. When it is

necessary to lift oil to the burner, a return line should be con-

nected between the fuel unit and tank. This requires insertion

of the "by-pass" plug into the fuel unit. If lift exceeds ap-

proximately 10 ft., a two-stage pump should be installed with

it return line.

When a rettlrnline is used, with either single or two-stage

pumps, air is automa!ically returned to the tank making the

unit self-purging.

Use of CCVItinuousruns of heavy wall copper tubing is recom.

mended. Always use flare fittings. Avoid use of fittings in inac.

cessible locations. Avoid running tubing against heating unit

and across ceiling or floor joists: If possible install under floor:

Specific information on piping, fuel unit connections, lift capa-

bilities, and tank installations is provided in the instructions

of the fuel unit manufacturer.

COMBUSTION AI R

Burner must be installed in area with adequate fresh air avail-

able to support combustion.

Appliances located in confined spaces: The confined space shall

be providad with two permanent openings, one near the top

of the enclosure and one near the bottom. Each opening shall

have a free area of not less than one square inch per 1,000

Btu per hour of the total input rating of all appliances in the

enclo'sl!re, freely communicating with interior areas having in

turn adequate infiltration from the outside.

WIRING

The wiring must be in accordance with the National Electric

Code and local codes and regulations.

Wiring diagrams are included in the heating unit installation

instructions.

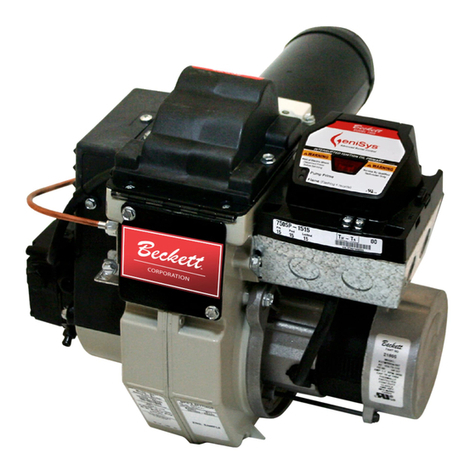

UPGRADING OR CONVERSION

ATTACHING AIR TUBE COMBINATION

(CHASSISPLAN ONLY)

If the air tube combination and oil burner chassis are pack-

aged separately, the assembly is completed as follows:

1.Attach air tube to burner housingusingfour sheet metal

screws. (If using an adjustable burner mounting flange, first

attach f.lange to air tube.) 2. Insert nozzle line electrode as.

sembly into tube and position nozzle from head, using 'Z'

dimension shown elsewhere in these instructions. Check to

be certain nozzle and head are concentric. 3. Secure escut-

cheon plate by tightening screw at side of housing. 4. Se-

cure nozzle line using bulkhead lock nut. When a knurled

lock nut is supplied, the recessed side is to face away from

burner housing. 5. Attach connector tube (from pump to

nozzle line). With long air tube combinations, insertion of

the nozzle line electrode assembly into the air tube is faci-

litated by rotating the assembly 1800 from its installed

position, inserting it partially into the air tube, and then

rotating it back to its proper position.

SETTING THE BURNER

Use a mounting flange or pedestal as required.

The end of the burner air tube should be %" back from

the inside surface of the front wall of the combustion

chamber.

Insulate around air tube to prevent overheating of tube,

nozzle and components. Make sure that insulation and

cement do not obstruct face of burner head.

IMPORTANT CAUTIONS

READ BEFORE STARTING

CAUTION:

STAINLESS STEEL COMBUSTION CHAMBERS

The higher temperature levels produced by high.perfornf'"'

flame retention burners may exceed the temperature ratin~

stainless steel combustion chambers and can result in chamber

burn-outs.

Where a burner upgrading is being made in a unit with a stainless

steel chamber, please observe at least one of these precautions:

1. Line the Chamber with a "wet-pac" ceramic liner.

2. Adjust inlet air to the burner so that the CO2 level is below

11%. Oil

Before starting the burner be sure fuel tank is adequately filled with

clean NO.1 or No.2 furnace oil. Crankcaseoil. wasteoil or GASOLINE

should neverbe used. Water.rust. or othercontaminationinthe fuel

supply system will cause malfunction and premature failure of the

internal parts of the fuel unit.

POWERCIRCUIT

Be sure that burner and controls are wired correctly and that the

line switch is properly fused (20 amp). In Canada wiring to be

done in accordance with the Canadian Electrical Code, Part I.

NOZZLE

Be sure that specified nozzle is installed and that any covering

over nozzle is removed prior to starting the burner.

NOZZLE AND ELECTRODE SETTING

Be sure nozzle and electrodes are positioned as shown elsewhere

in these instructions. Improper adjustment can resu It in oil im.

pingement or ignition difficulties. ~

AIR TUBE INSERTION ~

The burner head sholJlci bE:Y.,"back from the inside wall of the

combustion chamber. Under no circumstances should the burner

head extend into the combustion chamber.

FUEL UNIT

Besure that fuel unit is arranged for the type of oil supply system

installed. . . "One Pipe" or "Two Pipe". Be sure that all connec-

tions aretight.

Fuel units generally require manual venting of air when initially

started. Failure to vent the air from the fuel unit through the vent

plug provided may result in an air lock within the pump that will

prevent oil from being delivered to the nozzle. See also Fuel Unit

Manufacturer's instructions.

LINE OIL FILTER

Use an oil filter of generous capacity for all installations. Install

inside the building between the tank shutoff valve and the burner.

For ease of servicing, locate the filter and a shut-off valve close to

the oilburner.

Oil SHUTOFF VALVE

Install approved high quality shutoff valves in oil supply line in

accessible locations, one close to the tank and another close to oil

burner, but ahead of the filter. Note that some types of filters are

made with a built-in shutoff valve.

STARTING AND ADJUSTMENT PROCEDUR,",'

Caution: Do not attempt to start the burner when excess oil has

accumulated, when the furnace or boiler is full of vapour, or

when the combustion chamber is very hot.

1. Set thermostat substantially above room temperature.

2. Openshut-offvalves in the oil supply line to the burner.