Becx Machines OB90M User manual

Weed brush

Type: BECX OB90M

Version: 1

November 2019

Weed brush

OB90M

User manual

Weed brush

Type: BECX OB90M

Version: 1

November 2019

Page 2 of 24

Manufacturer Becx Machines B.V.

De Sonman 35

5066 GJ Moergestel

Tel: +31 (0) 13 2070760

http://www.becxmachines.com

© Copyright 2019

Nothing in this publication may be replicated and/or published in print, photocopy, microfilm, sound

recording, electronically or otherwise without the prior explicit written permission from Becx

Machines B.V.

Becx Machines B.V. retains the right to change parts of the system and the contents of this manual at

any time without prior notification giving or immediate notice to the customer.

Even though Becx Machines B.V. takes the greatest care to guarantee an accurate, and where

necessary, complete description of all parts, it cannot be held liable for damage due to inaccuracies

and/or deficiencies in this manual.

Weed brush

Type: BECX OB90M

Version: 1

November 2019

Page 3 of 24

Foreword

The Becx weed brush is specially developed to quickly and efficiently remove weeds growing in the

street. This machine can be mounted on virtually all wheel loaders/loaders. It makes it extremely

easy to brush or sweep the street.

•Please read this manual carefully before you use the weed brush.

Always observe the safety requirements as set out in Section 3.

•A copy of this manual must be kept with the weed brush and be

available to the user. All important maintenance work and relevant

notes must be recorded by the maintenance company.

•It is the user’s responsibility to select a suitable tool holder for the

weed brush and ensure that it is correctly attached and connected to

the arm.

Weed brush

Type: BECX OB90M

Version: 1

November 2019

Page 4 of 24

Table of contents

FOREWORD.................................................................................................................................. 3

TABLE OF CONTENTS .................................................................................................................... 4

OVERVIEW OF DIAGRAMS ............................................................................................................ 4

DECLARATION OF CONFORMITY (IIA) (COPY)................................................................................. 5

OVERVIEW OF SYMBOLS............................................................................................................... 6

1. TECHNICAL DETAILS............................................................................................................... 7

2SAFETY.................................................................................................................................. 8

2.1 GENERAL...................................................................................................................................... 8

2.2 DURING USE ................................................................................................................................. 8

2.3 OPERATING PERSONNEL:................................................................................................................. 8

2.4 WARNING SYMBOLS ON THE MACHINE .............................................................................................. 9

3DESCRIPTION OF COMPONENTS........................................................................................... 10

3.1 TOOL NESTING PLACE MECHANICAL COMPONENTS ............................................................................ 11

3.2 BRUSH MECHANICAL COMPONENTS ................................................................................................ 12

3.3 HYDRAULIC COMPONENTS ............................................................................................................ 13

4OPERATION......................................................................................................................... 14

4.1 READYING THE WEED BRUSH FOR USE ............................................................................................. 14

4.2 USING THE WEED BRUSH............................................................................................................... 15

5MAINTENANCE.................................................................................................................... 17

6MALFUNCTION ANALYSIS..................................................................................................... 19

7DISPOSAL ............................................................................................................................ 20

8LOGBOOK............................................................................................................................ 21

8.1 MAINTENANCE WORK,REPAIRS/REPLACEMENTS,MALFUNCTIONS AND INSPECTIONS .............................. 21

8.2 REPAIRS /REPLACEMENTS............................................................................................................. 22

8.3 MALFUNCTIONS .......................................................................................................................... 23

8.4 INSPECTIONS............................................................................................................................... 24

Overview of diagrams

FIGURE 1: OVERVIEW PHOTO....................................................................................................................... 10

FIGURE 2: OVERVIEW OF TOOL NESTING PLACE MECHANICAL COMPONENTS ........................................................ 11

FIGURE 3: OVERVIEW OF BRUSH MECHANICAL COMPONENTS ............................................................................ 12

FIGURE 4: OVERVIEW OF HYDRAULIC COMPONENTS......................................................................................... 13

Weed brush

Type: BECX OB90M

Version: 1

November 2019

Page 5 of 24

Declaration of conformity (IIa) (copy)

We:

Becx Machines B.V.

De Sonman 35

5066 GJ Moergestel

declare entirely under our own responsibility that the product:

Description :Becx Weed brush.

Type : BECX OB90M

Serial number :…….....................

with respect to this declaration, conforms to the provisions of the Directives:

Machinery directive 2006/42/EC

In accordance with the following standards:

NEN-EN-12100-1 Safety of machinery. Basic concepts, general principles for design.

Part 1: Basic terminology, methodology

NEN-EN-12100-2 Safety of machinery. General concepts for design. Part 2: Technical

principle and descriptions

NEN-EN 14121-1 Safety of machines –Risk assessment –Part 1: Principles

Director, Erwin Hommen

The Netherlands, Moergestel,

Date: .........................

Weed brush

Type: BECX OB90M

Version: 1

November 2019

Page 6 of 24

Overviewof symbols

All actions and situations risking the safety of the operator and/or technician and where actions must be

carried out carefully will refer to the following symbols in this user manual:

Take note!

Explanation.

Weed brush

Type: BECX OB90M

Version: 1

November 2019

Page 7 of 24

1. Technical details

Description

Value

Unit

General

Sound pressure

See tool holder

dB(A)

Vibration level during normal use

N/A

Physical data

Min. width

1100

mm

Max. width

1630

mm

Length

1415

mm

Height

600

mm

Dead weight

+/- 152

kg

Attachment details

Front side

Depending on the type of tool holder

-

-

Force on the attachment point

1,520

N

Suspension torque

+/- 890

Nm

Connection details

Maximum operating pressure

250

bar

Maximum RPM for brush

210

-/min

Nominal RPM

+/- 225

-/min

Maximum oil flow

60

L/min

Required oil flow for proper results

30

L/min

Brush motor connections

Pressure line connection

15L

Return line connection

15L

Leak line connection

12L

Maximum pressure on the leak line

no pressure

bar

Hydraulic oil

Requirements for filtering hydraulic oil

10

micron

Oil for the drive

HV-46 or

equivalent

Weed brush

Type: BECX OB90M

Version: 1

November 2019

Page 8 of 24

2Safety

2.1 General

•The weed brush may not be modified.

•It is the user’s responsibility to ensure that the correct tool holder is used (see

Section 1:Technical details). To this end, the following points are important:

•The maximum pressure and rotational speed (oil flow) must not be

exceeded. Exceeding these limits may damage the installation and injure

bystanders.

•The tool holder must be sufficiently strong and stable enough to bear the

forces and torques caused by the weed brush in all circumstances.

2.2 During use

•Consult the manual for the tool holder and the additionally attached options

to look up the resulting sound load. As the specified nominal RPMs is

significantly higher than the sound produced by the weed brush, the sound

load from the tool holder is leading.

•The installation may only be used for the work activities it is designed for.

•If people or animals approach or enter the safety zone, the weed brush and

the work activities must be stopped immediately.

•If passers by constantly interrupt the work activities too much, consideration

should be given to fencing off the work area.

•If the weed brush begins to make a different sound and/or starts to vibrate,

the work and the weed brush must be immediately stopped (see 4.2). The

work must not restart until the cause is found and resolved. .

•Inspection and maintenance work must be carried out.

•During inspection and maintenance, the installation must not be used for

other purposes.

•During inspection, maintenance, or cleaning, the hydraulic feed to the weed

brush must be disconnected to prevent it being accidentally switched on.

•The local work and safety regulations must be observed.

•If the installation is to be used in the dark, sufficient lighting must be used

(approx. 50 lux on the place of operation).

•To prevent damage to the installation, the device must be gradually switched

off using the lowest RPMs. Depending on the tool holder used, this is idling

speed or the minimal flow.

2.3 Operating personnel:

•Operating personnel must be older than 18 years of age.

Weed brush

Type: BECX OB90M

Version: 1

November 2019

Page 9 of 24

•Only individuals authorized by the owner may work on or with the installation.

•Operators may only perform work activities that they are trained for. This

applies to both the maintenance work and normal usage.

•The operating personnel must be acquainted with all situations that can

occur.

•If the operating personnel discover faults or risks or do not agree with the

safety measures, this must be reported to the owner or person in charge.

2.4 Warning symbols on the machine

1.

Read the manual before you use the machine!

2.

safety zone

Weed brush

Type: BECX OB90M

Version: 1

November 2019

Page 10 of 24

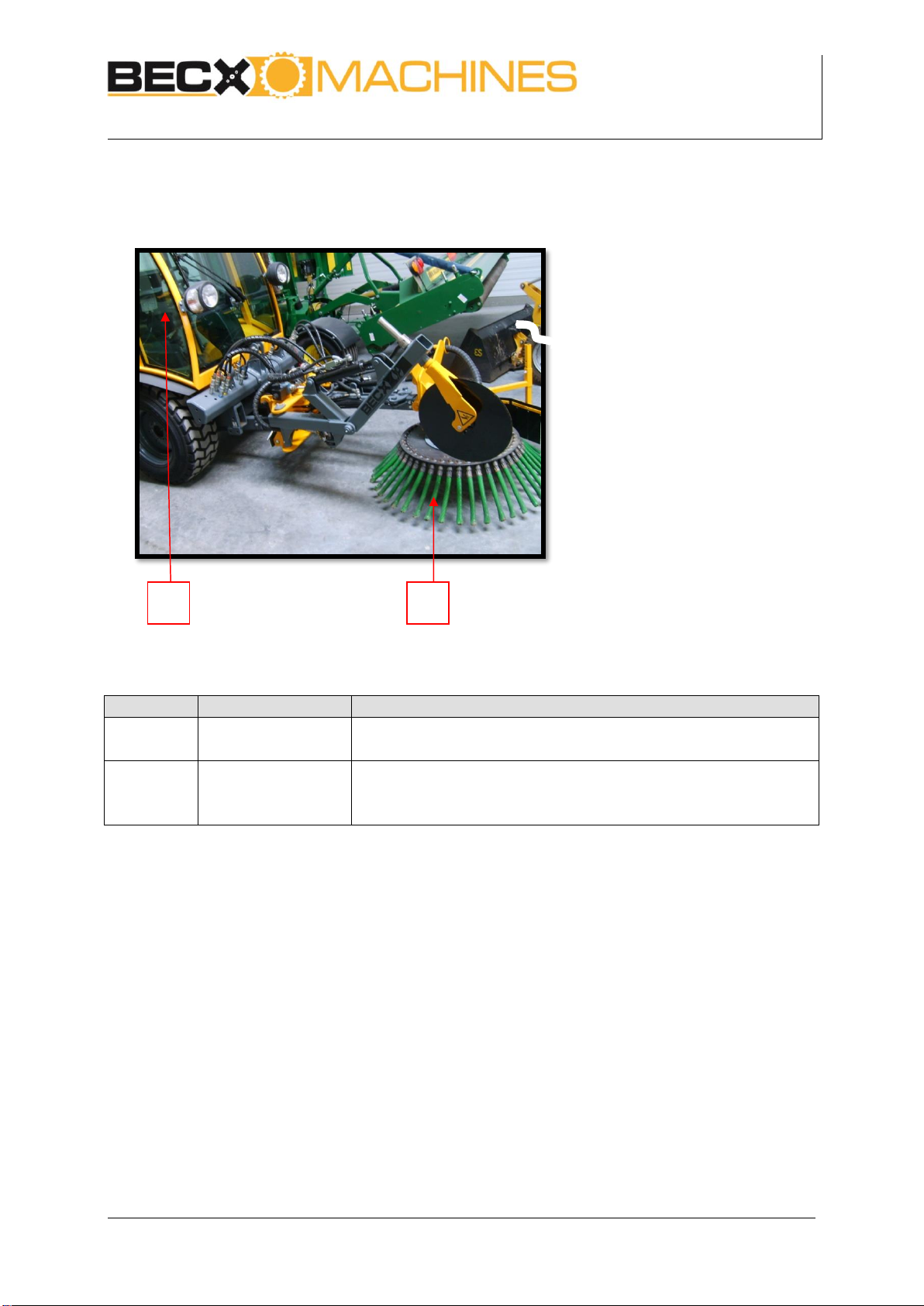

3Descriptionof components

Figure 1: Overview photo

Figure 1

Element

Explanation

1

Brush

•The brush sweeps away the weeds so that these are

completely removed from the ground.

2

Tool holder

•The tool holder is not part of the delivery. It is the user’s

responsibility to ensure that a suitable tool holder is used for

the weed brush.

1

2

Weed brush

Type: BECX OB90M

Version: 1

November 2019

Page 11 of 24

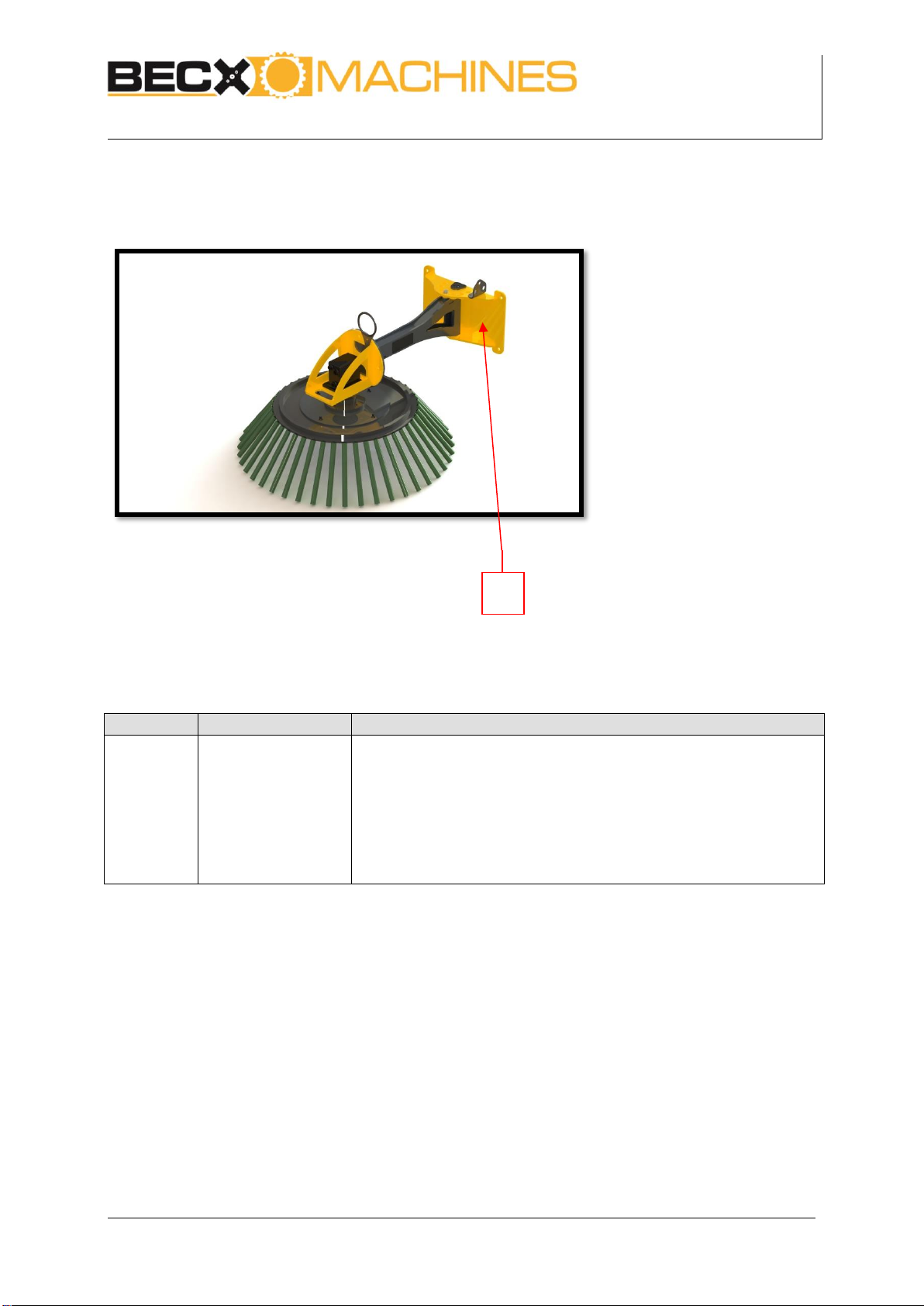

3.1 Tool nesting place mechanical components

Figure 2: Overview of tool nesting place mechanical components

Figure 2

Element

Explanation

1

Tool nesting place

•The unit is fastened to the tool holder using an adapter

(Figure 2:1).

•The type of adapter and its fastening in the tool holder is

dependent on the type of tool holder.

•The up and down movement is achieved by controlling the

tool nesting place. The is not part the brush arm, but part of

the tool holder.

1

Weed brush

Type: BECX OB90M

Version: 1

November 2019

Page 12 of 24

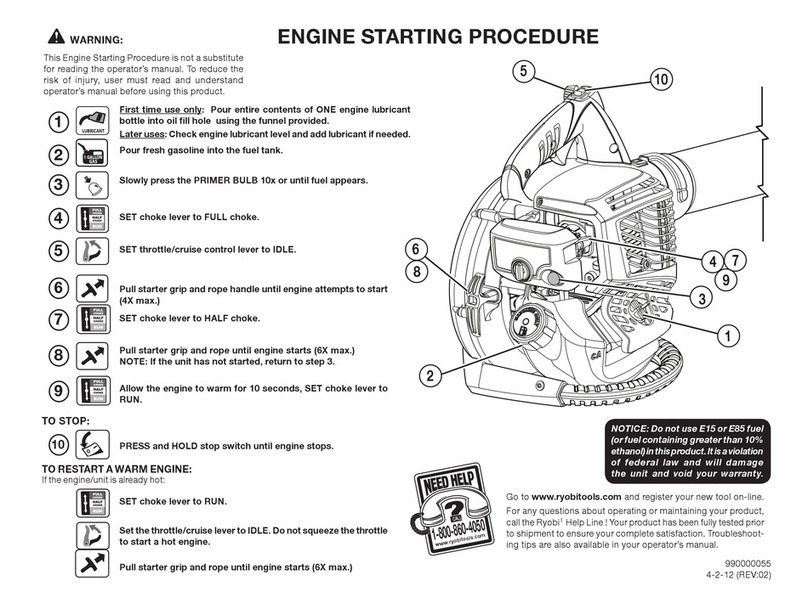

3.2 Brush mechanical components

Figure 3: Overview of brush mechanical components

Figure 4

Element

Explanation

1

Width position

adjustment point

•The brush position can be manually adjusted using the

adjusting pin. (

•Figure 3:1)

2

Brush attachment

•If the brush is worn, it can be easily replaced. To do so, the

insert nuts must be loosened and removed. The brush can

then be removed from the holder. (Figure 4:2)

3

Brush angle

adjustment

•The angle in which the brush must clean the streets can be

manually adjusted using three bolts that can be moved (

•Figure 3:3).

2

3

1

Weed brush

Type: BECX OB90M

Version: 1

November 2019

Page 13 of 24

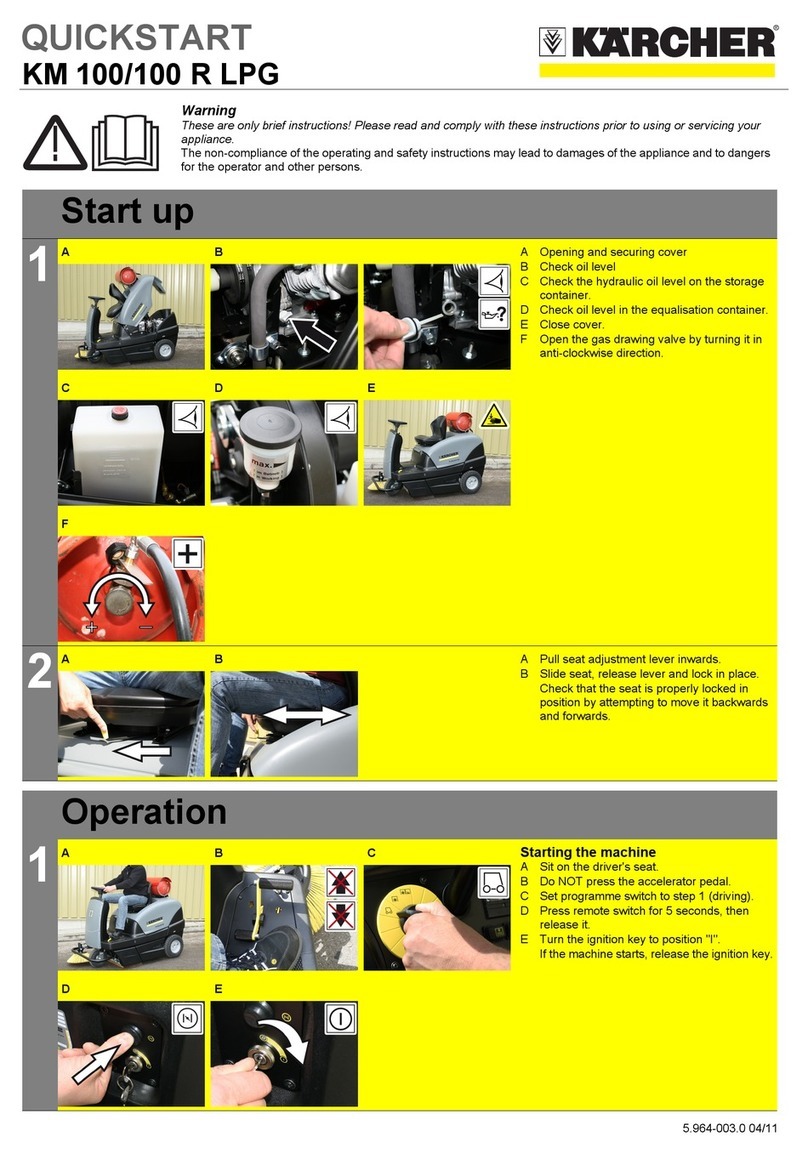

3.3 Hydraulic components

Figure 4: Overview of hydraulic components

Figure 3

Element

Explanation

1

Brush hydraulic

motor

•The hydraulic motor has a connection for a supply line, a return

line, and a leak line. (Figure 5:1)

2

By-pass valve

•To prevent damage to the hydraulic motor, the hydraulic motor

slows down using this valve.

1

1

Weed brush

Type: BECX OB90M

Version: 1

November 2019

Page 14 of 24

4Operation

4.1 Make the weed brush ready for use

No.

What to do

Action

Result

1

Select the correct tool

holder.

•Ensure that the tool holder is sufficiently

strong and stable enough for the weed

brush (see Section 1:Technical details for

the unladen weight, the load in the nesting

place, and the resulting torque in the

nesting place).

•Ensure that the maximum pressure and

rotational speed (oil flow) cannot be

exceeded.

•Ensure the correct quick-release couplings

are attached for the supply, return, and

leak lines.

•Ensure that the correct adapter is

attached.

Not respecting the

specified limits may

damage the

installation and

injure bystanders.

2

Connect the hoses

•Connect the quick-release couplings for the

supply, return, and leak lines.

•See the tool holder manual for the correct

connection positions.

3

Adjust the oil supply.

•Adjust the generator for the tool holder so

that the maximum pressure and rotational

speed cannot be exceeded.

•This depends on the type of tool holder

used. See the tool holder manual.

4

Adjust the brush to

the desired position

•Various settings allow the brush to be

adjusted so that the optimal setting is

achieved for the tool holder and operator.

Weed brush

Type: BECX OB90M

Version: 1

November 2019

Page 15 of 24

4.2 Using the weed brush

No.

What to do

Action

Result

1

Check the installation

•Check the following points:

•Check the rotational speed of the brush

motor. In practice, 50% of the capacity

(30 liters) is sufficient for decent results.

•Check that the brush motor runs without

vibration and there are no irregular

sounds.

•If one of the above checks discovers a

deficiency, it must first be rectified before

the weed brush can be used.

2

Drive to the work

area

•Always switch off the brush motor when it

is not being used.

3

Switch on the brush

motor

•For detailed instructions, see the tool

holder manual.

•To prevent damage to the installation, it is

important that the weed brush is gradually

switched on or off using the lowest RPMs.

Once the installation is switched on, the

RPMs can be increased.

Switching on or off

at high RPMs causes

high loads on the

installation.

4

Adjust the brush to

the desired position

•Use the width setting and the height

setting to achieve the correct brush

position. For detailed instructions, see the

tool holder manual.

•Check that no one is in the work area.

5

Brushing

•Drive with the tool holder over the street.

6

Stop in the following

situations!

•The weed brush and the work activities

must be stopped immediately in the

following situation:

•People or animals are present in the

work area. The driver must make this

assessment.

•The weed brush starts making a

different sound or starts to vibrate.

If you do not stop

promptly in the

above situations, it

may lead to serious

injury.

Weed brush

Type: BECX OB90M

Version: 1

November 2019

Page 16 of 24

No.

What to do

Action

Result

7

Switch off the weed

brush

•Once the work activities are complete,

switch off the weed brush. For detailed

instructions, see the tool holder manual.

•To prevent damage to the installation, it is

important that the weed brush is gradually

switched on or off using the lowest RPMs.

Once the installation is switched on, the

RPMs can be increased.

Switching on or off

at high RPMs causes

high loads on the

installation.

Weed brush

Type: BECX OB90M

Version: 1

November 2019

Page 17 of 24

5Maintenance

•Components may only be replaced or repaired using components delivered by

or approved by the manufacturer.

•If work activities will be carried out on the installation, the weed brush must

always be disconnected from the power supply. You can do so using the quick-

release couplings.

•Only trained and/or experienced individuals who can demonstrate they have

sufficient knowledge of mechanical and hydraulic installations may perform

the maintenance work.

•The installation may be spray cleaned using a high-pressure jet cleaner.

However, never spray the hydraulic components.

Weekly maintenance

No.

What to do

Action

Result

1

Lubricate pivot points

•Spray grease in the grease nipples. These

are located:

•at all of the articulating points.

2

Tighten bolts

•Check the fastener bolts.

3

Visual inspection

•Visually inspect the structure and the

hydraulic installation for damage and

cracks.

4

Retighten adjusting

bolts

•Whitin 4 working hours, tighten the set

screws of the clamping sleeve mouting on

the motor shaft and then check it regularly!

(45NM) See image on page 18

Weed brush

Type: BECX OB90M

Version: 1

November 2019

Page 18 of 24

Image of clamping sleeve bottom of brush head.

Yearly maintenance

No.

What to do

Action

Result

1

Inspect

•Check the following parts for damage,

cracks, and play:

•The tubes and sleeves of the width

setting.

•The bearing and seal.

Weed brush

Type: BECX OB90M

Version: 1

November 2019

Page 19 of 24

6Malfunction analysis

Malfunction

Solution

1

After switching on, the brush

motor does not rotate

•Check that the hydraulic hoses are connected.

2

The machine works, but has no

or insufficient brush force.

•Check that the motor rotation direction is correct. If this

is not the case, you can change it using the quick-release

coupling to switch the pressure and return hoses.

If you cannot resolve the malfunction using the recommendations in the above table, consult with

your dealer or maintenance department.

Weed brush

Type: BECX OB90M

Version: 1

November 2019

Page 20 of 24

7Disposal

When replacing components or at the end of the lifespan, ensure that all materials are disposed of,

destroyed, or reused in a “legally” responsible and environmentally friendly manner.

Table of contents