en

7

1

SAFETY RULES

Basic Safety Precautions

• Read this manual carefully until you completely understand

and can follow all safety rules, precautions, and operating

instructions before attempting to use the unit.

• Restrict the use of your blower to adult users who understand

and can follow safety rules, precautions, and operating

instructions found in this manual. Minors should never be

allowed to use a blower.

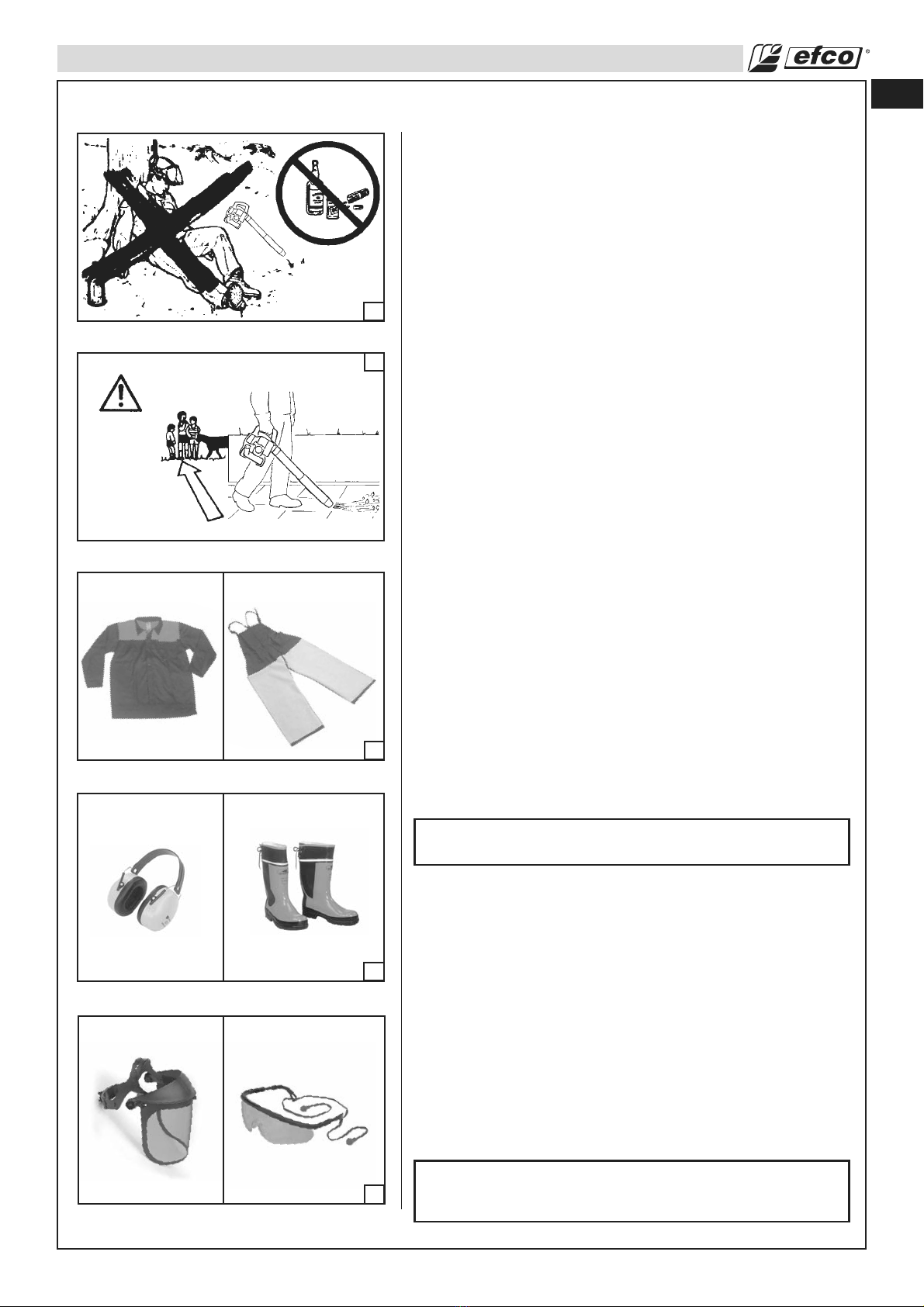

• Do not handle or operate a blower when you are fatigued, ill,

or upset, or if you have taken alcohol, drugs, or medication.

You must be in good physical condition and mentally alert.

Blower work is strenuous. If you have any condition that might

be aggravated by strenuous work, check with your doctor

before operating a blower (Fig. 1). Be more cautious before

rest periods and towards the end of your shift.

• Keep children, bystanders, and animals a minimum of 35 feet

(10 meters) away from the work area. Do not allow other

people or animals to be near the blower when starting or

operating the blower (Fig. 2).

• While working with the blower, always use safety protective

approved clothing. The use of protective clothing does not

eliminate injury risks, but reduces the injury effects in case of

accident. Consult your trusted supplier to choose equipment in

compliance with legislation. The clothing must be proper and

not an obstacle. Wear adherent protective clothing. Protective

jackets (Fig.3) and dungarees (Fig.3) are ideal. Do not wear

clothes, scarves, ties or bracelets that get stuck in wood or

twigs. Tie up and protect long hair (example with foulards, cap,

helmets, etc.). Wear safety boots having skid-proof sole

and anti-piercing insert (Fig.4). Wear protective goggles

or face screens (Fig.5). Use protections against noises: for

example noise reduction ear guards (Fig.4) or earplugs.

The use of protections for the ear is very important, because

the perception of danger audio signals (screaming, alarms,

etc.) is limited. Always remove your hearing protection as

soon as the engine stop. Wear gloves (Fig.6, page 8) that

permit the maximum absorption of vibrations.

WARNING – Wear face mask when operating the

blower in dusty environments.

• Only loan your blower to expert users who are completely

familiar with blower operation and correct use. Give other

users the manual with operating instructions, which they have

to read before using the blower.

• Check the blower each day to ensure that each device,

whether for safety or otherwise, is functional.

• Never use a damaged, modified, or improperly repaired or

assembled blower. Do not remove, damage or deactivate any

of the safety devices.

• Carefully plan your blowing operation in advance. Do not start

blowing until you have a clear work area, secure footing.

• All blower service, other than the operations shown in the present

manual, have to be performed by competent personnel.

• It is unadvisable to hitch tools or applications to the P.t.o. that

are not specified by the manufacturer.

WARNING - The blower may throw objects at high

velocity that can ricochet and hit the operator. This may

cause serious eye damage. Always wear eye protection.

2

3

4

5

≥ 35 ft