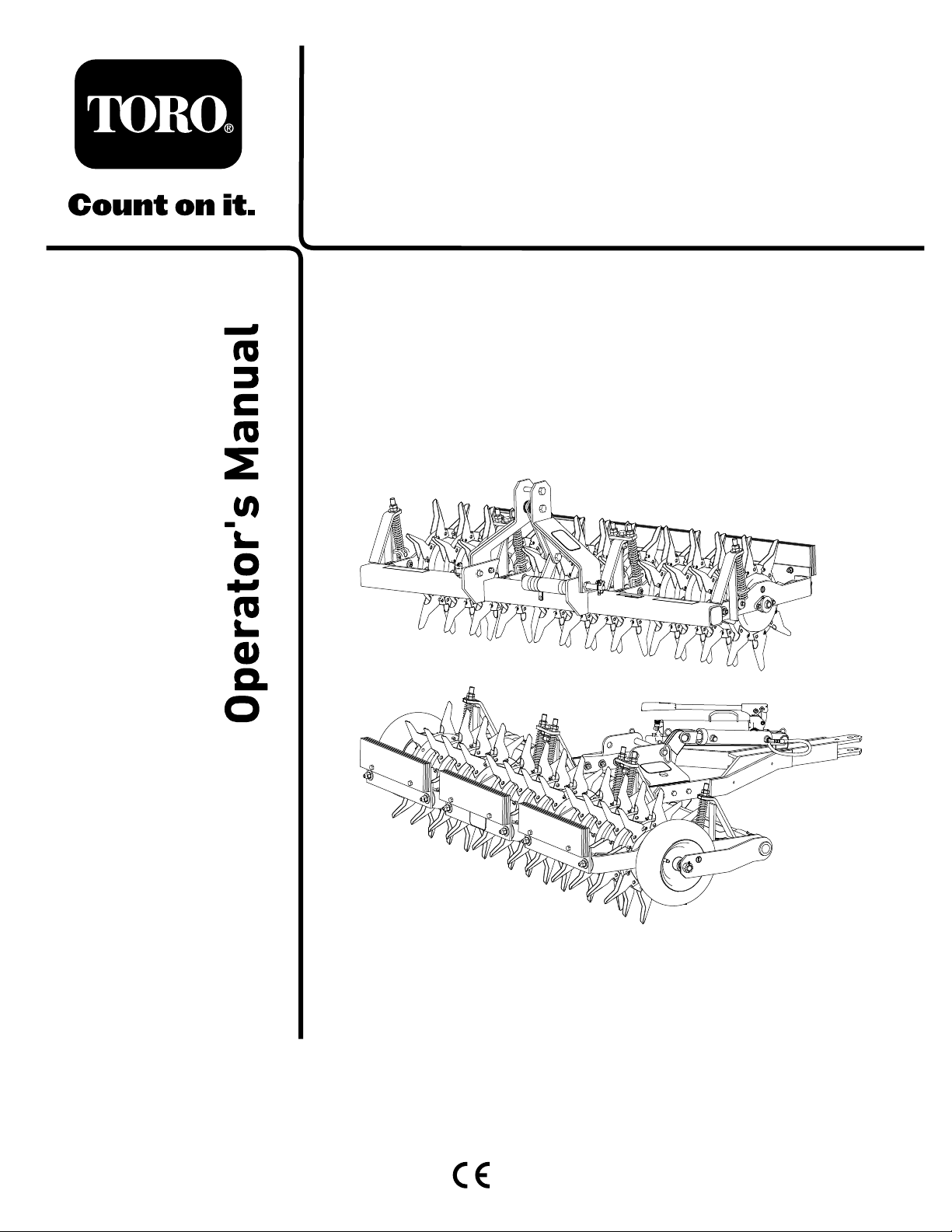

Contents

Safety.......................................................................3

GeneralSafety...................................................3

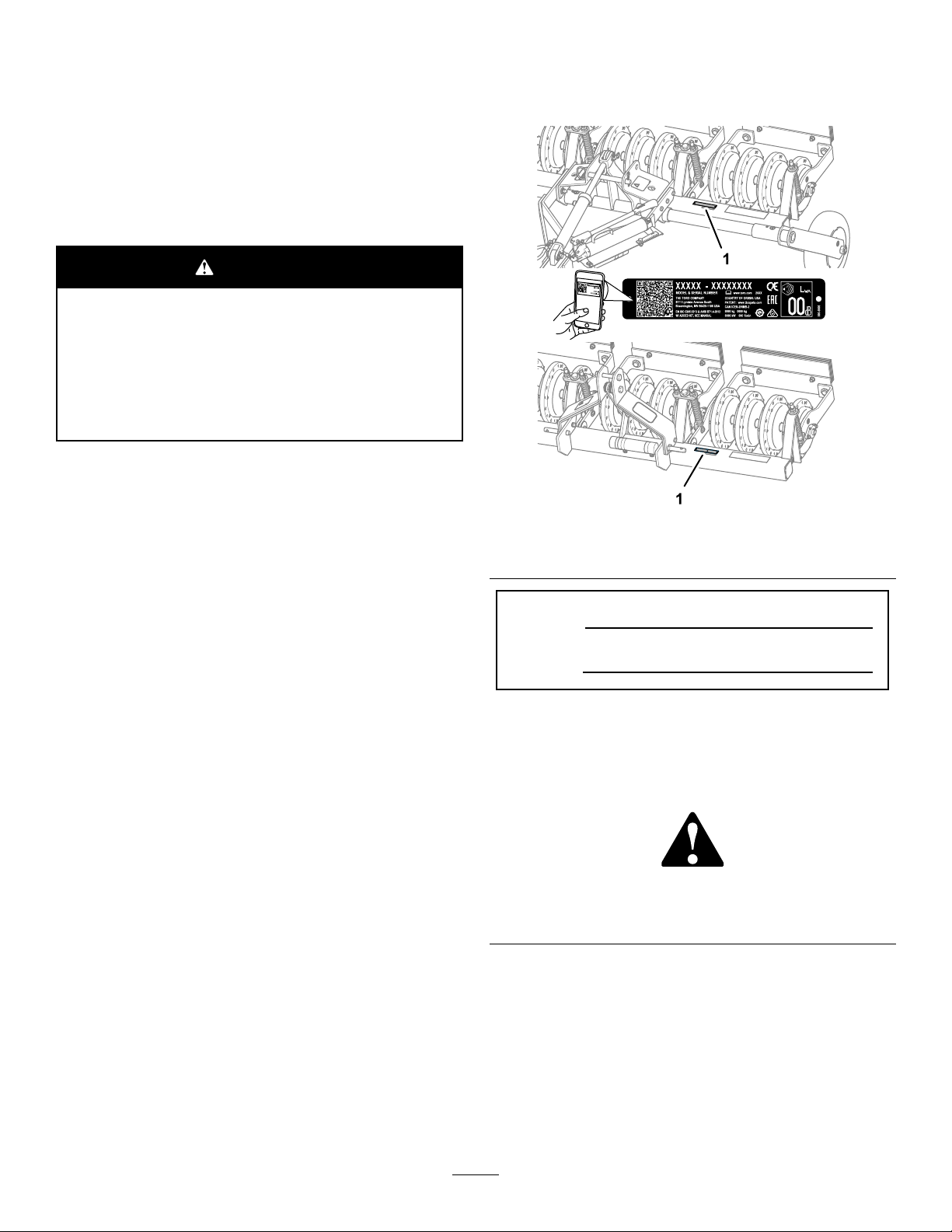

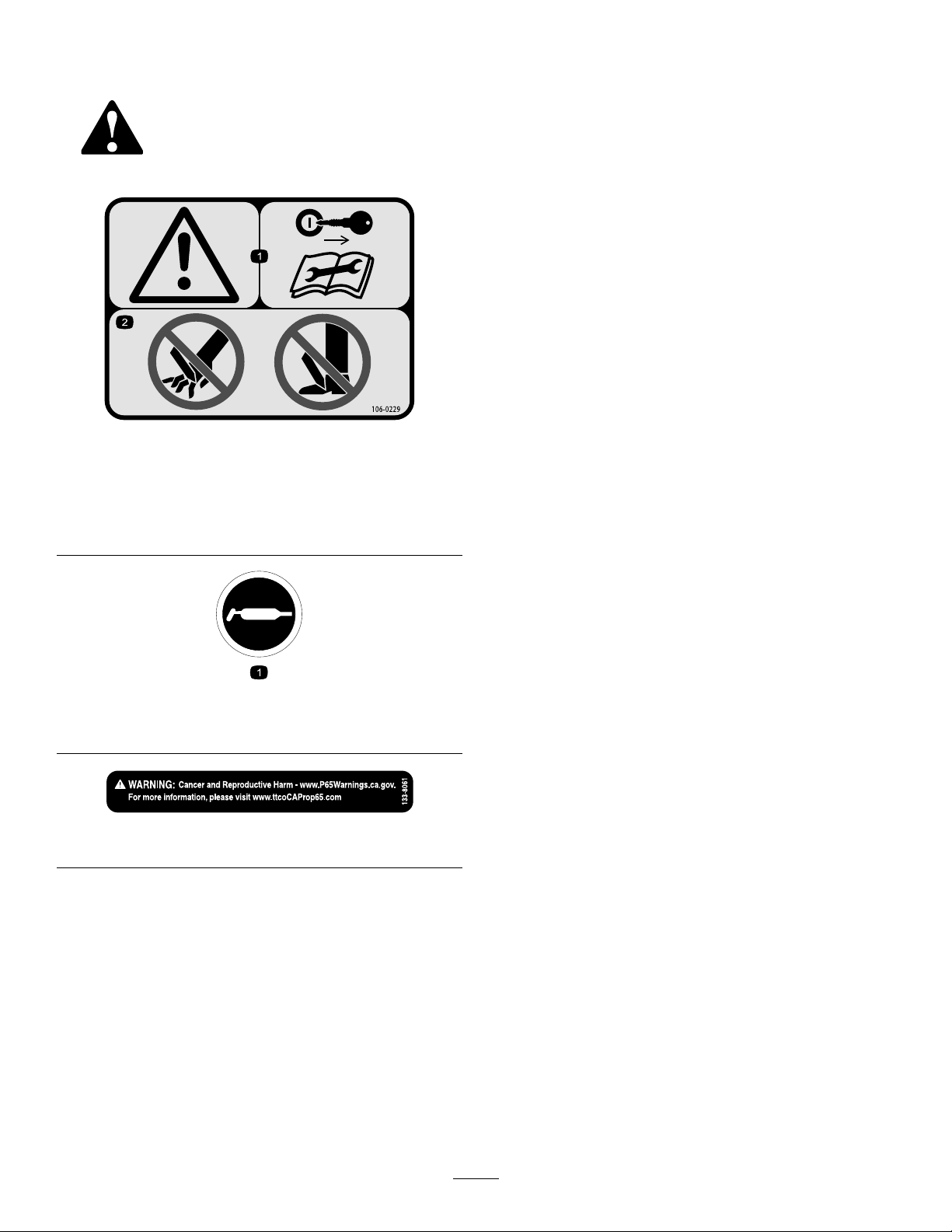

SafetyandInstructionalDecals..........................4

Setup........................................................................5

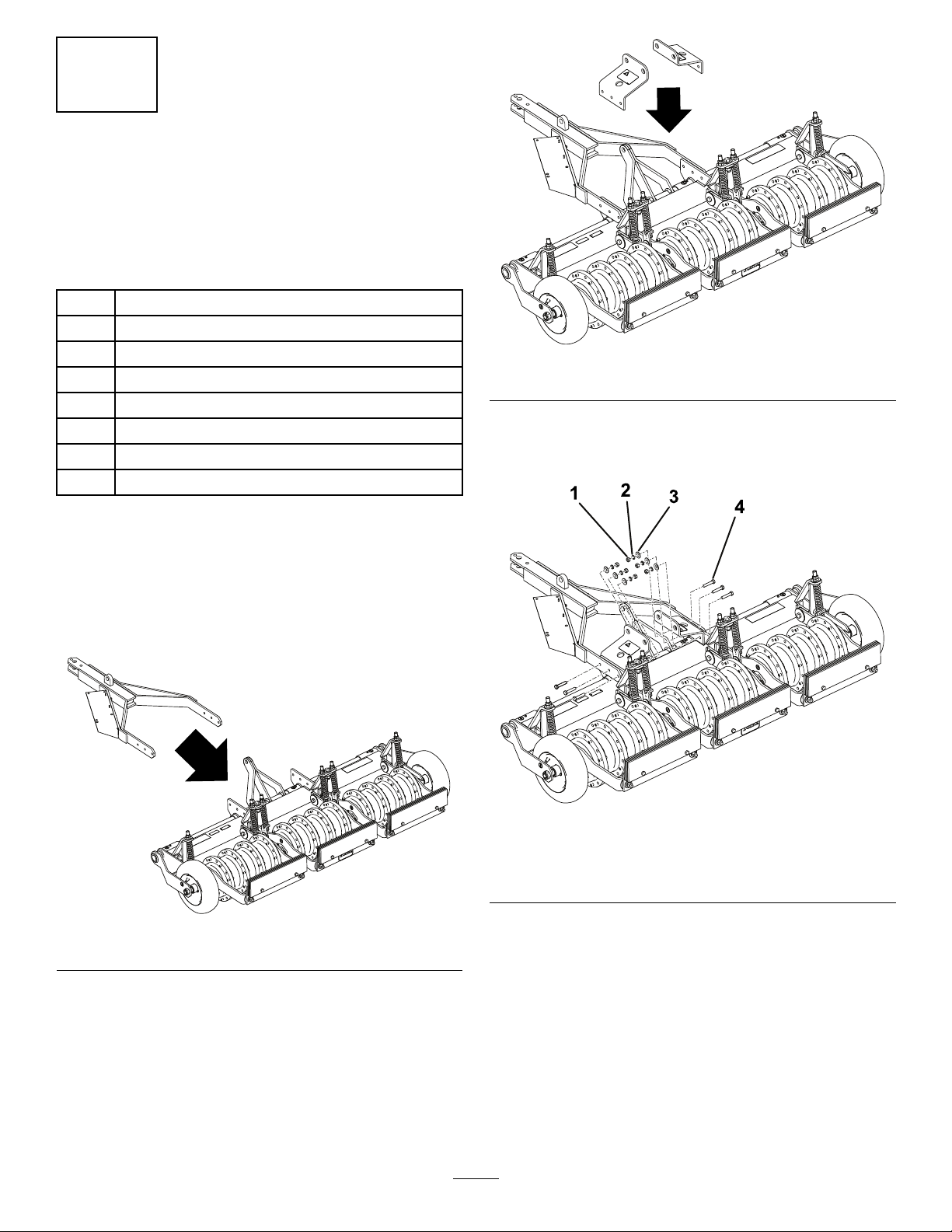

1InstallingtheWheels........................................6

2InstallingtheWeights.......................................6

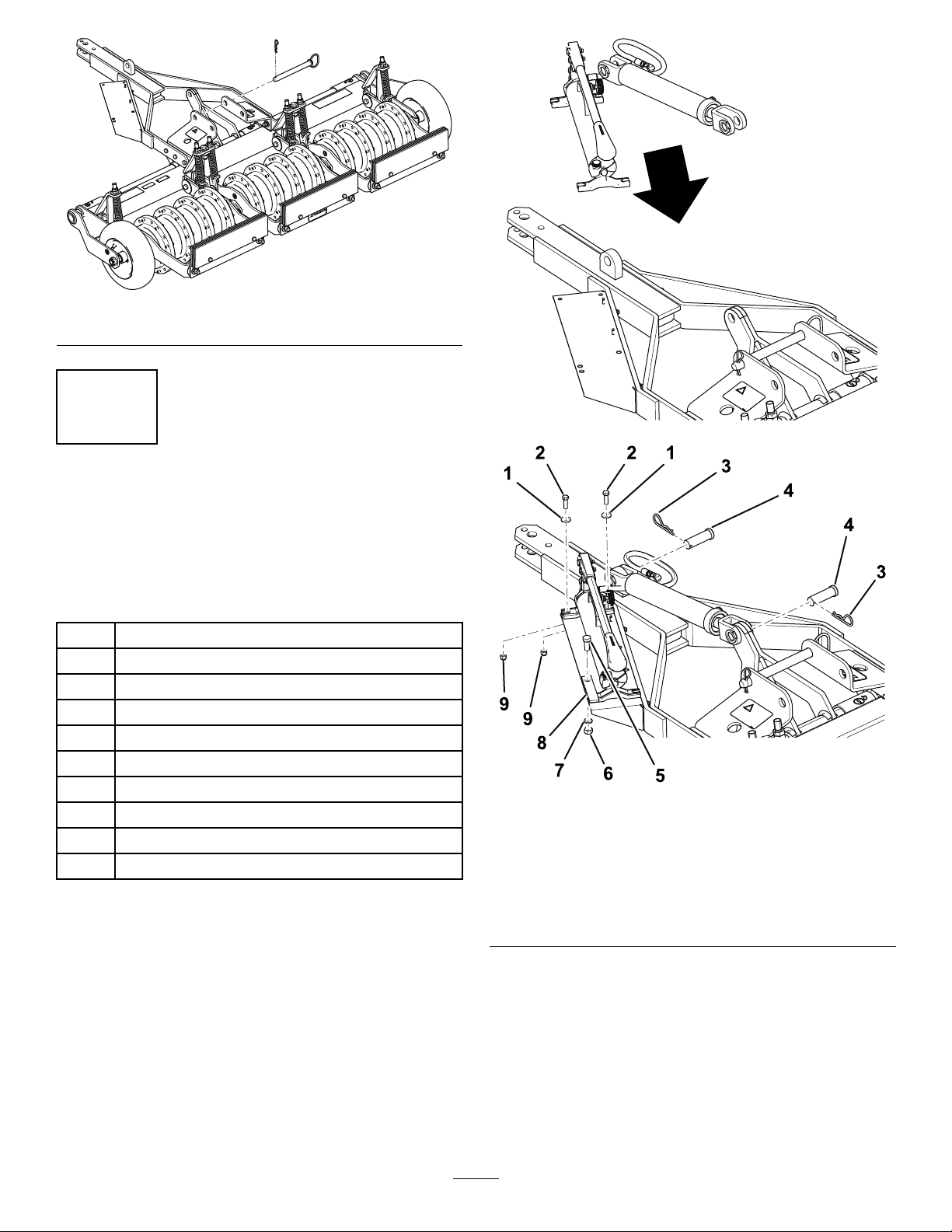

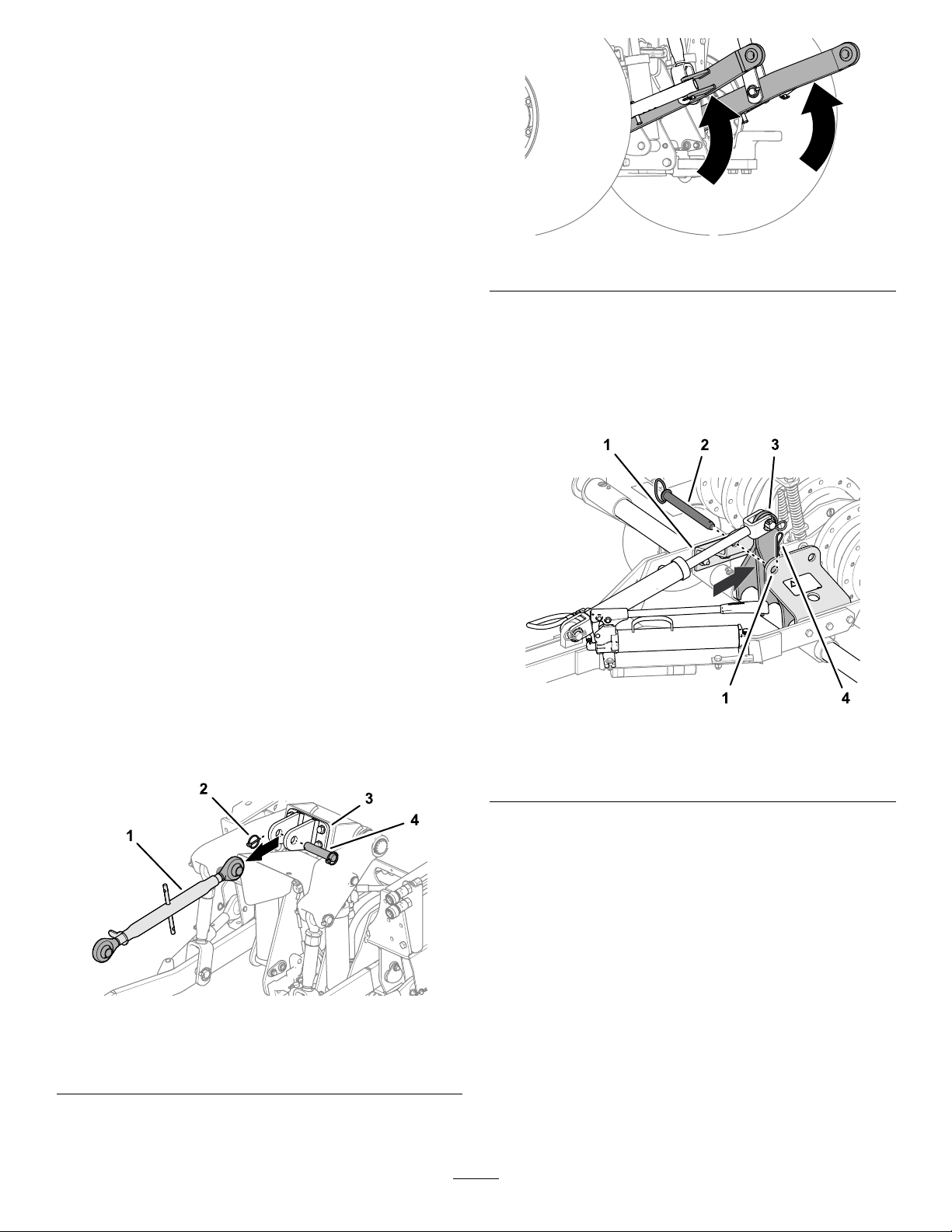

3MountingtheT ongueAssembly.......................6

4AttachingthePumpandCylinder

Assembly........................................................8

ProductOverview.....................................................9

Specications....................................................9

Attachments/Accessories...................................9

Operation................................................................10

AssemblingtheAeratortotheTraction

Unit...............................................................10

InstallingtheTines............................................12

UsingtheAerator..............................................12

Maintenance...........................................................14

RecommendedMaintenanceSchedule(s)...........14

Lubrication..........................................................14

LubricatingtheBearings...................................14

ChassisMaintenance...........................................15

CheckingTireAirPressure...............................15

CheckingtheMainArmsBushings....................15

AdjustingtheSprings........................................16

CheckingtheTines...........................................16

Storage...................................................................17

Safety

GeneralSafety

•Readandunderstandthecontentsofthe

Operator’sManualforboththeaeratorandthe

tractionunit.

•Trainalloperatorsandservicepersonnelonthe

aerator.

•Raisethetines,slowdown,andusecautionwhen

crossingsurfacesotherthangrassandwhen

transportingthemachine.

•Donotoperatethemachinewhenill,tired,or

undertheinuenceofalcoholordrugs.

•Useextremecarewhenloadingorunloadingthe

aeratorintoatrailerortruck.

•Operatetheaeratoratalowerspeedwhenyou

areonaslope.

•Donotusetheaeratorneardrop-offs,ditches,

embankments,orbodiesofwater.Theaerator

couldsuddenlyrolloverifawheelgoesoffthe

edge.

•Stopthetractionunit,raisethetines(aerator

model44867),shutofftheengine,engagethe

parkingbrake,removethekey,andwaitforall

movementtostopbeforeadjusting,cleaning,or

repairingtheaerator.

•Alwaysweargloveswhenservicingthetines.

Replacedamagedtines.

•Donotputhandsorfeetnearmovingcomponents

ofthemachine.

Improperlyusingormaintainingthismachinecan

resultininjury.Toreducethepotentialforinjury,

complywiththesesafetyinstructionsandalways

payattentiontothesafety-alertsymbol,which

meansCaution,Warning,orDanger—personalsafety

instruction.Failuretocomplywiththeseinstructions

mayresultinpersonalinjuryordeath.

Youcanndadditionalsafetyinformationwhere

neededthroughoutthismanual.

3