Bedrock SPS.500 User manual

Revision 7 September 2021

Bedrock OSA

SPS.500

User Manual

Copyright © 2021 Bedrock Automation Platforms, Inc. All rights reserved.

This manual is provided solely for informational purposes in connection with the authorized installation, use, and maintenance

of Bedrock Automation’s products. The information in this manual is subject to change without notice. The most recent

versions of our manuals are posted on our website at https://bedrockautomation.com/support/support-documentation. No

part of this publication may be distributed or transmitted in any form or by any means for charge or for use other than in

connection with the authorized installation, use, and maintenance of Bedrock Automation’s products, without the prior

written permission of Bedrock Automation.

Disclaimer

This manual is provided “as is” without any representations or warranties, express or implied. To the extent allowed by law,

Bedrock Automation makes no, and disclaims any and all, representations or warranties with respect to this manual and the

information and materials provided herein, including without limitation, any implied warranties of non-infringement,

merchantability, fitness or sufficiency for a particular purpose, or arising from the course of dealing, usage, or trade. Although

we use reasonable efforts to include accurate, up-to-date, and comprehensive information, Bedrock Automation does not

warrant the information in this manual is correct, current, or complete. The examples and diagrams in this manual are included

solely for illustrative purposes, and throughout this manual we use notes to make you aware of safety considerations. However,

because of the many variables and requirements associated with any installation, Bedrock Automation cannot assume

responsibility or liability for actual use based on the examples, diagrams, or information included in this manual. Nothing in this

disclaimer excludes or limits any warranty that is unlawful to disclaim, exclude, or limit.

Under no circumstances will Bedrock Automation or its employees, officers, directors, agents, successors, or assigns be liable,

under any contract, tort (including negligence), strict liability or other legal or equitable theory, whether or not foreseeable or

foreseen, for any special, incidental, exemplary, indirect, or consequential damages, including without limitation, any cost of

rework, retesting, procurement of substitute goods, removal and reinstallation of goods, business interruption costs, or lost

revenue, profits, or data, regardless of whether Bedrock Automation has been advised or is aware of the possibility of such

damages or any remedy fails of its essential purpose. Nothing herein will exclude or limit Bedrock Automation’s liability in

respect of any: (1) death or personal injury caused by Bedrock Automation’s negligence; (2) fraud or fraudulent

misrepresentation on the part of Bedrock Automation; or (3) matter which it would be illegal or unlawful for Bedrock

Automation to exclude or limit, or to attempt or purport to exclude or limit, its liability.

By using this manual, you agree these disclaimers, exclusions, and limitations of liability are reasonable. If you do not think they

are reasonable, do not use this manual.

For further information, contact:

Bedrock Automation Platforms, Inc.

171 Forbes Boulevard, Suite 1000

Mansfield, Massachusetts 02048

(781) 821-0280

www.bedrockautomation.com

Trademarks

Bedrock®, Black Fabric®, and OSA® are registered trademarks of Bedrock Automation Platforms, Inc. All other trademarks are the

properties of their respective owners.

Contents

9/3/21 Bedrock SPS.500 User Manual - BRDOC125_007 i

Contents

Safety Warning and Precautions .........................................iii

Warnings ................................................................................................................ iii

Cautions.................................................................................................................. iii

Bedrock SPS.500 Overview .................................................. 1

SPS.500 Installation ............................................................ 7

Important User Information..................................................................................7

Hazardous Location Information .................................................................7

Environment and Enclosure..........................................................................8

Installation Configurations....................................................................................8

Panel Mount Installation........................................................................................9

Pipe Mount Installation........................................................................................10

Installing the SPS.500 ...........................................................................................11

SPS.500 Wiring................................................................. 15

Important User Information................................................................................15

Power and Relay Cables........................................................................................15

Cable Pin Out Information..................................................................................17

Configuration and Status .................................................. 21

Network Setup .......................................................................................................21

Bedrock IDE Device Management .....................................................................21

Displaying SPS.500 Data ............................................................................23

Configuration Data .....................................................................................24

Overcurrent Behavior ..........................................................................27

Diagnostic Data...........................................................................................29

Logging Information....................................................................................31

Log Entry Format.................................................................................32

Logged Events.......................................................................................33

Logged Faults .......................................................................................34

Additional Items Logged by the SPS.500 ............................................35

Storing SPS Logging Information in an ODBC Database..................37

Updating SPS Firmware ..............................................................................37

OPC UA..................................................................................................................37

SPS.500 Status LEDs .............................................................................................39

SPS.500 Specifications.............................................................A-1

SPS.500 Electrical Specifications...........................................................................1

Contents

ii Bedrock SPS.500 User Manual - BRDOC125_007 9/3/21

SPS.500 Environmental Specifications.................................................................2

SPS.500 General Specifications .............................................................................2

Part Numbers ..........................................................................B-1

Certifications, Approvals, and Testing ...................................C-1

CE Testing ................................................................................................................1

IEC Environmental Testing....................................................................................1

Underwriters Laboratories (UL) Safety Compliance..........................................1

FCC Testing..............................................................................................................2

EMP Testing.............................................................................................................2

Achilles Certification..............................................................................................2

Log Index Table...................................................................... D-1

Acronyms.................................................................................E-1

9/3/21 Bedrock SPS.500 User Manual - BRDOC125_007 iii

Safety Warning and Precautions

Observe the following warnings and precautions during installation and use of

the SPS.500.

Warnings

WARNING: Dangerous voltages are present within the

power supply. Do not attempt to open the SPS.500 enclosure.

Do not come in contact with the incoming line voltage.

WARNING: Prior to connecting the cables, refer to the

SPS.500 Wiring chapter for important electrical and safety

information.

WARNING: If using revision A of the SPS.500, never use the

Power Out port and “OR”ing output at the same time.

Cautions

CAUTION: Never attempt to open the SPS.500 enclosure.

The enclosure is securely sealed. Opening the enclosure will

void the warranty and cause the SPS.500 to be inoperable.

CAUTION: Always use an appropriate fuse on the Power In

and Power Out connections.

CAUTION: Each contact in the output connectors is rated for

6 amps at 25°C. All wires must be connected to the load in

parallel. Do not use separate wires. Do not connect separate

wires to separate loads. Failure to follow these instructions

will void any warranty.

CAUTION: For both the panel-mount and pipe-mount

configurations, it is required that the SPS.500 universal

mounting bracket is grounded.

Chapter 1

9/3/21 Bedrock SPS.500 User Manual - BRDOC125_007 1

Bedrock SPS.500 Overview

The Bedrock SPS.500 is an Ethernet enabled, 24 V DC power supply designed

for use in a number of applications including IIoT, distributed control systems,

and industrial automation applications. Users of existing applications can retrofit

using the SPS.500 inside or outside enclosures, anywhere in a plant, and in harsh

environments. Product specifications, installation instructions, and operating

information are included in this manual.

The SPS.500 accepts universal AC input voltages. An “OR”ing output is

available for a redundant power supply configuration. The SPS.500 can be

integrated with a Bedrock UPS.500 to provide continuous power to a Bedrock

Control System in the event of a power failure. See the Bedrock UPS.500 User

Manual for more information.

The SPS.500 supports 10/100 Mbit Ethernet IPv4 and IPv6 communication.

Network clock synchronization is provided using the IEEE-1588 Precision Time

Protocol (PTP) for devices that support the protocol.

A real-time clock (RTC) provides up to 21 days of hold up time in the event of a

loss of power to the SPS.500 (product revision B or later).

An OPC UA compliant server provides access to diagnostic and status

information and configuration parameters. OPC UA tags are available using a

single connection to an OPC UA client. Diagnostic, status, and configuration

information is also available using a single connection to the Bedrock IDE.

The SPS.500 can be installed in either panel or pipe mount configuration. The

enclosure is compliant with IP66/67 (dust tight, protection against water jets,

and immersion) and NEMA ratings 4 and 6 (dust tight, water tight, protection

against hose directed water, and immersible).

Bedrock Automation has received several certifications for FCC, CE, IEC, and

EMP testing as well as UL approval for Industrial Control Equipment (UL 508).

See Appendix C, Certifications, Approvals, and Testing for a complete list.

Additional features include:

• tri-colored status LED and network activity LEDs

• two type C relay outputs.

Chapter 1 Bedrock SPS.500 Overview

2 Bedrock SPS.500 User Manual - BRDOC125_007 9/3/21

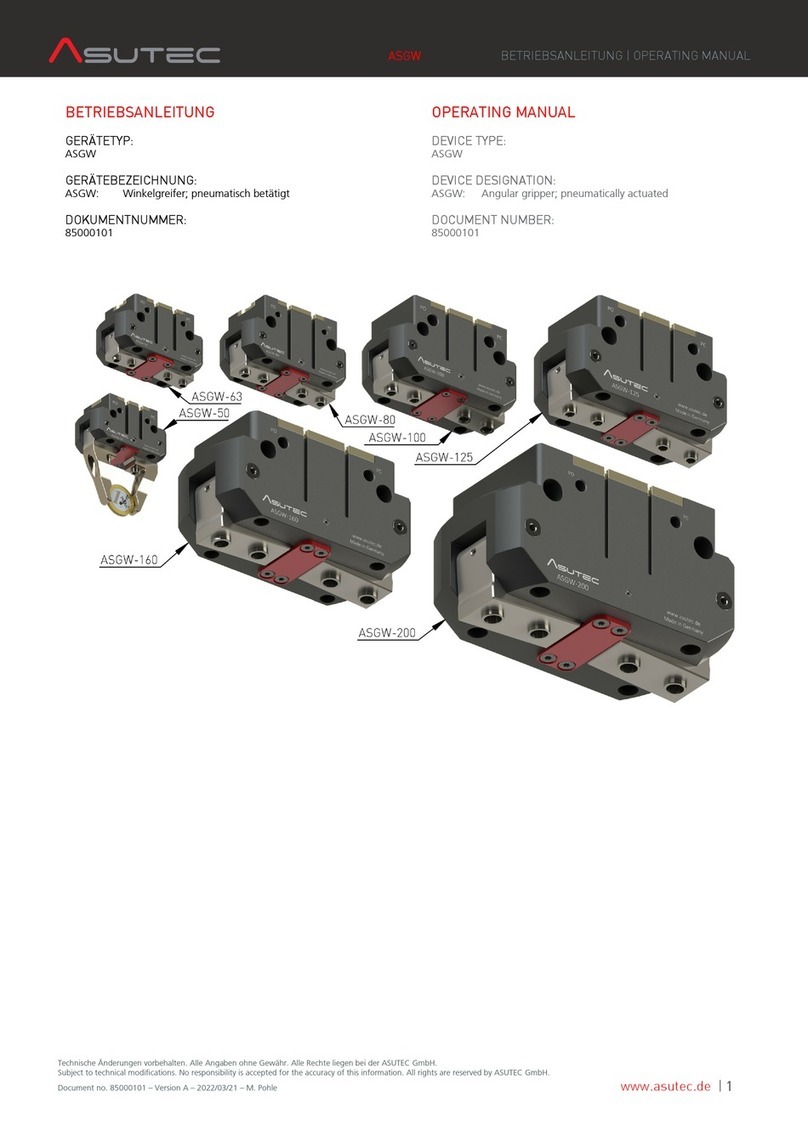

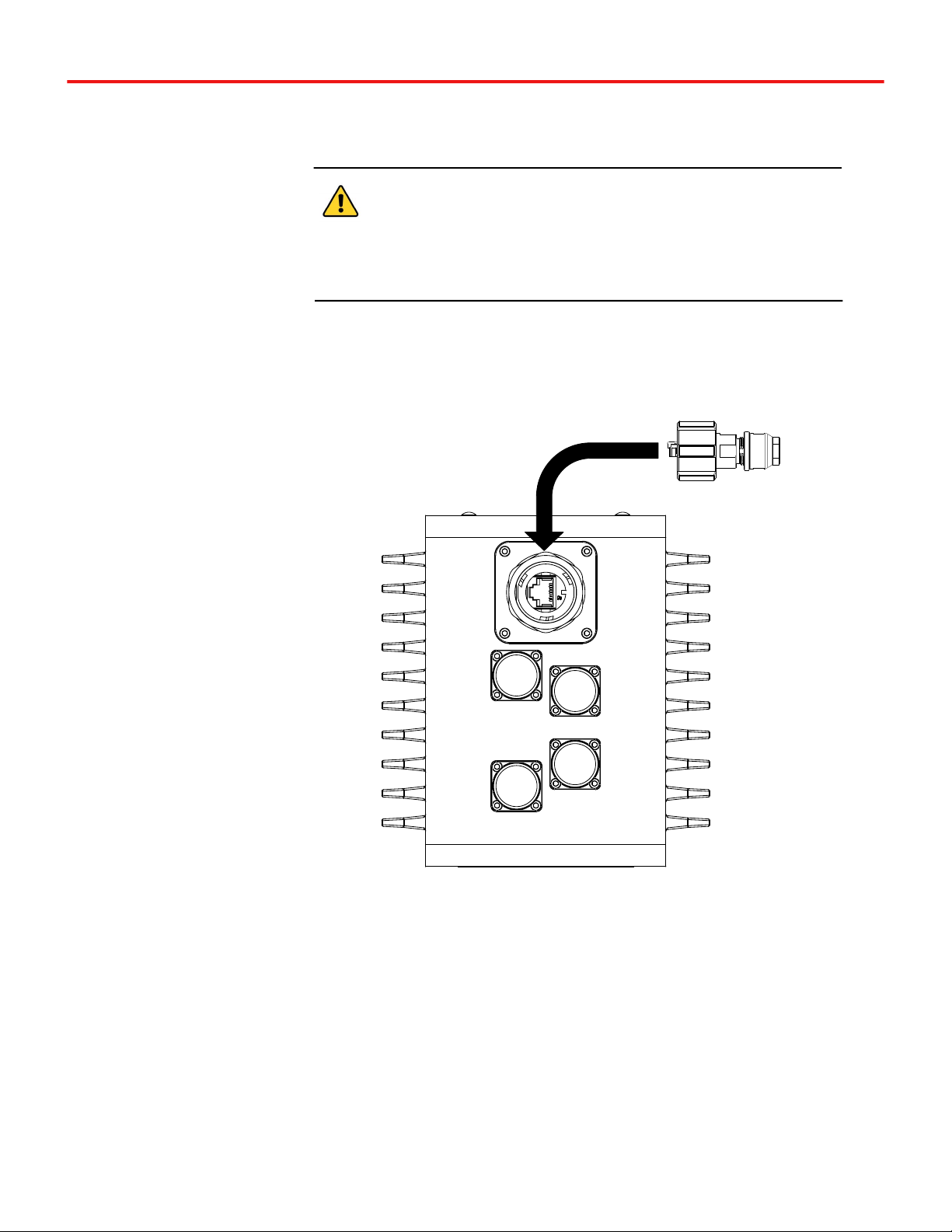

Ports for power cables, communication connections, and the “OR”ing output

are shown in Figure 1-1.

Important

AC Power must be rated for PLTC cable with AWG 14.

DC Power must be rated for PLTC cable with AWG 16.

Relay cabling must be rated for MC, MV, or PLTC with AWG 20.

Figure 1-1 Ports on the SPS.500

Note: Bedrock part no. CI00131 or

TE Connectivity part no. 2ϯϲϮϳϲϬ-2 must

be used for the Ethernet connector

in

order to maintain the IP66/IP67 rating.

Note: A shielded

Ethernet cable is

required.

Relay

Power

In

“OR”ing

Output

Power

Out

Ethernet

Bedrock SPS.500 Overview Chapter 1

9/3/21 Bedrock SPS.500 User Manual - BRDOC125_007 3

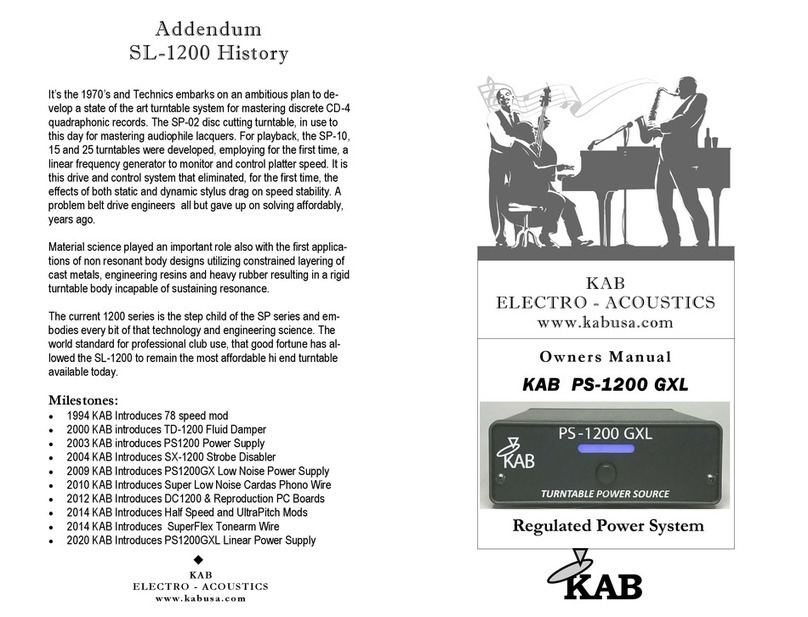

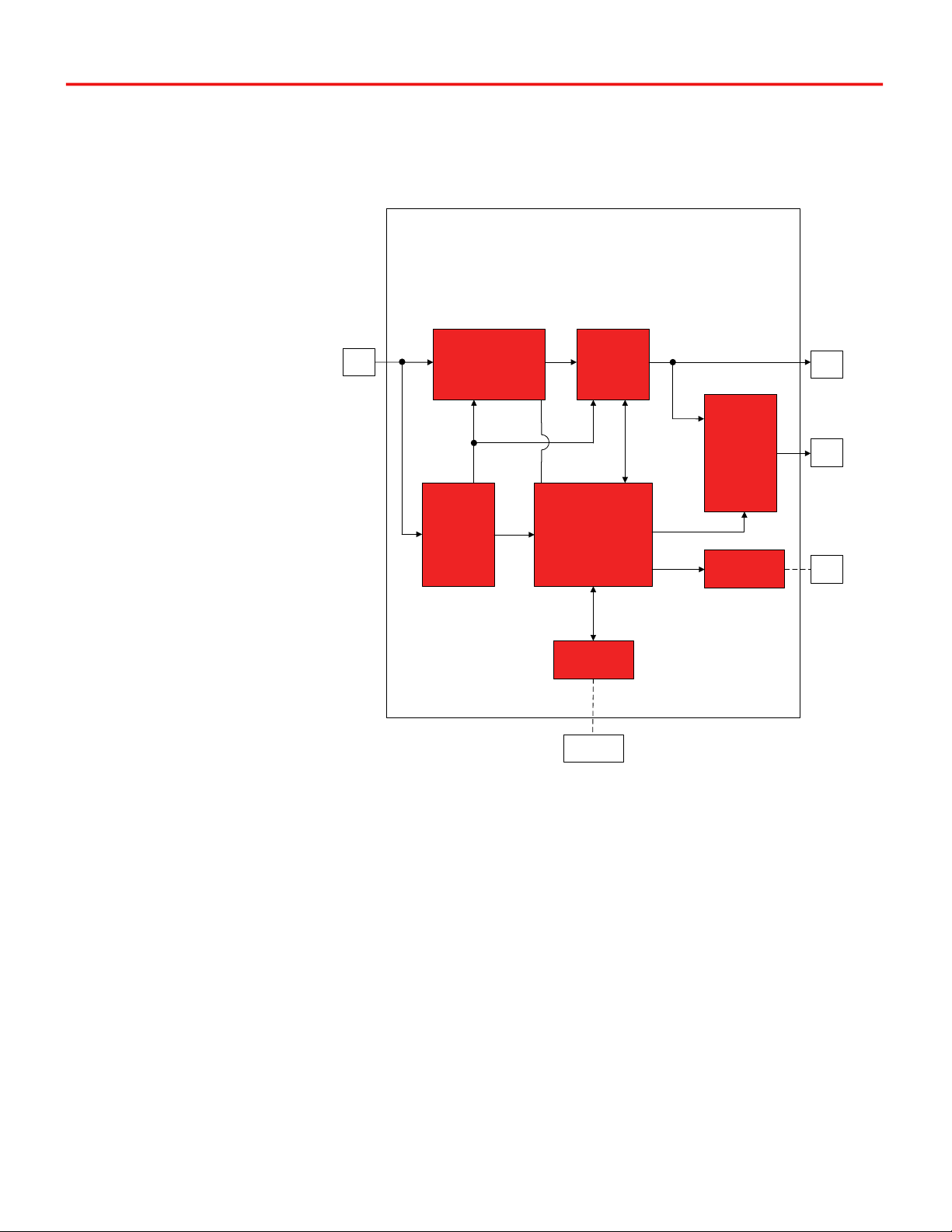

A block diagram for the SPS.500 is shown in Figure 1-2.

Figure 1-2 SPS.500 Block Diagram

Ideal

Diode

Controller

AUX

Supply

PWM

AC

In

OR

Out

PFC

Microcontroller

Relay

DC

Out

Ethernet

Port

Ethernet

Controller

Dual

Relays

DC

Chapter 1 Bedrock SPS.500 Overview

4 Bedrock SPS.500 User Manual - BRDOC125_007 9/3/21

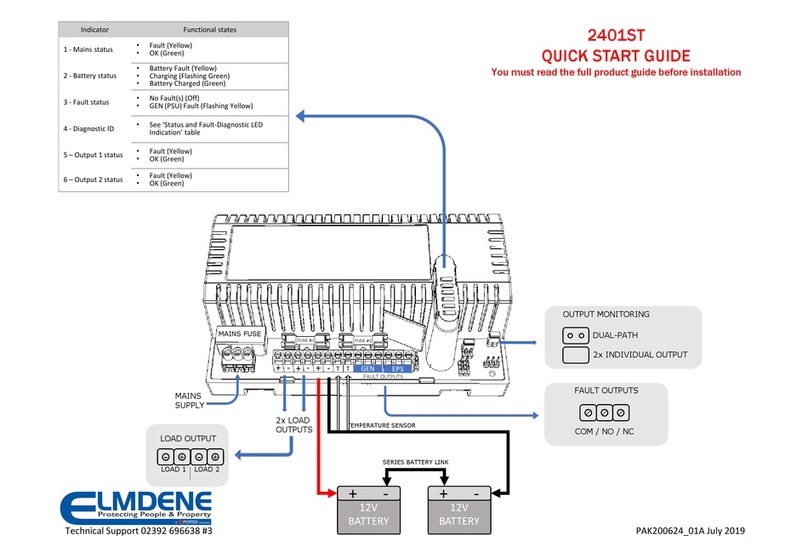

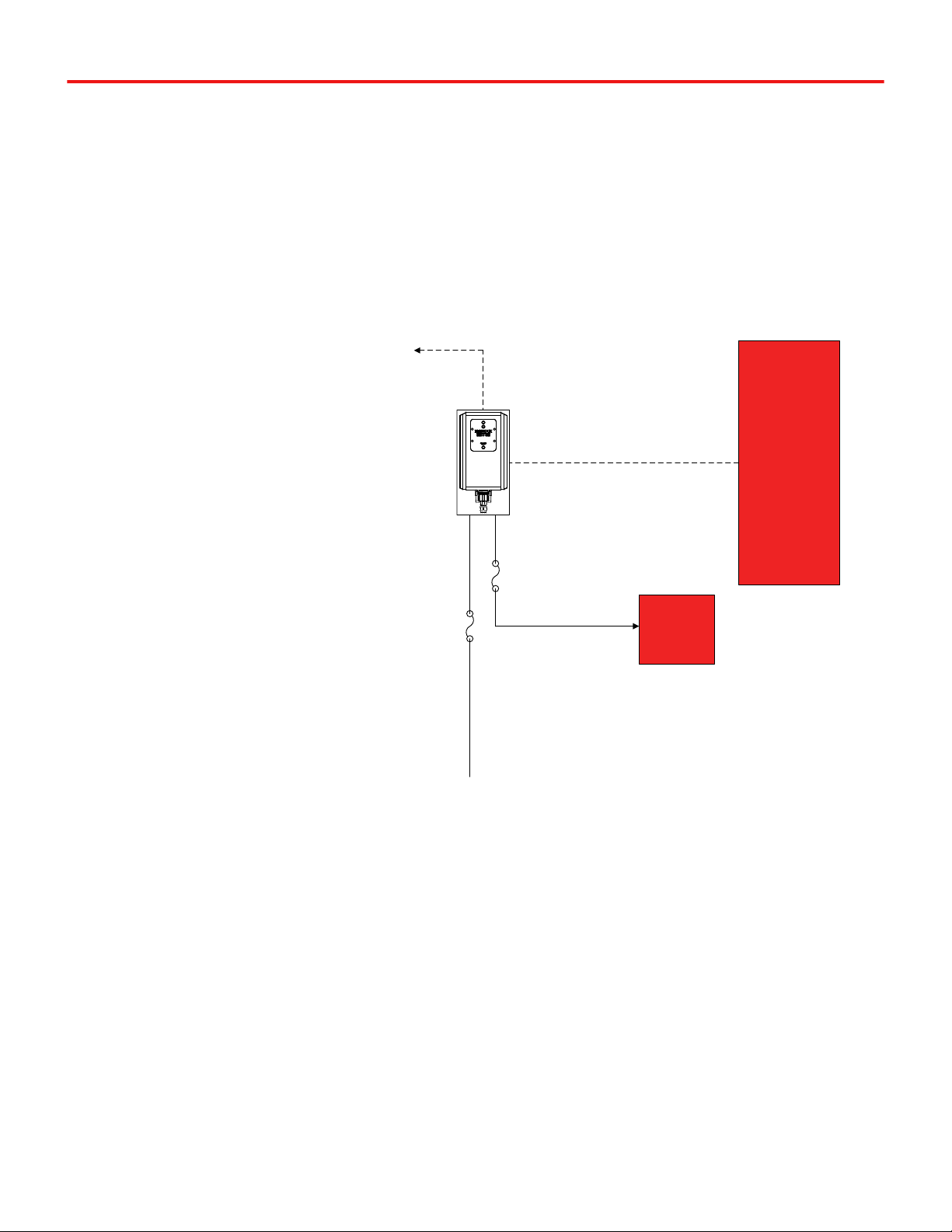

A wiring diagram for a typical non-redundant SPS.500 configuration is shown

in Figure 1-3. Note that the Power Out connector must be used in this

configuration.

Figure 1-3 SPS.500 Wiring Diagram

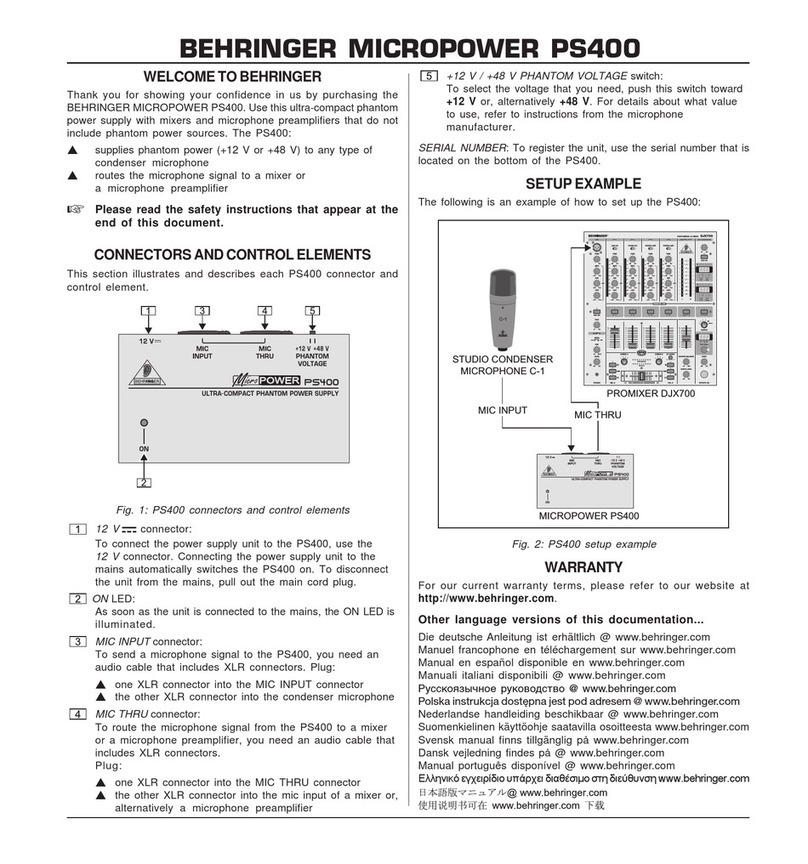

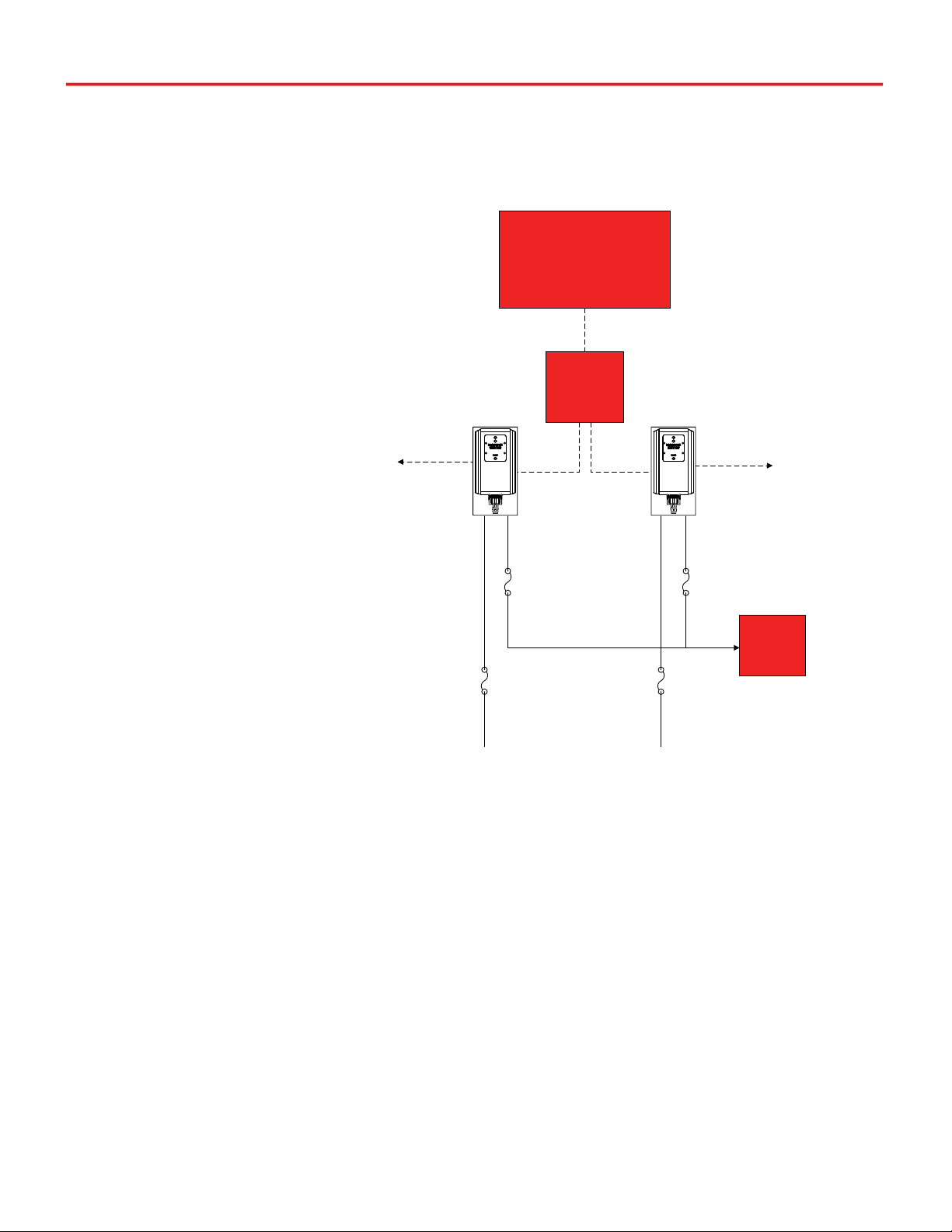

Two SPS.500 power supplies can be used together in a redundant

configuration. In a redundant configuration, the ORed output controller acts

like an ideal diode. The power supplies do not share the load so that only one

power supply carries the load. The power supply with the highest output

voltage carries the load. The Bedrock IDE or an OPC UA client can determine

which SPS.500 carries the load by checking the amount of current draw of each

supply.

A wiring diagram for a redundant configuration consisting of two SPS.500

power supplies is shown in Figure 1-4. The SPS.500 power supplies can be

connected to a workstation running an OPC UA client by way of an Ethernet

switch. Alternatively, the redundant power supplies can be configured to

Recommended

Fusing / Circuit

Breaker

Power

In

Power

Out

Recommended

Fusing / Circuit

Breaker

Relay

Output

(optional)

Ethernet

AC Mains

Load

One of the

following:

x Workstation

Running

OPC UA

x Bedrock

SIO4.E comm.

module

x UCG.5

x OSA Remote

Bedrock SPS.500 Overview Chapter 1

9/3/21 Bedrock SPS.500 User Manual - BRDOC125_007 5

communicate with a Bedrock SIO4.E communications module or UCG.5

gateway. Note that the “OR”ing Output connector must be used for redundant

configurations.

Figure 1-4 SPS.500 Redundant Configuration

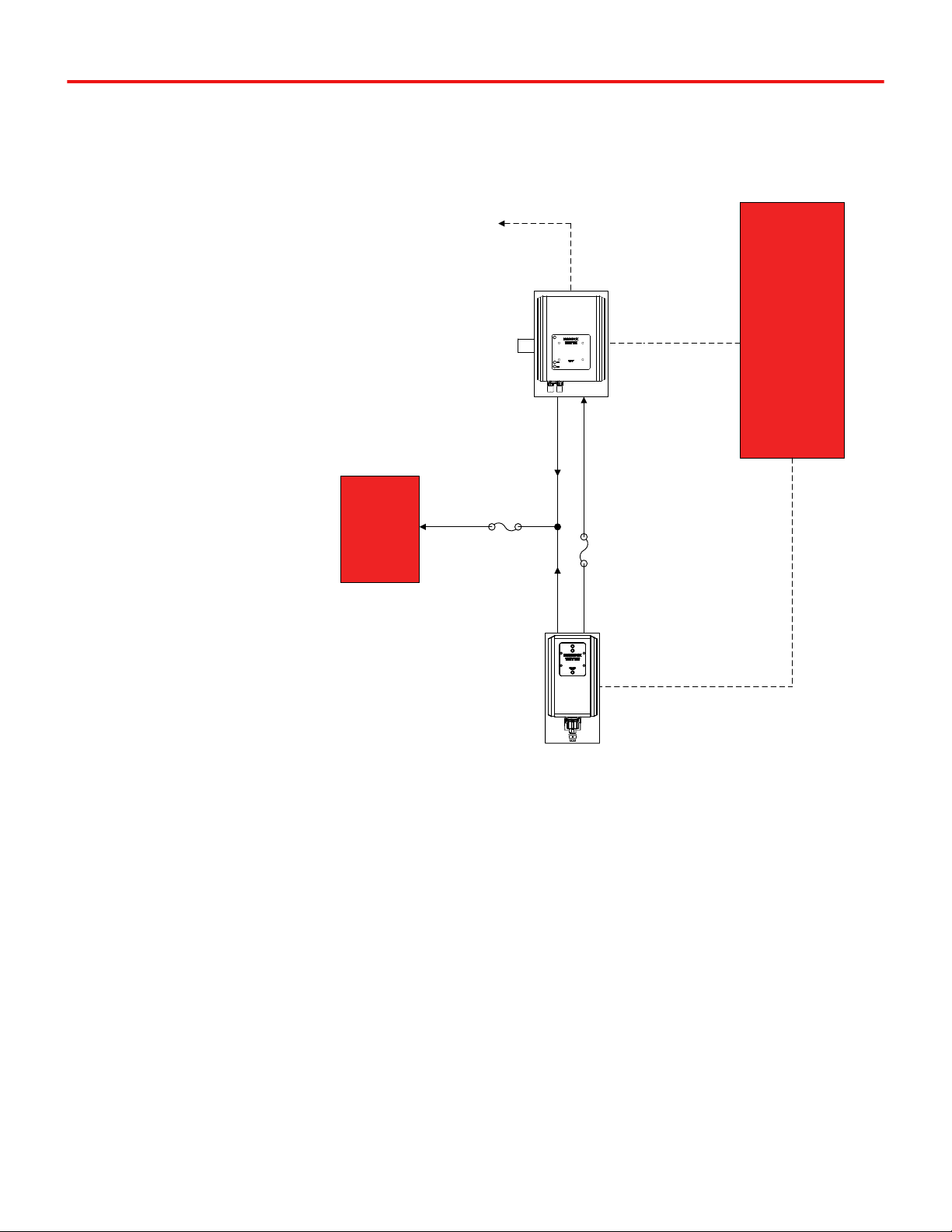

The SPS.500 can be placed in a parallel configuration with an UPS.500. A

parallel configuration will continue to power the load if either the SPS.500

power supply or the UPS.500 is no longer supplying power. The load must be

capable of accepting ORed inputs. Figure 1-5 shows a wiring diagram with the

Recommended

Fusing / Circuit

Breaker

Power

In

“OR”ed

Power Out

Recommended

Fusing / Circuit

Breaker

Relay

Output

(optional)

Ethernet

AC Mains A

Load

Ethernet

Switch

(not needed with

SIO4.E, UCG.5, or

OSA Remote)

Power

In

“OR”ed

Power Out

Recommended

Fusing / Circuit

Breaker

Recommended

Fusing / Circuit

Breaker

AC Mains B

10/100

Ethernet

10/100

Ethernet

Relay

Output

(optional)

Workstation

Running OPC UA

or

SIO4.E, UCG.5, or OSA Remote

Chapter 1 Bedrock SPS.500 Overview

6 Bedrock SPS.500 User Manual - BRDOC125_007 9/3/21

SPS.500 in a parallel configuration with an UPS.500. This is the preferred

configuration for wiring an SPS.500 with an UPS.500.

Figure 1-5 SPS.500 Parallel Wiring Diagram with UPS.500

One of the

following:

x Workstation

Running

OPC UA

x Bedrock

SIO4.E comm.

module

x UCG.5

x OSA Remote

Load

Recommended

Fusing

Power

Out

Power

In

Recommended

Fusing

To Discrete

Inputs for

Alarming

Relay

Output

(optional)

Ethernet

Battery

Enable

Connector

Ethernet

ORed

Output

Power

Out

SPS.500

UPS.500

Chapter 2

9/3/21 Bedrock SPS.500 User Manual - BRDOC125_007 7

SPS.500 Installation

Important User

Information

Read the instructions and follow all warnings and notes prior to beginning

installation.

Complete these tasks before installing and using the SPS.500.

• Verify that you have the components required to install the SPS.500.

• Read and understand the safety and environmental warnings and

considerations explained in the installation instructions.

Hazardous Location

Information

WARNING

EXPLOSION HAZARD - DO NOT DISCONNECT EQUIPMENT WHILE THE CIRCUIT IS

LIVE OR UNLESS THE AREA IS KNOWN TO BE FREE OF IGNITABLE

CONCENTRATIONS.

Important

Note the following with regard to installation of Bedrock SPS.500 equipment in

Class I, Division 2, Groups A, B, C, and D hazardous locations:

THE EQUIPMENT IS SUITABLE FOR USE IN CLASS I, DIVISION 2, GROUPS A,

B, C, AND D HAZARDOUS LOCATIONS, OR NONHAZARDOUS LOCATIONS

WHEN INSTALLED PER CONTROL DOCUMENT BRDOC135_002 (BEDROCK

SPS.500 INSTALLATION GUIDE FOR HAZARDOUS LOCATIONS).

Important

Substitution of components may impair suitability for operation in a Class I,

Division 2, hazardous location.

Chapter 2 SPS.500 Installation

8 Bedrock SPS.500 User Manual - BRDOC125_007 9/3/21

Important

Perform all power wiring in accordance with Class I, Division 2 wiring methods

as defined in Article 501-4 (b) of the National Electrical Code, NFPA 70 (for

installation within the United States) or as specified in Section 18-152 of the

Canadian Electrical Code (for installation in Canada).

Environment and

Enclosure

Important

Subsequent sections of this publication may contain information regarding

specific enclosure type ratings that are required to comply with certain product

safety certifications

In addition to this publication, see the following: NEMA Standard 250 and

IEC 60529, as application for explanation of the degrees of protection provided

by enclosure.

The following information applies when operating the equipment in hazardous

locations:

Products marked “CL I, DIV 2, GP A, B, C, D” are suitable for use in Hazardous

Locations and nonhazardous locations only. Each product is supplied with

markings on the rating nameplate indicating the hazardous location

temperature code. When combining products within a system, the most

adverse temperature code (lowest “T” number) may be used to help determine

the overall temperature code of the system. Combinations of equipment in

your system are subject to investigation by the local Authority Having

Jurisdiction at the time of installation.

Temperature Code T4 has been established for the SPS.500 Power Supply.

The SPS.500 can operate in an ambient temperature range of -25°C to 50°C.

Installation

Configurations

The Bedrock SPS.500 can be installed in one of the following configurations:

• Panel-mount configuration - use four self-tapping screws to secure

the SPS.500 universal mounting bracket to a surface such as a

cabinet or a wall.

• Pipe-mount configuration - hex bolts and nuts secure the SPS.500

universal mounting bracket and bracket straps to a two inch pipe.

SPS.500 Installation Chapter 2

9/3/21 Bedrock SPS.500 User Manual - BRDOC125_007 9

CAUTION: For both the panel-mount and pipe-mount

configurations, it is required that the SPS.500 universal

mounting bracket is grounded.

Panel Mount

Installation

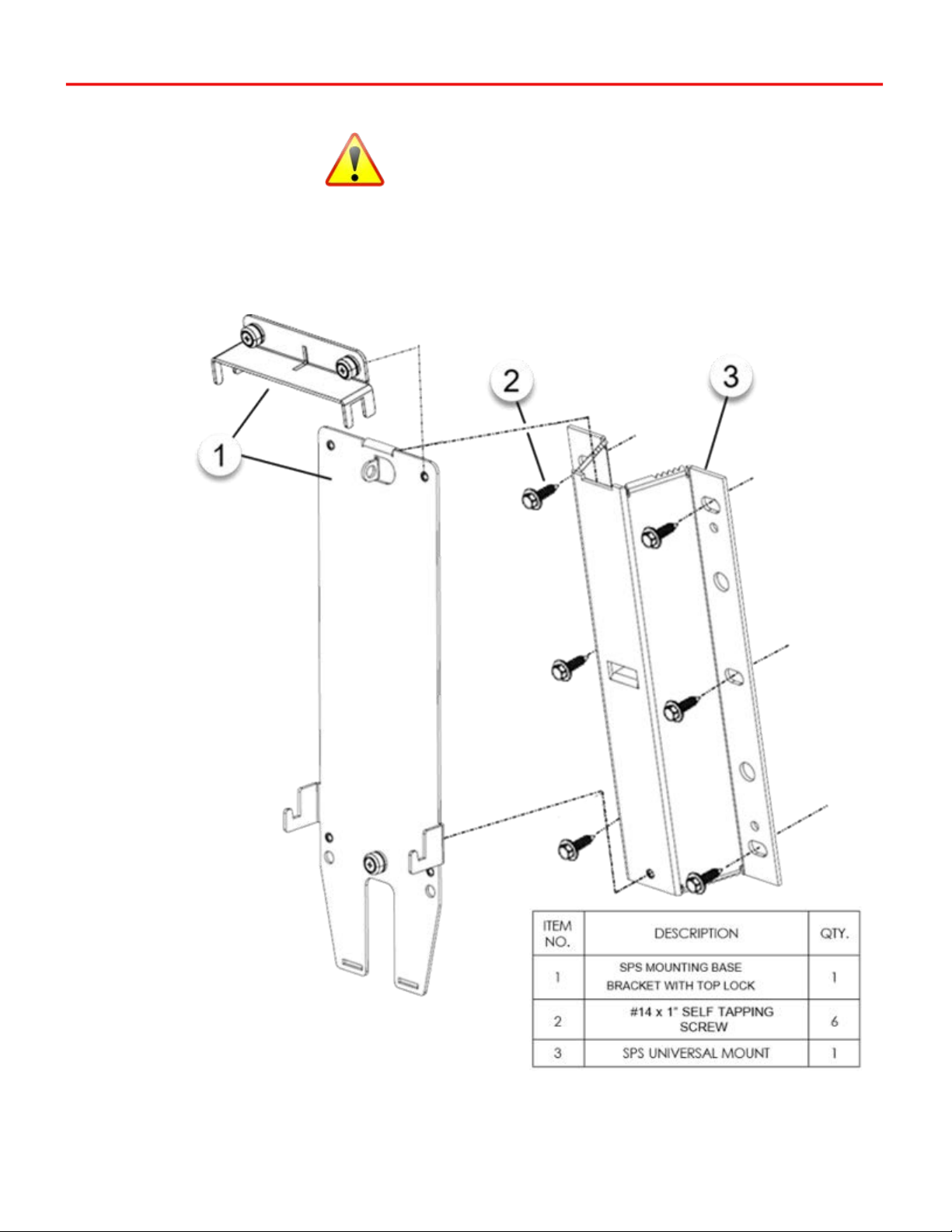

Figure 2-1 shows the bracket assembly for the SPS.500 panel-mount

configuration. Items 1 and 3 are the primary components for the assembly.

Fastener type is dependent on panel mount material. See Table B-1.

Figure 2-1 Bracket Assembly - Panel Mount Configuration

Chapter 2 SPS.500 Installation

10 Bedrock SPS.500 User Manual - BRDOC125_007 9/3/21

After securing the universal mount (Item No. 3) with the appropriate fasteners

(Item No. 2), do the following:

1. Hook the mounting bracket (Item No. 1) onto the SPS universal mount

(Item No. 3).

2. Secure the mounting bracket by tightening the captive screw with a #2

cross-tip screwdriver.

Note: The top lock is used in final assembly when installing the UPS.500

to the mounting bracket.

Pipe Mount

Installation

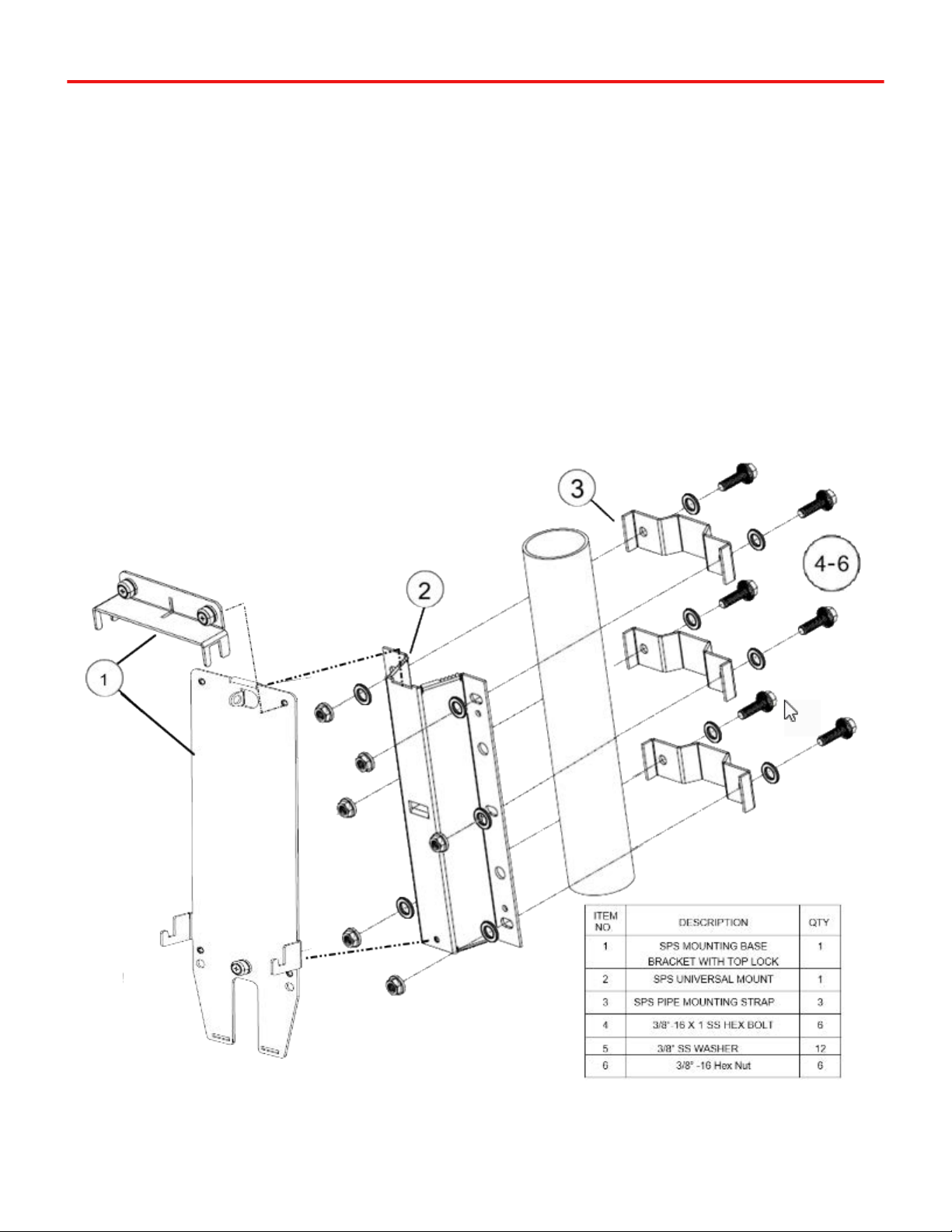

Figure 2-2 shows the bracket assembly for the SPS.500 pipe-mount

configuration. Use a 3/8 in. socket and open-end wrench to tightening the

universal bracket to the pipe. The steps to secure the mounting base bracket to

the SPS universal mount is described above. See Table B-1 for part numbers.

Figure 2-2 Bracket Assembly - Pipe Mount Configuration

SPS.500 Installation Chapter 2

9/3/21 Bedrock SPS.500 User Manual - BRDOC125_007 11

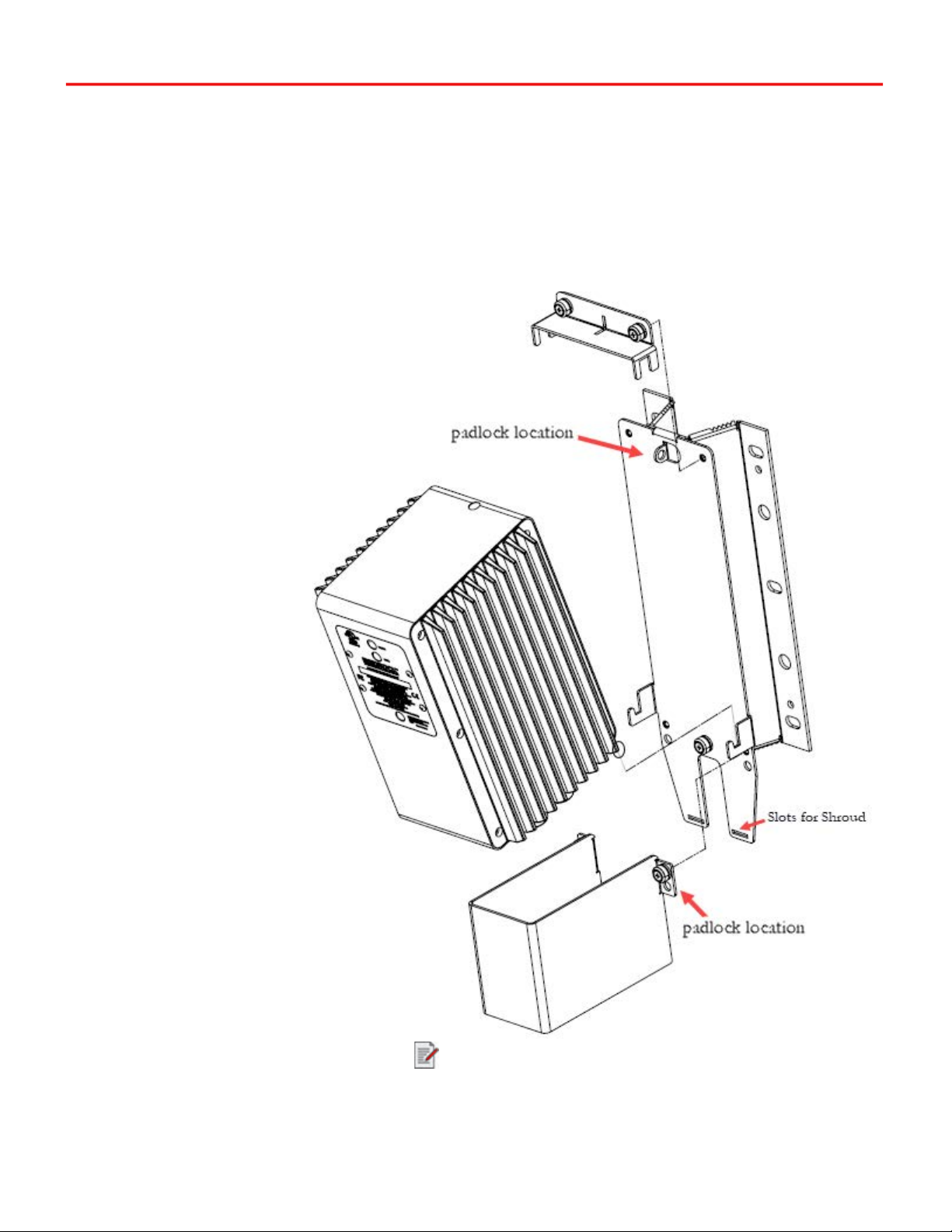

Installing the SPS.500 Figure 2-3 shows the SPS.500 installation to the mounting bracket (no cables

installed). The shroud gets installed after connecting cables. See Table B-1 for

part numbers.

1. Place the SPS.500 into the J-brackets, and then place the top locking

bracket onto the unit.

2. Tightened the top locking bracket’s two captive screws with a #2 cross-

tip screwdriver.

Figure 2-3 SPS.500 Installation to Bracket Hardware

Padlocks are required for hazardous locations.

Chapter 2 SPS.500 Installation

12 Bedrock SPS.500 User Manual - BRDOC125_007 9/3/21

WARNING: Prior to connecting the cables, refer to the SPS.500

Wiring chapter for important electrical and safety information.

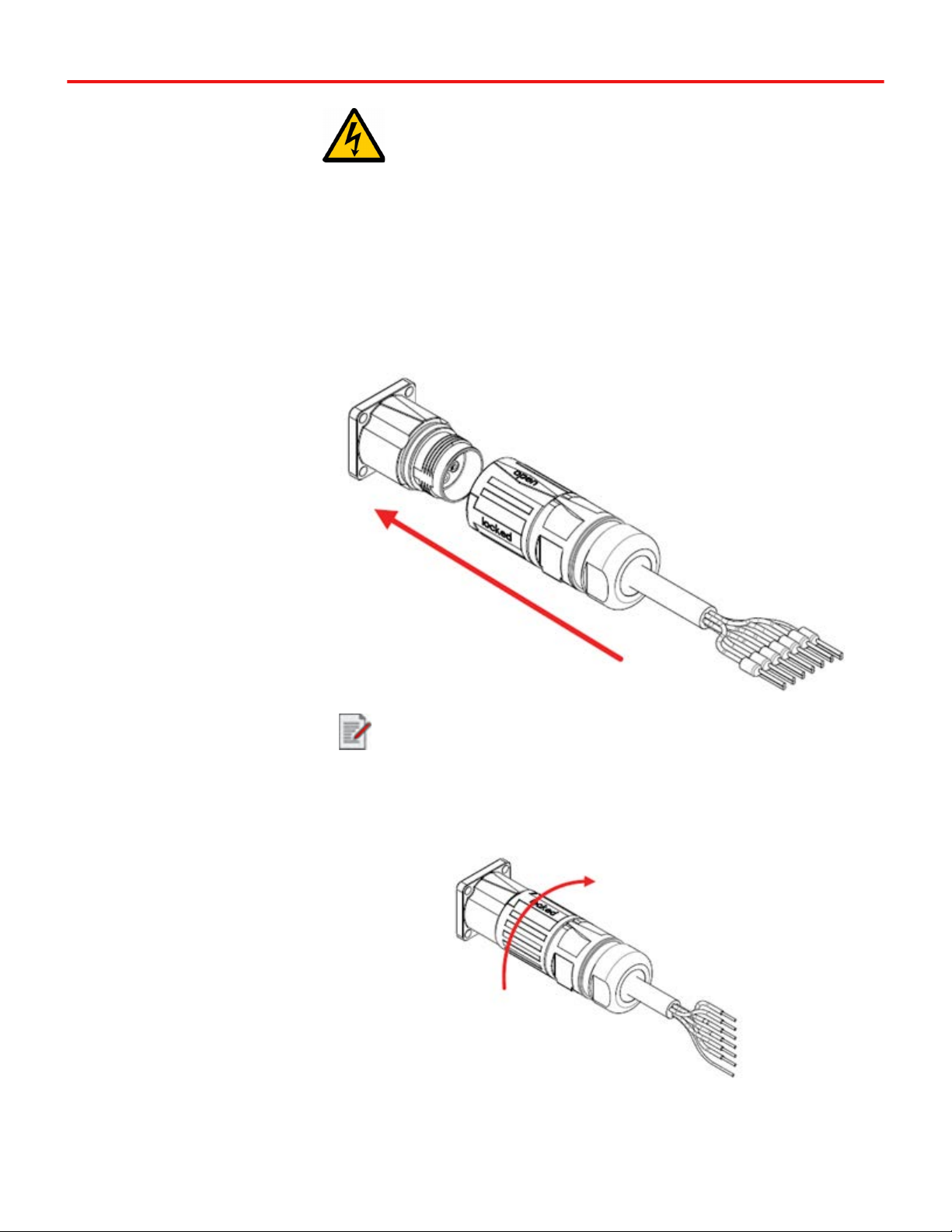

3. Connect the AC Power In cable, Power Out cable (use the “OR”ing

out cable in a redundant configuration), and the Relay cable

(optional) to the SPS.500. Connections are made as follows:

a. Align the Open arrow with the arrow on the mating connector and

then press together as shown in Figure 2-4.

Figure 2-4 Connector Alignment

b. Rotate 1/4 turn clockwise to the locked position.

Figure 2-5 Locked Connector

Although a power cable is shown, the connection method applies to

all connections except for the Ethernet cable.

SPS.500 Installation Chapter 2

9/3/21 Bedrock SPS.500 User Manual - BRDOC125_007 13

Figure 2-6 shows the SPS.500 with connectors locked and Ethernet cable

connected.

Figure 2-6 SPS.500 with Installed connectors

Important Notes:

AC Power must be rated for PLTC cable with AWG 14.

DC Power must be rated for PLTC cable with AWG 16.

Relay cabling must be rated for MC, MV, or PLTC with AWG 20.

Chapter 2 SPS.500 Installation

14 Bedrock SPS.500 User Manual - BRDOC125_007 9/3/21

The shroud secured over the connectors prevents the SPS.500

cables from disconnecting The shroud is required in Class I,

Division 2 hazardous locations. See the Bedrock SPS.500

Installation Guide for Hazardous Locations for additional

information.

After, the connectors have been attached and locked, place the shroud over the

connectors. Do the following:

1. Insert the bottom of the shroud into the two mounting bracket slots (as

shown in Figure 2-3).

2. Tighten the shroud’s two captive screws with a #2 cross-tip screwdriver.

Figure 2-7 Shroud in Closed Position Showing Padlock Locations

Padlocks are required for hazardous locations

Chapter 3

9/3/21 Bedrock SPS.500 User Manual - BRDOC125_007 15

SPS.500 Wiring

Important User

Information

Be sure to observe the following when working with the SPS.500.

WARNING: Dangerous voltages are present within the power

supply. Do not attempt to open the SPS.500 enclosure. Do not

come in contact with the incoming line voltage.

CAUTION: Always use an appropriate fuse on the power in

and power out connections.

CAUTION: Never attempt to open the SPS.500 enclosure. The

enclosure is securely sealed. Opening the enclosure will void

the warranty and cause the SPS.500 to be inoperable.

Power and Relay

Cables

Wire labels for the power in, power out, “OR”ing output, and relay cables for the

SPS.500 are illustrated in Figure 3-1.

WARNING: If using revision A of the SPS.500, never use the

Power Out port and “OR”ing output at the same time.

NOTE: For all cables, connect the drain wire to panel ground.

CAUTION: See the Specifications appendix for relay contact

rating information.

Table of contents