BEER Uno Top Hot Installation manual

Uno Top Hot

Mini-Vitrine

Instruction for installation and start up

Beer Grill AG

Beer Grill GmbH

Allmendstrasse 7

Tel. +41 (0)56 618 7800

Körnerstrasse 14 a

Tel. +49 (0)71 61 659 876

CH –5612 Villmergen

Fax +41 (0)56 618 7849

D –79539 Lörrach

Fax +49 (0)71 61 659 879

www.beergrill.com

Seite 2

Before you switch-on your Uno Top the first time, read this

instruction carefully.

CONTENTS

1 Introduction..........................................................................................................................3

2 Information of danger...........................................................................................................4

2.1 Heating with steam .......................................................................................................4

2.2 Heating dry (without steam) ..........................................................................................4

2.3 Attention! Danger of burning! ........................................................................................5

2.4 Procedure by lamp bursting and breakage of glass.......................................................5

2.5 Glazing / Danger of accident.........................................................................................5

3 Start up ................................................................................................................................7

3.1 Option Timer - check water level.................................................................................10

4 Transport and installation of Uno Top Hot..........................................................................11

5 Electrical connection ..........................................................................................................11

6 Classification and dimensions............................................................................................12

7 Technical data....................................................................................................................12

7.1 Units with cold and warm light (warm light dimmed or not dimmed) ............................12

7.2 Units with warm light (warm light dimmed or not dimmed)...........................................12

7.3 Units with cold light (without heating element in lower part) ........................................12

8 Cleaning and servicing.......................................................................................................13

8.1 Cleaning .....................................................................................................................13

8.2 Maintenance...............................................................................................................13

9 Guide to install the touch-guard (optional)..........................................................................15

10 After sales service..............................................................................................................16

11 Appendix............................................................................................................................17

!

Beer Grill AG

Beer Grill GmbH

Allmendstrasse 7

Tel. +41 (0)56 618 7800

Körnerstrasse 14 a

Tel. +49 (0)71 61 659 876

CH –5612 Villmergen

Fax +41 (0)56 618 7849

D –79539 Lörrach

Fax +49 (0)71 61 659 879

www.beergrill.com

Seite 3

1 Introduction

This operating and installation manual contains important basic information which needs to

be considered during installation, operation and maintenance. Therefore, the operations

manager and the operators must read the entire manual before the unit is installed and put

into operation. The manual must always be kept close to the unit and easily accessible.

Important!

Beer Grill AG cannot assume any responsibility or warranty obligations for any damage

sustained due to non-adherence to the installation and operating instructions or due to

improper use.

Symbols and notes

This symbol indicates important references for the proper use of the unit.

Not paying attention to these references can lead to malfunctions of the unit

or adverse effects to the environment.

Caution –hot surface!

Indicates a possibly dangerous situation due to hot surfaces. Failure to

observe the instruction may result in burns and/or damage to property.

This symbol points to operation tips and especially useful information.

Helps you to use all functions on your unit optimally.

This symbol indicates references to materials or operating media that

must be handled and/or disposed according to legal standards and

regulations.

!

i

Beer Grill AG

Beer Grill GmbH

Allmendstrasse 7

Tel. +41 (0)56 618 7800

Körnerstrasse 14 a

Tel. +49 (0)71 61 659 876

CH –5612 Villmergen

Fax +41 (0)56 618 7849

D –79539 Lörrach

Fax +49 (0)71 61 659 879

www.beergrill.com

Seite 4

2 Information of danger

2.1 Heating with steam

It is absolutely prohibited to run the Uno Top with empty water bins. Therefore the

water level has to be checked at least every 3 hours. See markings on both sides of the

bins. Use the built-in timer. Timer and flashlight is an option and has to be ordered

separately.

Beer Grill AG repudiates liability for consequential damage to ascribe to running

the Uno Top without water!

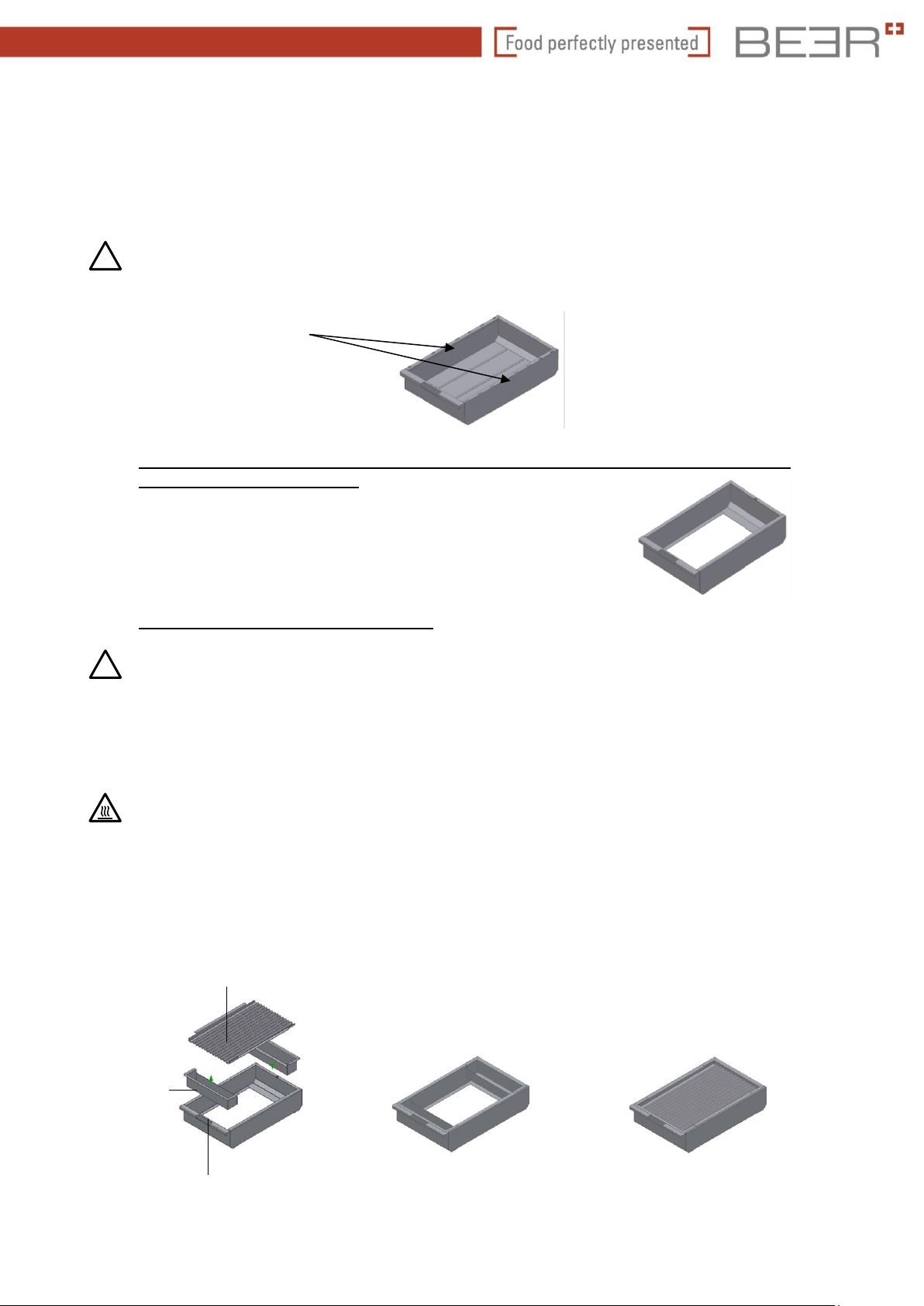

2.2 Heating dry (without steam)

Uno Top has to be equipped with a universal frame (accessories) in place of a

water bin.

Lower heating elements max. level 5

Caution, danger of fire!

When running dry, ceran heating plate gets very hot. Danger of fire, when oil or liquid fat

drops onto hot heating plate. Therefore mount universal frame, grill plate and fat collecting

bowls correctly, so fat or oil flows into bowls. Check fat or oil level in fat collecting bowls

frequently and drain it if necessary. (Dispose oil or fat according to regulations of local

authorities!)

Caution, when draining fat collecting bowls! Oil or fat is very hot. Touch and carry bowls

with protective gloves or cloth only. When lifting out fat collecting bowl be careful that oil

does not slope onto heating plates (fire danger) or on hands or legs (danger of getting

burned).

Never put out fire with water!

Use always fire blankets.

When getting burned consult doctor.

Universal frame

Fat collecting

bowl

Grill plate

!

!

Beer Grill AG

Beer Grill GmbH

Allmendstrasse 7

Tel. +41 (0)56 618 7800

Körnerstrasse 14 a

Tel. +49 (0)71 61 659 876

CH –5612 Villmergen

Fax +41 (0)56 618 7849

D –79539 Lörrach

Fax +49 (0)71 61 659 879

www.beergrill.com

Seite 5

2.3 Attention! Danger of burning!

The following parts will become very hot, when Uno Top is activated and, if touched, it exists

danger of burning:

- Ceran plate, if heating elements switched on and until they are completely cooled

down.

- Water bins and parts which are in touch with it.

- Infrared heater and lamp housing

- Cover of illumination bridge

Before water bins are drained (tap) and/or taken out, the Uno Top has to be cooled

down completely. This should also happen, before Uno Top is displaced.

2.4 Procedure by lamp bursting and breakage of glass

The infrared lamps are equipped with a shatter protection. This protection prevents touching

of lamps. In case of lamp bursting (infrared and compact fluorescent lamps) glass shelves,

sneeze screen, front and lateral glasses, proceed immediately as follows:

- Switch off and close counter.

- Self-service counter: Avoid guests taking food contaminated with glass splinter.

- Collect and replace all plates filled with food of guests, who have been nearby when

the incident happened.

- Take out all food containers of the counter. Dispose food in rubbish bin (not in bin for

leftovers).

- Take off shatter protection glass of defective lamp and clean it.

- Clean the Uno Top and floor.

- Replace broken items.

- Refit shatter protection glass with bracket.

- Refill counter.

- Counter is ready for reopening.

2.5 Glazing / Danger of accident

Incorrect, badly mounted or damaged glass may fall out and cause serious injuries. Be sure

to check before opening the self-service counter, but also after cleaning the glass (especially

the front- glass) if:

- The glass is placed properly e.g.: In the lower glass holders in the intended slots (not in

the rack separations, nor the discontinued racks). Both sides in the above designed

mounted holders.

- The glasses have no damage (damaged edges and corners = cut risk and insufficient

support). The safety glass may crack or burst due to internal tension, even without contact

with the damaged edge.

- The glass holder for damage and upper front holder (customer side) is well fitted. (Upper

part must rest on the upper glass edge). These holders are glued. Loosen holders must

be re-glued byqualified personnel.If the glass holder moves upwards, the upper stop ridge

(arrest) of the front glass may be affected and the glass can fall out by strong contrast

shock.

Damaged glass panels must be replaced immediately, glass holders refitted by

qualified personnel. In a pinch, continue working without the glass panels until the

required spare parts arrive.

Table of contents