beevision 183 User manual

BeeVision 183

Version 1.1

USER

MANUAL

1

CONTENTS

1.Preface ....................................................................................... 2

2.Description of The Product and Intended Use ........................... 3

2.1 Important Information ........................................................ 3

3.General Information ................................................................... 3

3.1 Overall Dimensions ............................................................. 4

3.2 Main Parts ........................................................................... 5

4.Using the Device ......................................................................... 7

4.1 Turning On/Off .................................................................... 8

4.2 Measurement Area ............................................................. 9

4.3 Volumizer .......................................................................... 10

4.4 Operation .......................................................................... 17

2

1. Preface

This document describes the usage of the BeeVision 183

dimensioning and weighing system. Permission must be obtained

from 3DTİM Elektronik A.Ş. to copy, reprint and translate this

document in whole or in part. This manual may not be published, in

whole or in part, or used without authorization for competitive

purposes. We reserve the right to make technical changes for

improvement.

This device can only be used for dimensioning and weight

measurements of 800x800x600 mm (WxDxH) opaque objects with a

maximum weight of 20 kg. Any use other than this purpose is

deemed illegal and constitutes a misuse of the machine. If it is used

in this way, all responsibility will be on the user.

BeeVision 183 is covered by a 1-year warranty. Malfunctions

resulting from user error or the use of the device not in accordance

with the user manual are not covered by the warranty.

3

2. Description of The Product and

Intended Use

BeeVision 183 is an industrial product used for dimensioning

and weighing. This device is designed for dimensioning and weighing

measurements of 800mmx800mx600mm (WxDxH) opaque loads

with a maximum weight of 20 kg. Provides flexibility in warehouses

by becoming portable with the cart shipped with the device.

Make sure that the feet that allow the device to be

attached to the vehicle from below are attached.

2.1 Important Information

• The maximum weight capacity is 20 kg.

• The device may not work properly if the slides that provide

the device movement are damaged.

• If the encoder in the moving parts is disconnected from the

gears, the device cannot measure correctly.

• BeeVision 183 cannot measure transparent objects such as

glass.

3. General Information

4

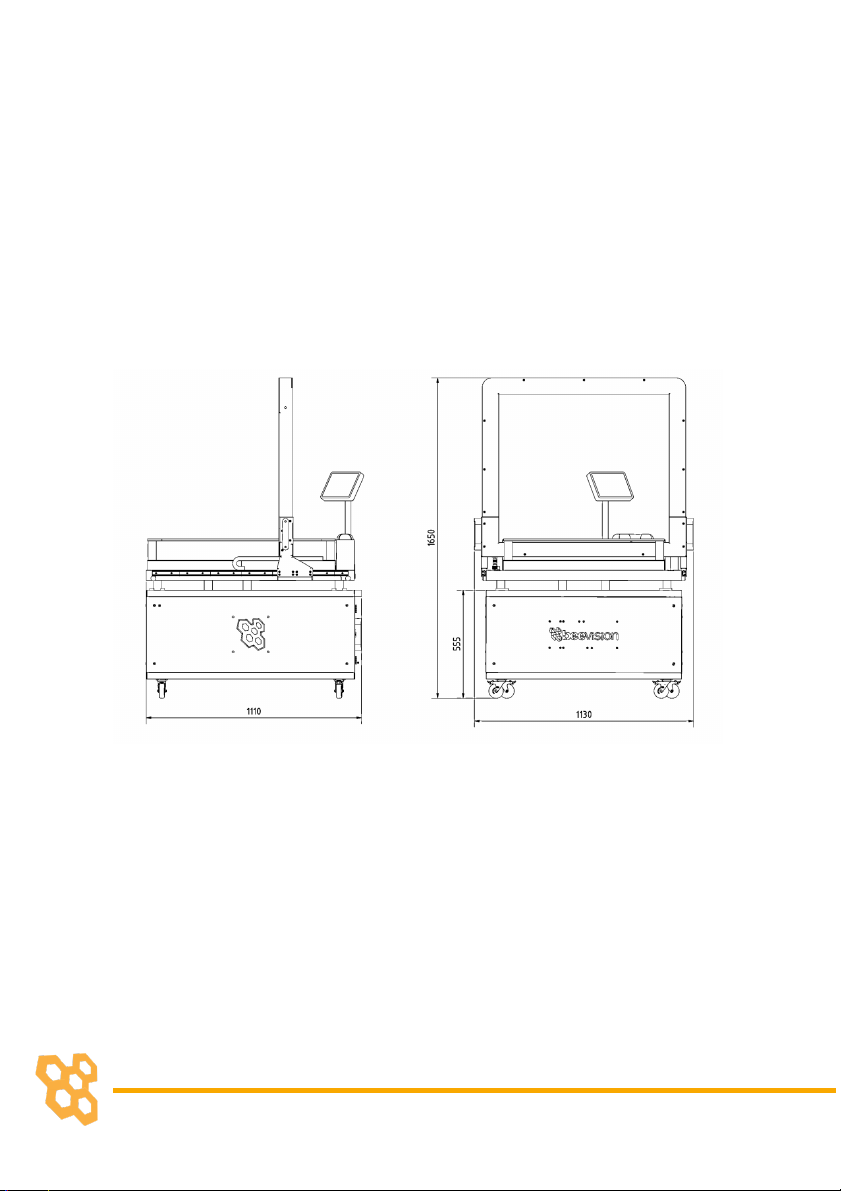

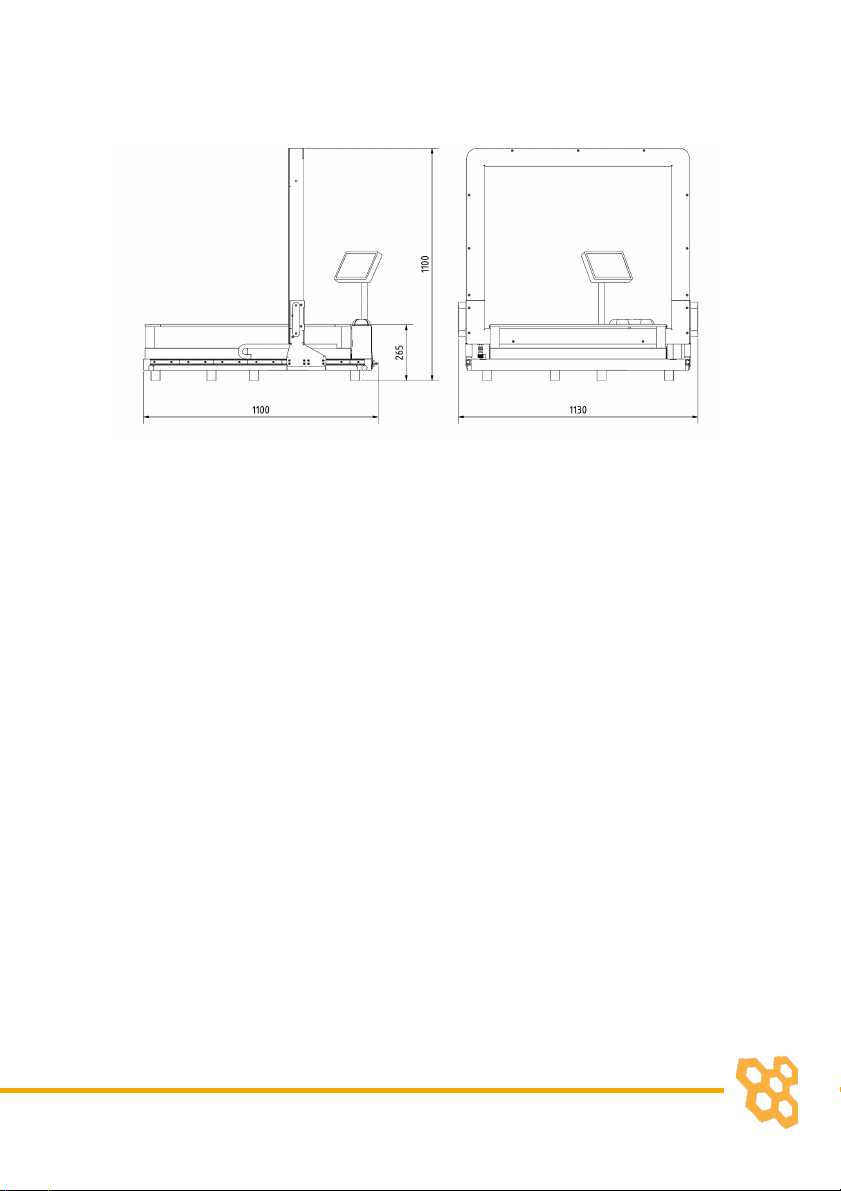

3.1 Overall Dimensions

The dimensions of the BeeVision 183 without cart are

1100x1100x1015 mm. The dimensions of the device together with

the car are 1100x1100x1570 mm. The specified dimensions are

shown in the figure below. (units are in mm)

Figure 3. 1

5

Figure 3. 2

3.2 Main Parts

Scanner: It is the orange group with handles. It moves with help of

linear guideways located on both sides of the device. The Scanner

allows the size of the object to be measured with an accuracy of 0,5

mm. Therefore, it should be used sensitively.

Weighing: It consists of the metal table where glass and legs are

joined. It measures the weight of the load placed on it with an

accuracy of 5 grams.

Monitor: This touchscreen monitor displays device controls,

measuring and weighing results.

Barcode Reader: It allows the product dimensions to be transferred

directly to the system by reading the barcodes of the products to be

measured

6

Indicator: The indicator, which is directly connected to the scale,

allows the weighing to be converted into numerical values.

Calibration of the balance is done from this section. The indicator is

located on the back of the device.

Rack Gear and Pinion: It is another element that allows the

measurement of the object to be taken. Any jamming will adversely

affect measurement accuracy.

Cart: It allows the device to be moved manually.

Figure 3. 3

7

USB 3.0 Port: There is one USB 3.0 port on the backside of the device.

In this way, users will be able to receive data from this port with the

help of a flash memory.

Ethernet Port: To communicate with any computer or a local server

for the data transfer.

Figure 3. 4

Rotary Switch: It is used to turn the system off and on. When the

switch is in position 0, all components of the system are turned off.

Wireless Antenna: Antenna, which is mounted on the dimensioner,

performs data transfer by establishing wireless communication with

a wireless modem device/PC.

4. Using the Device

8

4.1 Turning On/Off

When the power cord is inserted into the power port and

given mains voltage, turn the power switch shown in Figure 3. 4 to

position 1 and the system will be ready for use. The input mains

voltage BeeVision dimensioner must be at an interval between 100V-

240V and 50Hz-60Hz.

To turn off the device, simply unplug the power cord or turn

the power switch to ‘0’ state.

The mouse cursor is by default hidden in Volumizer UI. If you

would like to connect a mouse and a keyboard, you can

enable/disable the mouse cursor with Ctrl+Shift+M combinations on

your keyboard.

Please refer to the Software Guide for more

details on how to integrate BeeVision into your

system.

9

4.2 Measurement Area

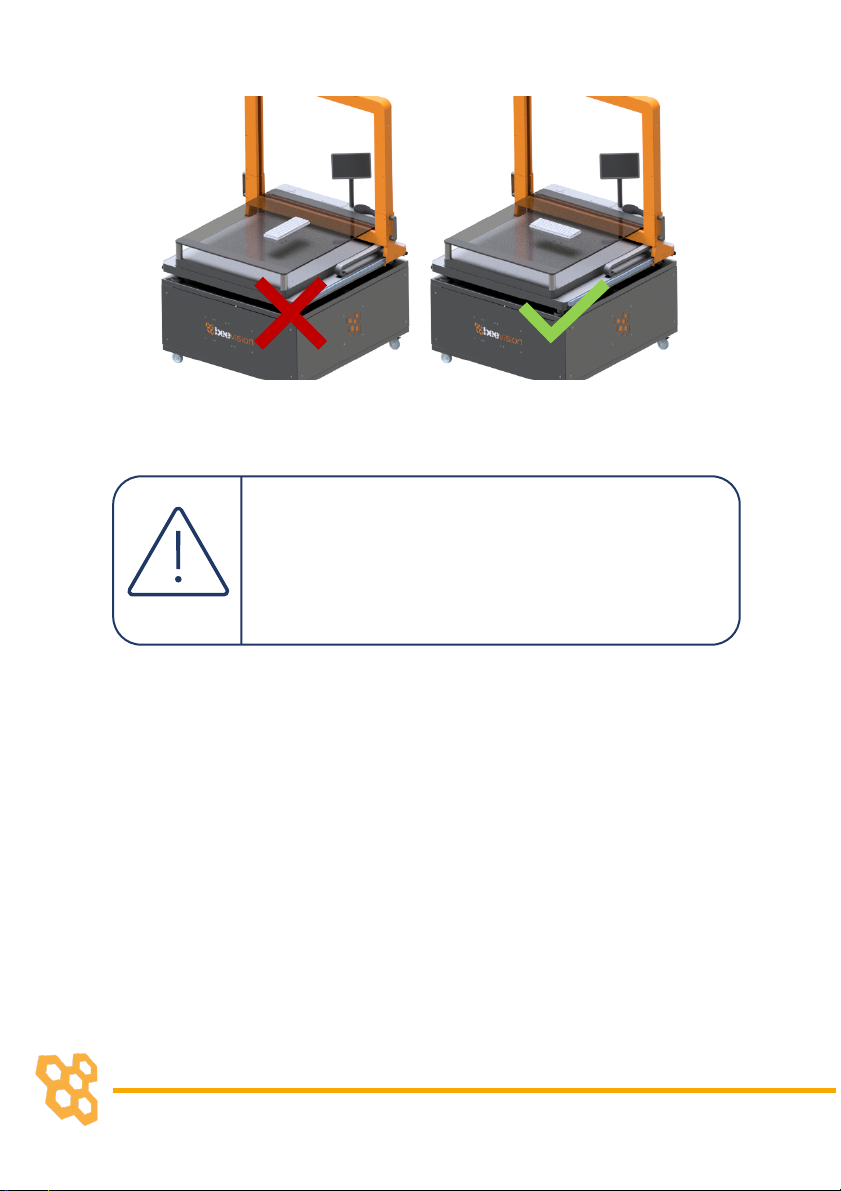

For the device to measure the object, the object must be

placed on the glass.

There is a color transition on the glass to make sure the object

does not stick out. Objects that overflow onto the painted part of the

glass cannot be measured.

Figure 4. 1

For better measurement, you have to put the

object horizontally. Also, the bigger dimension of

the object has to be perpendicular to the linear

channels.

10

Make sure that the dimensions of objects are less

than 800x800x600 (WxDxH) mm. Otherwise, the

object will overflow into the painted part of the

glass and correct measurement will not be

achieved.

4.3 Volumizer

Volumizer is the software installed in the BeeVision

dimensioners that enables users to control the device, perform

calibration and measurements. It has a graphical user interface (GUI)

that can be used when BeeVision is connected to a monitor.

11

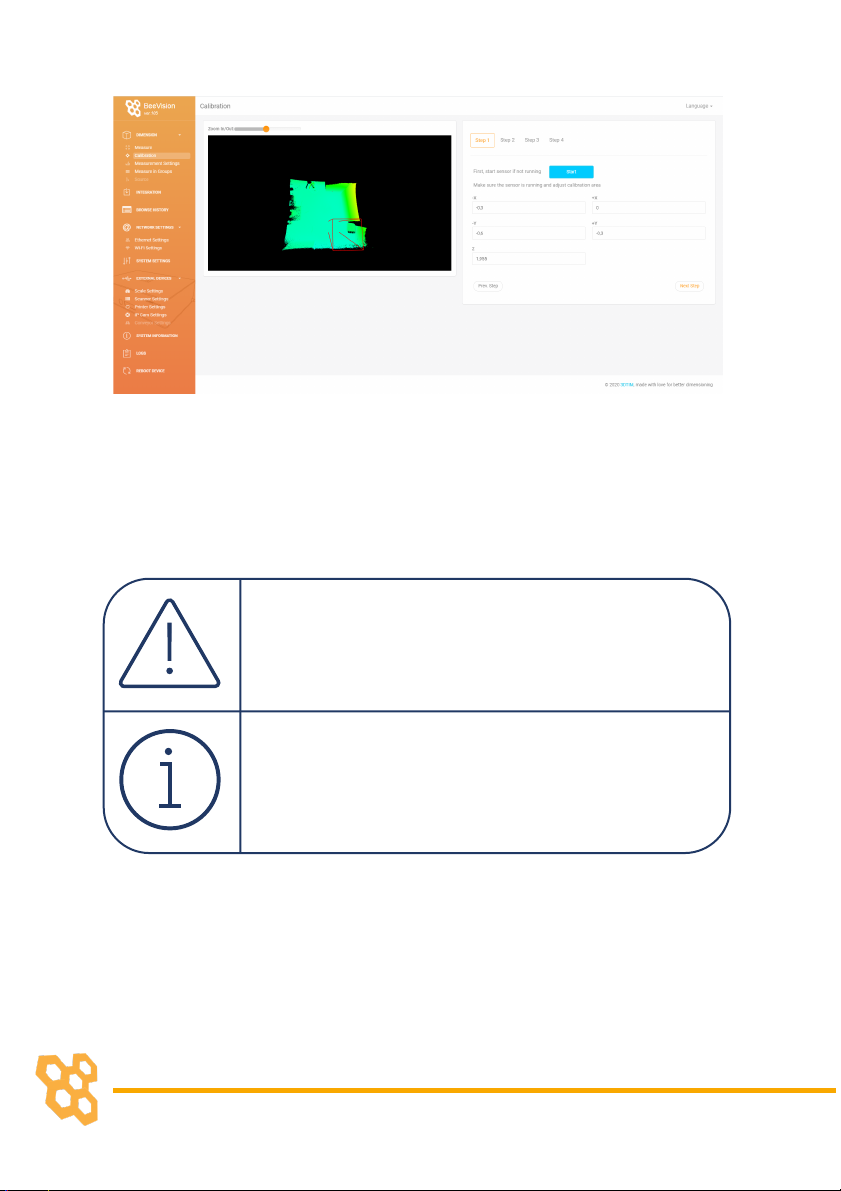

Figure 4. 2

It also has a web-based user interface (Web UI) that can be

accessed from a browser with the following address:

http://IP_address_of_device. The officially supported browser is

Google Chrome.

12

Figure 4. 3

If you use a different browser than Google Chrome,

some functions may not work as expected.

Users can navigate to the pages from the main

menu as shown in Figure 4. 2 and Figure 4. 3.

13

Following pages are included in Volumizer GUI and Web UI:

Brings up dimensioning

submenu

Dimension

Measure

Trigger measurement and

display results

Perform calibration and view 3D,

2D, and model data

Calibration

Measurement

Settings

Change measurement settings

Measurement in

Groups

Perform measurements in

groups and save results to a

remote address as an XML file

per group

14

Source

Merge 3D data with a slave,

remote BeeVision device

Brings up the barcode decoding

submenu (might be disabled

depending on the model)

Decode

Integration

Change result sharing options

Change Ethernet and Wi-Fi

settings

Network Settings

Change system settings such as

language, time, date, and device

operation mode

System Settings

Brings up the external devices

submenu

External Devices

15

Scale Settings

Change scale connection

settings

Scanner Settings

Change handheld and fixed-

mount barcode scanner

connection settings

Printer Settings

Change label printer settings

Conveyor Settings

Change conveyor and PLC

connection settings (might be

disabled based on the model)

Ip Cam Settings

Change IP camera settings

(might be disabled based on the

model)

Browse History

Browse previous measurement

results

16

View information about the

system such as model name,

certification status, SW

checksum, etc.

System Information

Restarts the device.

Reboot

View system log and parameter

changelog.

Logs

GUI Navigation Icons:

Opens up the previous upper menu page.

Opens up the main menu page.

17

4.4 Operation

BeeVision 183 dimensioning system is delivered as pre-

calibrated. If there is nothing wrong with delivery and installation,

there is no need to recalibrate the device.

The measurement area is to the border of the painted side

of the glass. Read the Measurement Area chapter if you need

support in this case.

Figure 4. 4

Steps of Measurement

18

• To perform a measurement, an object must be placed into

the measurement area and measurement and weighing

should be triggered by moving the scanner.

• When the user moves the scanner to measure, it must be

moved along the entire object.

Figure 4. 5

19

During the measurement, there must be only one

object in the measurement area.

No part other than the scanner should be touched

to accurately measure the weight of the item.

• Whether the user scans the barcode just before or right after

weighing, the product measurement data will reach the

system directly via Wi-Fi.

• The user can view the results on the touch monitor at this

stage.

• The user can take the object and can move on to measure

the next one.

Objects can be placed to any location on the

measurement area to measure.

For more information, please contact us.

Table of contents

Other beevision Measuring Instrument manuals

Popular Measuring Instrument manuals by other brands

Woodley

Woodley InSight V3 PLUS Operator's manual

Keysight Technologies

Keysight Technologies N6705C Operating and service guide

CYP

CYP CPHD-V4 Operation manual

Teledyne Lecroy

Teledyne Lecroy DL03-ISO user manual

Spirax Sarco

Spirax Sarco ILVA20 Installation

Qstarz

Qstarz Explore 2000 Quick installation guide

DeFelsko

DeFelsko PosiTest PC instruction manual

getemed

getemed PhysioMem PM 100 4G Instructions for use

PR electronics

PR electronics 5714 product manual

iLine microsystems

iLine microsystems microINR Instructions for use

Trotec

Trotec BP21 operating manual

PCB Piezotronics

PCB Piezotronics 357B45 Installation and operating manual