VCMC v1.1 - ASSEMBLY GUIDE Rev Apr 2021

THANKS FOR CHOOSING ONE OF OUR KITS!

This assemb y guide is a bit different from the other Befaco ones. We wi be assemb ing sections, and testing them one

by one, so we wi not keep bui ding unti we make sure it is working nice y.

This wi make our bui d a bit s ower and carefu , as this is quite a tricky build.

Some steps are not obvious, so even if you're an experienced DIYer, p ease take the time to read the steps thorough y

before starting.

If this is your first project, p ease read this artic e before you start assemb ing the kit:

www.befaco.org/howto/

VC C can be assembled as an Standalone unit. During the build we will point out the components you might

change. Check page 2 for details on this odification from Eurorack version.

OPEN BAG A

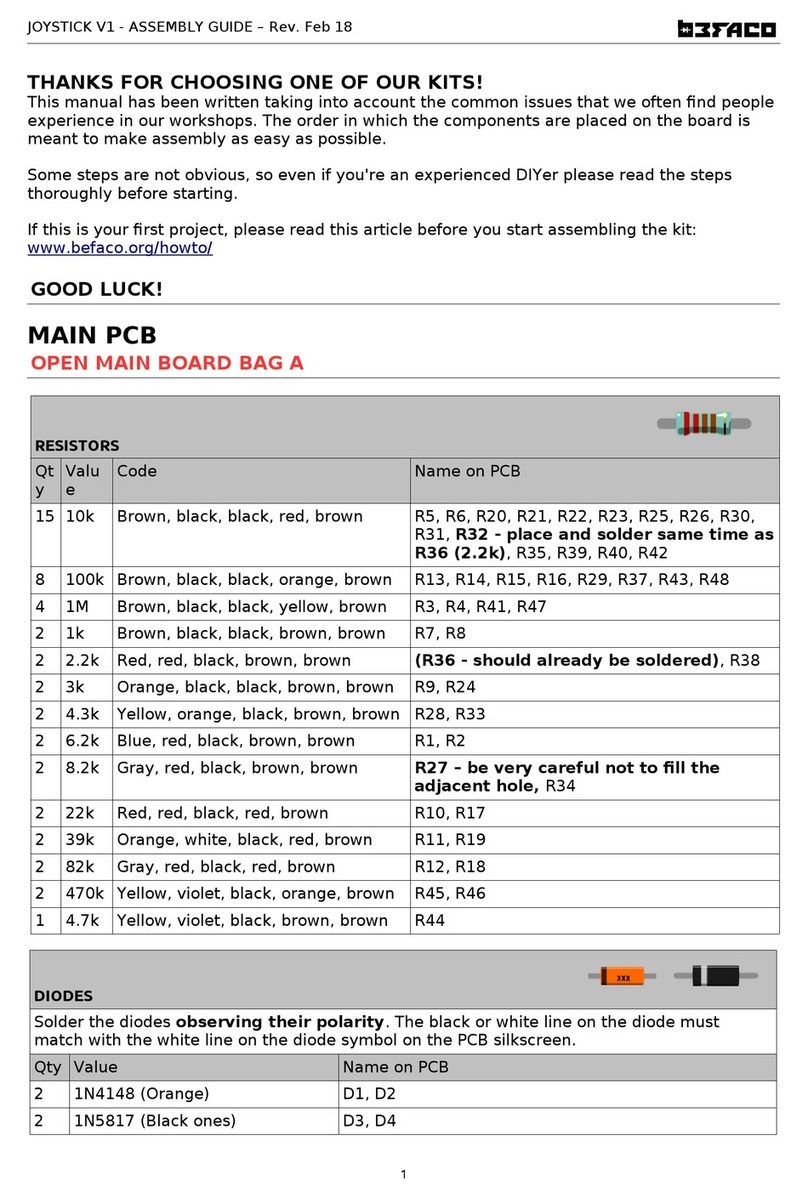

RESISTORS

Qty Va ue Code Name on PCB

14 100k Brown, b ack, b ack, orange, brown R6, R7, R11, R13, R14, R15, R16, R17, R18, R19, R20,

R21, R26, R29

11 1k Brown, b ack, b ack, brown, brown R12, R25, R27, R30, R31, R32, R33, R34, R35, R36,

R37

4 10k Brown, b ack, b ack, red, brown R1, R2, R9, R10

5 33k Orange, orange, b ack, red, brown R5, R22, R23, R24, R28

2 56 ohm Green, b ue, b ack, go d, brown R4, R8

1 2k2 Red, Red, b ack, brown, brown R3

DIODES

So der the diodes observing their polarity. The b ack or white ine on the diode must match with the white ine on

the diode symbo on the PCB si kscreen.

Qty Va ue Name on PCB

2 1N5817 D1, D2

6 BAT85 D3, D4, D5, D6, D7, D8

FERRITES

So der the two ferrite beads by using a recyc ed diode eg passed through each ferrite and proceed as if it were a

resistor. Ferrite beads don't have po arity.

Qty Name on PCB+

2 F1, F2

1