C R U S H D E L A Y P O W E R & I T R O

P O W E R I G

T H E M O D U L E

U S E R M A U A L

T H A K S F O R P U R C H A S I G A M O D U L E F R O M B E FA C O !

B E F O R E Y O U P L U G T H I S M O D U L E I . . .

1.

Disconnect our cabinet from the mains.

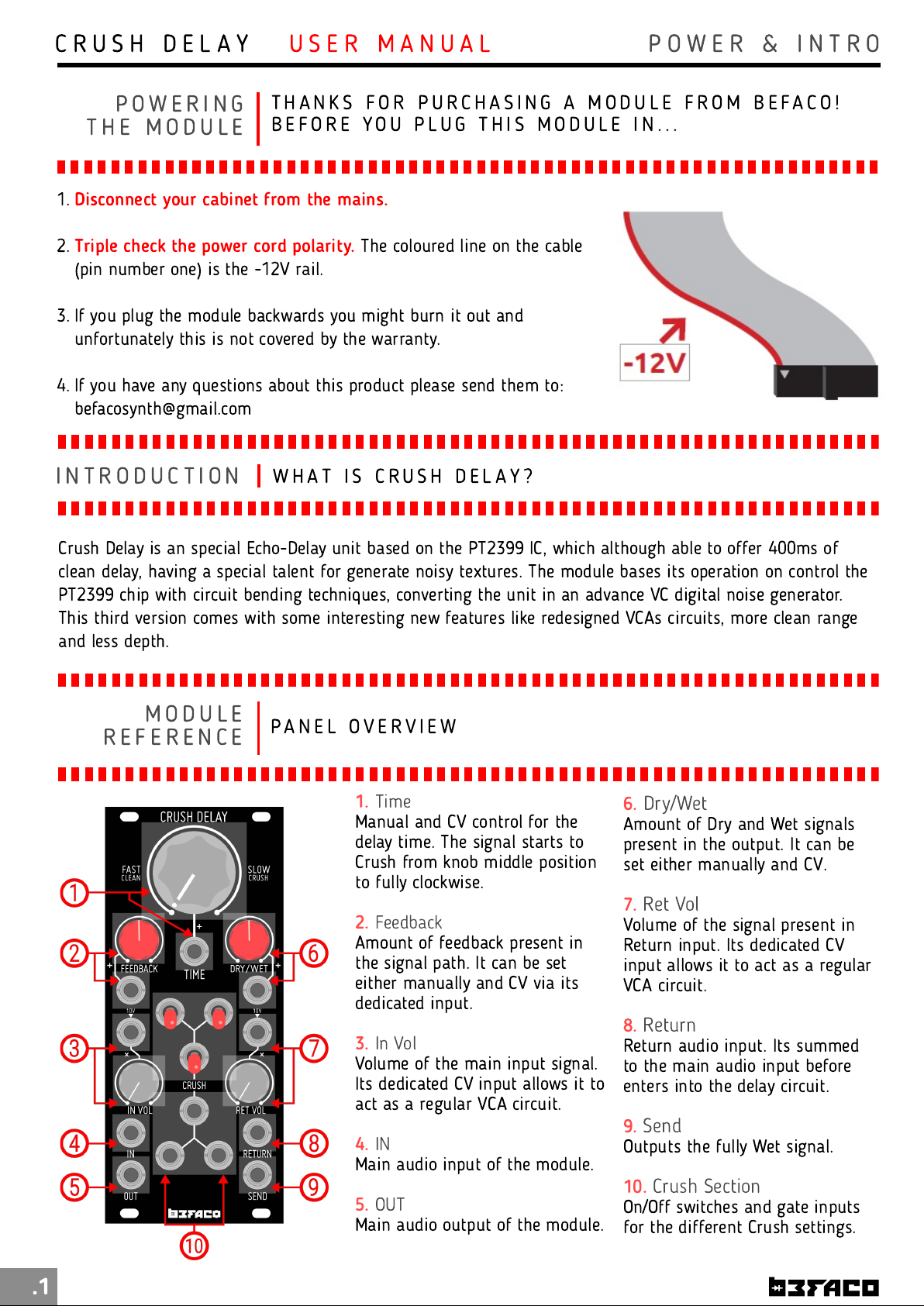

2.

Triple check the power cord polarit .

The coloured line on the cable

(pin number one) is the -12V rail.

3. If you plug the module backwards you might burn it out and

unfortunately this is not covered by the warranty.

4. If you have any questions about this product please send them to:

befacosynth@gmail.com

I T R O D U C T I O W H A T I S C R U S H D E L A Y ?

Crush Delay is an special Echo-Delay unit based on the PT2399 IC, which although able to offer 400ms of

clean delay, having a special talent for generate noisy textures. The module bases its operation on control the

PT2399 chip with circuit bending techniques, converting the unit in an advance VC digital noise generator.

This third version comes with some interesting new features like redesigned VCAs circuits, more clean range

and less depth.

M O D U L E

R E F E R E C E PA E L O V E R V I E W

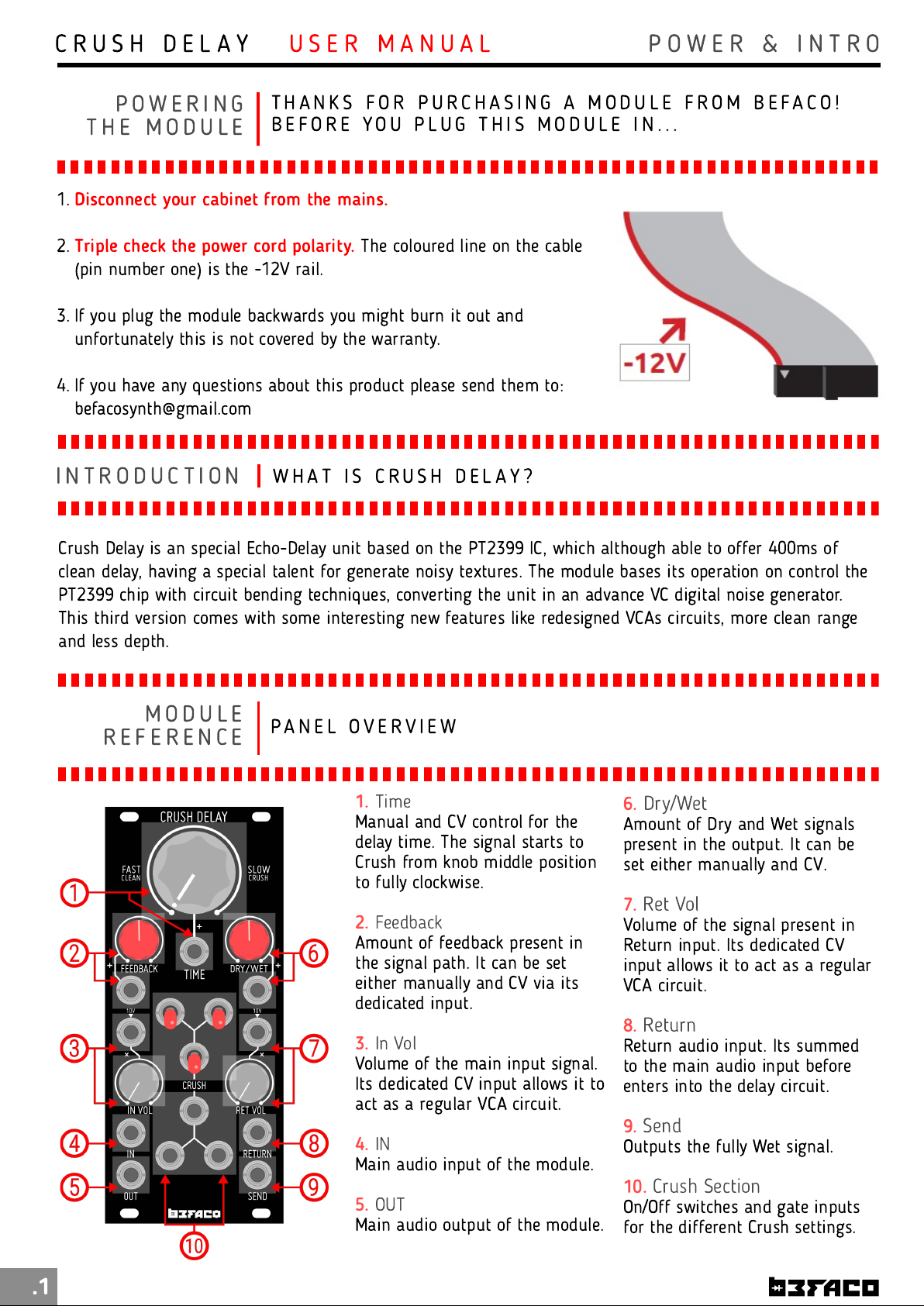

1.

Time

Manual and CV control for the

delay time. The signal starts to

Crush from knob middle position

to fully clockwise.

2.

Feedback

Amount of feedback present in

the signal path. It can be set

either manually and CV via its

dedicated input.

3.

In Vol

Volume of the main input signal.

Its dedicated CV input allows it to

act as a regular VCA circuit.

4.

IN

Main audio input of the module.

5.

OUT

Main audio output of the module.

.1

6.

Dry/Wet

Amount of Dry and Wet signals

present in the output. It can be

set either manually and CV.

7.

Ret Vol

Volume of the signal present in

Return input. Its dedicated CV

input allows it to act as a regular

VCA circuit.

8.

Return

Return audio input. Its summed

to the main audio input before

enters into the delay circuit.

9.

Send

Outputs the fully Wet signal.

10.

Crush Section

On/Off switches and gate inputs

for the different Crush settings.