2

86105 BA-en/01

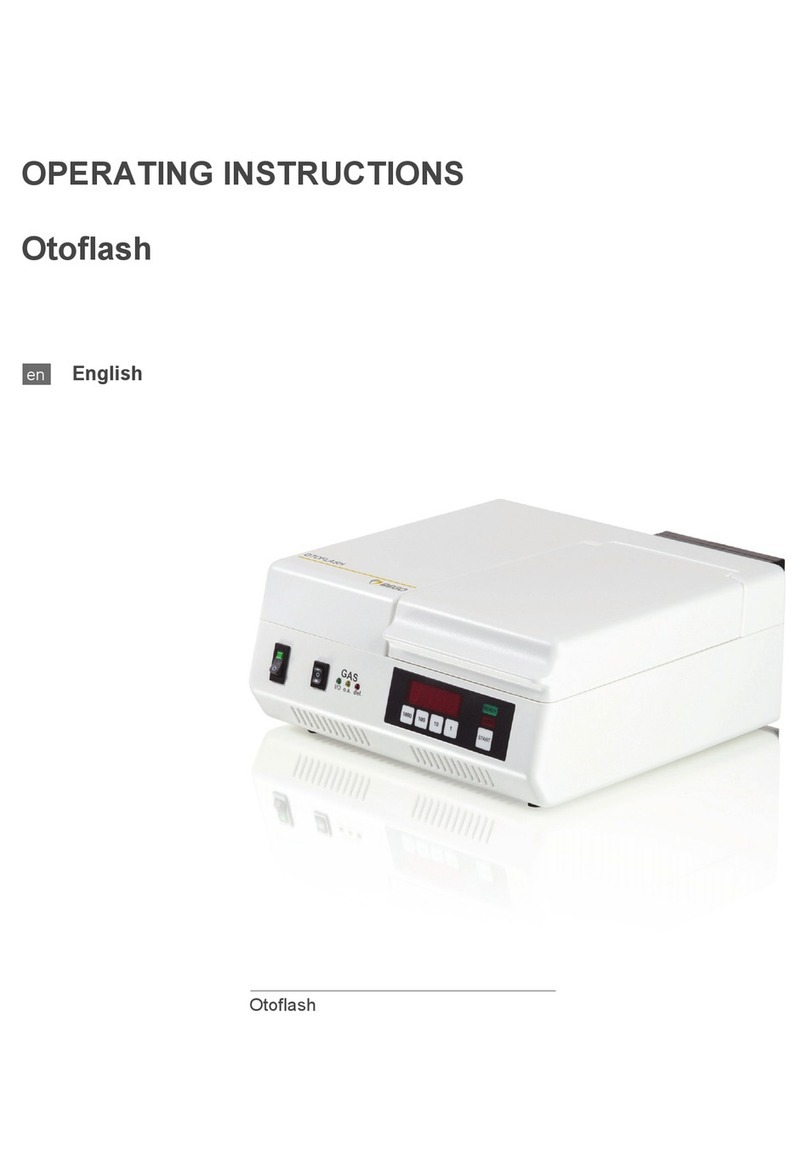

English ⋅ Nautilus®CC plus ⋅ Nautilus®T

This device documentation is part of the device

and must be enclosed when selling or trans-

ferring the device.

• The device has been designed solely for use in

dental laboratories and comparable institutions

for research, commercial and training purpos-

es. The device must only be operated by dental

professionals; trainees and other persons oper-

ating the device must be supervised.

• The operating manual must be read and under-

stood before the device is used. This applies, in

particular, to the safety Instructions. Damage

caused by non-compliance with this operating

manual will invalidate any and all warranty

claims. We will also assume no liability for any

resulting consequential damage.

Contents

General Information............................................... 4

Important notes ..................................................... 6

Unpacking / Packing.............................................. 7

Safety instructions ................................................. 8

Device description ................................................11

Scope of delivery and extras ............................... 13

Technical data ..................................................... 15

Installation ........................................................... 16

Switching on ........................................................ 18

Initial commissioning ........................................... 19

Basic principles: Wax-up ..................................... 23

Basic principles: Crucible .................................... 25

Basic principles: Moulds...................................... 27

Basic principles: Work ......................................... 28

Program table (BEGO alloys).............................. 34

Table of holding times / further heating times...... 36

Settings ............................................................... 38

NAUTILUS®CC plus

Device description ........................................... 44

Casting process settings ................................. 45

Casting ............................................................ 49

NAUTILUS®T

Device description ........................................... 60

Casting process settings ................................. 61

Casting ............................................................ 63

Service and Maintenance.................................... 70

Troubleshooting................................................... 79

Signs and labels .................................................. 82

Disposal............................................................... 84

Declaration of Conformity......................... Appendix