Beijer Electronics X2 control User manual

Foreword

Installation manual for X2 base 5 v2

Foreword

All operator panels are developed to satisfy the demands of human-machine

communication. Built-in functions such as displaying and controlling text,

dynamic indication, time channels, alarm and recipe handling are included.

The operator panel works primarily in an object-oriented way, making it easy to

understand and use. Configuration is carried out on a PC using iX Developer

software. The project can then be transferred and stored in the operator panel

itself.

Various types of automation equipment such as PLCs, servos or drives can be

connected to the operator panels. In this manual, the term “the controller” refers

to the connected equipment.

This manual explains how to install the operator panel. Please refer to the

iX Developer reference manual for further information.

Order no: MAEN328

Copyright © 2021-05 Beijer Electronics AB. All rights reserved.

The information in this document is subject to changewithoutnoticeandisprovidedasavailableatthe

time of printing. Beijer Electronics AB, including all its group companies, reserves the right to change any

information without updating this publication. Beijer Electronics AB, including all its group companies,

assumesnoresponsibilityforanyerrorsthatmayappearinthisdocument. Readtheentireinstallation

manual prior to installing and using this equipment. Only qualified personnel may install, operate or repair

this equipment. Beijer Electronics AB, including all its group companies, are not responsible for modified,

altered or renovated equipment. Because the equipment has a wide range of applications, users must acquire

the appropriate knowledge to use the equipment properly in their specific applications. Persons responsible

for the application and the equipment must themselves ensure that each application is in compliance with

all relevant requirements, standards and legislationinrespecttoconfigurationandsafety. Onlypartsand

accessories manufactured according to specifications set by Beijer Electronics AB, including all its group

companies, may be used.

BEIJER ELECTRONICS AB, INCLUDING ALL ITS GROUP

COMPANIES, SHALL NOT BE LIABLE TO ANYONE FOR ANY

DIRECT, INDIRECT, SPECIAL, INCIDENTAL OR CONSEQUENTIAL

DAMAGES RESULTING FROM THE INSTALLATION, USE OR

REPAIR OF THIS EQUIPMENT, WHETHER ARISING IN TORT,

CONTRACT, OR OTHERWISE. BUYER'S SOLE REMEDY SHALL

BE THE REPAIR, REPLACEMENT, OR REFUND OF PURCHASE

PRICE, AND THE CHOICE OF THE APPLICABLE REMEDY SHALL

BE AT THE SOLE DISCRETION OF BEIJER ELECTRONICS AB,

INCLUDING ALL ITS GROUP COMPANIES.

Beijer Electronics, MAEN328

Contents

Contents

1 SafetyPrecautions ....................................................... 4

1.1 General ........................................................... 4

1.2 Hazardous Materials ............................................. 4

1.3 DisposalRequirementsUnderWEEERegulations ........... 5

1.4 DuringInstallation .............................................. 5

1.5 DuringUse ....................................................... 5

1.6 Service and Maintenance ........................................ 5

1.6.1 CleaningtheDisplay ............................................ 5

1.7 Dismantling and Scrapping ..................................... 6

1.8 Appearance of Air in Touch Screen ............................. 6

2 NamingConvention .................................................... 7

3 Installation ............................................................... 8

3.1 SpaceRequirements ............................................. 8

3.2 InstallationProcess .............................................. 8

3.2.1 ConnectionstotheController ..................................10

3.2.2 OtherConnectionsandPeripherals .............................10

3.2.3 OpenPorts .......................................................10

4 TechnicalData ........................................................... 11

5 ChemicalResistance .................................................... 13

5.1 Touch Screen and Overlay Material ............................ 13

5.1.1 ProtectiveFilm ...................................................13

5.1.2 TouchScreenSurface ............................................14

5.1.3 TouchScreenProtector ..........................................14

6 OperatorPanelDrawings .............................................. 15

6.1 Connectors ....................................................... 15

6.2 X2base5v2Outline ............................................. 17

7 Additional Installation Tips ............................................ 18

7.1 Grounding the operator panel .................................. 18

7.2 EthernetConnectionintheOperatorPanel ................... 19

7.3 To Achieve Better EMC Protection ............................. 20

7.4 AmbientTemperature ........................................... 21

7.5 Safety ............................................................. 23

7.6 GalvanicIsolation ................................................ 24

7.7 Cable and Bus Termination RS-485 ............................ 26

7.8 USBMemorystick ............................................... 26

Beijer Electronics, MAEN328

Safety Precautions

1SafetyPrecautions

Both the installer and the owner and/or operator of the operator panel must read

and understand this installation manual.

1.1 General

•Read the safety precautions carefully.

•Check the delivery for transportation damage. If damage is found, notify the

supplier as soon as possible.

•Do not use the operator panel in an environment with high explosive hazards.

•The supplier is not responsible for modified, altered or reconstructed

equipment.

•Use only parts and accessories manufactured according to specifications of

the supplier.

•Read the installation and operating instructions carefully before installing,

using or repairing the operator panel.

•Neverallowfluids,metalfilingsorwiringdebristoenteranyopeningsinthe

operator panel. This may cause fire or electrical shock.

•Only qualified personnel may operate the operator panel.

•Storing the operator panel where the temperature is lower/higher than

recommended in this manual can cause the LCD display liquid to

congeal/become isotropic.

•The LCD display liquid contains a powerful irritant. In case of skin contact,

wash immediately with plenty of water. In case of eye contact, hold the eye

open,flushwithplentyofwaterandgetmedicalattention.

•Thefiguresinthismanualserveanillustrativepurpose. Becauseofthemany

variables associated with any particular installation, the supplier cannot

assume responsibility for actual use based on the figures.

•The supplier neither guarantees that the operator panel is suitable for your

particular application, nor assumes responsibility for your product design,

installation or operation.

•It is recommended to turn on and shut down the operator panel at least once

before installing any components/cards or before connecting the operator

panel to external devices; for example serial devices.

•For Marine panels only:

–The operator panel must be installed and operated as described in this

document to meet this certification.

–Observe precautions for handling electrostatic discharge sensitive devices

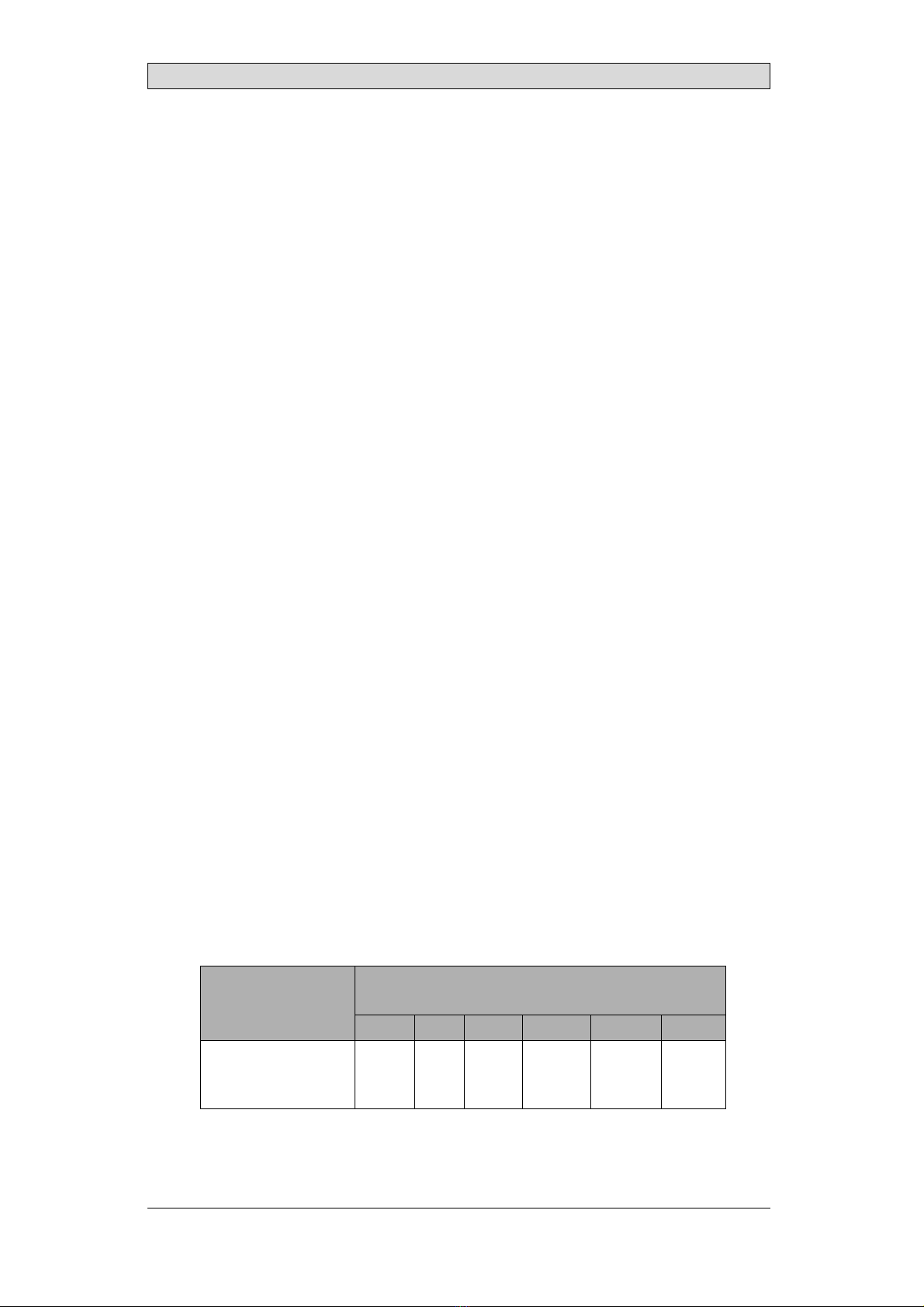

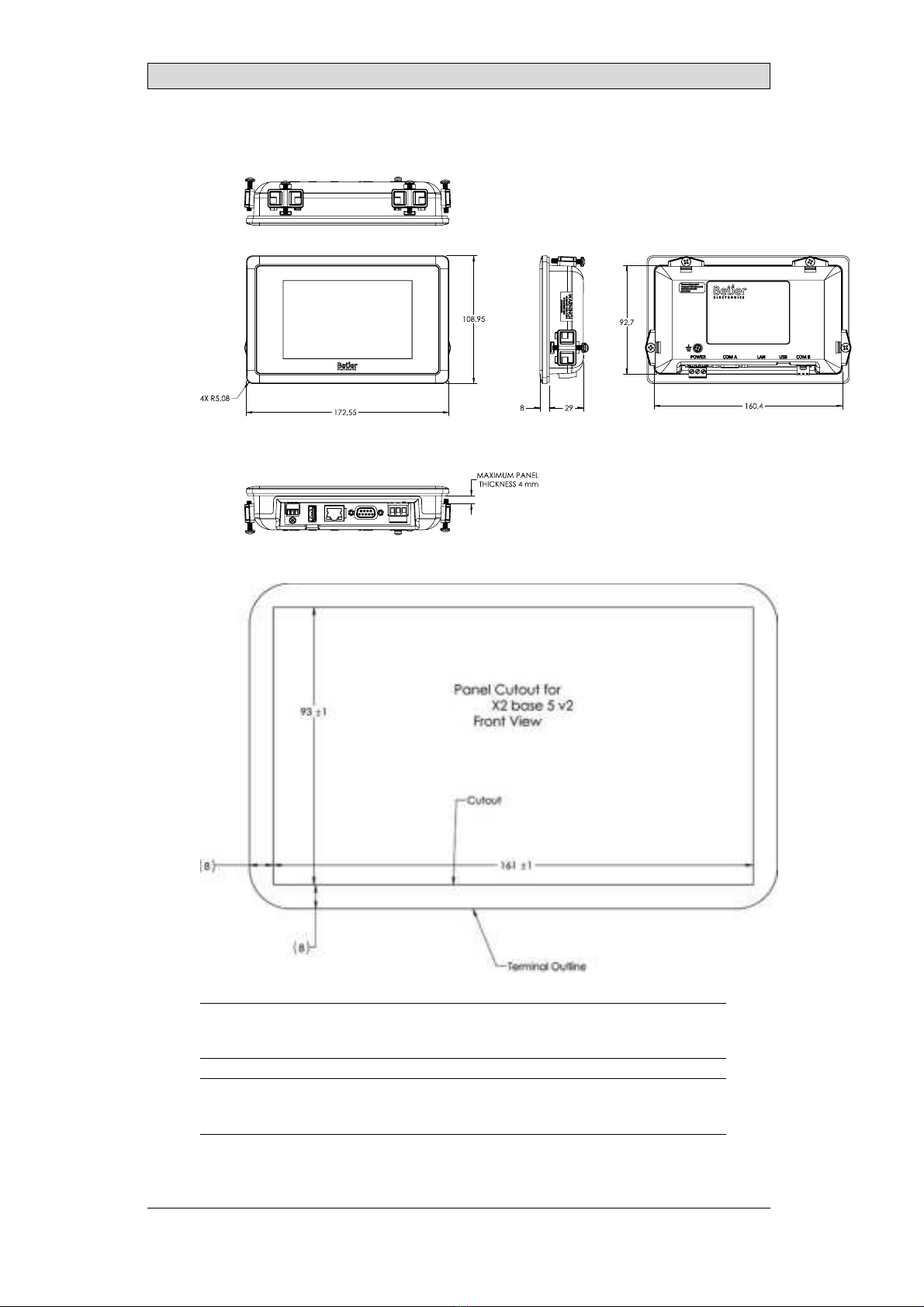

1.2 HazardousMaterials

Toxic and hazardousmaterialsor elements

有毒和有害的材料或元素

Part description

零件描述

Pb Hg Cd Cr6+ PBB PBDE

PCBand elect ronic

component s

PCB和电子元件

XOO O O O

Beijer Electronics, MAEN328 4

Safety Precautions

1.3 Disposal RequirementsUnder

WEEERegulations

For professional users in the European Union: If you wish to discard electrical

and electronic equipment (EEE), please contact your dealer or supplier for further

information.

For disposal in countries outside of the European Union: If you wish to discard

this product please contact your local authorities or dealer and ask for the correct

method of disposal.

1.4 DuringInstallation

•Install the operator panel according to the accompanying installation

instructions.

•Ground the operator panel according to the accompanying installation

instructions.

•Only qualified personnel may install the operator panel.

•Separate the high voltage, signal, and supply cables.

•Make sure that the voltage and polarity of the power source is correct before

connecting the operator panel to the power outlet.

•Peripheral equipment must be appropriate for the application and location.

1.5 DuringUse

•Keep the operator panel clean.

•Emergency stop and other safety functions may not be controlled from the

operator panel.

•Do not use excessive force or sharp objects when operating the touch screen.

1.6 Service and Maintenance

•Only qualified personnel should carry out repairs.

•The agreed warranty applies.

•Before carrying out any cleaning or maintenance operations, disconnect the

equipment from the electrical supply.

•Clean the display and surrounding front cover with a soft cloth and mild

detergent.

1.6.1 Cleaningthe Display

We recommend using a dry, clean cloth to wipe off dust regularly. Use alcohol or

ammonia-based cleaning agent for cleaning only when necessary. When other

solvents or cleaning agents are used, be sure to follow manufacturers’ instructions.

The agent should be applied to a clean cloth and should not be sprayed directly

onto the panel surface. After cleaning the agent should be removed.

Ammonia based glass cleaners (typically 5-10% ammonia) or 75% alcohol can be

used to clean the surface of PCAP and resistive touch panels.

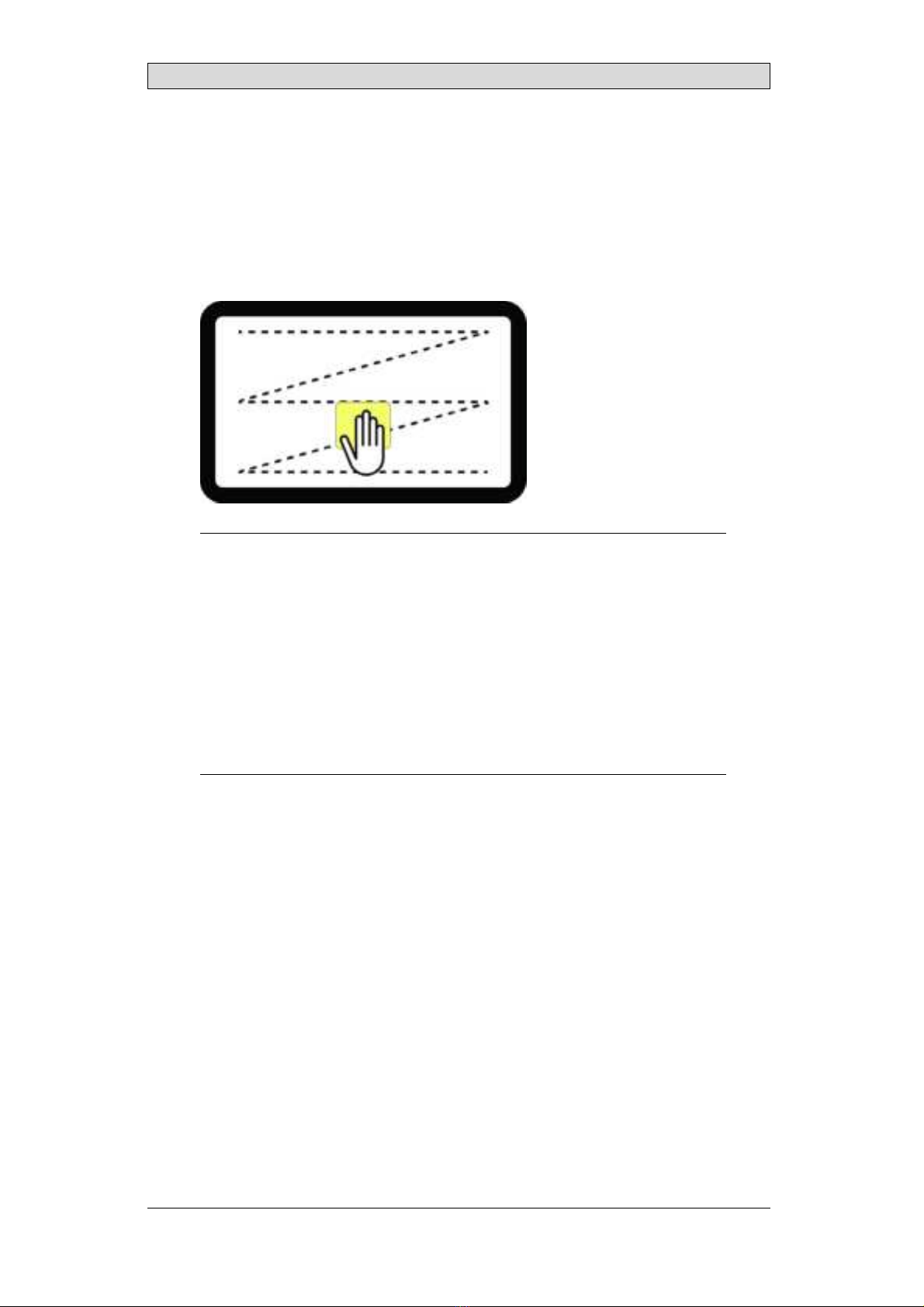

When you clean the surface of your touch panel, please follow these steps:

Beijer Electronics, MAEN328 5

Safety Precautions

1. Apply cleaning agent (alcohol, bleach, or glass cleaner) to a clean cloth. Make

sure the cloth is well saturated.

2. Wipe touch panel in a “Z” motion on the touch panel surface.

3. Dry the panel thoroughly with a dry cloth, removing as much of the cleaning

solution as possible.

4. Do not mix bleach and ammonia because this will produce a dangerous

chemical reaction.

5. Please do not spray cleaning solution directly onto the touch panel surface.

Note:

•Cleaning solut ions cont aining bleach, alcohol, and ammonia are cor rosive t o

t ouch panel sur face coat ingsand ITOfil m. So, you shoul d not leave t he sol ut ion on

t he t ouch panel surface f or more t han 2 minut es. Make sure t o remove all residue

when finished cleaning.

•Do not use sharp t oolst o clean t he surf ace of t he t ouchscreen.

•Do not use air guns, wat er j et s, or st eam, t o clean t he surf ace of t ouchscreens as

t hey may damage t ouchscreen f unct ional it y.

•If condiment s, food, or drinksare spil led on t he surf ace of t he t ouchscreen, please

remove t hem immediat ely.

•Ensure moist ure doesnot seep t hrough t he cabl e connect i on ar ea f r om t he edges

during cleaning.

1.7 Dismantlingand Scrapping

•The operator panel or parts thereof shall be recycled according to local

regulations.

•The following components contain substances that might be hazardous to

health and the environment: lithium battery, electrolytic capacitor, and

display.

1.8 Appearance of Air in Touch Screen

The layer structure of the touch screen contains air. In rare cases, the appearance

of bubbles can arise. This is purely cosmetic and does not affect the functionality

of the operator panel. The appearance can occur under certain environmental

conditions such as temperature, humidity, and atmospheric pressure.

Beijer Electronics, MAEN328 6

Naming Convention

2 NamingConvention

The name of each panel is based on its properties according to the table below.

X2 family Size (inches)

Genera-

tion/ Version Variant

base

pro

marine (= wit h

BL)

cont r ol (= wit h

SC)

mot i on (= wit h

SM)

ext reme

4

5

7

10

12

15

21

v2 SC

SM

HB

HP

BL

12V

SL

RO

CO

web

Soft Cont rol

Soft Mot ion

High Bright ness

High perf ormance

Black

12 Volt

Sealed

Rugged Only

Cer t ificat ion Only

Examples:

•X2 base 5 v2

•X2 pro 7

•X2 control 10

•X2 marine 12 SC

•X2 marine 15 HB SC

•X2 extreme 7 12V*

•X2 extreme 12 HP SC*

•X2 extreme 7 SL HP*

•X2 extreme 12 SL HP SC*

•X2 extreme 7 CO*

•X2 extreme 12 SL HP RO

Note:

Not all combinat ionsare available.

Note:

* indicat esvariant sincl uding IECEx\ ATEXand C1D2 accredit at ion.

Beijer Electronics, MAEN328 7

Installation

3Installation

3.1 Space Requirements

•Maximum installation plate thickness: 4 mm.

The following drawings show the space requirements in millimeters when

installing the operator panel. The drawings are only illustrative and may be out of

proportion.

100,00

50,00

100,00

50,00

100,00

3.2 Installation Process

The following is needed:

•A Phillips/slot screwdriver

Do the following:

1. Unpack and check the delivery. If damage is found, notify the supplier.

Note:

Place t he operat or panel on a st able surf ace during inst allat ion.

Dropping t he operat or panel or let t ing it f all may cause damage.

2. To cut a correct opening for the operator panel, use the cut out dimensions

in the outline drawing.A separate cut out drawing is available for download

from the Beijer Electronics web site. For more information, see sections

Operator Panel Drawings and Technical Data.

Beijer Electronics, MAEN328 8

Installation

3. Make sure that the mounting surface of the cutout is smooth and cleaned from

any burrs or debris.

4. Install the operator panel into the cutout.

5. In cases where the front panel seal is critical, use a torque wrench to ensure all

screws are torqued within the specification above.

6. Connect the cables in the specified order, according to the drawing and steps

below.

Caution:

•The oper at or panel must be brought t o ambient t emperat ure bef ore it isst art ed

up. If condensat ion f orms, ensure t hat t he operat or panel is dry before connect ing

it t o t he power out l et .

•Ensure t hat t he operat or panel and t he cont roller syst em have t he same elect rical

grounding (ref erence vol t age level), ot herwise errors in communicat ion may

occur.

•Ensure t hat t he volt age and pol arit y of t he power source iscorrect .

•Separat e high volt age cables from signal and supply cables.

•Shielded communicat ion cablesare recommended.

24V DC

RS232/

RS422/

RS485

24V DC

A

D

Controller

Power

B

Ethernet

C

The image is illustrative only and may differ slightly from the actual panel.

–Connect cable A.

–Connect cable B, using 14-20 AWG (2.08–0.52 mm2), 180–220 N-cm

torque.

–Connect cable C.

–Connect cable D. The recommended cross-section of the cable is 1.5

mm2.

7. Carefully remove the protective film over the operator panel display, take care

to avoid static electricity that could damage the panel.

Beijer Electronics, MAEN328 9

Installation

3.2.1 Connectionsto the Controller

For information about the cables to be used when connecting the operator panel to

the controller, please refer to the help file for the driver in question.

3.2.2 Other Connectionsand Peripherals

Cables, peripheral equipment and accessories must be suitable for the application

and its environment. For further details or recommendations, please refer to the

supplier.

3.2.3 Open Ports

In the firmware there are some ports that are open by default due to the operating

system or that the internal application requires it.

Type Descript ion Open by default

UDP Proj ect t ransf er (9999) Yes

UDP Net bios(137) Yes

UDP Net bi os(138) No(1)

(1) Filt ered.

Beijer Electronics, MAEN328 10

Technical Data

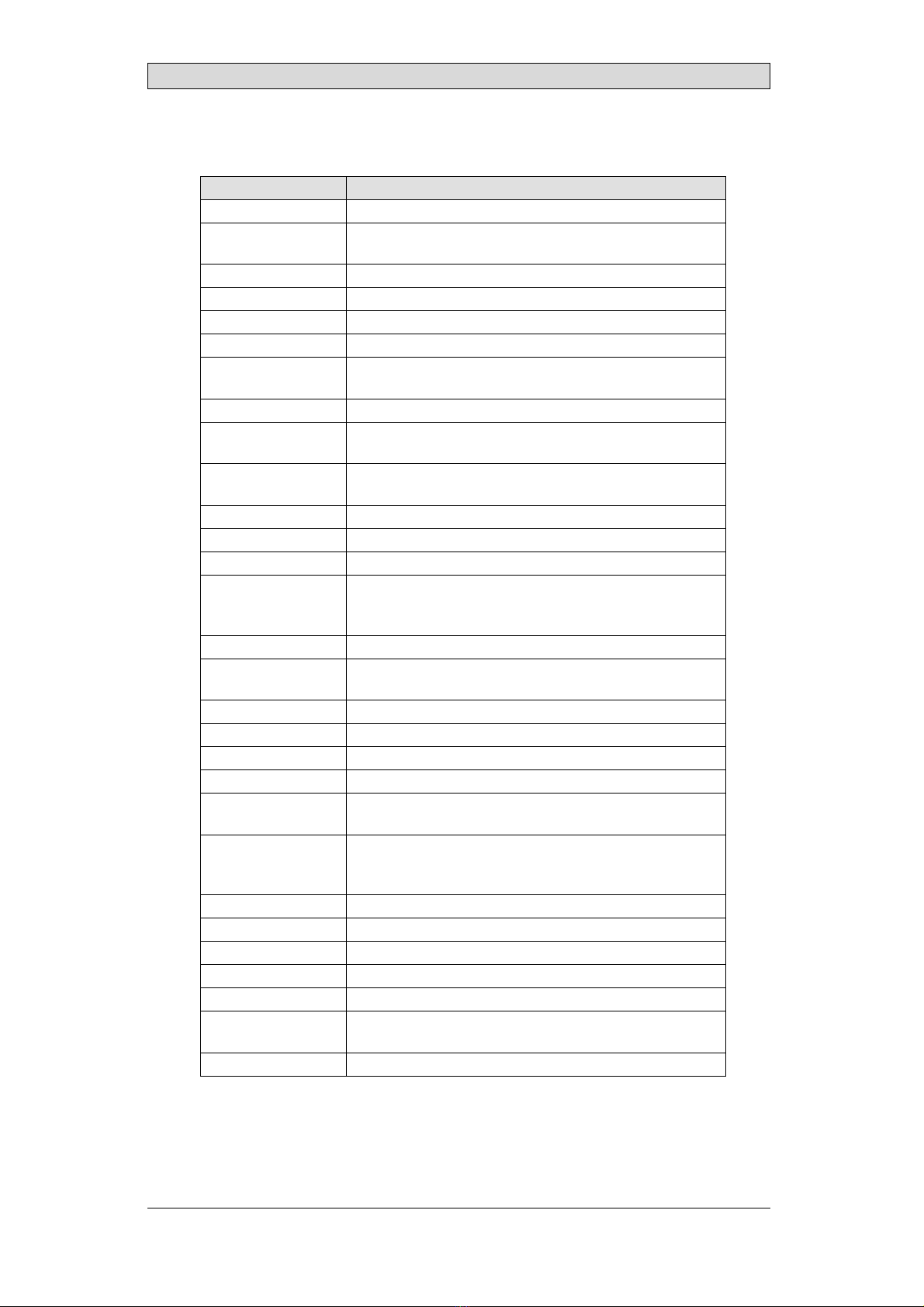

4TechnicalData

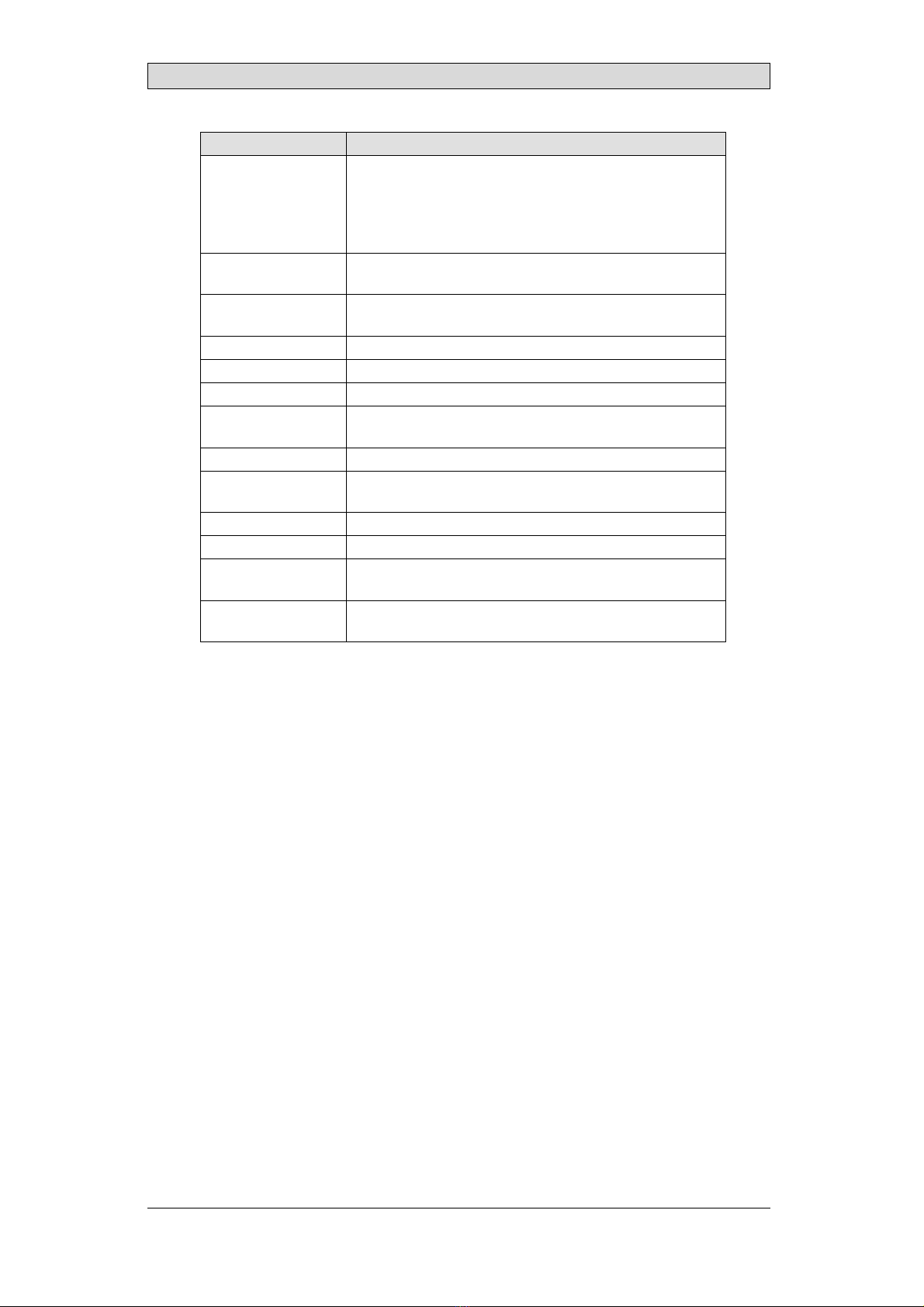

Paramete r X2 base 5 v2

Front panel, W×H×D 172x109x37mm

Cut out dimensions,

W×H

161x93 (+/ -1) mm

Mount ing dept h 32 mm (132 mm including cl earance)

Mount ing Swit chboard inst all at ion

Front panel seal IP65

Rear panel seal IP 20

Touch screen

mat erial

Polyest er on glass, ITO film, resist ive

Frame overl ay Aut oflex EBA 180L

Touch screen

operat ions

1 million finger t ouch operat ions

Re ve r se si de

mat erial

Pl ast ic

Frame mat erial Plast ic

Weight 0.32 kg

CPU TI Sit ara AM335x Single Core 600MHz, (TI AM3352BZCZ60)

Seri al por t COM A St andard DSUB (9-pin, f emal e).

1x RS232 RX/ TXwit h RTS/ CTS

1x RS422 or 2x RS485

Serial port COMB N/ A

Serial port COMC 3 pin screw connect or

1x RS485

Et hernet LAN A 10/ 100 Mbit / s. Shielded RJ 45

Et hernet LAN B N/ A

USB-A 1 × USBHost 2. 0, max out put 500 mA

USB-B N/ A

Ext ernal st orage

media

N/ A

Flash memory

(appl icat ion

memory)

2GB

Memory RAM 512 MB(DDR3)

NVRAM N/ A

LED N/ A

Re al t i m e cl ock Yes

Bat t ery Lit hium bat t ery t ype CR2032, exchangeabl e

Pow er con sum pt i on

at rat ed volt age

4.8 W

Fuse Int ernal DCf use, 3 AT, SMD

Beijer Electronics, MAEN328 11

Technical Data

Paramete r X2 base 5 v2

Power supply +24 VDC(18-32 V DC)

CE: The power suppl y must conf orm wit h t he requirement s

according t o EN/ IEC60950 and EN/ IEC61558-2-4.

UL and cUL: The power supply must conf orm wit h t he

requirement s for class2 power supplies.

Di splay 5. 0” TFT-LCDwit h LEDbacklight . 800x480 pixels, 16. 7M

colors

Act ive area of

display, W × H

108. 00 x 64.80

Pixel errors ClassI (ISO9241-307)

Backlight bright ness 250 cd/ m2

Backlight l if et ime 20000 hours

Operat ing

t emperat ure

0°C–+50°C

St orage t emperat ure -20 ° C–+60 ° C

Relat ive humidit y in

operat ion

5 - 90%non-condensed / 25° C

Vibrat ion 1g, according t o IEC60068-2-6, Test Fc

Mechanical shock 10g, half -sine, 6msaccording t o IEC60068-2-27

Approvalsand

cert ificat ions

CE/ FCC

Inf ormat ion isavailable on www.beij erelect ronics.com

UL approval Inf ormat ion isavail abl e on ht t p:/ / www.beij erelect ron-

ics.com and/ or ht t ps:/ / UL.com

Beijer Electronics, MAEN328 12

Chemical Resistance

5 Chemical Resistance

5.1 Touch Screen and Overlay Material

5.1.1 Protective Film

Solvent Resistance

The protective film withstands exposure of more than 24 hours duration under

DIN42115Part2tothefollowingchemicalswithoutvisiblechange:

Acet onit ril e Diesel Pet rol eum spirit (1)

Aj ax / Vim in solut ion Downy / Lenor(1) Phosph or i c ac i d ( <30%)

Alkalicarbonat e

solut ion(1) Et hanol Pot assium ferricyanide

Ammonia (<40%)(1) Glycerine Pot assium hydroxide (<30%)

Acet ic acid (<50%) Glycol Pure Turpent ine

Ariel powder in

solut ion(1) Gumpt ion(1) SBP60/ 95(1)

Bleach(1) Hydrochloric acid (<36%) Sulf uric acid (<10%)

Cast or oil Linseed oil Tomat o ket chup

Caust ic soda (<40%)(1) Met hanol Trichloroacet ic acid (<50%)

Cut t ing oil Nit ric acid (<10%) Whit e Spirit

Cycl ohexanol Paraf finoil Windex

(1)

Di acet one alcohol Persil powder in solut ion(1) Wisk

(1) Ext r emel y f aint gl ossing of t he t ext ur e w asnot ed.

The Autoflex protective film withstands DIN 42 115 Part 2 exposure of up to 1

hour duration to glacial acetic acid without visible change.

The Autoflex protective film is not resistant to high pressure steam at over 100

°C or the following chemicals:

Concent rat ed mineral acids Benzyl alcohol

Concent rat ed caust ic solut ion Met hylene chloride

Beijer Electronics, MAEN328 13

Chemical Resistance

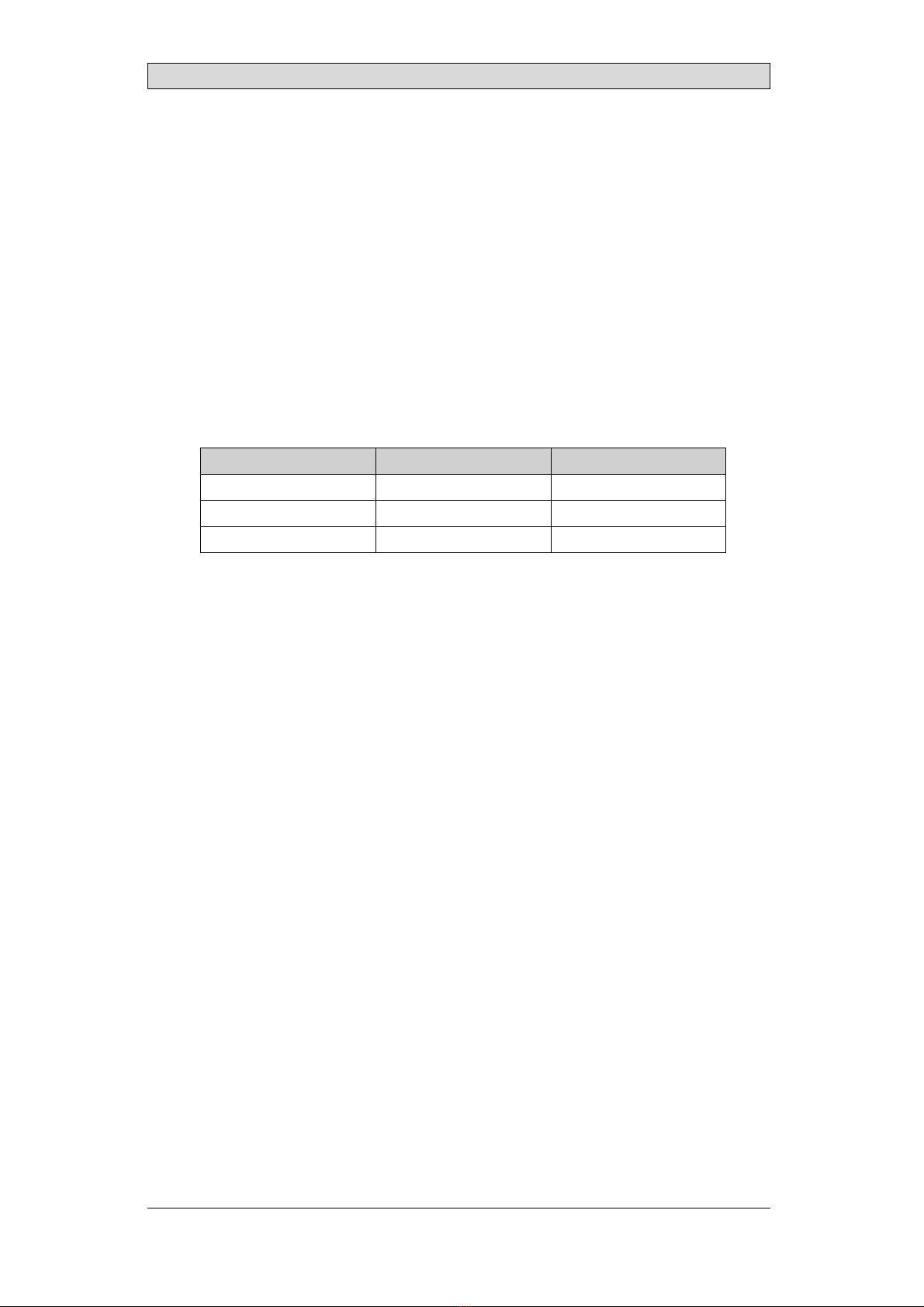

5.1.2 Touch Screen Surface

The touch screen surface on the operator panel withstands exposure to the

following solvents without visible change:

Solvents Time

Acet one 10 minut es

Isopropanol 10 minut es

To l u e n e 5 h o u r s

Thetouchscreensurfaceontheoperatorpanelismadeofpolyesterwithahard

coat to resist scratches and withstand exposure to many solvents without visible

change.

5.1.3 Touch Screen Protector

For harsh environments and exposure to outdoor conditions, it is recommended

to use a protective film to guard the touch screen from damage. This optional part

can be ordered from Beijer Electronics.

Beijer Electronics, MAEN328 14

Operator Panel Drawings

6 Operator Panel Drawings

6.1 Connectors

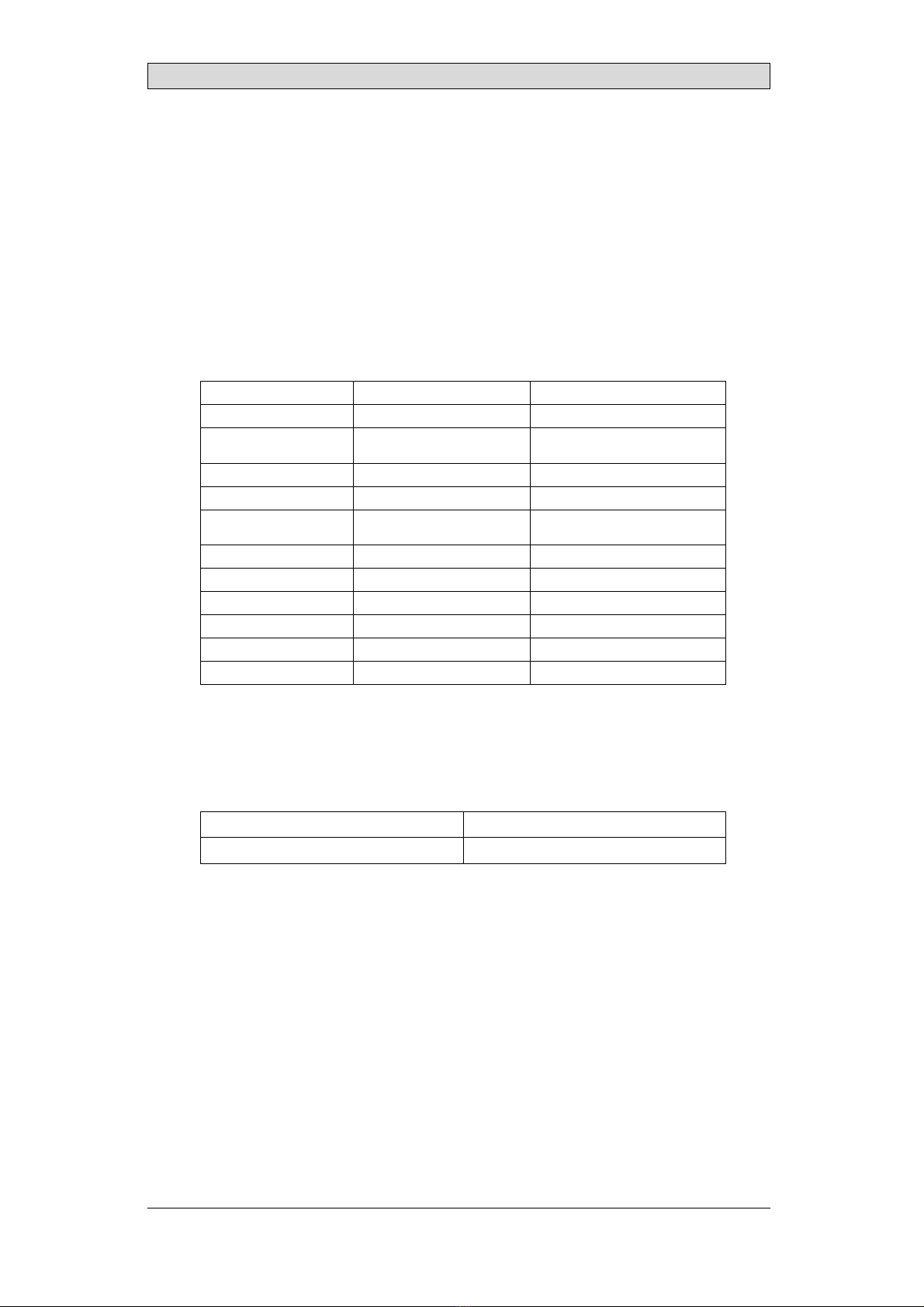

Pos Connect or Descript ion

1 Ground screw Screw t o connect f unct ional grund

2 Power supply 3-pin screw connect or, +24VDC(18-32V DC)

3 COM-A DSUB(9-pi n, f emal e), seri al communicat i on por t

4 LAN-A RJ 45 (shielded), 10/ 100Mbit

5 USB-A USB2. 0 Host , max out put current 500 mA

6 COM-Cscrew Screw t o connect COM-Ccable shield

7 COM-C 3-pin screw connect or

COM-A

Serial port pin assignment

Pin COM1 COM2 COM3

1RS422 TX+ or

RS485 Tx+/ Rx+

2 RS232 RxD

3 RS232 TxD

4 RS422 RX+ RS485 Tx+/ Rx+

5 GND GND GND

6RS422 TX- or

RS485 Tx-/ Rx-

7RS232RTS

8RS232CTS

9 RS422 RX- RS485 Tx+/ Rx-

The connect or support sup t o t hree independent serial communicat ion channel sand

can be configured f or RS-232 and RS-422 or 2×RS-485.

Beijer Electronics, MAEN328 15

Operator Panel Drawings

COM-C

Serial port pin assignment

Pi n COM 6

1GND

2 RS485 Tx+/ Rx+

3 RS485 Tx-/ Rx-

Beijer Electronics, MAEN328 16

Operator Panel Drawings

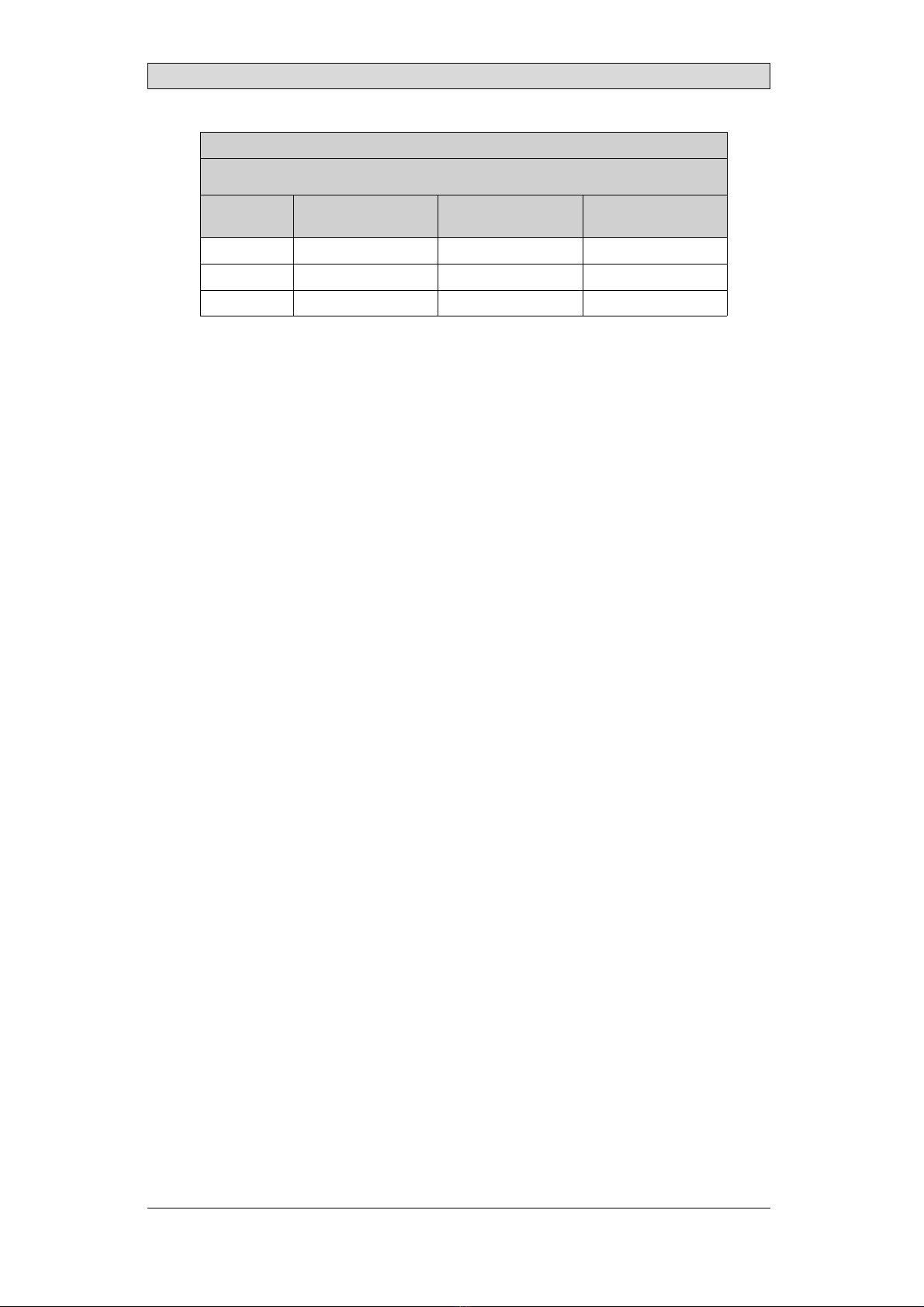

6.2 X2 base 5 v2 Outline

X2 base 5 v2

Note:

Minimum t hickness f or t he f ront pl at e is 2. 0 mm.

Note:

AStepCADfile is avail able on t he web sit e www. beij erelect ronics.com

Beijer Electronics, MAEN328 17

Additional Installation Tips

7 Additional Installation Tips

When experiencing communication problems in noisy environments or when

operating close to temperature limits, the following recommendations are to be

noticed.

7.1 Groundingthe operator panel

1

2

3

4

5

6

5350

Door

Operator panel

Ferrite core

Mounting plate in the cabinet

Power supply

24 V DC

The mounting clamps of the operator panel do not provide a secure grounding

connection between the panel and the device cabinet, see 1 in drawing above.

1. Connect a wire, that is sized correctly according to local electrical codes,

between the quick-connect terminal connector on the operator panel and the

chassis of the panel, see 2 in drawing above.

2. Connect a wire or grounding braid, that is sized correctly according to local

electrical codes, between the chassis of the operator panel and the closest

grounding point on the door, see 3 in drawing above.

3. Connect a strong but short grounding braid between the door and the device

cabinet, see 4 in drawing above.

4. Twist the cables onto the 24 V DC feed, see 5 in drawing above.

2 turns around the ferrite core provide 4 times the suppression of 1 turn.

3 turns around the ferrite core provide 9 times the suppression of 1 turn.

Connect a wire or grounding braid, that is sized correctly according to local

electrical codes, between the chassis of the operator panel and the closest

grounding point.

Beijer Electronics, MAEN328 18

Additional Installation Tips

Note:

The groundi ng wi resshould be short and t he conduct or should have a l arge ar ea.

A long, t hin grounding wire hasa very high impedance (resist ance) at high frequencies

and does not guide dist urbancest o t he ground.

Mult i-wire conduct orsare bet t er t han singlewireconductorswiththesamearea.

A braided conduct or wire wit h t he same area iseven bet t er. The best isa short , t hick

grounding braid.

7.2 Ethernet Connection in the

Operator Panel

1

2

3

4

5

RJ45

RJ45

RJ45

RJ45

RJ45

RJ45

RJ45

RJ45

Industrial Ethernet

Operator panel

Operator panel

Operator panel

Operator panel

Shielded

Short and

unshielded

0.1 μF

250 V

1-1

3-3

8-8

2-2

In some industrial units for Ethernet, the RJ45 contact’s shield is connected to the

chassis via a capacitor, see 1 in drawing above.

The operator panel’s Ethernet shield is directly connected to the chassis, see 2 in

drawing above.

1. Check whether the other Ethernet unit has its shield directly grounded or

grounded via a capacitor.

Note:

In many cases, connect ing t he shielded Et hernet cabling t o t he chassisat bot h endsis

inappropriat e. Hum or grounding loopscan occur. Unshiel ded cabling may even result

in f ewer communicat i on errors.

Beijer Electronics, MAEN328 19

Additional Installation Tips

A good solution may be to use a shielded Ethernet cable, but to connect the shield

at one end only.

One option is to break the shield, see 3 in drawing above.

A more elegant method is to expand the shielded Ethernet cabling with a piece of

unshielded Ethernet cable, see 4 in drawing above.

The shield can be grounded via an external 0.1 μF/250 V film capacitor, see 5 in

drawing above. This connects the HF transients to ground.

7.3 To Achieve Better EMCProtection

•Initially, use the original cabling from Beijer Electronics primarily.

•Place the 24 V DC and communications cabling in one cable trunk/cable duct

and 230/380 V AC in another. If the cables need to be crossed, cross them at

90° only. Avoid combining the cabling for stronger 24 V DC outputs with

the communication cabling.

•Initially, use the original cabling from Beijer Electronics primarily.

•Use shielded cables for RS-232 communication.

•Use twisted pair and shielded cabling for RS-422 and RS-485.

•Use the cabling intended for the bus type; Ethernet, Profibus, CC-Link,

CAN, Device Net etc.

•Use the cabling intended for the bus type; Ethernet and CAN

•Install and connect according to applicable specifications for the relevant bus

standard.

•Use shielded cabling for Ethernet, preferably with foil and a braided shield.

•D-sub covers should be shielded, and the shield should be connected to the

cover 360° where the cable enters.

•Connect the shield at both ends.

Shielded cable

Not same potential

Ground plane 1 Ground plane 2

Ground plate Ground plate in another building

0.1 μF/250 V

With longer distances, there is a risk that the ground potential may be different. In

that case, the shield should only be connected at one end. A good alternative is to

connect the other end of the shield to the ground via a 0.1 μF/250 V film capacitor.

Both ends are then connected to the ground in terms of HF, but only connected to

the ground at one end in terms of LF, thus avoiding the 50/60 Hz grounding loops.

Beijer Electronics, MAEN328 20

Other manuals for X2 control

12

Table of contents

Other Beijer Electronics Marine Equipment manuals

Popular Marine Equipment manuals by other brands

Teleflex

Teleflex MV-2 Series owner's manual

Furuno

Furuno Navigational Echo Sounder FE851S Operator's manual

Argus Security

Argus Security SGWS-MOD/865 manual

Kongsberg

Kongsberg EM 2040P Maintenance manual

AUTOHELM

AUTOHELM ST50 Wind Trim Operation and installation

Simrad

Simrad NX40 Installation & operation manual