Beijer Electronics X2 control User manual

X2extreme7

English

MAEN249B,2021-11

Foreword

InstallationmanualforX2extreme7

Foreword

All operator panels are developed to satisfy the demands of human-machine

communication. Built-in functions such as displaying and controlling text,

dynamic indication, time channels, alarm and recipe handling are included.

The operator panel works primarily in an object-oriented way, making it easy to

understand and use. Configuration is carried out on a PC using iX Developer

software. The project can then be transferred and stored in the operator panel

itself.

Various types of automation equipment such as PLCs, servos or drives can be

connected to the operator panels. In this manual, the term “the controller” refers

to the connected equipment.

This manual explains how to install the operator panel. Please refer to the

iX Developer reference manual for further information.

Order no: MAEN249B

Copyright © 2021-11 Beijer Electronics AB. All rights reserved.

The information in this document is subject to changewithoutnoticeandisprovidedasavailableatthe

time of printing. Beijer Electronics AB, including all its group companies, reserves the right to change any

information without updating this publication. Beijer Electronics AB, including all its group companies,

assumesnoresponsibilityforanyerrorsthatmayappearinthisdocument. Readtheentireinstallation

manual prior to installing and using this equipment. Only qualified personnel may install, operate or repair

this equipment. Beijer Electronics AB, including all its group companies, are not responsible for modified,

altered or renovated equipment. Because the equipment has a wide range of applications, users must acquire

the appropriate knowledge to use the equipment properly in their specific applications. Persons responsible

for the application and the equipment must themselves ensure that each application is in compliance with

all relevant requirements, standards and legislationinrespecttoconfigurationandsafety. Onlypartsand

accessories manufactured according to specifications set by Beijer Electronics AB, including all its group

companies, may be used.

BEIJER ELECTRONICS AB, INCLUDING ALL ITS GROUP

COMPANIES, SHALL NOT BE LIABLE TO ANYONE FOR ANY

DIRECT, INDIRECT, SPECIAL, INCIDENTAL OR CONSEQUENTIAL

DAMAGES RESULTING FROM THE INSTALLATION, USE OR

REPAIR OF THIS EQUIPMENT, WHETHER ARISING IN TORT,

CONTRACT, OR OTHERWISE. BUYER'S SOLE REMEDY SHALL

BE THE REPAIR, REPLACEMENT, OR REFUND OF PURCHASE

PRICE, AND THE CHOICE OF THE APPLICABLE REMEDY SHALL

BE AT THE SOLE DISCRETION OF BEIJER ELECTRONICS AB,

INCLUDING ALL ITS GROUP COMPANIES.

BeijerElectronics, MAEN249B

Contents

Contents

1 SafetyPrecautions ....................................................... 4

1.1 General ........................................................... 4

1.2 Hazardous Materials ............................................. 4

1.3 DisposalRequirementsUnderWEEERegulations ........... 5

1.4 UL and cUL Installation ......................................... 5

1.5 IECEx/ATEX Certificate and Dust Rating .................... 6

1.6 ConditionsofSafeUseforZone2/22ATEX/IECEx .......... 7

1.7 DuringInstallation .............................................. 7

1.8 DuringUse ....................................................... 7

1.9 Service and Maintenance ........................................ 7

1.9.1 CleaningtheDisplay ............................................ 8

1.10 Dismantling and Scrapping ..................................... 8

1.11 Appearance of Air in Touch Screen ............................. 9

2 NamingConvention .................................................... 10

3 Installation ............................................................... 11

3.1 SpaceRequirements ............................................. 11

3.2 InstallationProcess .............................................. 11

3.2.1 ConnectionstotheController ..................................13

3.2.2 HazardousLocationInstallation ................................14

3.2.3 OtherConnectionsandPeripherals .............................14

4 TechnicalData ........................................................... 15

4.1 CompassSafeDistance .......................................... 16

5 ChemicalResistance .................................................... 17

5.1 MetalCasing ..................................................... 17

5.2 Touch Screen and Overlay Material ............................ 17

5.2.1 ProtectiveFilm ...................................................17

5.2.2 TouchScreenSurface ............................................19

5.2.3 TouchScreenProtector ..........................................19

6 OperatorPanelDrawings .............................................. 20

6.1 Connectors ....................................................... 20

6.1.1 CommunicationPorts ...........................................20

6.2 X2extreme7Outline ............................................ 21

7 Additional Installation Tips ............................................ 23

7.1 Grounding the operator panel .................................. 23

7.2 EthernetConnectionintheOperatorPanel ................... 24

7.3 To Achieve Better EMC Protection ............................. 25

7.4 AmbientTemperature ........................................... 26

7.5 Safety ............................................................. 28

7.6 GalvanicIsolation ................................................ 29

7.7 Cable and Bus Termination RS-485 ............................ 31

7.8 CANInterface ................................................... 31

7.8.1 CableRecommendations ........................................31

7.8.2 Termination .....................................................31

7.8.3 RestrictionsandRecommendations ............................32

7.9 ImageSticking ................................................... 32

BeijerElectronics, MAEN249B

Safety Precautions

1SafetyPrecautions

Both the installer and the owner and/or operator of the operator panel must read

and understand this installation manual.

1.1 General

•Read the safety precautions carefully.

•Check the delivery for transportation damage. If damage is found, notify the

supplier as soon as possible.

•Do not use the operator panel in an environment with high explosive hazards.

•The supplier is not responsible for modified, altered or reconstructed

equipment.

•Use only parts and accessories manufactured according to specifications of

the supplier.

•Read the installation and operating instructions carefully before installing,

using or repairing the operator panel.

•Neverallowfluids,metalfilingsorwiringdebristoenteranyopeningsinthe

operator panel. This may cause fire or electrical shock.

•Only qualified personnel may operate the operator panel.

•Storing the operator panel where the temperature is lower/higher than

recommended in this manual can cause the LCD display liquid to

congeal/become isotropic.

•The LCD display liquid contains a powerful irritant. In case of skin contact,

wash immediately with plenty of water. In case of eye contact, hold the eye

open,flushwithplentyofwaterandgetmedicalattention.

•Thefiguresinthismanualserveanillustrativepurpose. Becauseofthemany

variables associated with any particular installation, the supplier cannot

assume responsibility for actual use based on the figures.

•The supplier neither guarantees that the operator panel is suitable for your

particular application, nor assumes responsibility for your product design,

installation or operation.

•It is recommended to turn on and shut down the operator panel at least once

before installing any components/cards or before connecting the operator

panel to external devices; for example serial devices.

•For Marine panels only:

–The operator panel must be installed and operated as described in this

document to meet this certification.

–Observe precautions for handling electrostatic discharge sensitive devices

1.2 HazardousMaterials

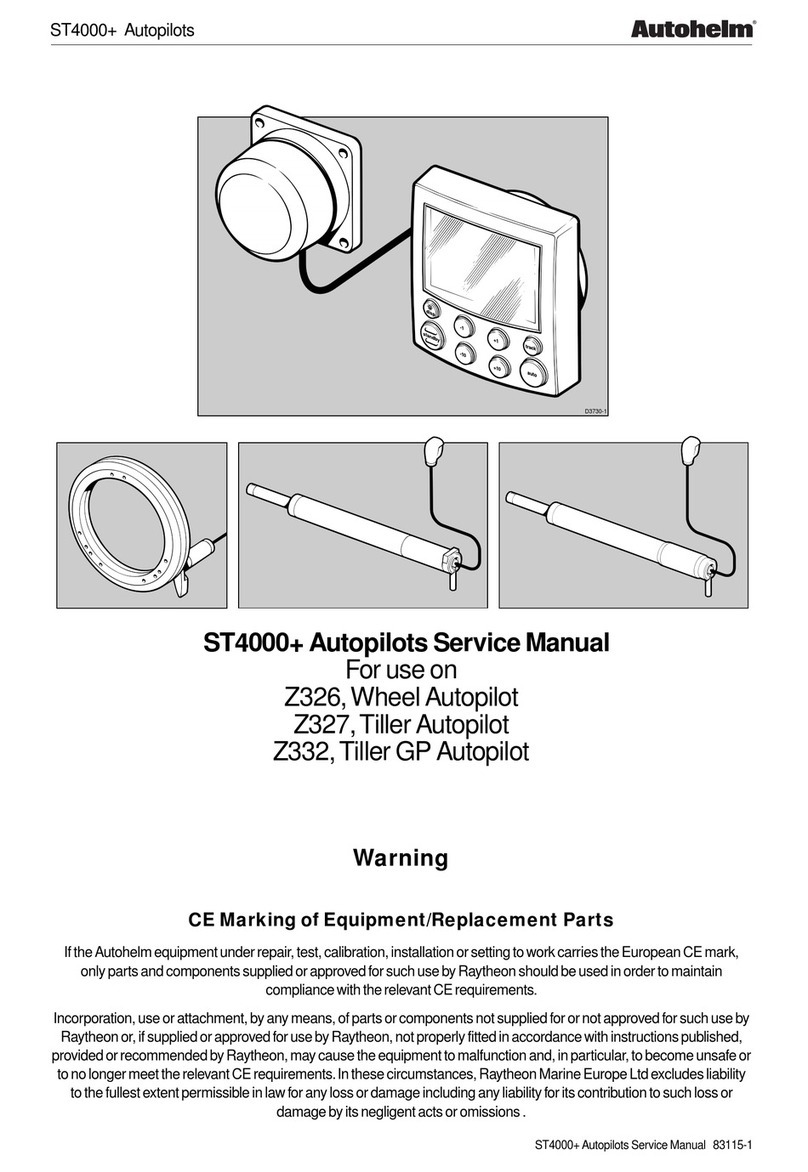

Toxicandhazardousmaterialsorelements

有毒和有害的材料或元素

Partdescription

零件描述

Pb Hg Cd Cr6+ PBB PBDE

PCBandelectronic

components

PCB和电子元件

XOO O O O

O:Indicatesthatthistoxicorhazardoussubstancecontainedinallofthehomogenous

materialsforthispartisbelowthelimitrequirementinSJ/T11363–2014.

BeijerElectronics, MAEN249B 4

Safety Precautions

O:表示该有害物质在该部件所有均质材料中的含量均在 SJ/T11363–2014规定的限

量要求以下。

X:Indicatesthatthistoxicorhazardoussubstancecontainedinatleastoneofthe

homogenousmaterialsforthispartisabovethelimitrequirementinSJ/T11363–2014.

X:表明该有害物质至少在部件的某一均质材料中的含量超出SJ/T11363–2014规定

的限量要求。

1.3 DisposalRequirementsUnder

WEEERegulations

For professional users in the European Union: If you wish to discard electrical

and electronic equipment (EEE), please contact your dealer or supplier for further

information.

For disposal in countries outside of the European Union: If you wish to discard

this product please contact your local authorities or dealer and ask for the correct

method of disposal.

1.4 ULandcULInstallation

•All devices have to be supplied by a Class 2 power supply.

Warning:

Donotseparatewhenenergized.

AVERTISSEMENT,NEPASSEPARERSOUSTENSION.

Warning:

Donotopenwhenanexplosiveatmosphereispresent.

NEPASOUVRIRSIUNEATMOSPHEREEXPLOSIVEESTPRÉSENT.

Warning:

Batterymayexplodeifmistreated. Donotrecharge,disassembleordispose

ofinfire.

Thisproductcontainsabatterythatisnotuserreplaceable.

LABATTERIEPEUTEXPLOSERENCASDEMAUVAISEMANIPULATION.

NELARECHARGEZPAS,NELADÉMONTEZPASETNELAJETEZ

PAS DANS LE FEU.

CEPRODUITCONTIENTUNEPILEQUINEPEUTPASÊTRE

REMPLACÉEPARL'UTILISATEUR.

Warning:

Potentialelectrostaticcharginghazard,seeinstrucions.

Toavoidelectrostaticchargebuild-up,itmustnotberubbedorcleanedwith

solventsoradryclothwheninstalled/usedwithinapotentiallyexplosive

atmosphere.

BeijerElectronics, MAEN249B 5

Safety Precautions

POTENTIELÉLECTROSTATIQUERISQUEDECHARGEMENT,

VOIRINSTRUCTIONS.

Warning:

Explosionhazard! Substitutionofcomponentsmayimpairsuitabilityfor

ClassI,Division2.

RISQUED'EXPLOSION!LASUBSTITUTIONDECOMPOSANTSPEUT

NUIREÀLACONFORMITÉDECLASSEI,DIVISION2.

•Use minimum 85°C copper conductors only.

•To make wiring connections to the power supply connector, follow the table

with cable and torque specifications below:

•ThesedevicesareClass2suppliesprogrammablecontrollers(industrialPCs)

or the use in industrial control equipment and are intended to be (front) panel

mounted.

•For use on a flat surface of an enclosure.

TerminalBlockConnector WireSize Torque(Nm)

PhoenixContact 0.5–3.3mm20.6–0.8

Caution:

Theequipmentshallbeinstalledinanenclosurethatprovidesadegreeofprotection

notlessthanIP66inaccordancewithEN/IEC60079-0whenusedinZone2/22

applications.

Theinsideoftheenclosurethedeviceismountedinshallnotbemorethanpollution

degree2,asdefinedinEN/IEC60664-1.

CETÉQUIPEMENTESTTESTÉENTANTQUECOMPOSANTETDOITÊTRE

INSTALLÉDANSUNBOÎTIERAVECINDICEDEPROTECTIONIP66MINIMUM.

Caution:

TemperaturecodeT4IEC/EN60079-0,IEC/EN60079-7,IEC/EN60079-15andIEC/

EN60079-31.

ProtectionstringExecnCIICT4GcandExtcIIICT82°CDc.

CODESDETEMPÉRATURET4IEC/EN60079-0,IEC/EN60079-7,IEC/EN60079-15et

IEC/EN60079-31.

CHAîNEDEPROTECTIONExecnCIICT4GcetExtcIIICT82°CDc.

1.5 IECEx/ATEXCertificateandDust

Rating

II3GExecnCIICT4Gc

II3DExtcIIICT82°CDc

BeijerElectronics, MAEN249B 6

Safety Precautions

1.6 ConditionsofSafeUseforZone

2/22ATEX/IECEx

•In a Zone 2 environment, this equipment shall be installed in an enclosure

that provides a degree of protection not less than IP54 in accordance with

IEC/EN 60079-0. The IP rating of the equipment is limited to the IP rating

of the enclosure it is to be installed into.

•In a Zone 22 environment, this equipment shall be installed in an enclosure

that provides a degree of protection not less than IP64 in accordance with

IEC/EN 60079-0. The IP rating of the equipment is limited to the IP rating

of the enclosure it is to be installed into.

•To avoid electrostatic charge build-up, it must not be rubbed or cleaned with

solvents or a dry cloth when installed/used within a potentially explosive

atmosphere.

•Theareathedeviceismountedinshallnotbemorethanpollutiondegree2,as

defined in IEC/EN 60664-1.

1.7 DuringInstallation

•Install the operator panel according to the accompanying installation

instructions.

•Ground the operator panel according to the accompanying installation

instructions.

•Only qualified personnel may install the operator panel.

•Separate the high voltage, signal, and supply cables.

•Make sure that the voltage and polarity of the power source is correct before

connecting the operator panel to the power outlet.

•Peripheral equipment must be appropriate for the application and location.

1.8 DuringUse

•Keep the operator panel clean.

•Emergency stop and other safety functions may not be controlled from the

operator panel.

•Do not use excessive force or sharp objects when operating the touch screen.

1.9 ServiceandMaintenance

•Only qualified personnel should carry out repairs.

•The agreed warranty applies.

•Before carrying out any cleaning or maintenance operations, disconnect the

equipment from the electrical supply.

•Clean the display and surrounding front cover with a soft cloth and mild

detergent.

•The battery must be replaced by an authorized Beijer Electronics service

center.

BeijerElectronics, MAEN249B 7

Safety Precautions

1.9.1 CleaningtheDisplay

We recommend using a dry, clean cloth to wipe off dust regularly. Use alcohol or

ammonia-based cleaning agent for cleaning only when necessary. When other

solvents or cleaning agents are used, be sure to follow manufacturers’ instructions.

The agent should be applied to a clean cloth and should not be sprayed directly

onto the panel surface. After cleaning the agent should be removed.

Ammonia based glass cleaners (typically 5-10% ammonia) or 75% alcohol can be

used to clean the surface of PCAP and resistive touch panels.

When you clean the surface of your touch panel, please follow these steps:

1. Apply cleaning agent (alcohol, bleach, or glass cleaner) to a clean cloth. Make

sure the cloth is well saturated.

2. Wipe touch panel in a “Z” motion on the touch panel surface.

3. Dry the panel thoroughly with a dry cloth, removing as much of the cleaning

solution as possible.

4. Do not mix bleach and ammonia because this will produce a dangerous

chemical reaction.

5. Please do not spray cleaning solution directly onto the touch panel surface.

Note:

•Cleaningsolutionscontainingbleach,alcohol,andammoniaarecorrosiveto

touchpanelsurfacecoatingsandITOfilm. So,youshouldnotleavethesolutionon

thetouchpanelsurfaceformorethan2minutes. Makesuretoremoveallresidue

whenfinishedcleaning.

•Donotusesharptoolstocleanthesurfaceofthetouchscreen.

•Donotuseairguns,waterjets,orsteam,tocleanthesurfaceoftouchscreensas

theymaydamagetouchscreenfunctionality.

•Ifcondiments,food,ordrinksarespilledonthesurfaceofthetouchscreen,please

removethemimmediately.

•Ensuremoisturedoesnotseepthroughthecableconnectionareafromtheedges

duringcleaning.

1.10 DismantlingandScrapping

•The operator panel or parts thereof shall be recycled according to local

regulations.

BeijerElectronics, MAEN249B 8

Safety Precautions

•The following components contain substances that might be hazardous to

health and the environment: lithium battery, electrolytic capacitor, and

display.

1.11 AppearanceofAirinTouchScreen

The layer structure of the touch screen contains air. In rare cases, the appearance

of bubbles can arise. This is purely cosmetic and does not affect the functionality

of the operator panel. The appearance can occur under certain environmental

conditions such as temperature, humidity, and atmospheric pressure.

BeijerElectronics, MAEN249B 9

Naming Convention

2 NamingConvention

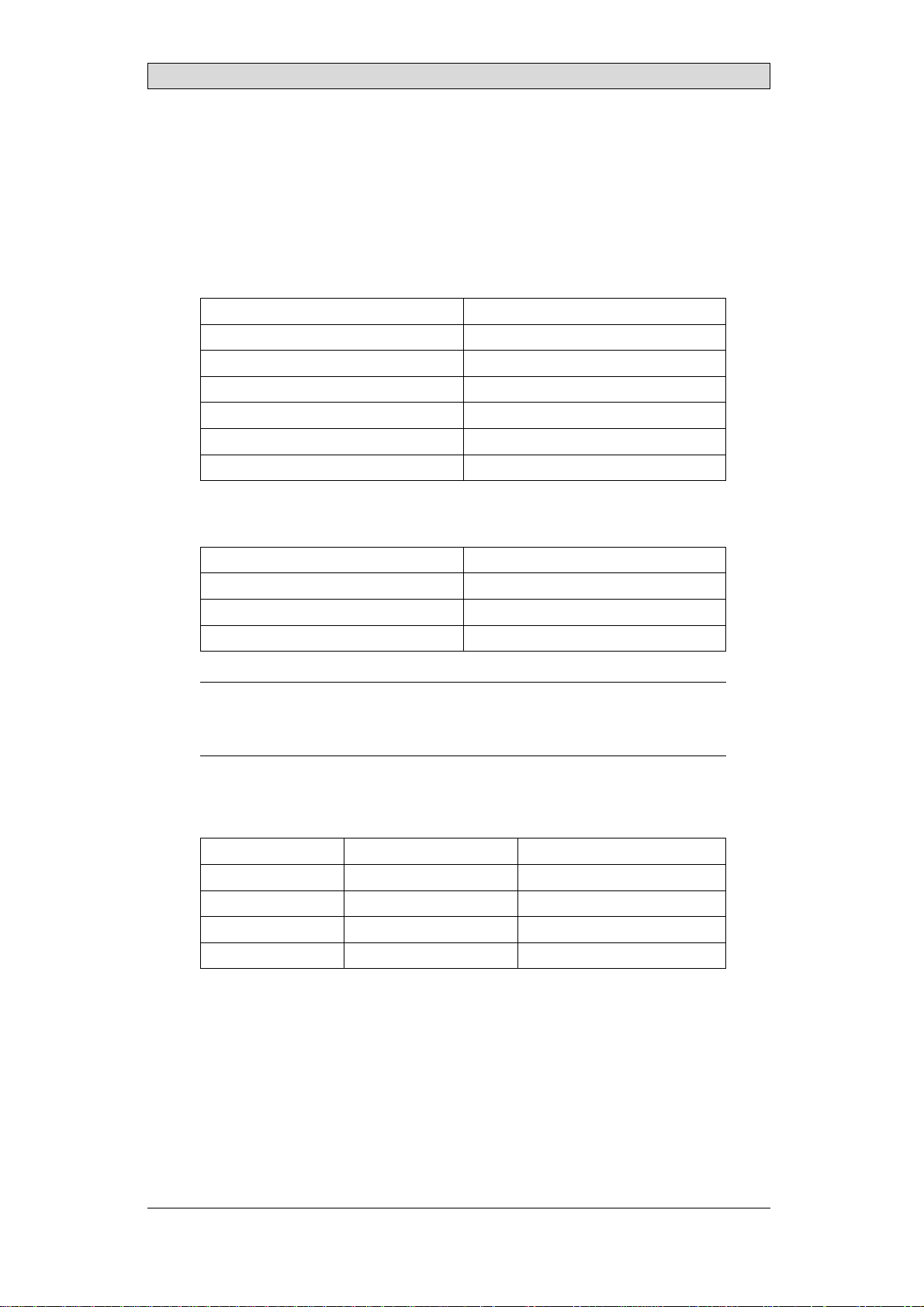

The name of each panel is based on its properties according to the table below.

X2family Size(inches) Genera-

tion/Version Variant

base

pro

marine(=with

BL)

control(=with

SC)

motion(=with

SM)

extreme

4

5

7

10

12

15

21

v2 SC

SM

HB

HP

BL

12V

SL

RO

CO

web

SoftControl

SoftMotion

HighBrightness

HighPerformance

Black

12Volt

Sealed

RuggedOnly

CertificationOnly

Examples:

•X2 base 5 v2

•X2 pro 7

•X2 control 10

•X2 marine 12 SC

•X2 marine 15 HB SC

•X2 extreme 7 12V*

•X2 extreme 12 HP SC*

•X2 extreme 7 SL HP*

•X2 extreme 12 SL HP SC*

•X2 extreme 7 CO*

•X2 extreme 12 SL HP RO

Note:

Notallcombinationsareavailable.

Note:

*indicatesvariantsincludingIECEx\ATEXandC1D2accreditation.

BeijerElectronics, MAEN249B 10

Installation

3Installation

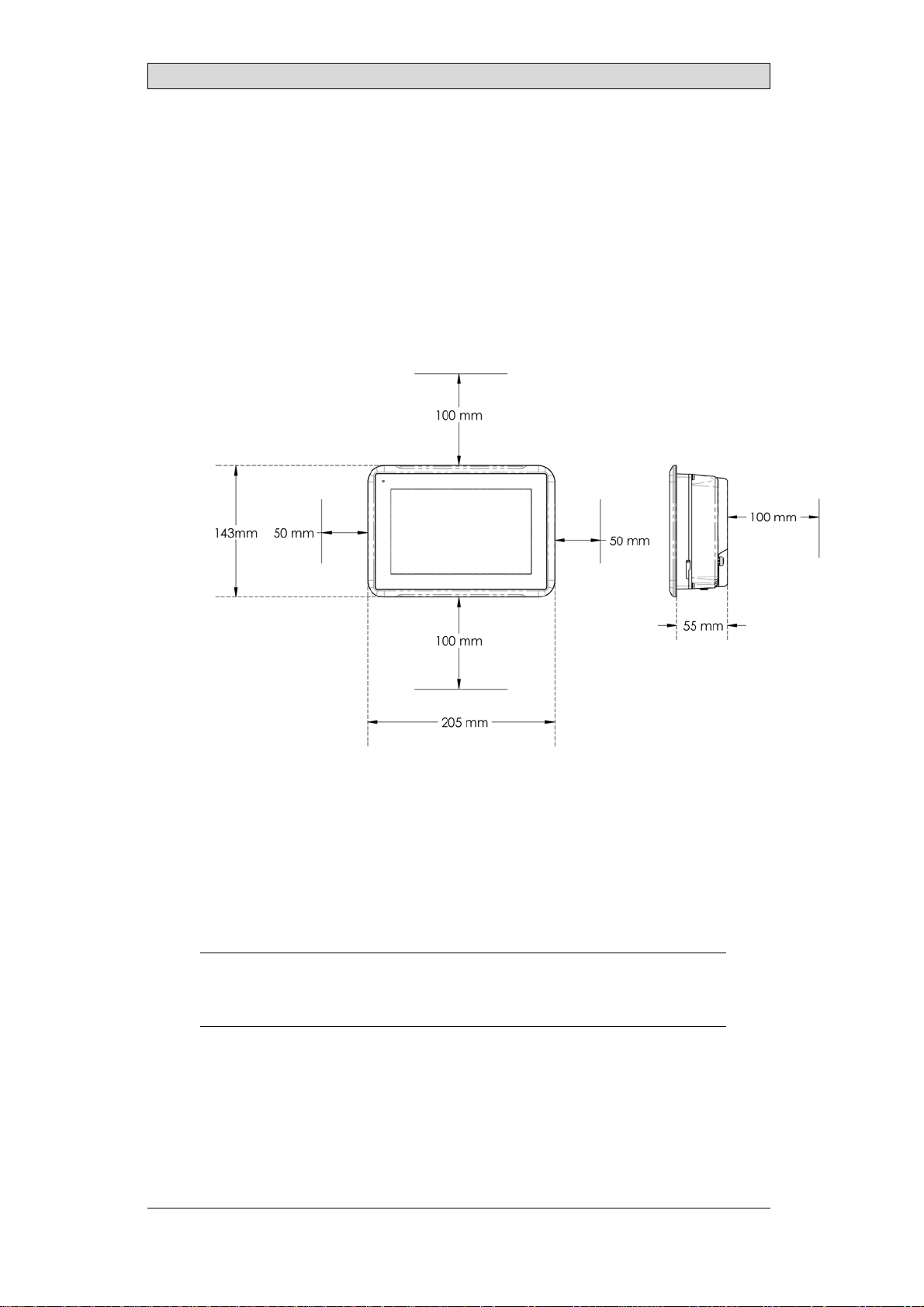

3.1 SpaceRequirements

•Maximum installation plate thickness: 7 mm .

•Installation plate thickness range: 2 - 7 mm +/- 0.1 mm.

The following drawings show the space requirements in millimeters when

installing the operator panel. The drawings are only illustrative and may be out of

proportion.

3.2 InstallationProcess

The following is needed:

•A Phillips/slot screwdriver

Do the following:

1. Unpack and check the delivery. If damage is found, notify the supplier.

Note:

Placetheoperatorpanelonastablesurfaceduringinstallation.

Droppingtheoperatorpanelorlettingitfallmaycausedamage.

2. To c u t a c o r re ct opening for the operator panel, use the cut out dimensions

in the outline drawing. A separate cut out drawing is available for download

from the Beijer Electronics web site. For more information, see sections

Operator Panel Drawings and Technical Data.

BeijerElectronics, MAEN249B 11

Installation

3. Make sure that the mounting surface of the cutout is smooth and cleaned from

any burrs or debris.

4. Install the operator panel into the cutout.

5. Secure the operator panel in position by inserting and sliding the terminal

mounting clips into position as shown. Screw the slotted thumb screws

clockwise, allowing the screws to tighten against the cabinet.

Tighten the screws to 0.7 Nm ± 0.2 Nm.

6. In cases where the front panel seal is critical, install terminal mounting

ring and use a torque wrench to ensure all screws are torqued within the

specification above. For IP66 UL/NEMA Type 4X, Type12, panel must

maintain a flatness < 1 mm overall and < 0.05 mm/mm with a surface

roughness, Ra < 1.6 μm

7. Installation to be through an EPL (Db)(Dc) enclosure for the applicable Dust

Group, Temperature classification and Ambient temperature range.

BeijerElectronics, MAEN249B 12

Installation

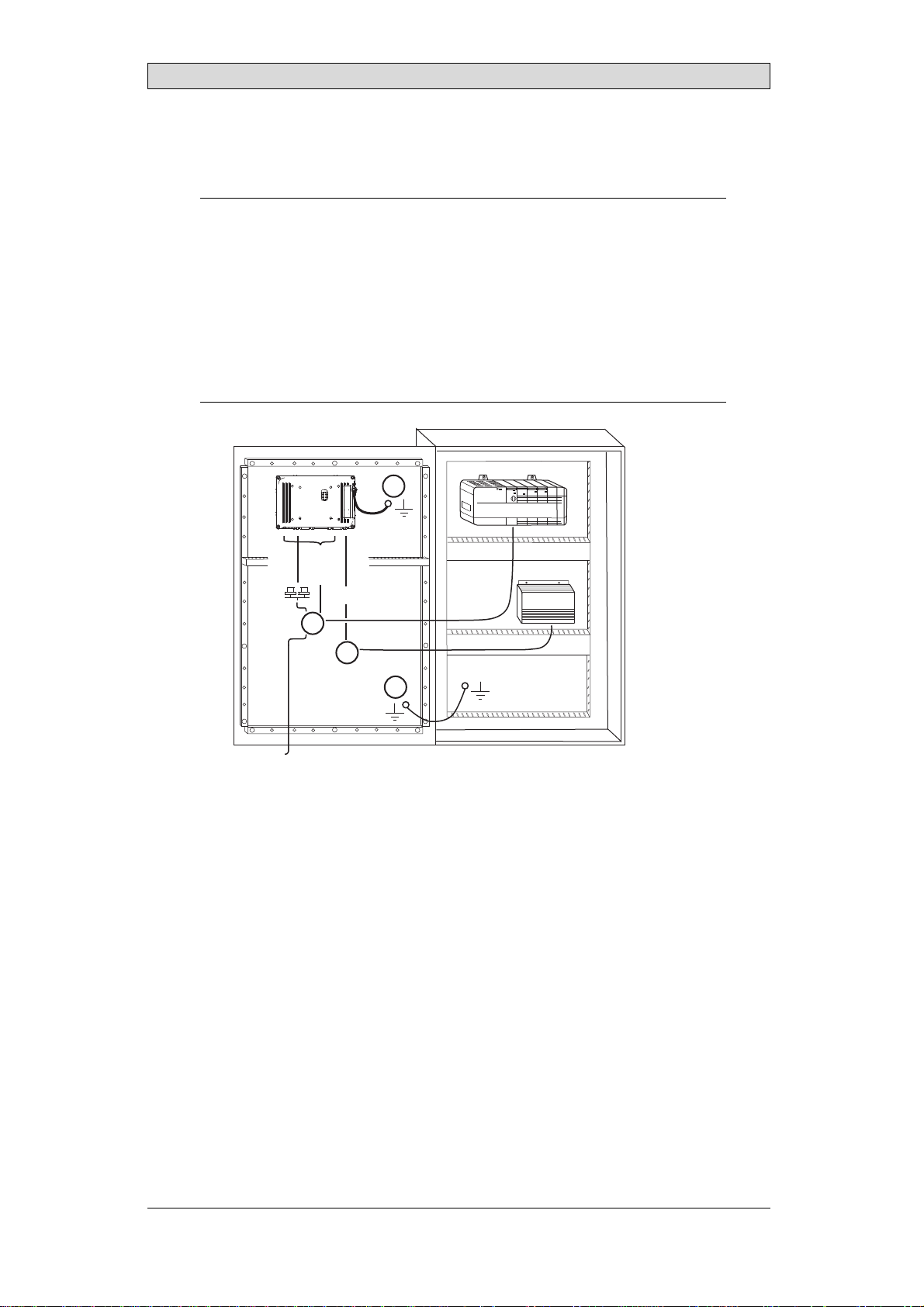

8. Connect the cables in the specified order, according to the drawing and steps

below.

Caution:

•Theoperatorpanelmustbebroughttoambienttemperaturebeforeitisstarted

up. Ifcondensationforms,ensurethattheoperatorpanelisdrybeforeconnecting

ittothepoweroutlet.

•Ensurethattheoperatorpanelandthecontrollersystemhavethesameelectrical

grounding(referencevoltagelevel),otherwiseerrorsincommunicationmay

occur.

•Ensurethatthevoltageandpolarityofthepowersourceiscorrect.

•Separatehighvoltagecablesfromsignalandsupplycables.

•Shieldedcommunicationcablesarerecommended.

24V DC

RS232/

RS422/

RS485

24V DC

A

D

Controller

Power

B

Ethernet

C

The image is illustrative only and may differ slightly from the actual panel.

–Connect cable A.

–Connect cable B, using 14-20 AWG (2.08–0.52 mm2), 180–220 N-cm

torque.

–Connect cable C.

–Connect cable D. The recommended cross-section of the cable is 1.5

mm2.

9. Carefully remove the protective film over the operator panel display, take care

to avoid static electricity that could damage the panel.

3.2.1 ConnectionstotheController

For information about the cables to be used when connecting the operator panel to

the controller, please refer to the help file for the driver in question.

BeijerElectronics, MAEN249B 13

Installation

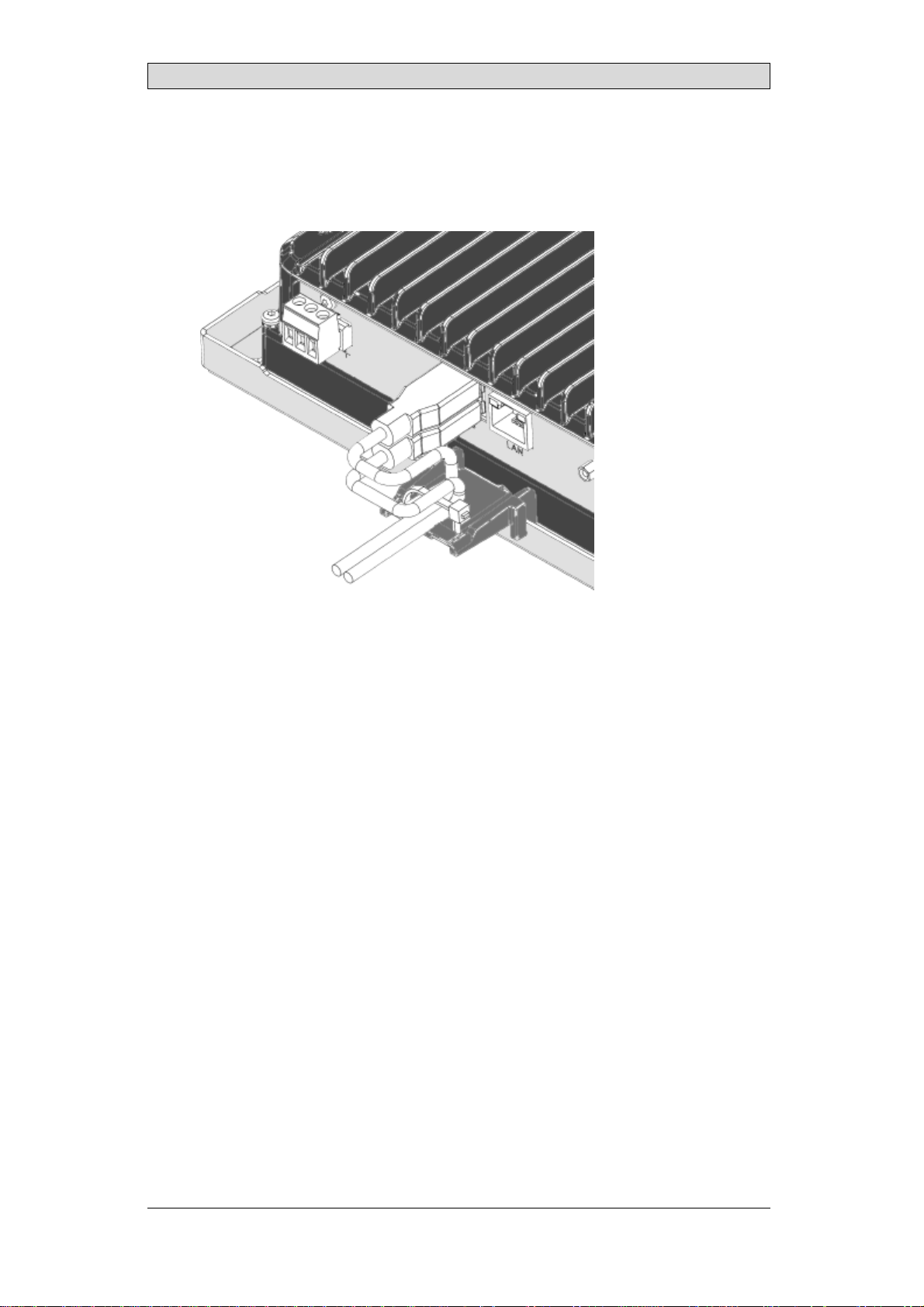

3.2.2 HazardousLocationInstallation

Connect the desired cables and attach them to strain relief plate with cable ties

provided.

3.2.3 OtherConnectionsandPeripherals

Cables, peripheral equipment and accessories must be suitable for the application

and its environment. For further details or recommendations, please refer to the

supplier.

BeijerElectronics, MAEN249B 14

Technical Data

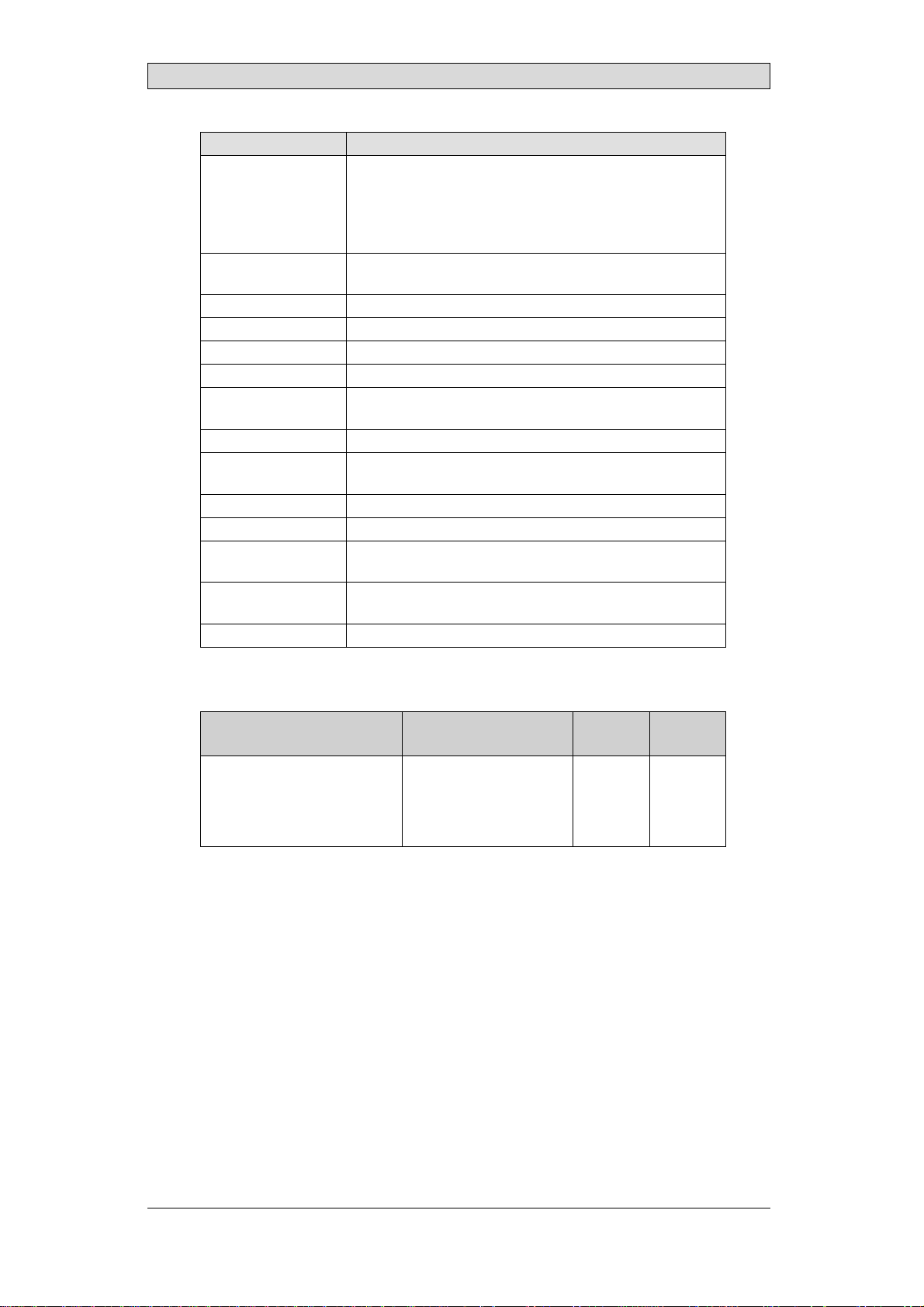

4TechnicalData

Parameter X2extreme7

Frontpanel,W×H×D 205×143×7mm

Cutoutdimensions,

W×H 188±1mm×127±1mm

Maximumcornerradius:4mm.394x270mm.

Mountingdepth 55mm(155mmincludingclearance)

Frontpanelseal IP66UL/NEMAType4X,Type12

Rearpanelseal IP20

Touchscreen

material Polyesteronglass,ITOfilm,resistive

Frameoverlay AutoflexEBA180L

Touchscreen

operations 1millionfingertouchoperations

Reverseside

material Powder-coatedaluminum

Framematerial Powder-coatedaluminum

Weight 1.2kg

CPU i.MX6DualLite

DualARMCortex-A9Core

800MHz

512kBL2cache

Serialports StandardD-sub(9Pin,female)

COM1: RS-232withRTS/CTS

COM2: RS-422/RS-485

COM3: RS-485

1×RS-232Rx/TxwithRTS/CTSand1×RS-422,or2×RS-485

or2×CAN2.0B

*NotsupportedforX2control7/10/15weborX2extreme

7/12/15HPweb.

Ethernet 10/100MbitBase-T(shieldedRJ45withLEDs)

USB StandardUSBTypeAconnector,dualstackhorizontal

SupportsuptoUSB2.0HighSpeed

Externalstorage

media 1×SDcard

Flashmemory

(application

memory)

1.5GBSSD(eMMC)

MemoryRAM 1GBDDR3

NVRAM N/A

LED 1×Multicolor

Realtimeclock Yes

Battery BR2330A/GANlithiumbattery,

nonreplaceable

Powerconsumption

atratedvoltage 10W

Fuse InternalDCfuse,4ATSMT

BeijerElectronics, MAEN249B 15

Technical Data

Parameter X2extreme7

Powersupply +24VDC(18–32VDC)

CE:Thepowersupplymustconformwiththerequirements

accordingtoEN/IEC60950andEN/IEC61558-2-4.

ULandcUL:Thepowersupplymustconformwiththe

requirementsforclass2powersupplies.

Display TFT-LCDwithLEDbacklight

800×480pixels,262kcolors

Activeareaofdisplay 7”diagonal

Pixelerrors ClassI(ISO9241-307)

Backlightbrightness 500Cd/m2

Backlightlifetime 50,000hours

Operating

temperature -30°Cto+70°C

Storagetemperature -40°Cto+80°C

Relativehumidityin

operation 5%–95%non-condensation

Vibration 4g,accordingtoEN/IEC60068-2-6,TestFc

Mechanicalshock 40g,half-sine,11msaccordingtoEN/IEC60068-2-27

Approvalsand

certifications CE/FCC/KCC

Informationisavailableonwww.beijerelectronics.com

ULapproval Informationisavailableonhttp://www.beijerelectron-

ics.comand/orhttps://UL.com

Marinecertificates Informationisavailableonwww.beijerelectronics.com

4.1 CompassSafeDistance

Variant Condition Standard

Compass Steering

Compass

X2extreme7 Non-energized

Non-energizedafter

magnetization

Energizedandoperating

15cm

40cm

15cm

10cm

25cm

10cm

BeijerElectronics, MAEN249B 16

Chemical Resistance

5 ChemicalResistance

5.1 MetalCasing

The frame and casing material is powder-coated aluminum. This powder paint

withstands exposure to the following chemicals without visible change:

Aceticacid10% Phosphoricacid4%

Citricacid10% Phosphoricacid10%

Diesel Seawater

Distilledwater Sodiumchloride2%

Edibleoil Sodiumchloride20%

Fueloil Sulphuricacid20%

Hydrogenperoxide3% Tapwater

The powder paint shows limited resistance to the following chemicals at room

temperature:

Butanol Nitricacid3%

Hydrochloricacid5% Nitricacid10%

Isopropylalcohol Phosphoricacid43%

Sodiumhypochlorite10% Turpentine

Note:

Ifexposuretoanyoftheabovechemicalsisdemanded,itisrecommendedtofirsttest

thechemicalinahiddenspotofthemetalcasing.

Thepowderpaintshowslittleornoresistancetothefollowingchemicalsatroom

temperature:

Aceticacid,conc. Methyl-ethylketone Toluene

Acetone Nitricacid30% Trichlorethylene

Ammonia5% Phenol Xylene

Ammonia,conc. Sodiumhydroxide5% 97octaneunleadedpetrol

Ethylacetate Sodiumhydroxide30% 98octaneleadedpetrol

5.2 TouchScreenandOverlayMaterial

5.2.1 ProtectiveFilm

Autoflex EBA 180L covers the overlay surrounding the screen.

BeijerElectronics, MAEN249B 17

Chemical Resistance

SolventResistance

The protective film withstands exposure of more than 24 hours duration under

DIN42115Part2tothefollowingchemicalswithoutvisiblechange:

Acetonitrile Diesel Petroleumspirit(1)

Ajax/Viminsolution Downy/Lenor(1) Phosphoricacid (<30%)

Alkalicarbonate

solution(1) Ethanol Potassiumferricyanide

Ammonia(<40%)(1) Glycerine Potassiumhydroxide(<30%)

Aceticacid(<50%) Glycol PureTurpentine

Arielpowderin

solution(1) Gumption(1) SBP60/95(1)

Bleach(1) Hydrochloricacid(<36%) Sulfuricacid(<10%)

Castoroil Linseedoil Tomatoketchup

Causticsoda(<40%)(1) Methanol Trichloroaceticacid(<50%)

Cuttingoil Nitricacid(<10%) WhiteSpirit

Cyclohexanol Paraffinoil Windex(1)

Diacetonealcohol Persilpowderinsolution(1) Wisk

(1)Extremelyfaintglossingofthetexturewasnoted.

The Autoflex protective film withstands DIN 42 115 Part 2 exposure of up to 1

hour duration to glacial acetic acid without visible change.

The Autoflex protective film is not resistant to high pressure steam at over 100

°C or the following chemicals:

Concentratedmineralacids Benzylalcohol

Concentratedcausticsolution Methylenechloride

BeijerElectronics, MAEN249B 18

Chemical Resistance

5.2.2 TouchScreenSurface

The touch screen surface on the operator panel withstands exposure to the

following solvents without visible change:

Solvents Time

Acetone 10minutes

Isopropanol 10minutes

Toluene 5 hours

Thetouchscreensurfaceontheoperatorpanelismadeofpolyesterwithahard

coat to resist scratches and withstand exposure to many solvents without visible

change.

5.2.3 TouchScreenProtector

For harsh environments and exposure to outdoor conditions, it is recommended

to use a protective film to guard the touch screen from damage. This optional part

can be ordered from Beijer Electronics.

BeijerElectronics, MAEN249B 19

Operator Panel Drawings

6 OperatorPanelDrawings

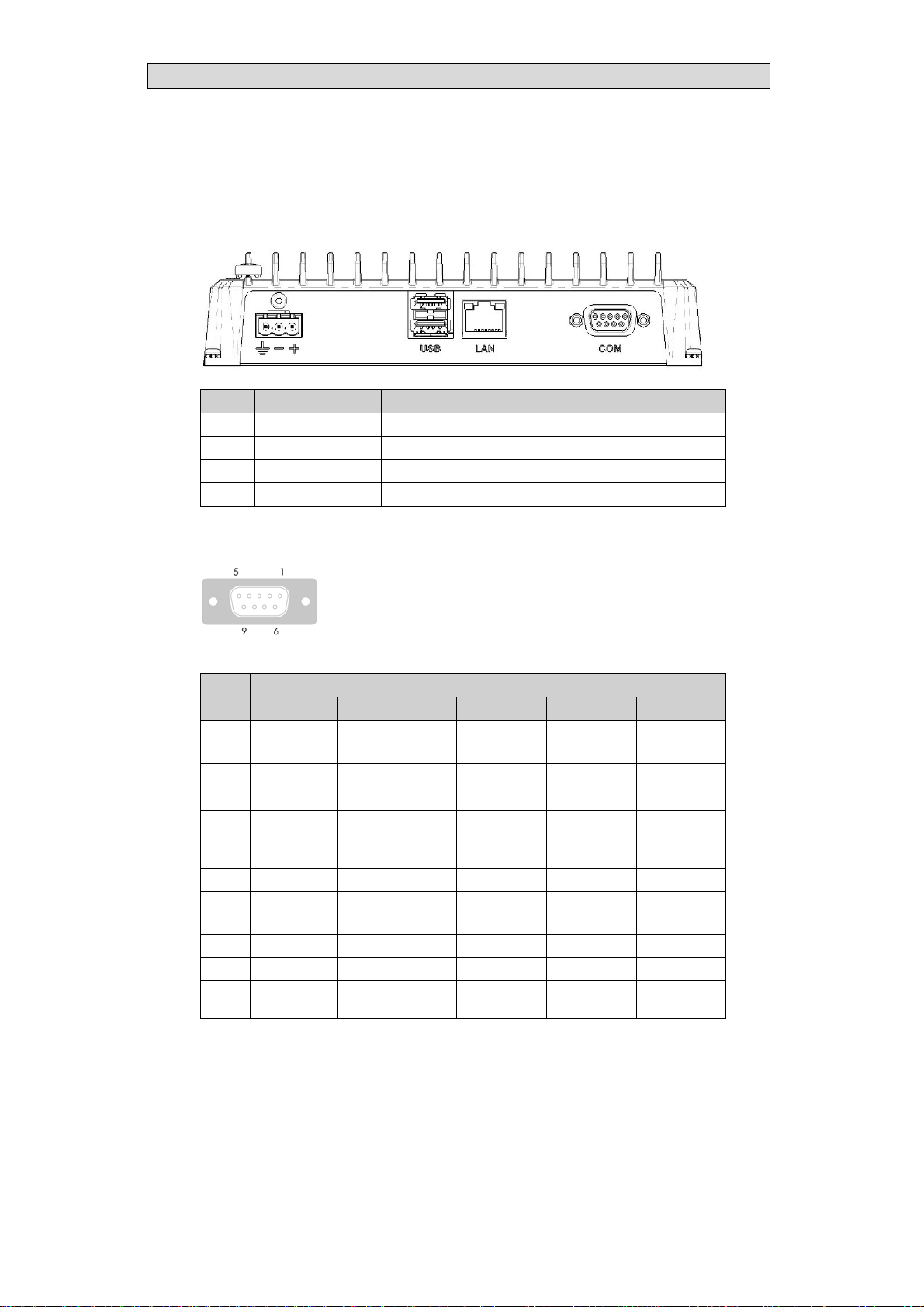

6.1 Connectors

Pos. Connector Description

1Powersupply+24VDC

2 USB 2×USBHost2.0,maxoutputcurrent500mA

3 LAN 1×10/100Base-T(shieldedRJ45)

4 COM Serialcommunicationport

6.1.1 CommunicationPorts

Serial connector

Serialport,9-pinfemale

Pin COM1 COM2 COM3 CAN1 CAN2

1- RS-422Tx+

RS-485Tx+/Rx+ -CAN1-H-

2 RS-232RxD - - - -

3RS-232TxD - - - -

4 - RS-422Rx+ RS-485

Tx+/Rx+ -CAN2-H

5 GND GND GND GND GND

6- RS-422Tx-

RS-485Tx-/Rx- -CAN1-L-

7 RS-232RTS - - - -

8RS-232CTS - - - -

9 - RS-422Rx- RS-485

Tx-/Rx- -CAN2-L

The connector supports up to three independent communication channelsand

can be configured for RS-232 and RS-422 or 2xRS-485 or 2x CAN.

BeijerElectronics, MAEN249B 20

Other manuals for X2 control

12

Table of contents

Other Beijer Electronics Marine Equipment manuals

Popular Marine Equipment manuals by other brands

Thrane&Thrane

Thrane&Thrane SAILOR 500 FleetBroadband user manual

E2S

E2S BExDTS110D instruction manual

Furuno

Furuno Navtex NX-700-B Operator's manual

Sealite

Sealite ATLANTIC-3000 Installation & service manual

Simrad

Simrad SX90 - DATASHEET FOR NAVAL AND COAST GUARD REV... quick start guide

JRC

JRC JFC-130 - instruction manual