PCI8757DataAcquisition V6.034

3.6 Methods of Realizing the Multi-card Synchronization

Three methods can realize the synchronization for the

PCI8757, the first method is using the cascade

master-slave card, the second one is using the common

external trigger, and the last one is using the common

external clock.

When using master-slave cascade card programs, the

master card generally uses the internal clock source

model, while the slave card uses the external clock

source mode. After the master card and the slave card are

initialized according to the corresponding clock source

mode. At first, start all the slave cards, as the main card

has not been activated and there is no output clock signal,

so the slave card enters the wait state until the main card

was activated. At this moment, the multi-card

synchronization has been realized. When you need to

sample more than channels of a card, you could consider

using the multi-card cascaded model to expand the

number of channels.

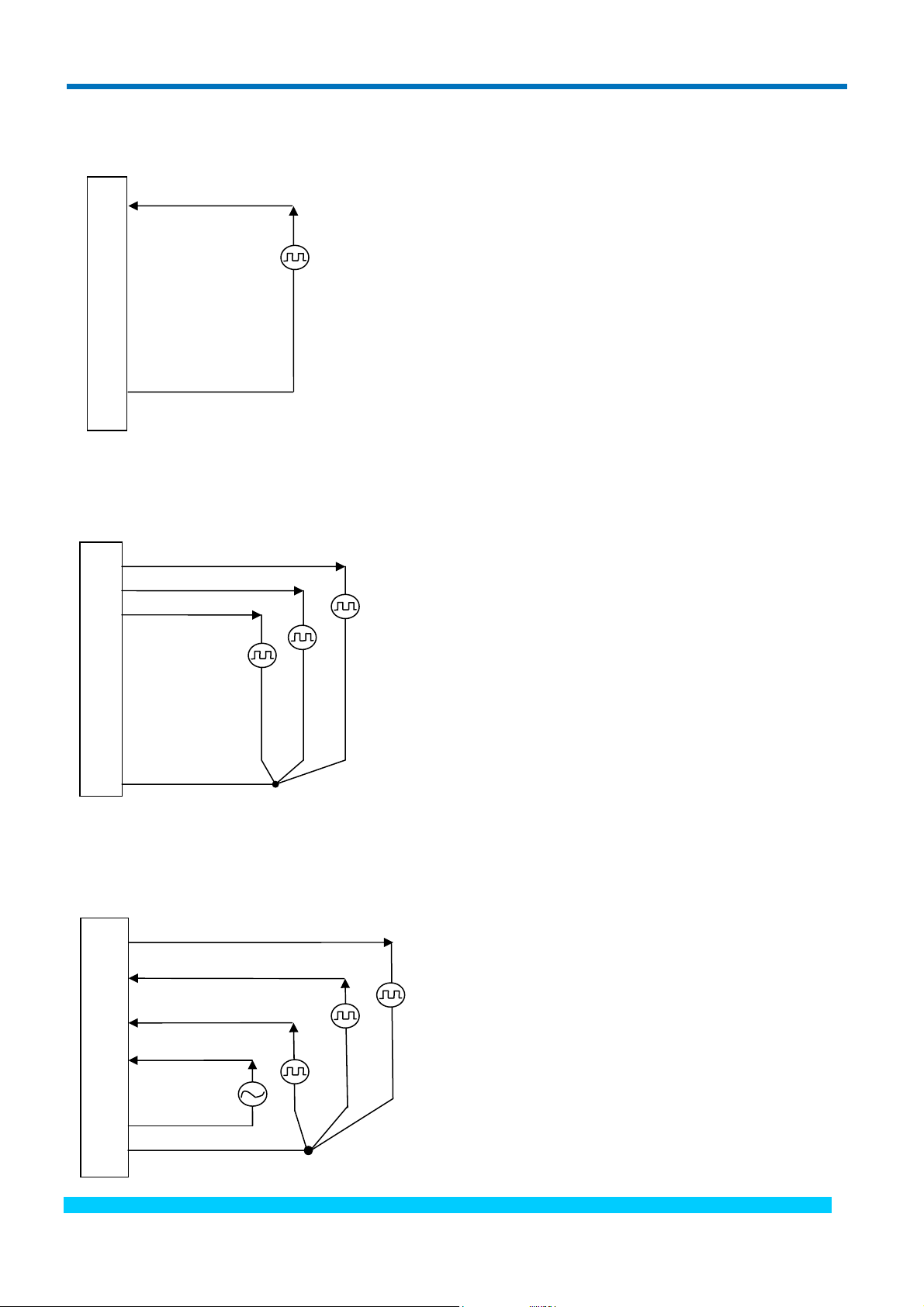

When using the common external trigger, please make

sure all parameters of different PCI8757 are the same. At

first, configure hardware parameters, and use analog or

digital signal triggering (ATR or DTR), then connect the

signal that will be sampled by PCI8757, input triggering

signal from ART pin or DTR pin, then click “Start

Sampling” button, at this time, PCI8757 does not sample

any signal but waits for external trigger signal. When

each module is waiting for external trigger signal, use

the common external trigger signal to startup modules, at

last, we can realize synchronization data acquisition in

this way. See the following figure:

Note: when using the DTR, use the internal clock mode

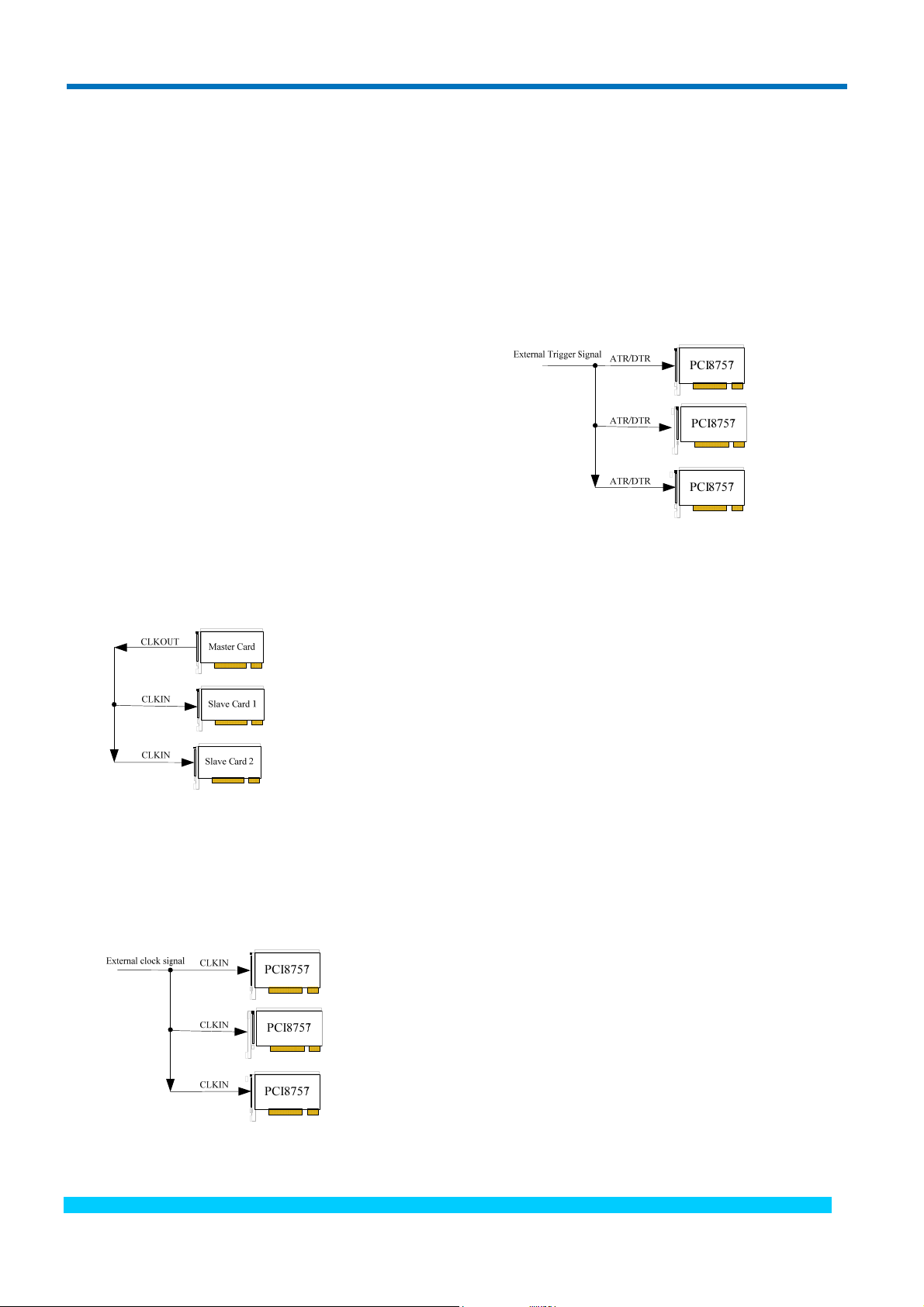

When using the common external clock trigger, please

make sure all parameters of different PCI8757 are the

same. At first, configure hardware parameters, and use

external clock, then connect the signal that will be

sampled by PCI8757, input trigger signal from ART pin

or DTR pin, then click “Start Sampling” button, at this

time, PCI8757 does not sample any signal, but wait for

external clock signal. When each module is waiting for

external clock signal, use the common external clock

signal to startup modules, at last, we realize

synchronization data acquisition in this way. See the

following figure:

BUY ONLINE at www.art-control.com/englishs or CALL (86)-10-62991792-609