Installation and operation instructions US-EN

2 DRYPOINT®M intelligence

Contents

1. Safety information.......................................................................................................................................... 4

1.1. Pictograms and symbols.......................................................................................................................... 4

1.1.1. In this documentation........................................................................................................................................................4

1.1.2. On the device.......................................................................................................................................................................4

1.2. Signal words according to ISO 3864 and ANSI Z.535 ................................................................................ 5

1.3. Safety instructions.................................................................................................................................. 5

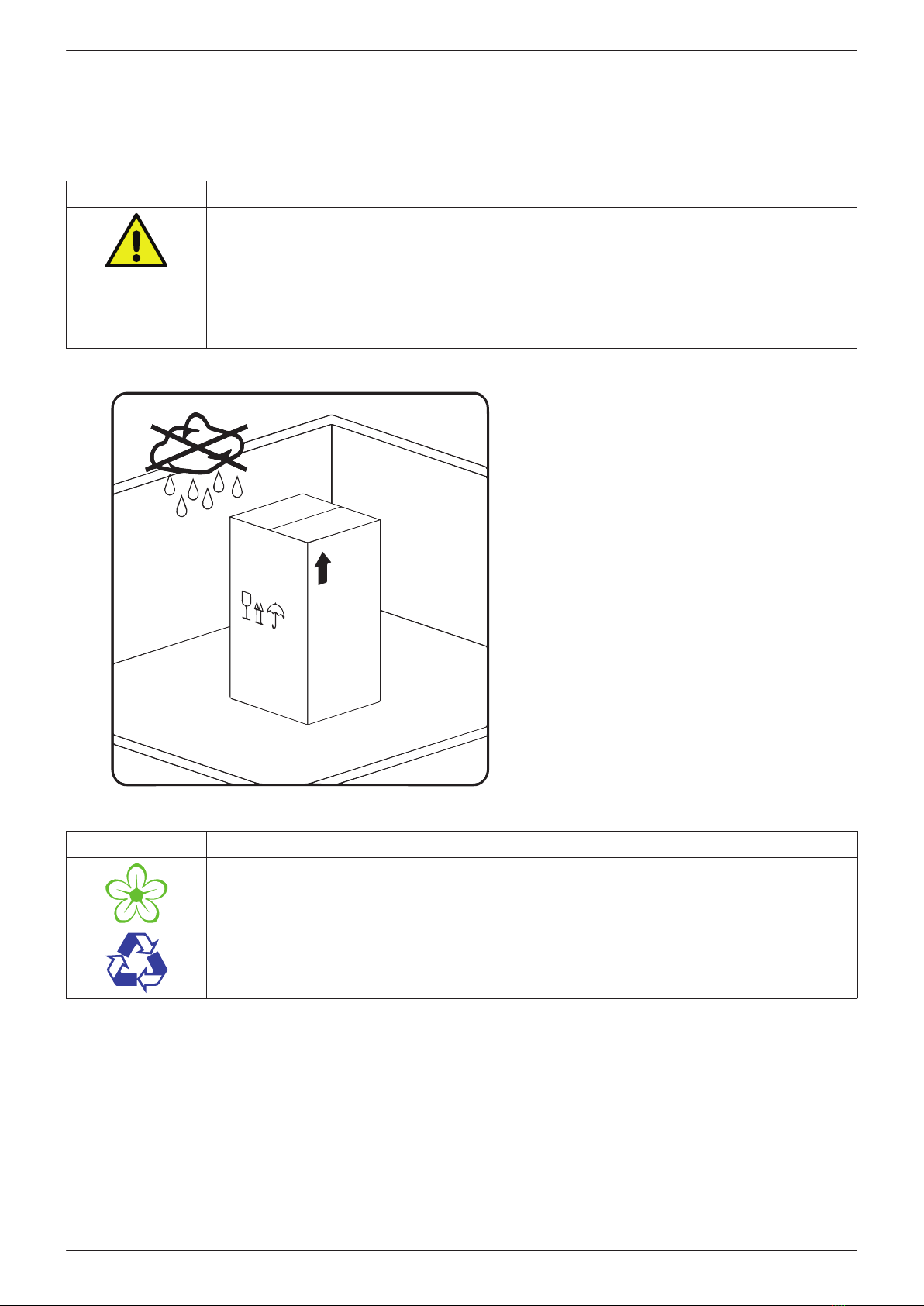

1.4. Transport and storage ............................................................................................................................. 6

1.5. Intended use........................................................................................................................................... 7

1.6. Warranty and liability ............................................................................................................................. 7

2. Product information ....................................................................................................................................... 8

2.1. Scope of delivery .................................................................................................................................... 8

2.2. Name plate ............................................................................................................................................. 8

2.2.1. Name plate of drying system............................................................................................................................................8

2.2.2. Type plate of control unit ..................................................................................................................................................9

2.3. Product overview and description ......................................................................................................... 10

2.3.1. Operating principle.......................................................................................................................................................... 11

2.3.2. Operating mode ............................................................................................................................................................... 12

2.4. Control and display elements ................................................................................................................ 13

2.5. 4 ... 20 mA interface.............................................................................................................................. 14

2.6. Alarm relay........................................................................................................................................... 14

2.7. Dimensions........................................................................................................................................... 15

2.8. Technical data....................................................................................................................................... 16

3. Installation................................................................................................................................................... 20

3.1. Preconditions ....................................................................................................................................... 20

3.2. Installation ........................................................................................................................................... 21

4. Electrical installation .................................................................................................................................... 22

4.1. Warning................................................................................................................................................ 22

4.2. Terminals.............................................................................................................................................. 22

4.3. Opening the control unit....................................................................................................................... 23

4.4. Connection of power cable to power supply board................................................................................. 24

4.5. Connection of 4 ... 20 mA interface to control unit PCB.......................................................................... 24

4.6. Connection of oating contact to control unit PCB ................................................................................ 24

5. Commissioning ............................................................................................................................................. 24

6. Operation..................................................................................................................................................... 25

6.1. LED signals during operation................................................................................................................. 25

6.2. Solenoid valve test function .................................................................................................................. 26

6.3. Adjust settings (setup mode) ................................................................................................................ 26

6.3.1. Change operating mode ................................................................................................................................................. 26

6.3.2. Changing settings ............................................................................................................................................................ 26

6.3.3. Service mode..................................................................................................................................................................... 27