Belanger insta-KLEEN User manual

insta-KLEEN™ System

1MANUAL334 Rev08

insta-KLEEN™System

1MANUL334

REV 07

Belanger®Equipment Owner’s Manual

insta-KLEEN™ System

Copyright 2020

Belanger, Inc®

This manual and the accompanying equipment are protected by United States trademark, copyright, and patent laws. You

may make one copy of this manual. Do not make additional copies of this manual or electronically transmit it in any form

whatsoever, in whole or in part, without the prior written permission of Belanger, Inc.®

The registered trademarks used in this document are the property of their respective owners. The use of such trademarks is

for reference purposes only and does not imply sponsorship or approval of Belanger, Inc.®by these companies or any

companies affiliated with their respective owners.

CURRENT REVISION LOG

Rev

Release

Date

Page

Description

08

04/14/2020

Manual

Revised manual to conform to CE Requirements

Manual

Updated Front Cover, Back Cover and Belanger®Logo

3

Updated Limited Warranty

3 & 8

Changed Bi-Flouride to Bi-fluoride

11

Updated Description of insta-Kleen™System to include: Gyro

Wrap™, DuraScrubber®, Top Wheel and Chameleon®Arch

descriptions

31-34

Added and updated Photo Eye section to manual

69

Changed 1CNTRL135 to 1CNTRL136

Changed 1ELECT-DS150 to 1ELECT-DS151

Changed 1ELECT-MS045 to 1ELECT-SW151

Removed 1ELECT-DS156(3) & 1ELECT-DS155 (3)

Added Note: Following components attach here. Shaft: 1SHAFT151

Handle: 1HANDLE151

Changed callout 1ELECT-MO121 (2) to Motor Starter: 1ELECT-

MO121 (2) or Soft Starter: 1ELECT-MS680 (2)

Changed callout 1ELECT-FS955 (31) to Non-CE: 1ELECT-FS955

(31) CE: 1ELECT-FS972 (31)

Added CE EMI Line Filter Part #: 1ELECT-LF001

insta-KLEEN™MANUAL

1MANUL334 Belanger, Inc. * PO BOX 5470 * Northville, MI 48167-5470 * Ph (248) 349-7010 * Fax (248) 380-9681 1

Table of Contents

Belanger Incorporated® Limited Warranty..................................................... 3

Introduction....................................................................................................... 4

IMPORTANT Safety Information –MUST READ....................................................................4

Operational Warning................................................................................................................8

Environmental Parameters ......................................................................................................9

Safeguards...............................................................................................................................9

Reasonable and Foreseeable Misuse .....................................................................................9

Do’s and Do Not’s ..................................................................................................................10

Description of insta-KLEEN™ System...................................................................................11

Before You Get Started..........................................................................................................13

Lag Bolt Usage Guidelines ....................................................................................................14

Specifications.................................................................................................. 16

Requirements.........................................................................................................................16

ICC space requirements ........................................................................................................16

Installation....................................................................................................... 17

Getting Started.......................................................................................................................17

Guide Rails.............................................................................................................................18

Optional Above-Ground Correlator ........................................................................................23

Optional In-Ground Correlator ...............................................................................................26

Optional Hydraulic Unit for In-Ground Conveyor (North American Option)...........................27

Photo Eye Tunnel Placement ................................................................................................31

Positioning the insta-KLEEN™Control Center (ICC)............................................................35

Placement ..............................................................................................................................36

Electrical Enclosure Overview ...............................................................................................37

Solution Delivery Overview....................................................................................................38

Utilities....................................................................................................................................39

System Startup................................................................................................ 42

Initial Start-up and Adjustment...............................................................................................42

Operation......................................................................................................... 43

Overview ................................................................................................................................43

insta-KLEEN™ Control Center (ICC).....................................................................................43

Maintenance .................................................................................................... 51

General ..................................................................................................................................51

Guide Rail ..............................................................................................................................51

Metering Pumps.....................................................................................................................52

ICC Parts Identification ..........................................................................................................72

ICC Panel Motor Starter Configurations ......................................................................................................... 72

Fluid Manifold Assembly: Part #102828 ......................................................................................................... 72

Electrical Panel Components.......................................................................................................................... 73

Solution Delivery Components........................................................................................................................ 74

Valve Assemblies............................................................................................................................................ 75

Schedule ................................................................................................................................76

insta-KLEEN™ MANUAL

2Belanger, Inc. * PO BOX 5470 * Northville, MI 48167-5470 * Ph (248) 349-7010 * Fax (248) 380-9681 1MANUL334

Table of Contents

Appendix A: CE Information...........................................................................77

Appendix B: De-Commissioning (Dismantling and Disposal).....................79

insta-KLEEN™MANUAL

1MANUL334 Belanger, Inc. * PO BOX 5470 * Northville, MI 48167-5470 * Ph (248) 349-7010 * Fax (248) 380-9681 3

Belanger Incorporated® Limited Warranty

LIMITED WARRANTY:

Equipment:

Subject to the limitations stated below, Seller warrants that the Equipment sold hereunder, which is fabricated by

Seller, shall be free from defects in workmanship and material under normal use and service for a period of 1 year

plus 30 days from the date of invoice - CATPumps will be warranted for 2 years from the date of invoice.

Parts:

Subject to the limitations stated below, Seller warrants that the Parts sold hereunder, shall be free from defects in

workmanship and material under normal use and service for a period of 30 days from the date of invoice.

Limitations on All Warranties:

The warranties contained in this Section 13 are subject to the following limitations: (1) they are void if the factory

specifications for operation and maintenance, found in original equipment manuals, and component manuals, are not

followed, or if other than factory authorized erection, alterations or modifications are made to any Parts or Equipment;

(2) defective Parts are warranted to the Purchaser only for repair or replacement through an authorized Purchaser or

Distributor of Seller, or direct with Seller for a period of 13 months from the date of invoice; however, this warranty

excludes all claims for failure resulting from normal wear and tear, improper installation, omission of factory specified

preventative maintenance, misuse, abuse, negligence, third party damages, or acts of God and Purchaser agrees to

submit to and assist Seller or its authorized Purchaser or Distributor in conducting in-warranty inspections of the

Goods including inspection of any Equipment or Parts claimed to be defective by the Purchaser; (3) the cost of

providing labor or repair to replace Equipment and Parts warranted to Purchaser will be included within the warranty

only if such claim is made within 120 days from the date of invoice and then only during normal business hours

through an authorized Purchaser or Distributor of Seller, or direct with Seller, and labor and service provided beyond

the labor warranty period shall be subject to labor charges at the rates established by the local authorized Purchaser

or Distributor or direct with Seller; (4) the warranties shall be void for all Equipment failures and premature Part wear

caused by the use of corrosive chemicals in the wash process, and the following list includes some, but not all, of the

particularly corrosive chemicals that if used in conjunction with Equipment or Parts will void the warranty: Hydrofluoric

Acid, Ammonium Bi-fluoride, Bromic Acid, Muriatic Acid, Sulfonic Acid, Phosphoric Acid, Hydrogen Cyanide,

Hydrochloric Acid, Sodium Hydroxide and Chlorinated Solvents; (5) Seller makes no warranty, express or implied, with

respect to the design or operation of any entire system, in which Seller’s Equipment or Parts sold hereunder are mere

components;(6) in no event shall Seller be liable for any incidental, special, consequential, punitive or exemplary

damages resulting from the furnishing, performance or use of any Goods or services sold pursuant hereto, whether

due to a breach of contract, breach of warranty, negligence or any other claim at law or equity. Seller shall not be

liable for any damages of any kind, including, but not limited to, loss of business; inconvenience, or property damage

of any kind; nor for any damages of whatever nature resulting in any way from the Purchaser’s selection and use of

any chemicals not manufactured exclusively by Seller but used with the purchased Equipment or Parts; or for any

service not expressly provided herein related to or arising from the Equipment or Parts sold. Seller shall not be liable

for damages resulting from Purchaser’s use of any engineering recommendations, sales representations, technical

assistance, advice or data other than that information contained in Belanger manuals; (7) all warranties, express,

implied, or statutory, pertaining to the Equipment and Parts apply to the Purchaser only; are not transferable; are fully

set forth herein; and no addition to or modification thereto shall be binding upon the Seller, unless made in writing and

signed by a duly authorized employee of Seller.

No Other Warranties:

THIS LIMITED WARRANTY FOR EQUIPMENT AND PARTS IS EXPRESSLY IN LIEU OF ALL OTHER

WARRANTIES, EXPRESS OR IMPLIED, WHETHER STATUTORY OR OTHERWISE, INCLUDING ANY

IMPLIED WARRANTY OF MERCHANTABILITY OR WARRANTY OF FITNESS FOR A PARTICULAR

PURPOSE. THE IMPLIED WARRANTIES OF MERCHANTABILITY AND FITNESS FOR PARTICULAR

PURPOSE CONTAINED IN THE UNIFORM COMMERCIAL CODE –SALES ARE EXPRESSLY

DISCLAIMED.

Copyright© 2013 by Belanger, Inc.®All rights reserved. No part of this work may be reproduced or transmitted in any

form or by any means, electronic or mechanical, including photocopying and recording, or by any information storage

or retrieval system, except as may be expressly permitted by the 1976 Copyright Act. Belanger® reserves the right to

change or modify the Belanger, Inc.® Limited warranty without notice.

insta-KLEEN™ MANUAL

4Belanger, Inc. * PO BOX 5470 * Northville, MI 48167-5470 * Ph (248) 349-7010 * Fax (248) 380-9681 1MANUL334

Introduction

IMPORTANT Safety Information –MUST READ

This section introduces the hazard and safety precautions associated with installing, maintaining or

servicing this product. Before performing any task on this product, read this safety information and

the applicable sections in this manual, where additional hazards and safety precautions for your task

may be found. Electrical shock could occur and cause death or serious injury if these safe service

procedures are not followed.

Safety Warnings Explanation

Throughout this manual, the following symbols are in effect:

The safety warning symbols used throughout the manual fall into the following categories:

Symbol Example

Definition

Yellow warning triangle/black graphical symbol indicates what the

hazard is.

Red circle-with-slash/black graphical symbol indicates a prohibited

action to avoid the hazard.

Blue mandatory action circles/white graphical symbol –indicates an

action to take to avoid the hazard.

Terms used throughout the manual are defined as follows:

DANGER - Indicates an imminently hazardous situation, which if not avoided, will result in

death or serious injury.

WARNING - Indicates a potentially hazardous situation, which if not avoided, could result in

death or serious injury.

CAUTION - Indicates a potentially hazardous situation, which if not avoided, may result in

minor or moderate injury.

Other helpful informational notes appear as follows:

!!IMPORTANT!!

Important information that has more impact than a note-not related to injury.

NOTE:

General and/or helpful information-not related to injury or damage.

Helpful tips.

insta-KLEEN™MANUAL

1MANUL334 Belanger, Inc. * PO BOX 5470 * Northville, MI 48167-5470 * Ph (248) 349-7010 * Fax (248) 380-9681 5

Introduction

IMPORTANT Safety Information –MUST READ

CAUTION –BEFORE YOU BEGIN, ONLY TRAINED OR AUTHORIZED

INDIVIDUALS KNOWLEDGEABLE IN THE RELATED PROCEDURES SHOULD

INSTALL, INSPECT, MAINTAIN OR SERVICE THIS EQUIPMENT.

CAUTION - DO NOT USE THIS EQUIPMENT FOR ANY PURPOSE NOT

DESCRIBED IN THIS MANUAL.

Read the Manual

Safety Warnings

WARNING –LOCKOUT/TAGOUT ELECTRICAL PRIOR TO OPENING FOR

SERVICE.

WARNING –LOCK ELECTRICAL EQUIPMENT.

DANGER –DISCONNECT MAIN POWER SUPPLY PRIOR TO SERVICING OR

MAINTAINING EQUIPMENT!

WARNING –LOCKOUT/TAGOUT AND REDUCE PNUEMATIC PRESSURE TO

ZERO PRIOR TO SERVICING.

Belanger recommends that all workers observe the OSHA (U.S. Department of Labor Occupational Safety

& Health Administration) Lockout / Tagout procedure prior to performing service or maintenance on

machinery and equipment. Doing so will prevent unexpected energization, startup, or release of hazardous

energy while maintenance and servicing activities are being performed.

CAUTION –EQUIPMENT OPERATES AT A VOLTAGE POTENTIAL WHERE ARC

FLASH MAY OCCUR. DISCONNECT THE UPSTREAM SOURCE AND USE

MEANS TO LOCKOUT/TAGOUT PRIOR TO OPENING FOR SERVICE.

WARNING –BE SURE TO OBSERVE OPERATING ENVELOPE. EQUIPMENT

MAY START UNEXPECTICALLY. OVERHEAD, ROTATING AND/OR MOVING

COMPONENTS COULD RESULT IN SERIOUS INJURY OR DEATH.

WARNING –BE AWARE OF FOREIGN OBJECTS IN THE AREA SURROUNDING

A ROTATING PIECE OF EQUIPMENT. OBJECTS MAY BECOME TANGLED WITH

EQUIPMENT AND COULD RESULT IN SERIOUS INJURY OR DEATH.

CAUTION –BE AWARE OF HAZARDS ASSOCIATED WITH EQUIPMENT

INSTALLED ON THE FLOOR THAT MAY BE A TRIP HAZARD.

WARNING - READ, UNDERSTAND AND FOLLOW THIS MANUAL AND ANY

OTHER LABELS OR RELATED MATERIALS SUPPLIED WITH THIS EQUIPMENT.

IF YOU DO NOT UNDERSTAND THE PROCEDURE, CALL A BELANGER, INC.

REPRESENTATIVE AT 248-349-7010. IT IS IMPERATIVE TO YOUR SAFETY

AND THE SAFETY OF OTHERS TO UNDERSTAND THE PROCEDURES BEFORE

BEGINNING WORK.

insta-KLEEN™ MANUAL

6Belanger, Inc. * PO BOX 5470 * Northville, MI 48167-5470 * Ph (248) 349-7010 * Fax (248) 380-9681 1MANUL334

Introduction

IMPORTANT Safety Information –MUST READ

Safety Warnings

CAUTION –SERVICE PERSON SHOULD USE APPROPRIATE FOOTWEAR AND

USE SAFETY CONSCIOUSNESS WHEN WORKING IN THE WASH BAY AREA.

WARNING –ELECTRICAL PANEL SHOULD BE MOUNTED SO THAT THE

DISCONNECT HANDLE IS BETWEEN 0.6 –1.99 m (24”–78”) IN HEIGHT ABOVE

THE FLOOR WITH THE IDEAL HANDLE HEIGHT BEING 1.7 m (67”). LOCAL

COMPLIANCE FOR HANDLE HEIGHT MUST BE CONFIRMED.

WARNING –MINIMUM SERVICE CLEARANCE OF 900 mm (35.5”) IS

REQUIRED IN FRONT OF ICC CONTROLLER ENCLOSURE DOOR. LOCAL

COMPLIANCE OR SITE CONDITIONS MAY INCREASE THIS DISTANCE.

WARNING –DISCONNECT AND LOCKOUT ELECTRICAL POWER BEFORE

SERVICING ANY EQUIPMENT!

WARNING –HIGH LEAKAGE CURRENT. EARTH

CONNECTION ESSENTIAL BEFORE CONNECTING SUPPLY.

3.3 mm2(Cu) MINIMUM FOR CE PANELS.

CAUTION –THE IP RATING OF THAT CABINET MUST BE MAINTAINED. FOR

EXAMPLE, USE ONLY STRAIN RELIEFS WITH AN IP RATING OF 66 OR BETTER.

WARNING –DO NOT OPERATE THIS EQUIPMENT FROM ANY POWER

SOURCE THAT DOES NOT MATCH THE VOLTAGE RATING LISTED ON THE

EQUIPMENT. REFER TO THE MANUFACTURER’S IDENTIFICATION LABEL FOR

OPERATIONAL REQUIREMENTS.

CAUTION –IT IS RECOMMENDED THAT A LICENSED ELECTRICIAN IS

CONTRACTED TO PERFORM ALL ELECTRICAL INSTALLATIONS.

CAUTION –ALL CONNECTIONS MADE TO THE ICC ENCLOSURE MUST BE

MADE THROUGH THE BOTTOM OF THE ENCLOSURE. HOLES ARE NOT PRE-

PUNCHED.

CAUTION –CLEANING IF IT SHOULD BECOME NECESSARY TO CLEAN THIS

EQUIPMENT, DISCONNECT THE UNIT FROM ITS POWER DURING CLEANING.

DO NOT USE LIQUID CLEANERS, AEROSOLS, ABRASIVE PADS, SCOURING

POWDERS OR SOLVENTS, SUCH AS BENZINE OR ALCOHOL. USE A SOFT

CLOTH LIGHTLY MOISTENED WITH A MILD DETERGENT SOLUTION.

CAUTION –A COMPRESSED AIR SYSTEM SHOULD BE SET CORRECTLY TO

SUPPORT 90 PSI / 620 kPa NECESSARY TO OPERATE EQUIPMENT BUT

SHOULD NEVER BE SET TO DELIVER MORE THAT 120 PSI / 827 kPa AIR

PRESSURE TO BELANGER® SPECIFIED EQUIPMENT. FIELD SUPPLIED

PNEUMATIC TUBING MUST HAVE A MINIMUM OF 2 TIMES THE BURST

STRENGTH OF SYSTEM PRESSURE.

insta-KLEEN™MANUAL

1MANUL334 Belanger, Inc. * PO BOX 5470 * Northville, MI 48167-5470 * Ph (248) 349-7010 * Fax (248) 380-9681 7

Introduction

IMPORTANT Safety Information –MUST READ

It is imperative to your safety and the safety of others to always follow

safe work procedures.

WARNING –WEAR APROPRIATE PERSONAL PROTECTION GEAR WHEN NEAR

POWERED UP EQUIPMENT WITH ENCLOSURE DOOR/COVER OPEN.

WARNING –IT IS THE RESPONSIBILITY OF THE SITE OWNER TO PROPERLY

INSTRUCT THE WASH USER ON THE PROPER USE OF THE WASH AND TO

INSTRUCT THEM THAT THE WASH BEGINS AUTOMATICALLY AFTER

PROPERLY LOADING THE VEHICLE.

WARNING –ALL MACHINE COMPONENTS HANDLED

DURING INSTALLATION, MAINTENANCE AND/OR SERVICE

MUST BE HANDLED WITH A DEVICE APPROPRIATELY RATED

AND IN SUITABLE CONDITION TO LIFT AND/OR HANDLE

THE WEIGHT OF THE COMPONENT. WHEN COMPONENTS

ARE HANDLED BY HAND, USE PROPER LIFTING

TECHNIQUES TO AVOID INJURY.

WARNING –DO NOT ATTEMPT TO SERVICE AREAS OF THIS EQUIPMENT

ABOVE 1.8 M (6 FT) WITHOUT WEARING AN APPROVED SAFETY HARNESS.

DO NOT ATTEMPT TO ACCESS UPPER AREAS OF THIS EQUIPMENT EXCEPT BY

USING AN APPROVED SAFETY LADDER IN GOOD OPERATING CONDITION.

DO NOT USE TABLES, CHAIRS, OR OTHER NON-APPROVED CLIMBING

EQUIPMENT OTHER THAN AS STATED HEREIN.

WARNING –HEARING PROTECTION IS REQUIRED FOR PERSONS SUCH AS

WASH ATTENDENT OR SERVICE TECHNICIAN IF PRESENT IN THE WASH BAY

OR THE AREA OF THE DRYER WHILE THE DRYER IS OPERATING. EQUIPMENT

OPERATES ABOVE 80 dB.

WARNING - DO NOT OPERATE THIS EQUIPMENT WITHOUT ALL GUARDS

AND COVERS IN PLACE.

CAUTION –ALWAYS WEAR SAFETY GLASSES WHEN PERFORMING

MAINTENANCE ON ANY EQUIPMENT.

WARNING - SITE OWNER RESPONSIBLE FOR CREATING WASH USE

INSTRUCTIONS VISIBLE TO USER IN NATIVE LANGUAGE.

insta-KLEEN™ MANUAL

8Belanger, Inc. * PO BOX 5470 * Northville, MI 48167-5470 * Ph (248) 349-7010 * Fax (248) 380-9681 1MANUL334

Introduction

Operational Warning

Formulations containing the chemicals listed below are particularly dangerous and should not be

used even at low concentrations:

•Hydrofluoric Acid

•Ammonium Bi-fluoride

•Bromic Acid

•Muriatic Acid

•Sulfonic Acid

•Phosphoric Acid

•Hydrogen Cyanide

•Hydrochloric Acid

•Chlorinated Solvents

Belanger, Inc., does not endorse or condone the use of chemicals that are potentially dangerous to

human health, the environment or property. Belanger recognizes that it is the right and sole decision

of the end user operators of our equipment as to the type and dilution ratio of the chemicals used in

their facilities. We strongly recommend that the end user does not select products containing any of

the chemicals listed above as an ingredient in the wash solutions. The chemicals listed above are

potentially dangerous to human health, and have a detrimental, deteriorating effect on the equipment

and the facility. Be advised that a portion of, or all of your warranty will be voided if you determine to

use any of the chemicals listed above as an ingredient in the wash solutions in conjunction with your

Belanger automatic car wash equipment:

Limitation (4), of Paragraph (8), Limited Warranty, of the Belanger Terms and Conditions of

Sales describes the potential limitation of warranty due to your chemical selection:

(4) This warranty shall be void for all equipment failures and premature component wear

caused by the use of corrosive chemicals in the wash process. The following list includes

some, but not all, of the particularly corrosive chemicals that if used in conjunction with

Belanger equipment will void the warranty: Hydrofluoric Acid, Ammonium Bi-fluoride, Bromic

Acid, Muriatic Acid, Sulfonic Acid, Phosphoric Acid, Hydrogen Cyanide, Hydrochloric Acid, and

Chlorinated Solvents. The Purchaser also agrees to accept the responsibility and liability for

the selection and use of any chemicals listed above;

However, should the end user decide to use formulations containing any of the above ingredients,

the end user should institute a comprehensive training program and implement detailed operational

parameters within their organization for the proper handling and treatment of such products to

minimize the potential dangers involved. Consult your chemical supplier for assistance in

establishing operational guidelines in the use of their products. MSDS (Material Safety Data Sheet)

should be obtained from the chemical supplier before using any chemical formulation.

CAUTION –DO NOT USE CHEMICALS THAT ARE CORROSIVE, CONTAIN

CONTAMINANTS, FOREIGN PARTICLES, AND/OR CORROSIVE ADDITIVES. DOING

SO WILL VOID MACHINE WARRANTY. CHEMICAL USED MUST BE COMPATIBLE

WITH LOCAL CODE REQUIREMENTS AND NOT HARMFUL TO PERSONS,

ANIMALS, OR THE ENVIRONMENT.

insta-KLEEN™MANUAL

1MANUL334 Belanger, Inc. * PO BOX 5470 * Northville, MI 48167-5470 * Ph (248) 349-7010 * Fax (248) 380-9681 9

Introduction

Environmental Parameters

•Operating Temperature. This equipment will operate correctly in its intended ambient, at a

minimum between +40ºF (+5ºC) and +104ºF (+40ºC).

•Relative Humidity. The equipment will operate correctly within an environment at 50% RH,

+104ºF (+40ºC). Higher RH may be allowed at lower temperatures. Measures shall be taken

by the Purchaser to avoid the harmful effects of occasional condensation.

•Altitude. This equipment will operate correctly up to 1000m above mean sea level.

•Transportation and Storage. This equipment will withstand, or has been protected against,

transportation and storage temperatures of -13ºF (-25ºC) to 131ºF (+55ºC) and for short

periods up to 158ºF (+70ºC). It has been packaged to prevent damage from the effects of

normal humidity, vibration and shock.

Safeguards

The following items have been incorporated into the design of the wash as safety features to protect

the user and maintenance person.

WARNING - DO NOT OPERATE THIS EQUIPMENT WITHOUT ALL GUARDS

AND COVERS IN PLACE.

WARNING - DO NOT OPERATE DURASCRUBBER® WITHOUT SAFEGUARD

INSTALLED.

WARNING - DO NOT OPERATE INSTA-KLEEN™IN NORMAL OPERATION

WITHOUT LOCK PREVENTING ACCESS TO ICC CONTROLLER.

•The dryer blowers have screens mounted to the inlet and outlets to prevent debris from

entering and exiting the blower as well as to prevent contact with body parts.

Reasonable and Foreseeable Misuse

The following conditions must be considered by the Owner Operator. It is his/her responsibility to

take precautions as described below.

•Do not allow users who are under the influence of alcohol, drugs, or controlled substances

to use the wash.

•Keep the wash bay clean and free of debris and objects that would confuse the user or

impede access into or out of the wash bay.

•Instruct the wash user to not enter the wash with the vehicle windows and/or vehicle

doors open and to keep windows and vehicle doors closed throughout the entire wash

process.

•Always instruct the wash user to remain in the vehicle throughout the wash process.

•Ensure that the wash bay is well lit so wash users can safely use the wash.

•Instruct the wash user to not use the wash if their vehicle has loose or broken parts that

may interfere with, damage, or result in unsafe operation of the wash.

•Instruct the wash user that the damage to or incidents caused by aftermarket vehicle

components is not the responsibility of the wash owner or manufacturer.

•Instruct the wash user to proceed slowly through the wash.

•Instruct the wash user to never back up inside the wash bay.

•Instruct personnel not to work on wash unless the entrance is blocked from vehicles

entering, this is in addition to all other safety precautions.

insta-KLEEN™ MANUAL

10 Belanger, Inc. * PO BOX 5470 * Northville, MI 48167-5470 * Ph (248) 349-7010 * Fax (248) 380-9681 1MANUL334

Introduction

Do’s and Do Not’s

DO

DO NOT

Read all manuals carefully and

completely prior to beginning the

process the manual describes.

DO NOT drill in top of any electrical enclosures.

Verify that all parts needed to perform a step

described in the manual are present prior to

beginning the process.

DO NOT install high voltage and low voltage supply

lines in the same conduit.

Study and understand all installation diagrams and

drawings.

DO NOT power-up controller without following

manual.

Carefully follow all instructions.

DO NOT operate machine without testing all

sensors for clearance and operation.

Use anti-seize lubricant on all threaded fasteners

(screws, bolts, nuts, etc.).

DO NOT operate machine until all safety features

are tested.

Use quality thread sealant on all plumbing

connections to eliminate leaking.

DO NOT service high- or low-pressure

pumps without turning main power off

and following Lock-Out/Tag-Out

Procedures. Severe injury could result.

Ask questions when they arise.

DO NOT service without turning main

power off and following Lock-Out/Tag-

Out procedures. Severe injury could

result.

Check amperage draw on all motors (refer to motor

name plate).

DO NOT attempt to add components to machine

without first contacting Belanger® Authorized Rep.

Check all overloads are set correctly (refer to motor

name plate ratings and actual amp draw).

DO NOT substitute machine components without

first contacting Belanger® Authorized Rep.

Check all electrical boxes are closed prior to spraying

water.

DO NOT replace fuses with oversized fuses. Refer

to the fuse replacement chart located inside of the

enclosure.

Check incoming electrical supply voltage to ensure it

matches equipment order.

Ensure all pump and motor rotations are correct

(observe rotation arrow on pump/motor).

Follow all maintenance schedules to ensure trouble-

free performance.

Periodically check all system stop circuits are

functional.

Table 1 Recommended General Practices to Do and Not Do when Installing, Maintaining, and/or Servicing Belanger® Equipment.

insta-KLEEN™MANUAL

1MANUL334 Belanger, Inc. * PO BOX 5470 * Northville, MI 48167-5470 * Ph (248) 349-7010 * Fax (248) 380-9681 11

Introduction

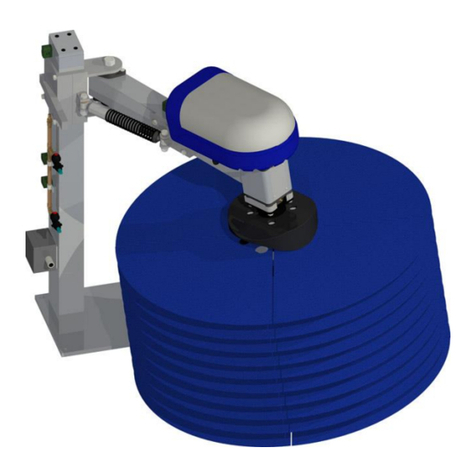

Description of insta-KLEEN™System

The insta-KLEEN™is a flexible customer configured system, designed to meet the needs of auto dealerships, fleet

operators and auto rental agencies. The base system comes with a “Quad” cloth curtain for cleaning the front, top

surfaces, and rear of vehicles up to 90” (2.29 m) tall. A set of tall wheels is included to clean the front, sides and rear of the

vehicles. The customer can select between a “Wash-A-Round” or a “Gyro Wrap™” for the tall wheels and can chose

between cloth or “Neo-Tex™” foam as a wash media. A “UNIARCH” is added to rinse the entire vehicle. The vehicle is

typically driven through the wash, as opposed to being pulled through with a conveyor system. This allows the operator to

control the speed of the wash and the wash quality. Slower speed results in optimum cleaning while a faster drive through

can meet the needs of a quick wash during times of peek demand. The entire system is tied together and controlled with

the insta-Kleen™Control Center (ICC). The ICC includes water solenoid valves, chemical pumps, motor starters, and a

powerful PLC to run the entire system. These items are pre-plumbed, wired and tested for faster and less expensive

installation costs. The ICC is designed with expandability to accommodate many customer-selected options. A plastic

coated, steel guide rail system is included when the optional conveyor is not selected.

From the base insta-KLEEN™, the following options can be selected:

1) Over/Under Conveyor: The Belanger conveyor is a very heavy-duty component that can now be added

to the insta-KLEEN™system. This will eliminate operator speed variation and supply the most consistent

wash quality. Studies show that system maintenance cost can be cut in half by minimizing damage

caused by drivers. Three different guide rail options can be chosen for the conveyor and the standard

insta-KLEEN™guide rail is omitted.

2) Titan VPS: An optional vehicle prep system. There are 2 pumps that pump 85 GPM (19.3 m3/h) of

reclaim water at 140 PSI (965 kPa) to the wheels and lower sides of the vehicle. This removes heavy dirt

prior to entering the curtain.

3) Presoak Arch: Includes a stainless steel UNIARCH, nozzles, check bodies, a chemical pump, and a

water solenoid valve assembly pre-wired and plumbed on the ICC. A soap fan spray option can be

added to apply a thick coating of presoak.

4) Wave Across: A second set of cloth mitters that oscillate from side to side for additional cleaning on the

horizontal surfaces and the sides.

5) Low Side Washer: A low side washer to give added cleaning to the lower 36” (91 cm) of the vehicle.

Available in Neo-Tex™foam or cloth, this option allows faster wash speeds when tunnel space allows for

them.

6) Gyro Wrap™: The Gyro Wrap™ only requires 134”(3.40 m) of tunnel space and has a flexible head at

the top of the assembly that self-centers the shaft as the wheel spins. This ‘Flex Head’enables the Gyro

Wrap™wheels to adjust to the contour of the front, sides and rear surfaces as it washes each vehicle.

7) DuraScrubber®: A wheel washer designed to scrub and brush off heavy residue, grime and break dust

by utilizing an alternating diameter nylon brush. At a length of 96”(2.44 m), the DuraScrubber®brush

provides an effective balance between firm bristled grime removal and soft bristle cleaning on the vehicle

wheels for one full rotation.

8) Top Wheel: Designed as a dedicated horizontal surface washer, it excels at cleaning hoods, roofs and

trunk lids. The Top Wheel features one of the industry’s highest pivot points, along with adjustable

counterweights allowing it to glide over vehicles with just the right pressure –maximizing cleaning

effectiveness and safety. The cleaning material for the Top Wheel hub is available in Neo-Tex™foam or

Whisper Wheel®packs.

9) UNIARCH: A second optional UNIARCH equipped with a stainless-steel foam coated arch with brass

fittings. One comes with the base system and adding a second rinse arch will also allow faster wash

speeds. Many times, this is connected to an optional spot free (R.O.) system when the dryer option is

not selected.

10) Air Cannon™Dryer: A premium Belanger dryer offering. There are 30 hp (22.4 kW), 50 hp (37.3 kW)

and 70 hp (52.2 kW) models available to meet our customer’s needs. When selected this option includes

a properly sized motor starter panel, a chemical pump for drying agent (wax) and the necessary fittings.

An optional dryer silencer can also be added, when noise is a problem.

11) Chemical Tire Applicator (CTA): When a tire drives over it, a strong tire/wheel-cleaning chemical is

applied with an air driven pump.

12) Prep-Jet: A high-powered, 2-gun spray pressure-washer. This can be used for prepping the vehicle prior

to washing, cleaning the engines, or even for washing down the bay.

13) Reclaim Systems: Offered in many sizes to meet our customer’s needs.

insta-KLEEN™ MANUAL

12 Belanger, Inc. * PO BOX 5470 * Northville, MI 48167-5470 * Ph (248) 349-7010 * Fax (248) 380-9681 1MANUL334

Introduction

Description of insta-KLEEN™System

From the base insta-KLEEN™, the following options can be selected (continued):

14) Reverse Osmosis (RO): Spot Free systems are available in several sizes and are great for final rinse

applications.

15) Weigand™ Wash Card Systems: These units can be added to the insta-KLEEN™system for tracking

vehicle washes and authorization.

16) IK™Standard Guide Rail: Guide rail system that captures the front driver-side tire of a vehicle, and

assists in proper vehicle alignment, guiding the vehicle throughout the length of the car wash.

17) IK™Right-hand Drive Guide Rail: Guide rail system that will capture the front driver-side tire of a

vehicle in the International market, and assists in proper vehicle alignment, guiding the vehicle

throughout the length of the car wash.

18) IK™Vehicle Width Guide Rail: Guide rail system that will capture and contain the entire vehicle, and

assists in proper vehicle alignment, guiding the vehicle throughout the length of the car wash.

19) Chameleon®Arch: The Chameleon® Arch is made of quality aluminum and stainless-steel construction,

bold colors, vibrant lighting, and flexible branding options. Offered in spray applicator and utility cross-

over arch configurations.

Important: Please refer to the system drawings in this manual for space requirements and typical

layouts. Refer to the supplied electrical prints for electrical requirements. Install all tunnel equipment

per its corresponding component manual and your site-drawings.

This document will cover topics that are specific to

the insta-KLEEN™Wash System. For information

on how to install wash components, refer to their

manuals, supplied electrical prints and site-

specific drawings.

insta-KLEEN™MANUAL

1MANUL334 Belanger, Inc. * PO BOX 5470 * Northville, MI 48167-5470 * Ph (248) 349-7010 * Fax (248) 380-9681 13

Introduction

Before You Get Started

Tools needed for installation:

Chalk line

Extension cord

Level

Hex wrench set

Wrench set

Square

Socket set

Ladder

Impact wrench

Tape measure (50 foot / 15 meter or greater)

Miscellaneous hand tools

Tin snips

Pry bar

Hammer drill with 1/2” (12.7mm) and 5/8” (15.8mm) bit

Forklift (5000 lb.) / (2200kg)

Safety glasses

Work gloves

Field Purchased Supplies Needed for Installation:

3HP / 2.25kW air compressor

What to Know Before You Get Started

The insta-KLEEN™is a flexible system. It can

be ordered in many configurations and with

many options. Please check your order against

your shipper and the equipment received. Verify

that you have received all the equipment

ordered.

NOTE: If any items listed below are not included in your shipment, contact your supplier.

NOTE: The insta-KLEEN™Wash System is completely electrically driven.

insta-KLEEN™ MANUAL

14 Belanger, Inc. * PO BOX 5470 * Northville, MI 48167-5470 * Ph (248) 349-7010 * Fax (248) 380-9681 1MANUL334

Introduction

Lag Bolt Usage Guidelines

(12.7 mm)

(12.7 mm)

(57.15 mm)

(57.15 mm)

Other manuals for insta-KLEEN

1

Table of contents

Other Belanger Washer manuals

Popular Washer manuals by other brands

Haier

Haier HWD80-1482-DF user manual

Bosch

Bosch WAY32880TI Instruction manual and installation instructions

Avanti

Avanti CTW10V0W instruction manual

Electrolux

Electrolux EWS 126410 W user manual

AEG

AEG oko lawamat 625 sensortronic operating instructions

Siemens

Siemens WM4HVGL9DN User manual and installation instructions