Belimo UK24MOD User manual

Product information

UK24MOD

www.belimo.com

T9-UK24MOD • en • v1.7 • 02.2014 • Subject to changes

1 / 20

Belimo Gateway

MP to Modbus RTU - UK24MOD

Contents

Complete overview 2

Technical data 3

Safety notes 4

Product features 4

Installation and commissioning 4

Electrical installation 5

Dimensions 7

Operation elements 8

Operation, behaviour 8

Modbus register overview 11

Modbus register description 13

Diagnostics and testing tool 16

Connecting the PC-Tool for parameterisation of the MP/MFT(2) actuators 16

Version overview 17

MODBUS RTU

UK24MOD

Belimo Gateway MP to Modbus RTU

2 / 20

T9-UK24MOD • en • v1.7 • 02.2014 • Subject to changes

www.belimo.com

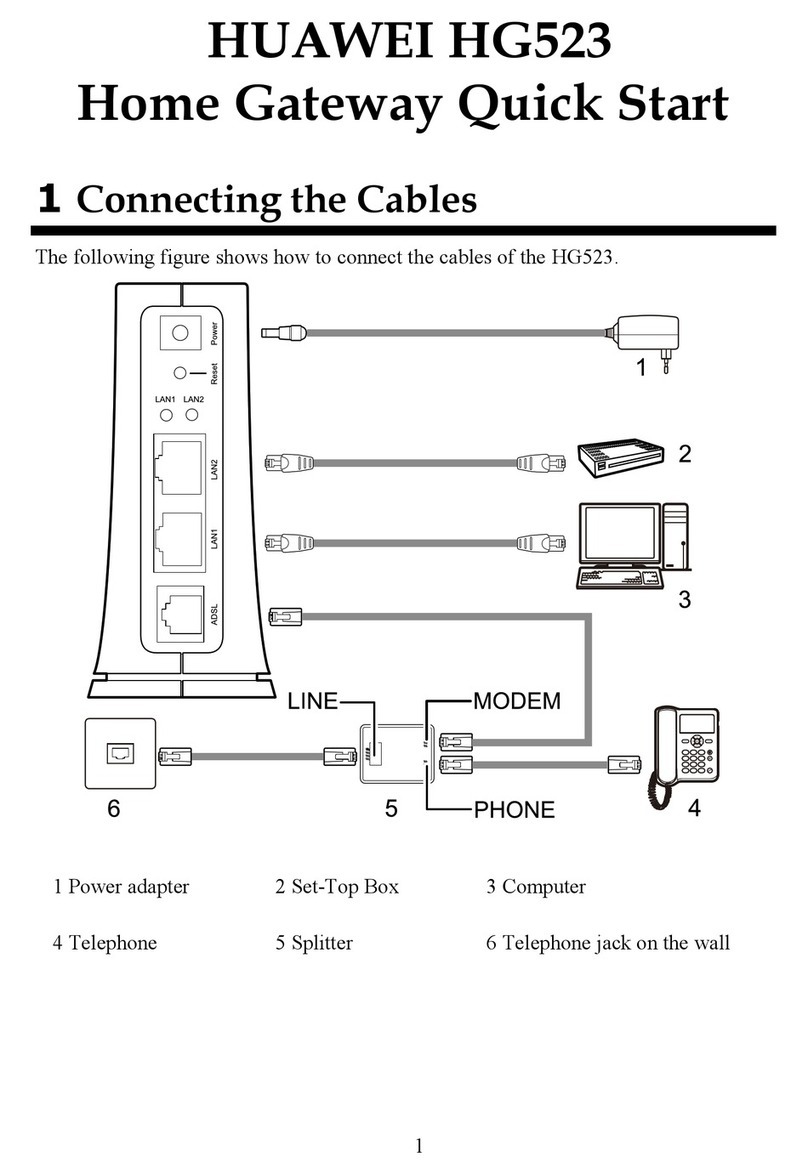

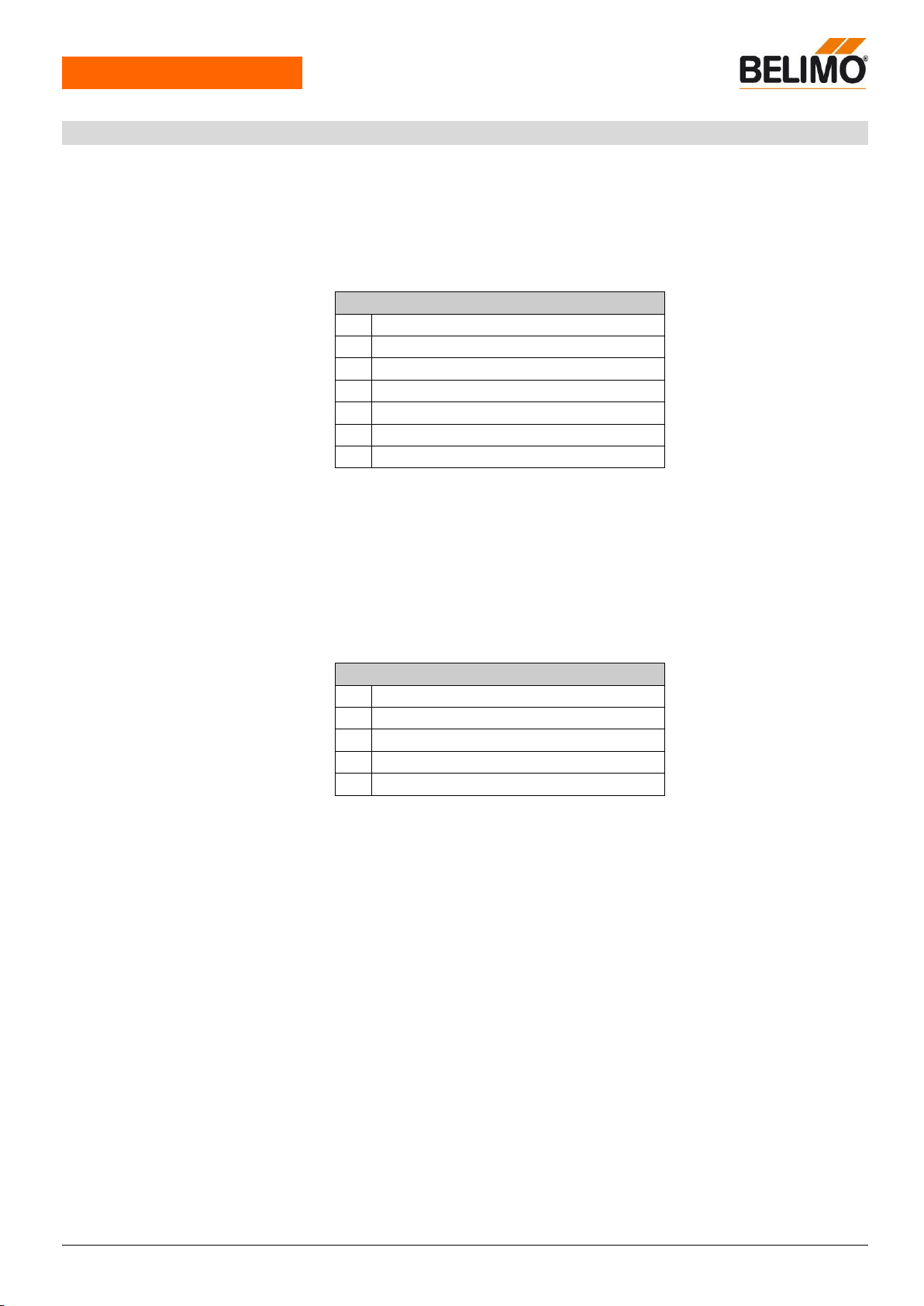

Complete overview

Gateway MP / Modbus RTU

Suitable MP/MPL/MFT(2) Actuators

Damper actuators

Fire damper actuators

VAV actuators

Actuators for characterised control valve, butterfly valves

and globe valves

EPIV actuators

MPL Actuators

UK24MOD

Belimo Gateway MP to Modbus RTU

www.belimo.com

T9-UK24MOD • en • v1.7 • 02.2014 • Subject to changes

3 / 20

Gateway MP to Modbus RTU. MP-bus-

capable Belimo actuators can be

connected on the MP-Bus side.

Interface MP/Modbus RTU

Connection of MP/MPL/MFT(2)

actuators and BF-TopLine

actuators to Modbus RTU

Up to 8 actuators and sensors can

be connected

Technical data

Electrical data

Nominal voltage

AC 24V, 50/60 Hz / DC 24V

Power supply range

AC / DC 21.6…26.4 V

For wire sizing

3 VA

Connection

Modbus RTU

Supply

MP-Bus

Tool

Plug-screw terminal, 3-pin

Plug-screw terminal, 2-pin

Plug-screw terminal, 3-pin

(All terminals suitable for 2 x 1.5 mm2)

RJ12

Functional data

Supported actuators

MP/MPL/MFT(2), BF-TopLine

Quantity of actuators

max. 8 pcs.

Communication with actuators

Belimo MP-Bus, Master-Slave, 1200 Bd

Maximum signal conductor lengths MP

Dependent on the number of connected actuators,

actuator type, type of supply and signal conductor

cross-section

For details see page 5

Modbus protocol

Modbus RTU

Supported functions: 3, 6

(For register assignment, see page 11)

Modbus medium

Medium

Parity

Number of nodes

Baud rates

Response delay

Termination

Polarisation

RTU / RS-485

NONE (1, 8, N, 2) or EVEN (1, 8, E, 1),

adjustable via DIP switch

max. 32 (without repeater)

9'600, 19'200, 38'400, 76'800 Bd,

adjustable via DIP switch

2…100 ms, adjustable via register

150

, adjustable via DIP switch

680

, adjustable via DIP switch

Safety

Protection class

III Safety extra-low voltage

EMC

CE pursuant to 2004/108/EC

Ambient temperature

0…+40° C

Installation / Dimension / Weight

Mounting

Control cabinet installation,

can be snapped onto top hat rail 35 mm

Dimensions

see page 7

Weight

ca. 100 g

UK24MOD

Belimo Gateway MP to Modbus RTU

4 / 20

T9-UK24MOD • en • v1.7 • 02.2014 • Subject to changes

www.belimo.com

Safety notes

The device is not allowed to be used outside the specified field of application.

It may be installed only by suitably trained personnel.

The device does not contain any parts that can be replaced or repaired by the user

and may only be opened at the manufacturer's site.

Product features

Mode of operation

The UK24MOD allows the actuators to be controlled digitally via the MP-Bus and send back

their current operating status. The control system information and the response is administered

in registers in the UK24MOD and can be processed with Modbus commands. This permits the

actuator functions to be integrated directly into the Modbus.

Sensor linking

One sensor can be connected per MP/MFT(2) actuator. This can be a passive resistance

sensor (PT1000, NI1000 or NTC), an active sensor (output DC 0…10 V), or a switching contact.

This provides a straightforward way of digitising the analogue signal of the sensors with the

Belimo actuator and transferring it via UK24MOD to the Modbus.

MPL actuators don't provide a sensor input.

Installation and commissioning

Installation and wiring

The device is mounted on 35 mm top hat rails. The wiring is accomplished with plug-screw

terminals.

Commissioning and parameterisation

Commissioning requires no configuration tools.

The Modbus parameterisation of the device is accomplished with DIP switches (address, baud

rate, parity, bus terminator, polarisation). The option exists of setting the response delay via

register entry (2..100 ms).

The addressing of the MP actuators is accomplished either with the keys under the front cover

or with the Belimo PC-Tool MFT-P.

The MP-Bus assignment is determined automatically and continuously updated. No backup of

the network structure takes place.

UK24MOD

Belimo Gateway MP to Modbus RTU

www.belimo.com

T9-UK24MOD • en • v1.7 • 02.2014 • Subject to changes

5 / 20

Electrical installation

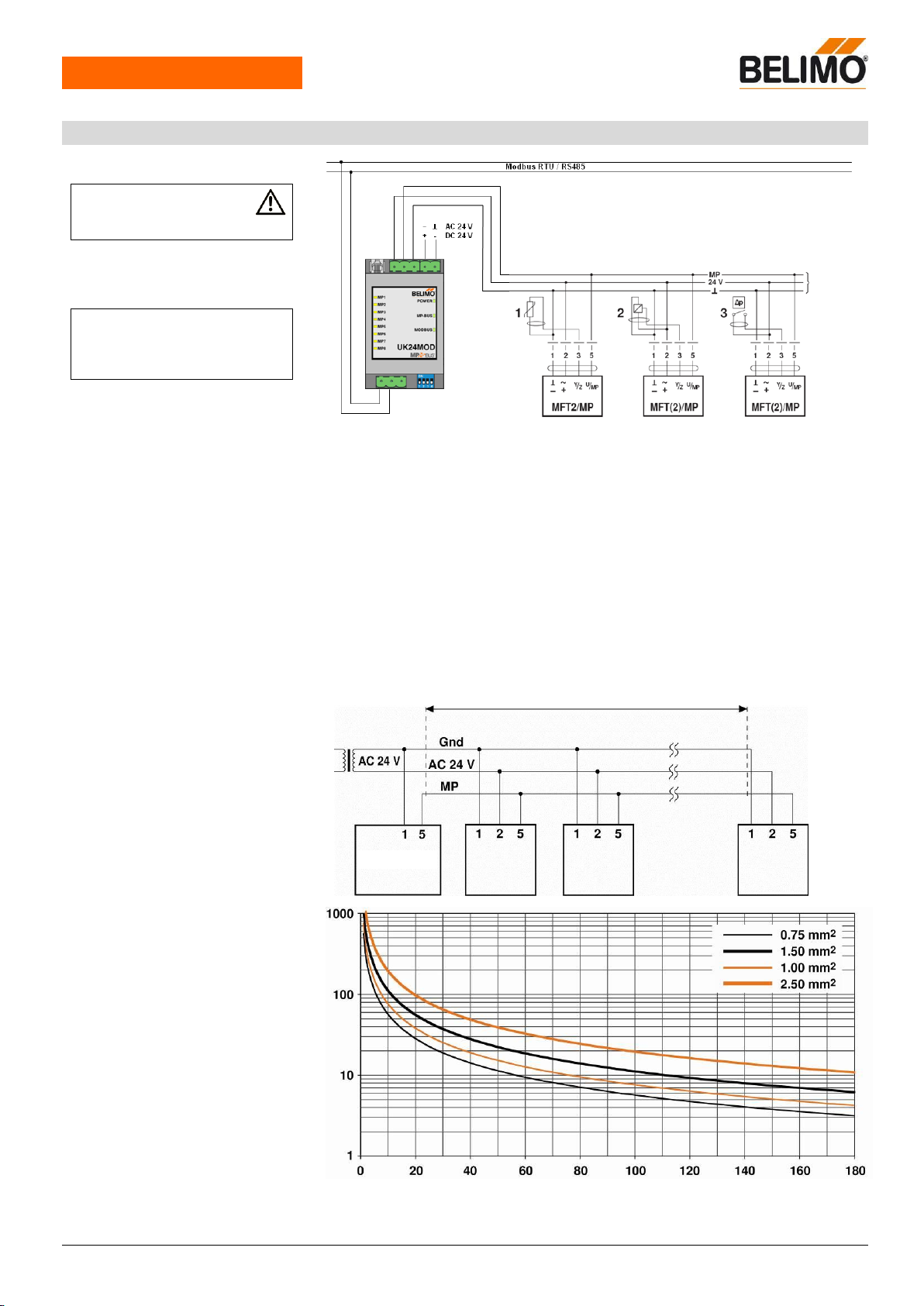

Wiring diagram

AC/DC 24 V supply

Connection via safety isolation

transformer!

Dimensioning of the supply

Also take into account the dimensioning

specifications of the connected

MP/MPL/MFT(2) actuators!

The wiring of Modbus RTU / RS485 is to be carried out in accordance with applicable directives

(www.modbus.org). The device possesses resistors which can be switched on for bus

connection and biasing.

Note: The GND of the RS485 line is galvanically isolated from the MP-Bus GND.

Connection of the MP-Bus

The network consists of a 3-pin connection

(MP communication and 24 V supply).

Possibility of connecting a maximum of 8 MP/MPL/MFT(2) actuators per network.

Neither a special cable nor terminating resistors are required.

The signal conductor lengths (for calculation, see below) are limited:

–by the sum of the signal conductor data of the connected MP/MPL/MFT(2) actuators,

–by the type of supply (AC 24 V via the bus or DC 24 V via the bus),

–by the signal conductor cross-section.

With AC 24 V supply:

Maximum signal conductor length

L = max. cable length [m]

With AC 24 V supply:

Total dimensioning

MP/MPL/MFT(2) actuators [VA]

Power rating [VA]

UK24MOD

More actuators

and sensors

(total 8)

UK24MOD

Belimo Gateway MP to Modbus RTU

6 / 20

T9-UK24MOD • en • v1.7 • 02.2014 • Subject to changes

www.belimo.com

Electrical installation

(continued)

With AC 24 V supply:

Calculation of the maximum signal

conductor lengths

To be read out from the mass of curves:

For cables with wire-Ø

[mm²]

Cable length

[m]

0.75

29

1.00

35

1.50

50

2.50

90

The power ratings [VA] of the MP/MPL/MFT(2) actuators used are to be added, and the

corresponding signal conductor lengths are to be read from the diagram.

Example:

The following is connected to the MP-Bus: 1 pc. NM24A-MP, 1 pc. SM24A-MP, 1 pc. LMV-D2-

MP… and 1 pc. NV24A-MP

Total power rating: 5.5 VA + 6 VA + 5 VA + 5 VA = 21.5 VA

With local supply AC 24 V (on site):

Maximum signal conductor length

Wire-Ø

[mm²]

L = max. cable length

[m]

0.75

800

1.00

1.50

2.50

The signal conductor lengths can be significantly increased if the actuators are supplied with AC

24 V locally via a separate transformer. The signal conductor lengths indicated in the table apply

regardless of the performance data of the actuators connected to the UK24MOD.

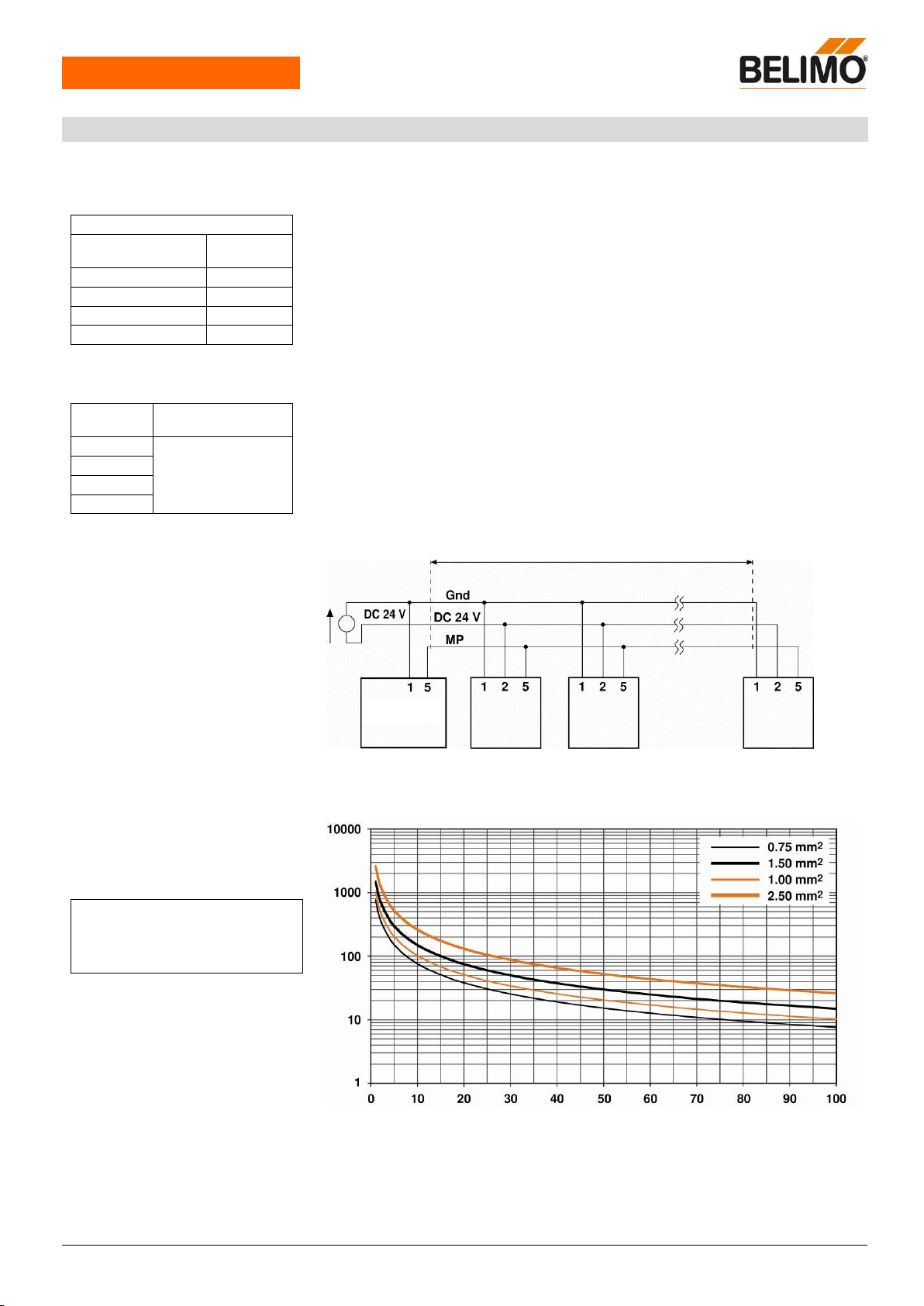

With DC 24 V supply:

Maximum signal conductor length

L = max. cable length [m]

With DC 24 V supply:

Total power consumption

MP/MPL/MFT(2) actuators [W]

Note

Cable length vs wire sizing power

applies to DC supply (minimum supply

voltage DC 24 V)

Cable length vs wire sizing power applies to DC supply (minimum supply voltage DC 24.0 V)

UK24MOD

UK24MOD

Belimo Gateway MP to Modbus RTU

www.belimo.com

T9-UK24MOD • en • v1.7 • 02.2014 • Subject to changes

7 / 20

Electrical installation

(continued)

With DC 24 V supply:

Calculation of the maximum signal

conductor lengths

To be read out from the mass of curves:

For cables with wire-Ø

[mm²]

Cable length

[m]

0.75

55

1.00

75

1.50

110

2.50

190

The power consumption [W] of the MP/MPL/MFT(2) actuators used is to be added, and the

corresponding signal conductor lengths are to be read from the diagram.

Example:

The following is connected to the MP-Bus: 1 pc. NM24A-MP, 1 pc. SM24A-MP, 1 pc. LMV-D2-

MP.. and 1 pc. NV24A-MP

Total power rating 3.5 W + 4 W + 3 W + 3 W = 13.5 W

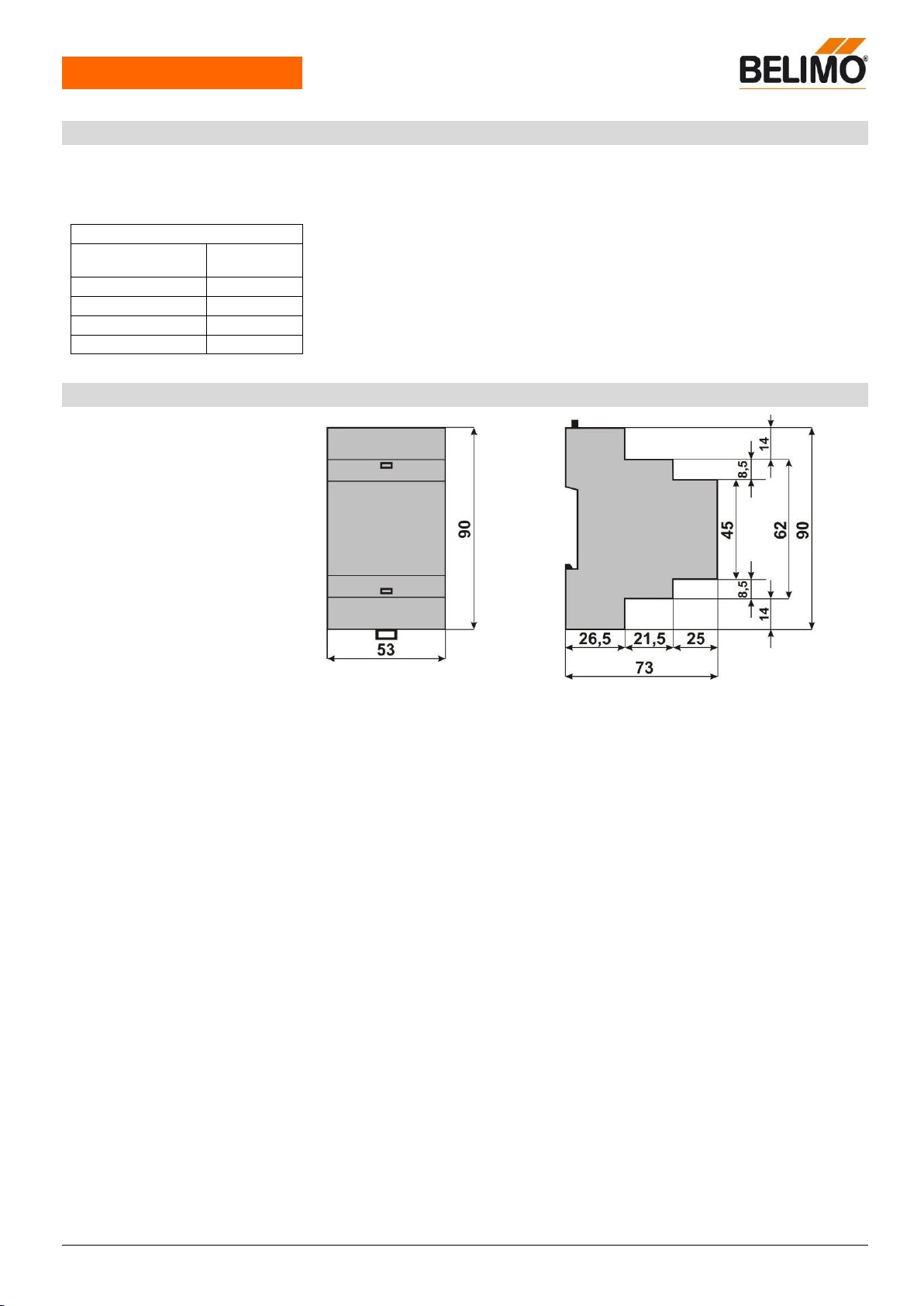

Dimensions

Dimensional drawings [mm]

UK24MOD

Belimo Gateway MP to Modbus RTU

8 / 20

T9-UK24MOD • en • v1.7 • 02.2014 • Subject to changes

www.belimo.com

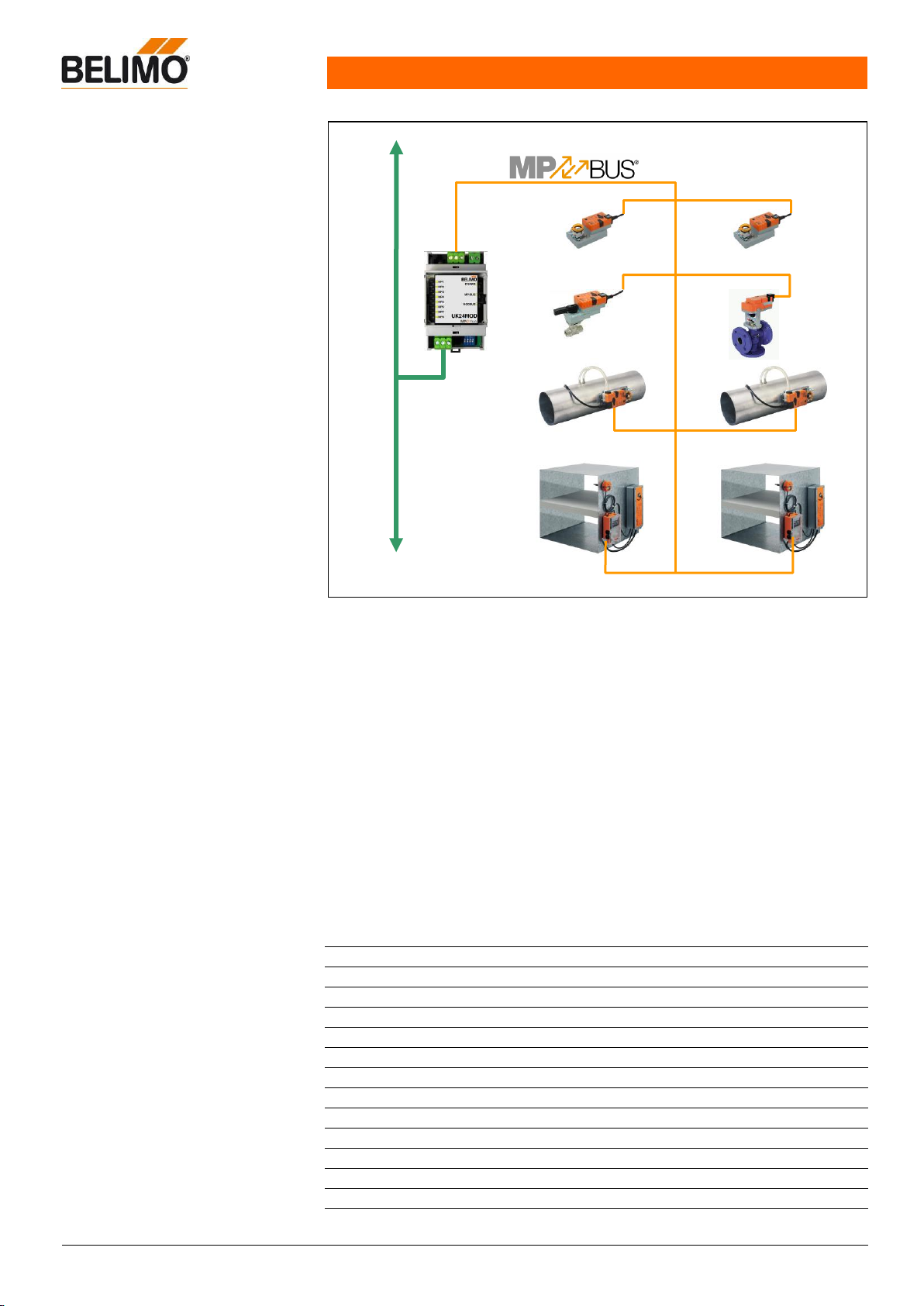

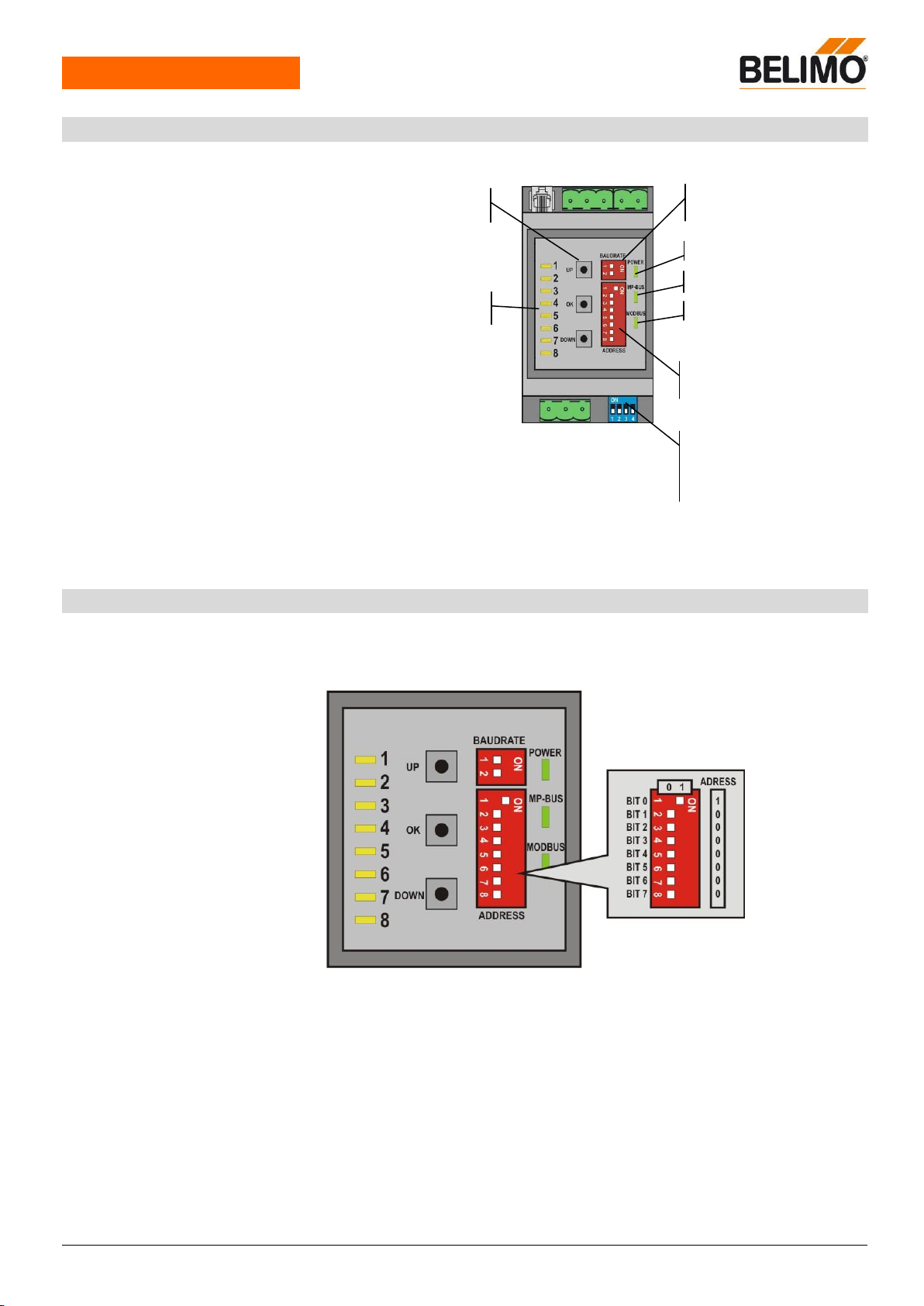

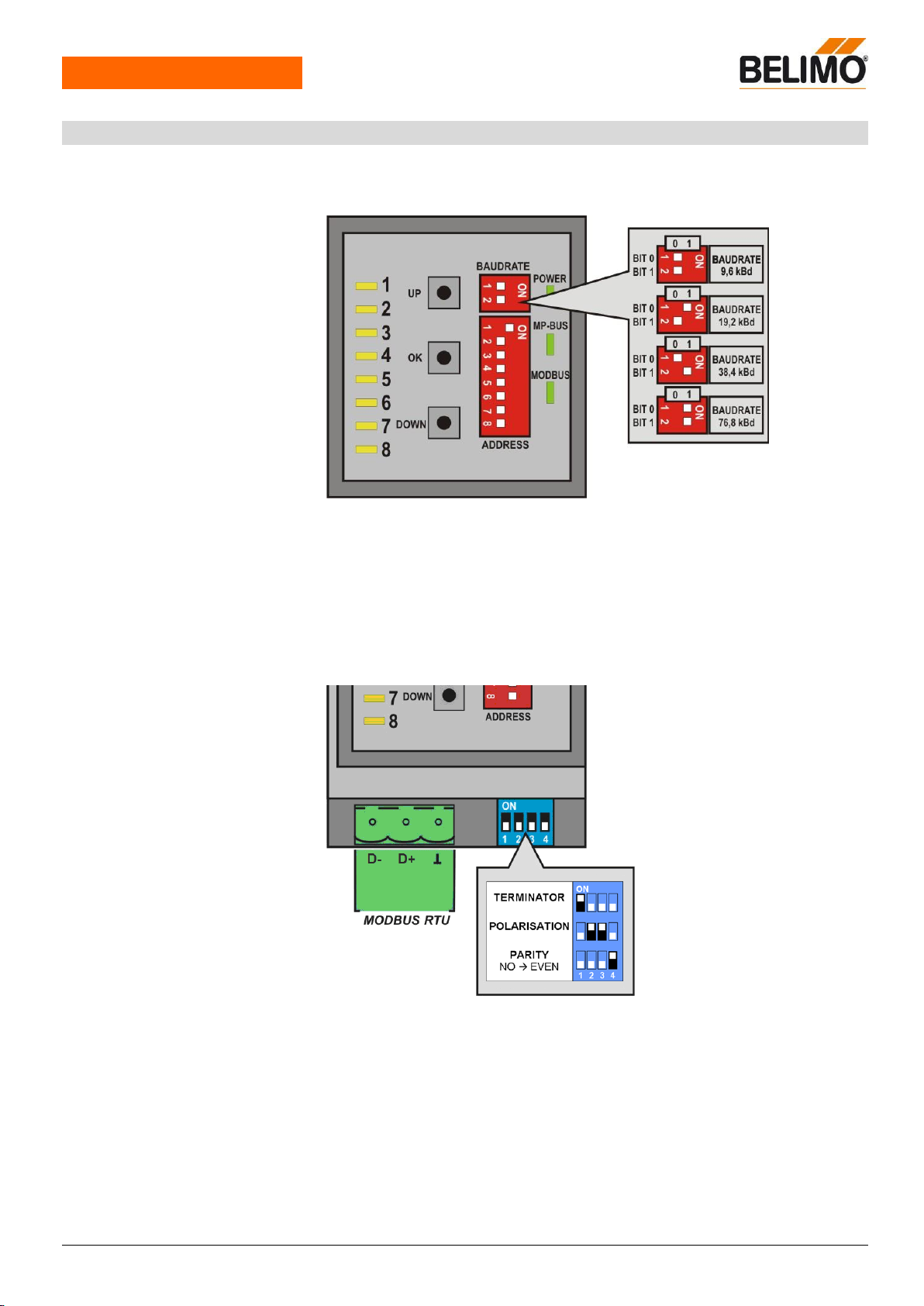

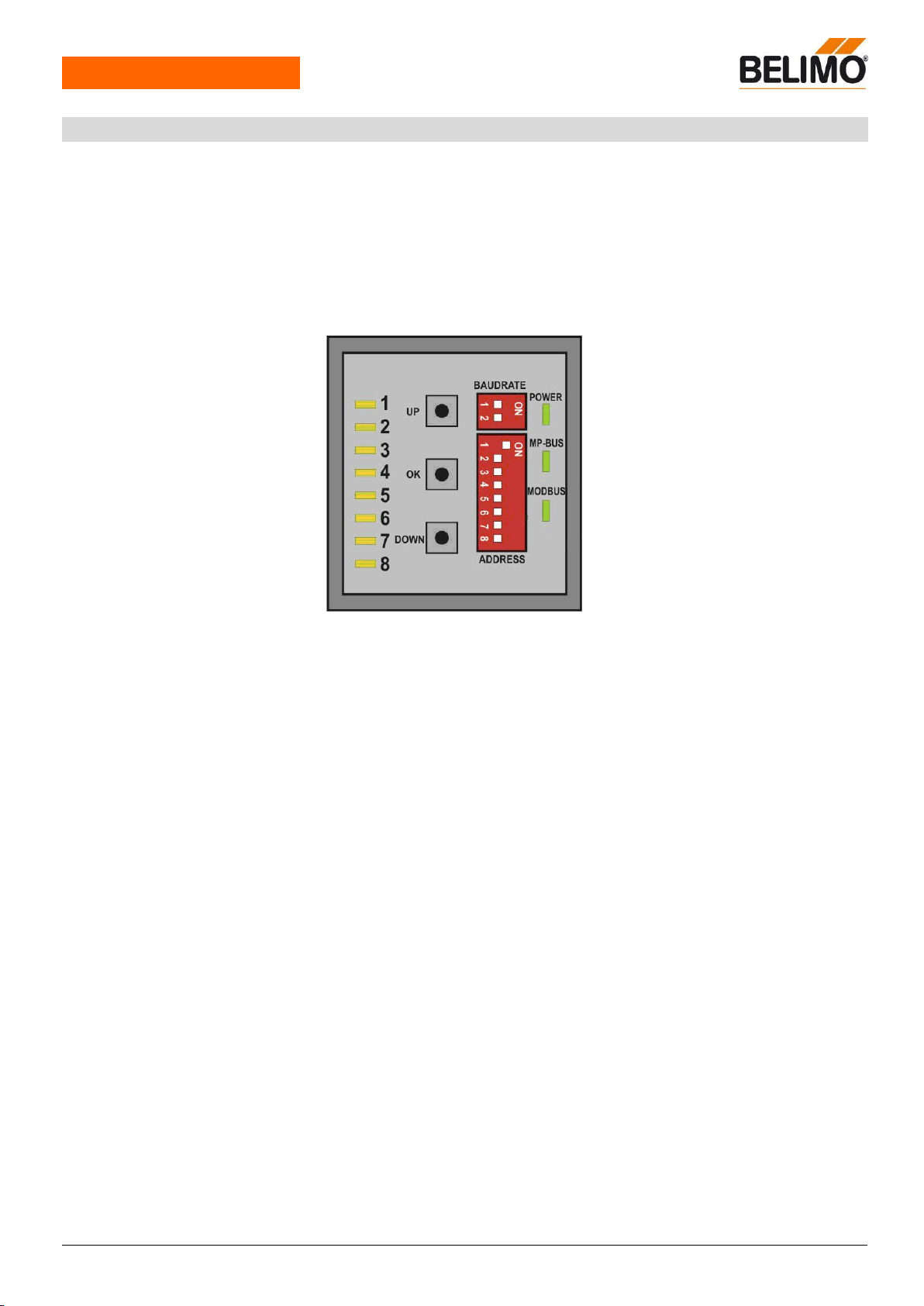

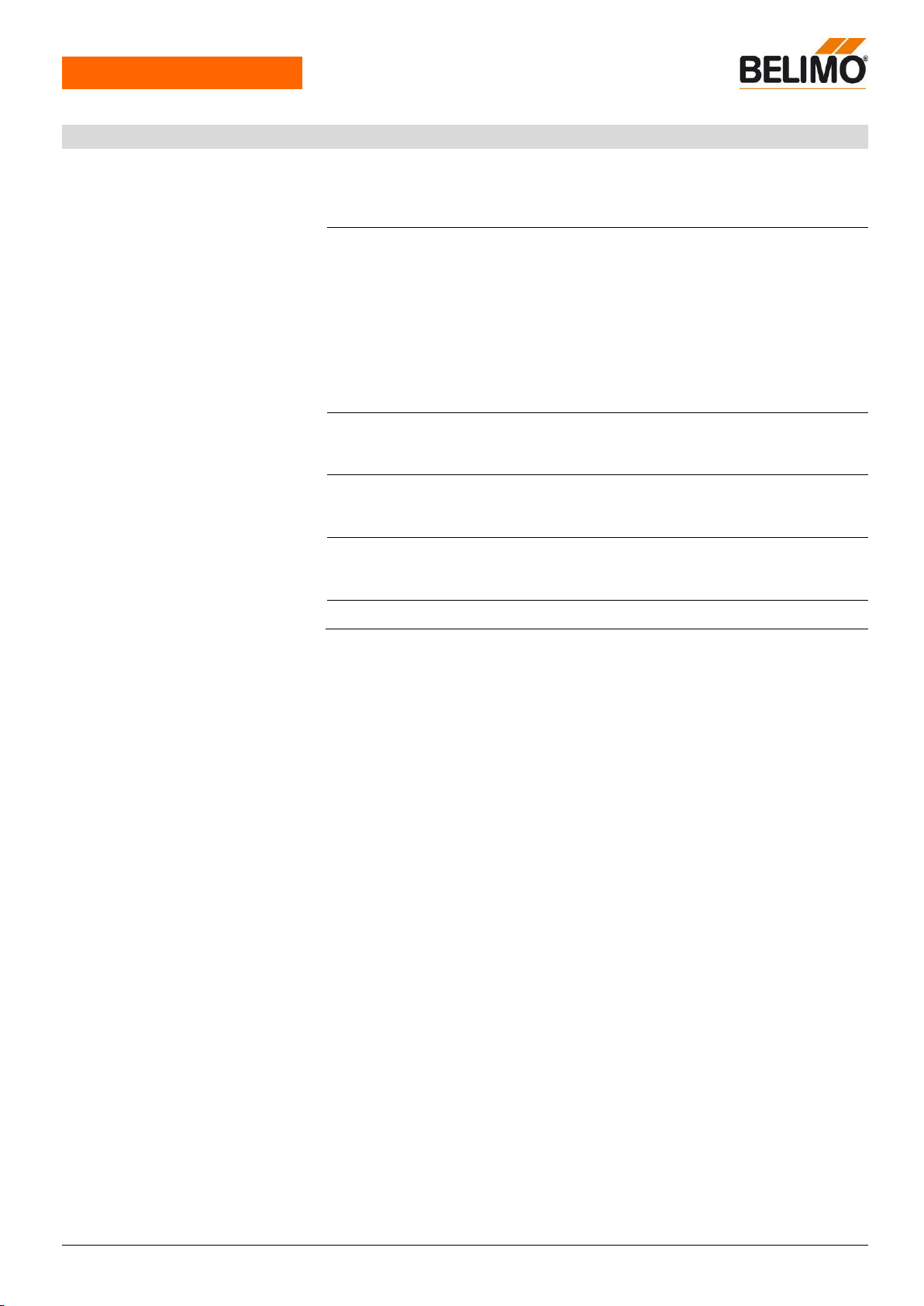

Operation elements

Legend

The illustration shows the operation elements of the device with the front cover open.

Operation, behaviour

Setting the Modbus address

The Modbus address is set in binary form with the 8 DIP switches under the front cover. The

valid address range is 1-247. Values outside of this range will be interpreted as either 1 or 247,

respectively.

+

~

+

~

-

┴

MP

-

┴

Display of the active

MP nodes

Addressing of the

MP nodes

Power LED

MP-Bus LED

Modbus LED

Setting

Baud rate

Setting

Modbus address

Setting

Terminator,

Polarisation,

Parity

D- D+

┴

UK24MOD

Belimo Gateway MP to Modbus RTU

www.belimo.com

T9-UK24MOD • en • v1.7 • 02.2014 • Subject to changes

9 / 20

Operation, behaviour

(continued)

Setting the Modbus baud rate

The Modbus baud rate is set using the DIP switches under the front cover to the values 9'600,

19'200, 38'400 and 76'800.

The response delay of the device is set to a fixed 4 ms with 9600 Bd. A delay of 2 ms is used as

a default with higher baud rates. A longer delay can be set if needed via register 163.

The RS485 line must be completed at both bus ends with one resistor each. A suitable 150

element is present in the Gateway which can be switched with DIP switch 1 on the base plate.

The RS485 line can be polarised with two resistors (DIP switches 2 and 3) in order to reduce

interference effects during communications pauses. The biasing is implemented as a rule at one

of the bus ends. Switches 2 and 3 must always be respectively activated or deactivated

together.

The character transmission uses either the settings NO parity (1 start bit, 8 data bits, no parity,

2 stop bits) or EVEN parity (1 start bit, 8 data bits, even parity, 1 stop bit), The setting is done

with DIP switch 4.

Important:

The generally valid guidelines for RS485 / Modbus RTU are to be observed!

UK24MOD

Belimo Gateway MP to Modbus RTU

10 / 20

T9-UK24MOD • en • v1.7 • 02.2014 • Subject to changes

www.belimo.com

Operation, behaviour

(continued)

Automatic scanning of the MP network

The MP-Bus assignment is determined automatically and continuously updated. No backup of

the network structure takes place. The actuator information (e.g. series number, actuator type)

is extracted as soon as one supported actuator is detected at the addresses MP1…MP8.

In the event of a communications interruption, the Gateway will discard the affected actuator

after 10 seconds and reset the actuator register. Monitoring of the actuator is accomplished

preferably with the Actuator type register (12).

Addressing MP actuators

The Gateway supports the assigning of addresses to the MP nodes by means of the keys UP,

OK and DOWN, located behind the front cover.

Procedure:

1. Press down the OK key and keep it down until LED1 and MODBUS are continuously

illuminated.

2. Select an address (LED1…LED8) with the keys UP and DOWN

3. Start addressing sequence with OK key

4. Acknowledge addressing of the respective actuator within 4 minutes;

(depending on the type, using the address key, direction of rotation switch, ...)

5. Successful acknowledgement is made visible by the rapid flashing of the corresponding

LEDx. Afterwards, the Gateway will switch to standard operation.

The addressing process can be interrupted at any time by pressing the OK key.

The de-addressing of a node is not supported.

UK24MOD

Belimo Gateway MP to Modbus RTU

www.belimo.com

T9-UK24MOD • en • v1.7 • 02.2014 • Subject to changes

11 / 20

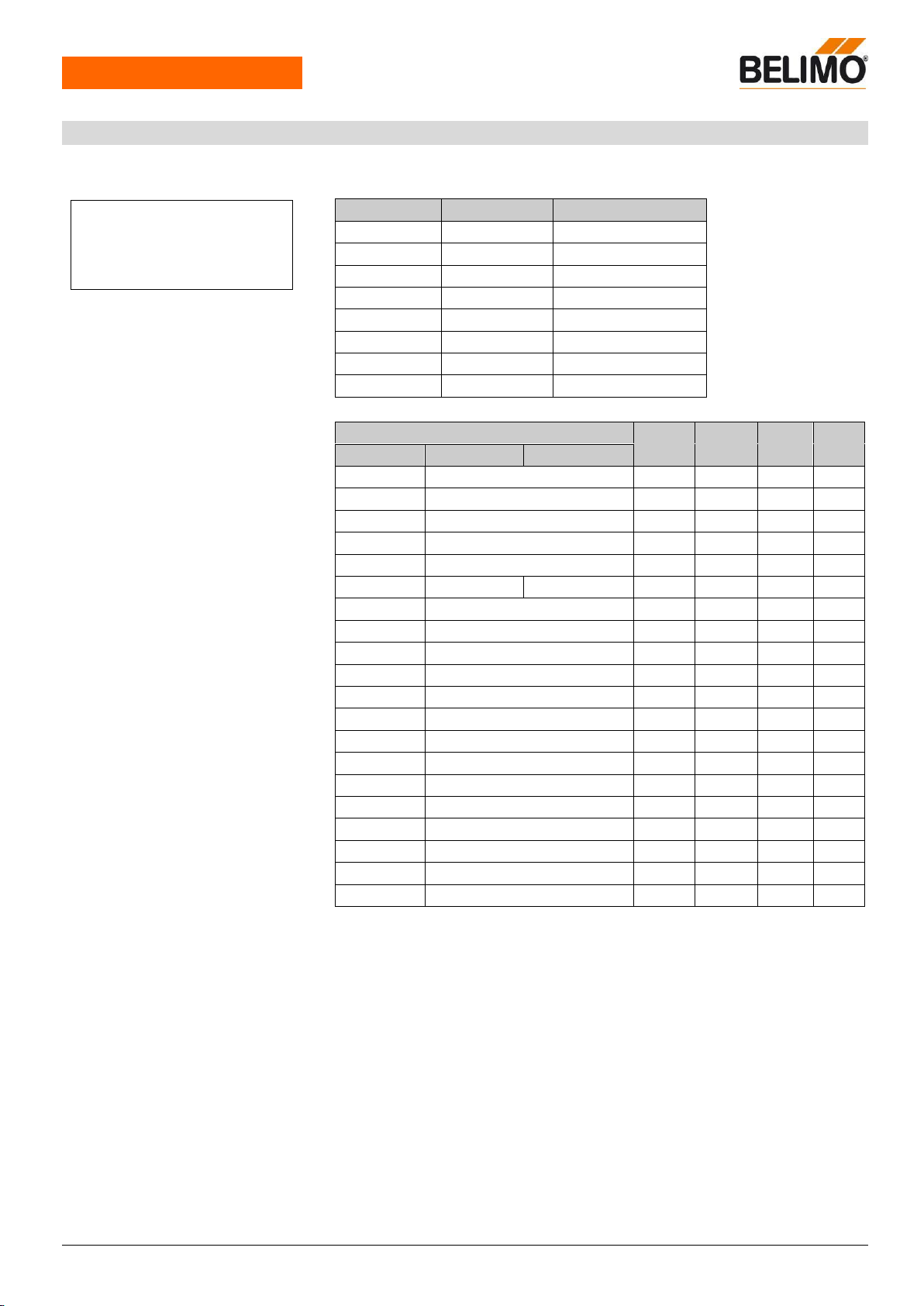

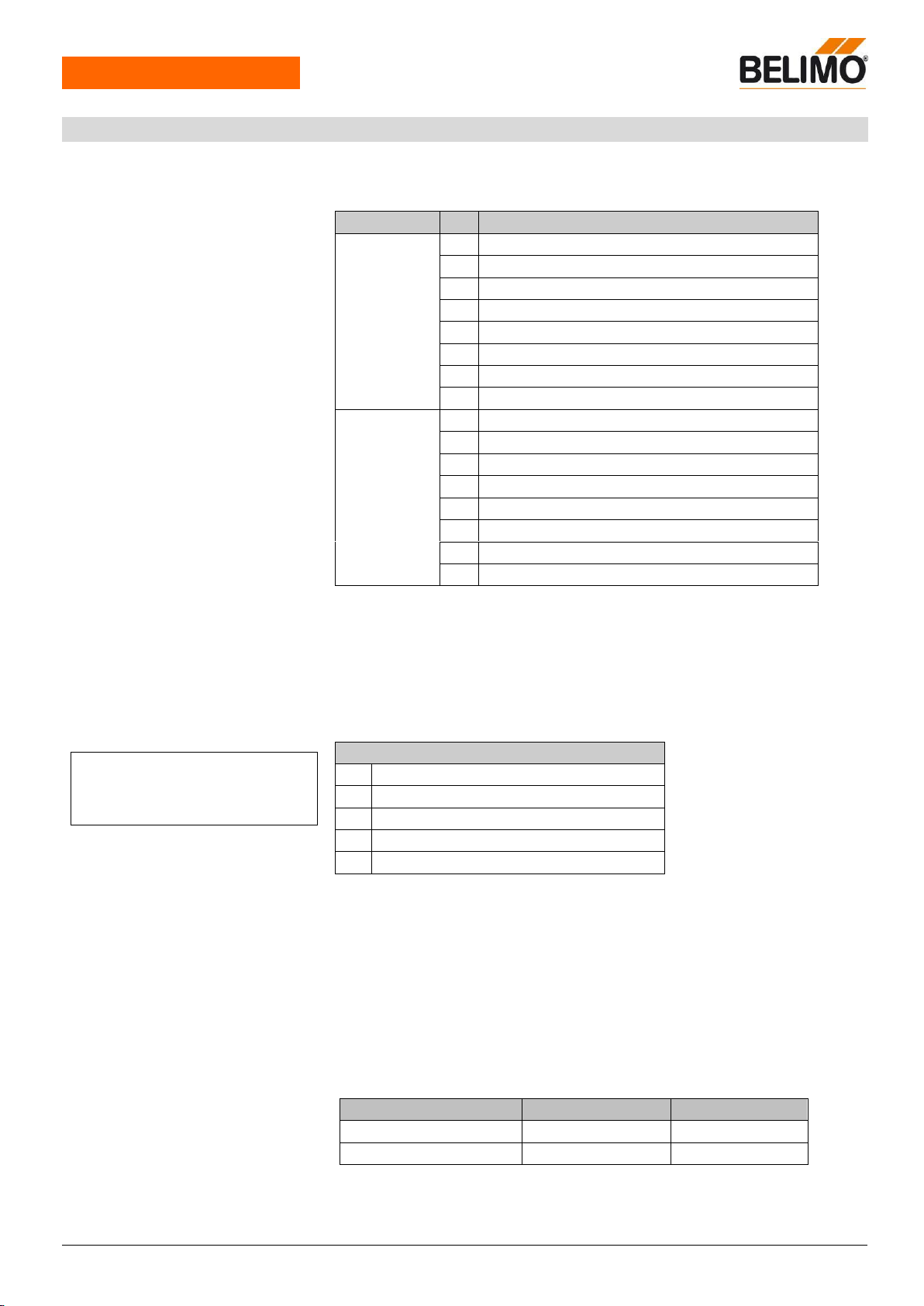

Modbus register overview

Note

Some Modbus master number the

registers starting with 0 (not 1).

In these cases the registers are shifted

by 1 (e. g. MP1

0-19).

The information of the connected actuators is digitised per node in 20 registers each (à 16 bit).

The resulting register ranges for the MP nodes 1-8 are:

MP Address

Offset MP[n]

Range

MP1

0

Registers 1 - 20

MP2

20

Registers 21 - 40

MP3

40

Registers 41 - 60

MP4

60

Registers 61 - 80

MP5

80

Registers 81 - 100

MP6

100

Registers 101 - 120

MP7

120

Registers 121 - 140

MP8

140

Registers 141 - 160

Actuator register

Register

Air

Water

VAV

EPIV

Fire

MPL

Number

High Byte

Low Byte

MP[n] + 1

Setpoint [%]

MP[n] + 2

Override control

MP[n] + 3

Command

MP[n] + 4

Actual position [%]

MP[n] + 5

Relative volumetric flow [%]

MP[n] + 6

Errors

Malfunctions

()

MP[n] + 7

Sensor type

MP[n] + 8

Current sensor value

MP[n] + 9

Series number 1st part

MP[n] + 10

Series number 2nd part

MP[n] + 11

Series number 4th part

MP[n] + 12

Actuator type

MP[n] + 13

Time monitoring [s]

MP[n] + 14

Min [%]

MP[n] + 15

Max [%]

MP[n] + 16

Absolute volumetric flow

MP[n] + 17

Nominal volumetric flow

MP[n] + 18

-

MP[n] + 19

-

MP[n] + 20

-

Modbus functions

The Modbus functions Read Holding Registers [3] and Preset Single Register [6] are available

for writing/reading access on the registers.

Registers with boldface script have writing access. Because of the fact that the registers are not

continuously backed up, they should be updated periodically. The Gateway sends the values to

the actuators at regular intervals.

The MP-Bus assignment is determined automatically and updated. The Actuator type register

(12) should be evaluated for the monitoring of a node.

UK24MOD

Belimo Gateway MP to Modbus RTU

12 / 20

T9-UK24MOD • en • v1.7 • 02.2014 • Subject to changes

www.belimo.com

Modbus register overview

(continued)

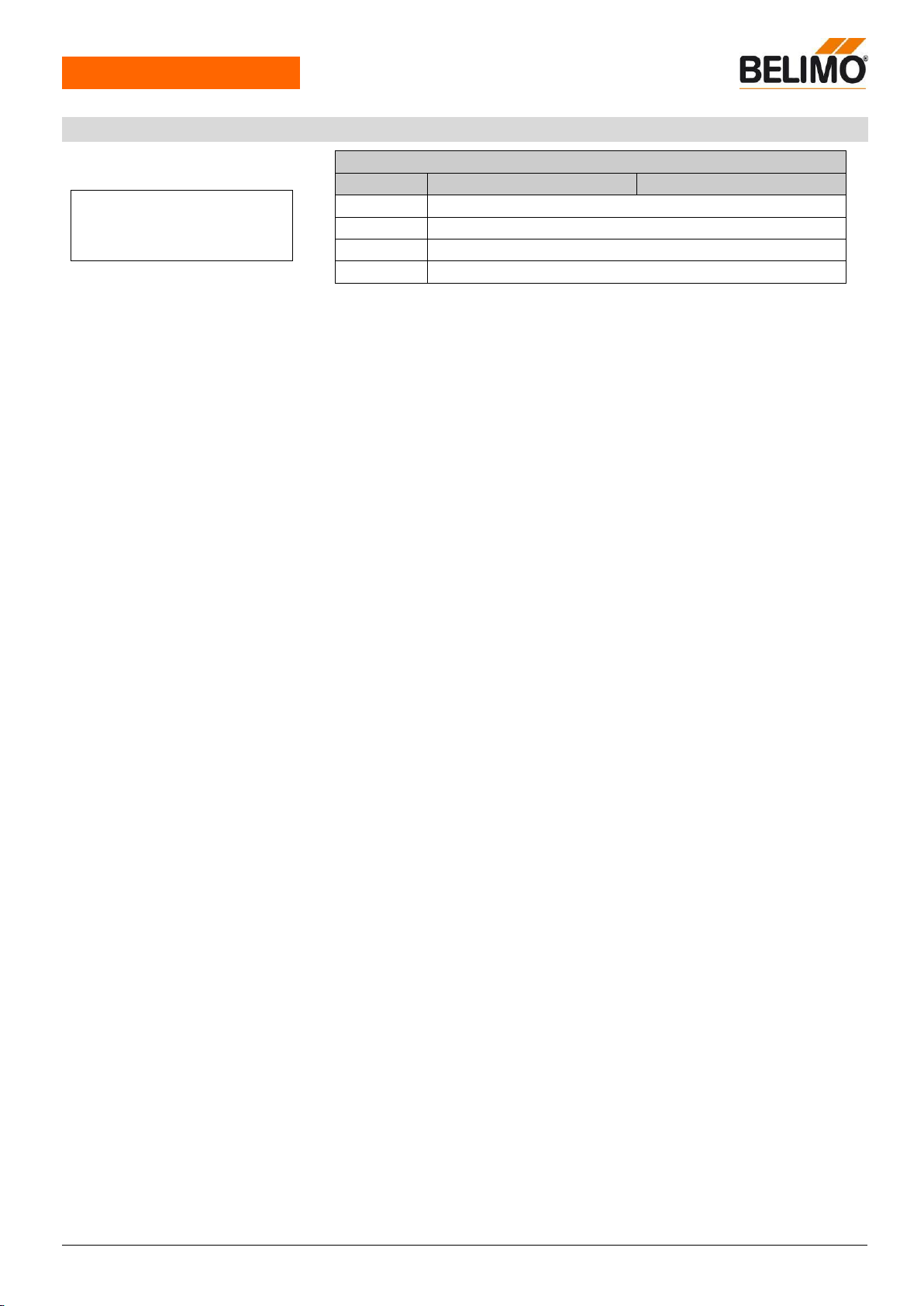

Service register

Note

Devices with V1.06 and older use

registers register 161 –164 for service

information.

Register

Number

High Byte

Low Byte

1001

Modbus baud rate

1002

Modbus address

1003

Response delay [ms]

1004

Firmware Version

The response delay (Register 1003) is backed up continuously.

UK24MOD

Belimo Gateway MP to Modbus RTU

www.belimo.com

T9-UK24MOD • en • v1.7 • 02.2014 • Subject to changes

13 / 20

Modbus register description

Register 1:

Setpoint

Setpoint for actuator setting in hundredths of one percent,

i.e. 0…10,000 corresponds to 0…100%

In the case of actuators for fire dampers, the control must be accomplished through the

Override control register (2). Writing access to the setpoint is refused (see Register 6).

Register 2:

Override control

Overriding the setpoint with defined values

Override control

0

None

1

Open

2

Closed

3

Min

4

Mid

5

Max

6

Fast_closed

Due to safety considerations, the only override values permitted in the case of actuators for fire

dampers are Open (1) and Fast_closed (6). The operating position (Open) must also be

repeated within 120 seconds (recommendation: 90 sec.).

If the override command is not renewed, then the Gateway will move the actuator into safety

position and signal an error (see Register 6). The remaining time for the renewal is visible in

Register 13.

Register 3:

Command

Initiation of actuator functions for Service and Test; the selected command is transmitted to the

actuator, after which the register will be reset once more.

Command

0

None

1

Adaption

2

Test run

3

Synchronisation

4

Reset actuator malfunctions

MPL actuators (Actuator Type: 6) support only the command Adaption.

Register 4:

Actual position

Actual position in hundredths of one percent,

i.e. 0…10,000 corresponds to 0…100%

Register 5:

Relative volumetric flow

Relative volumetric flow in hundredths of one percent of Vnom,

i.e. 0…10,000 corresponds to 0…100%

This value is available only for VAV controllers and EPIV units (Actuator Type: 5).

For all other types, 65535 will be entered.

UK24MOD

Belimo Gateway MP to Modbus RTU

14 / 20

T9-UK24MOD • en • v1.7 • 02.2014 • Subject to changes

www.belimo.com

Modbus register description

(continued)

Register 6:

Errors / Malfunctions

The status information is subdivided into actuator messages (malfunctions/maintenance) and

into errors detected by the Gateway. MPL actuators (Actuator Type: 6) don’t generate

Malfunctions/Maintenance information.

Bit

Description

Malfunctions

Maintenance

(Low Byte)

0

Excessive utilisation

1

Mechanical travel increased

2

Mechanical overload

3

-

4

Safety-relevant faults (fire & smoke only)

5

Damper test error (fire & smoke only)

6

Duct temperature too high (fire & smoke only)

7

Smoke detector tripped (fire & smoke only)

Faults

(High Byte)

8

No response from MP node

9

Checksum error MP node

10

Error message MP node

11

Value outside of range

12

Function not available for actuator type

13

Time exceeded (fire & smoke only)

14

-

15

-

The malfunction bits can be reset with Register 3 (command: 4) or with the Belimo PC-Tool.

Malfunctions 0 and 4 cannot be reset.

The error bits will be reset automatically by the Gateway.

Register 7:

Sensor type

Note

Switching of the sensor type may

necessitate a restart of the actuator in order

to read out correct sensor values.

Sensor type connected to the actuator; in the absence of sensor specification, the wiring at the

Y input of the MP actuator will have the effect of a local override.

Sensor type

0

None

1

Active sensor (mV)

2

Passive sensor 1k ()

3

Passive sensor 1…20k ()

4

Switching contact (0/1)

Note: The setting is not continuously backed up and should for that reason be updated

periodically.

Register 8:

Actual sensor value

Actual sensor value; dependent on the setting in Register 7

Register 9, 10, 11:

Series number

Each MP node has an unambiguous series number which is either impressed on or glued to the

node. The series number consists of 4 segments, although only parts 1, 2 and 4 are displayed

in the Gateway.

Example: 00839-31324-064-008

Register 9

Register 10

Register 11

1st part

2nd part

4th part

00839

31234

008

UK24MOD

Belimo Gateway MP to Modbus RTU

www.belimo.com

T9-UK24MOD • en • v1.7 • 02.2014 • Subject to changes

15 / 20

Modbus register description

(continued)

Register 12:

Actuator type

Actuator type; the allocation may deviate from the basic category with some actuators.

Actuator type

0

Actuator not connected / not known

1

Air/water actuators with/without safety function

2

Valve actuator, linear

3

Valve actuator, rotary

4

Fire damper actuator

5

VAV controller / EPIV

6

MPL actuator

Note: In the event of a communications interruption, the Gateway will discard the affected

actuator after 10 seconds and reset the actuator type to 0. Monitoring of the actuator is thus

accomplished preferably with this register.

Register 13:

Time monitoring

Remaining time in seconds for the renewal of the override control (fire & smoke only). The

counter will be set to 120 seconds with each writing access at Register 2.

Register 14:

Min / Vmin setting

Minimum limit (position or flow) in hundredths of one percent,

i.e. 0…10,000 corresponds to 0…100%

Attention: Changing the limit may result in malfunction of the device.

Register 15:

Max / Vmax setting

Maximum limit (position or flow) in hundredths of one percent,

i.e. 2000…10,000 corresponds to 20…100%

Attention: Changing the limit may result in malfunction of the device.

Register 16:

Absolute volumetric flow

Absolute volumetric flow (or pressure)

This value is available only for VAV controllers and EPIV units (Actuator Type: 5).

For all other types, 65535 will be entered.

The unit depends on the node type:

[m

3

/h] for VAV controllers

[Pa] for VAV controllers in STP mode

[l/min] for EPIV units

Register 17:

Nominal volumetric flow

Nominal volumetric flow (or pressure)

This value is available only for VAV controllers and EPIV units (Actuator Type: 5).

For all other types, 65535 will be entered.

The unit depends on the node type:

[m

3

/h] for VAV controllers

[Pa] for VAV controllers in STP mode

[l/min] for EPIV units

Service register 1001 (former 161):

Modbus baud rate

Modbus baud rate (=x*100) in accordance with the setting of the DIP switches,

i.e. 96

9600 Baud

Service register 1002 (former 162):

Modbus address

Modbus address (1..247) in accordance with the setting of the DIP switches

Service register 1003 (former 163):

Response delay

Response delay (2…100 ms); the default value is 2 ms; the response delay is set to a fixed 4

ms with a baud rate of 9600.

The response delay must be increased in the event that the Modbus Master is unable to switch

quickly enough from transmission to reception mode.

Service register 1004 (former 164):

Firmware Version

Firmware Version of the device

UK24MOD

Belimo Gateway MP to Modbus RTU

16 / 20

T9-UK24MOD • en • v1.7 • 02.2014 • Subject to changes

www.belimo.com

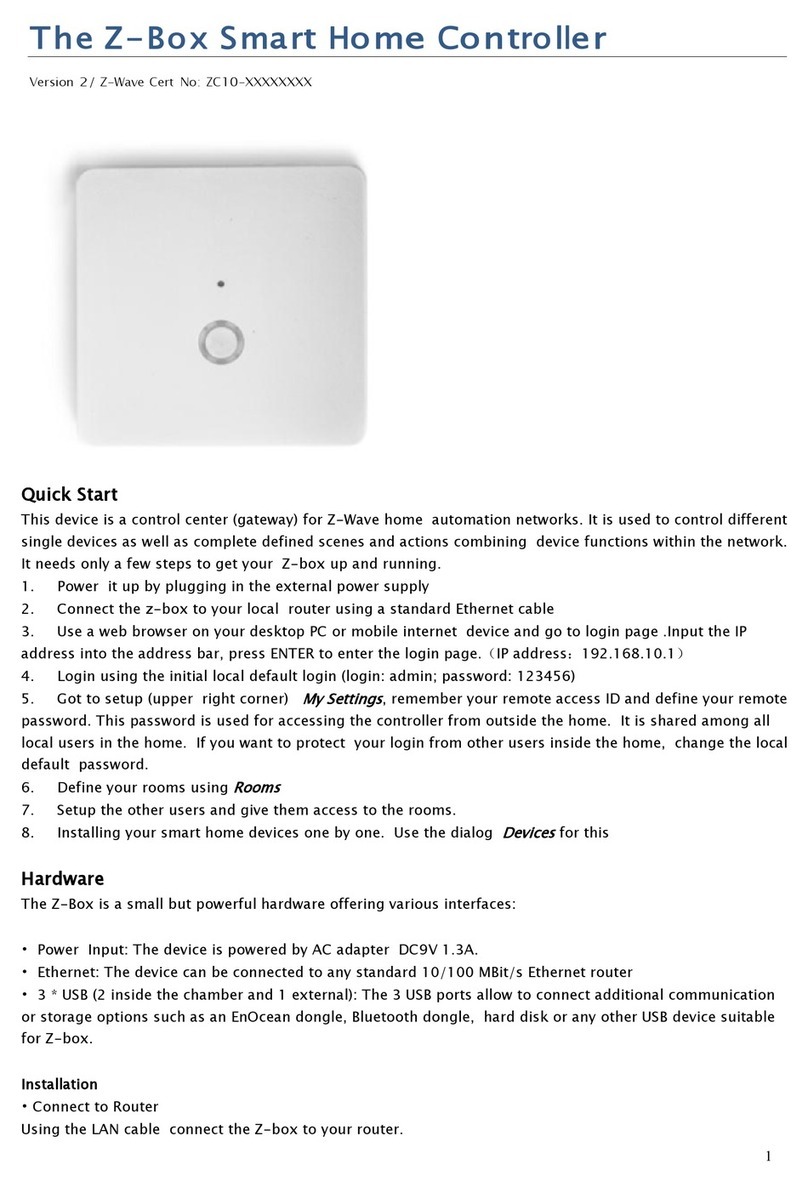

Diagnostics and testing tool

A PC-based tool is available for diagnostics and tests which can be utilised as a Modbus Master

and which uses graphics elements to depict the actuator information.

The UK24MOD Tool can be obtained through the Internet:

www.belimo.eu | Products … | Download Center

Connecting the PC-Tool for parameterisation of the MP/MFT(2) actuators

The MP network can be scanned, actuators can be addressed and actuator-specific parameters

(e.g. running time) can be readily adjusted with the Belimo PC-Tool.

The PC -Tool can be accessed directly on the MP-Bus via the RJ12 socket of the UK24MOD.

The Gateway recognises the connected PC-Tool automatically and stops communications with

the MP drives.

MP-Bus

Belimo

PC-Tool

ZK6-GEN

UK24MOD

Belimo Gateway MP to Modbus RTU

www.belimo.com

T9-UK24MOD • en • v1.7 • 02.2014 • Subject to changes

17 / 20

Version overview

Firmware V1.08

New functions/modifications:

Bug fix: Modbus telegrams longer than 20 Bytes (e.g. ReadHoldingRegister with more

than 8 registers) are properly handled

Bug fix: Detection of new MP actuator in operation

Firmware V1.07

New functions:

New register for reading of nominal volumetric flow

Support for MPL actuators

Note on compatibility:

Service information can be found in registers 1001 to 1004 (former 161 to 164)

Known issues:

Modbus telegrams longer than 20 Bytes (e.g. ReadHoldingRegister with more than 8

registers) cause wrong register entries.

Firmware V1.06

New functions:

Timeout period for fire & smoke increased from 60 to 120 seconds (Register 2).

Higher numbers of nodes realizable per Modbus master.

Firmware V1.05

New functions:

New registers for adjusting Min (14) and Max (15) setting.

New register for reading of absolute volumetric flow.

Firmware V1.04

New functions:

Parity/Character transmission adjustable via DIP switch:

NONE (1, 8, N, 2) or EVEN (1, 8, E, 1)

Firmware V1.03

Release without restrictions

Table of contents

Other Belimo Gateway manuals

Popular Gateway manuals by other brands

Z-Wave

Z-Wave Z-Box user manual

NETGEAR

NETGEAR CG814WG Connecting guide

AudioCodes

AudioCodes MediaPack MP-11x Series installation manual

Arris

Arris Touchstone TG9452 user guide

Planet Networking & Communication

Planet Networking & Communication WIPG-300H user manual

B&B Electronics

B&B Electronics Vlinx MESR9xx user manual

Bosch

Bosch CLIMATE 5000 VRF RDCI Series Installation and user manual

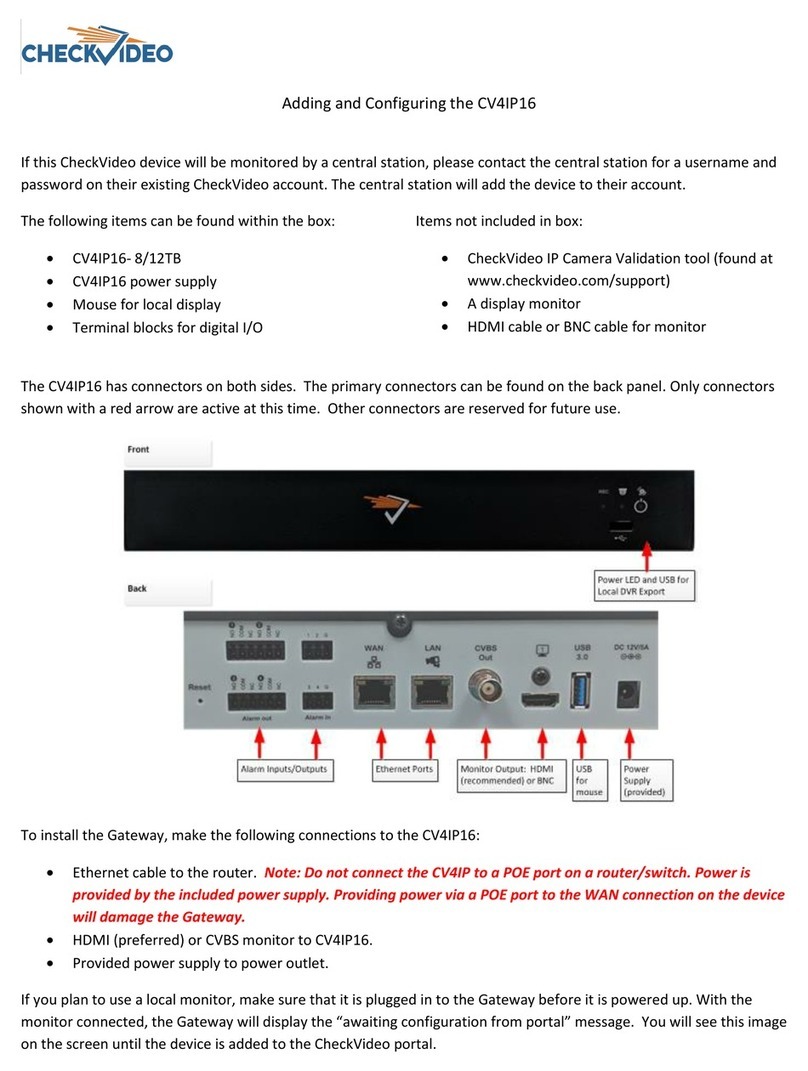

CheckVideo

CheckVideo CV4IP16 manual

Insevis

Insevis S7 manual

Freescale Semiconductor

Freescale Semiconductor Home Energy Gateway Reference Platform quick start guide

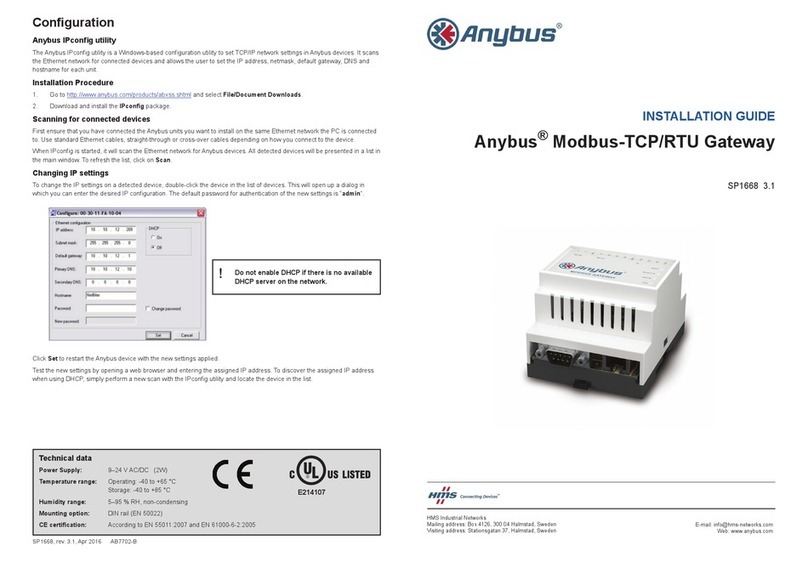

Anybus

Anybus AB7702 installation guide

tiko Energy Solutions

tiko Energy Solutions M-Box user manual