Belle Group PCX 12/36 User manual

1

12/36 & 13/40

- Spare Parts Book

- Pièces détachées

- Libro Despiece

- Lista de Peças

- Onderdelen Boekje

- Reservedele Skrift

- Ersatzteilhandbuch

- Manuale dei ricambi

- Bruksanvisning

- Bruksanvisning

- Varaosaluettelo

- Lista Części Zamiennych

- Запасные части Книга

- Varuosade nimekiri

- Rezerves daļu saraksts

- Atsarginiu daliu sarašas

- Част Списък

- αντικατάσταση κομμάτια βιβλίο

- Část Barevný pruh

- Lista Pieselor de Schimb

- Részek Oldalra dől

- Rezervni djelovi Knjiga

Operators Manual

Operators Manual

Manuel De L'Opérateur

Manual del Operador

Manual de Operação

Handleiding

Betjeningsvejledning

Bedienungshandbuch

Manuale Dell'Operatore

Bruksanvisning

Betjene Håndbok

Käyttöohje

Instrukcja Obsługi

Руководство по эксплуатации

Kasutusjuhend

Lietotāja rokasgrāmata

Naudojimo Instrukcija

Oпepaтop Pъчeн

χειριστής χειροποίητοs

Na’vod K Obzluze

Manualul Operatorului

Kezelõk Kézi

Uputstvo za rukovatelja

GB

F

E

P

NL

DK

D

I

S

US

SF

PL

RUS

EST

LV

LT

BG

RO

6

17

28

39

50

61

72

83

94

105

116

127

138

149

160

171

182

193

260

870/10011/1

HUN

204

HR

215

226

237

GR

CZ

NO

248

6

How To Use This Manual

GB

Before you operate or carry out any maintenance on this machine YOU MUST READ and STUDY

this manual.

WARNING

The product can be at risk. The machine or yourself can be damaged or injured if procedures are not

carried out in the correct way.

CAUTION

The life of the operator can be at risk.

WARNING

WARNING

GB

Contents

KNOW how to safely use the unit’s controls and what you must do for safe maintenance. (NB Be sure that you know how to switch the

machine off before you switch on, in case you get into difficulty.)

ALWAYS wear or use the proper safety items required for your personal protection. If you have ANY QUESTIONS about the safe use

or maintenance of this unit, ASK YOUR SUPERVISOR OR CONTACT: BELLE GROUP (UK): +44 (0) 1298 84606

GB

This manual has been written to help you operate and service the PCX Plate Compactor safely.

This manual is intended for dealers and operators of the PCX Plate Compactor.

Foreword

The ‘Environment’ section gives instructions on how to handle the recycling of discarded apparatus in an environmentally friendly way.

The ‘Machine Description’ section helps you to familiarise yourself with the machine’s layout and controls.

The ‘General Safety’ and ‘Health and Safety’ sections explain how to use the machine to ensure your safety and the safety of the

general public.

The ‘Start and Stop Procedure’ helps you with starting and stopping the machine.

The ‘Trouble Shooting’ guide helps you if you have a problem with your machine.

The ‘Servicing’ section is to help you with the general maintenance and servicing of your machine.

The ‘Warranty’ Section details the nature of the warranty cover and the claims procedure.

The ‘CE certificate’ section shows the standards that the machine has been built to.

Directives with regard to the notations.

Text in this manual to which special attention must be paid are shown in the following way:

Belle Group reserves the right to change machine specification without prior notice or obligation.

How to use this manual ............................................................................................................................................................................6

Warning ....................................................................................................................................................................................................6

Machine Description ........................................................................................................................................................................... 7 - 8

Environment .............................................................................................................................................................................................9

Technical Data ..........................................................................................................................................................................................9

General Safety .......................................................................................................................................................................................10

Health and Safety ...................................................................................................................................................................................10

Pre-Start Checks ....................................................................................................................................................................................11

Reasons for Compaction ........................................................................................................................................................................11

Applications ............................................................................................................................................................................................11

Start & Stop Procedure ..........................................................................................................................................................................12

Operating the Compactor .......................................................................................................................................................................13

Trouble Shooting Guide .........................................................................................................................................................................13

Servicing .................................................................................................................................................................................................14

Assembly Instructions .............................................................................................................................................................................15

Fitting Instructions ...................................................................................................................................................................................15

Warranty .................................................................................................................................................................................................16

C.E. Certificate .........................................................................................................................................................................................2

7

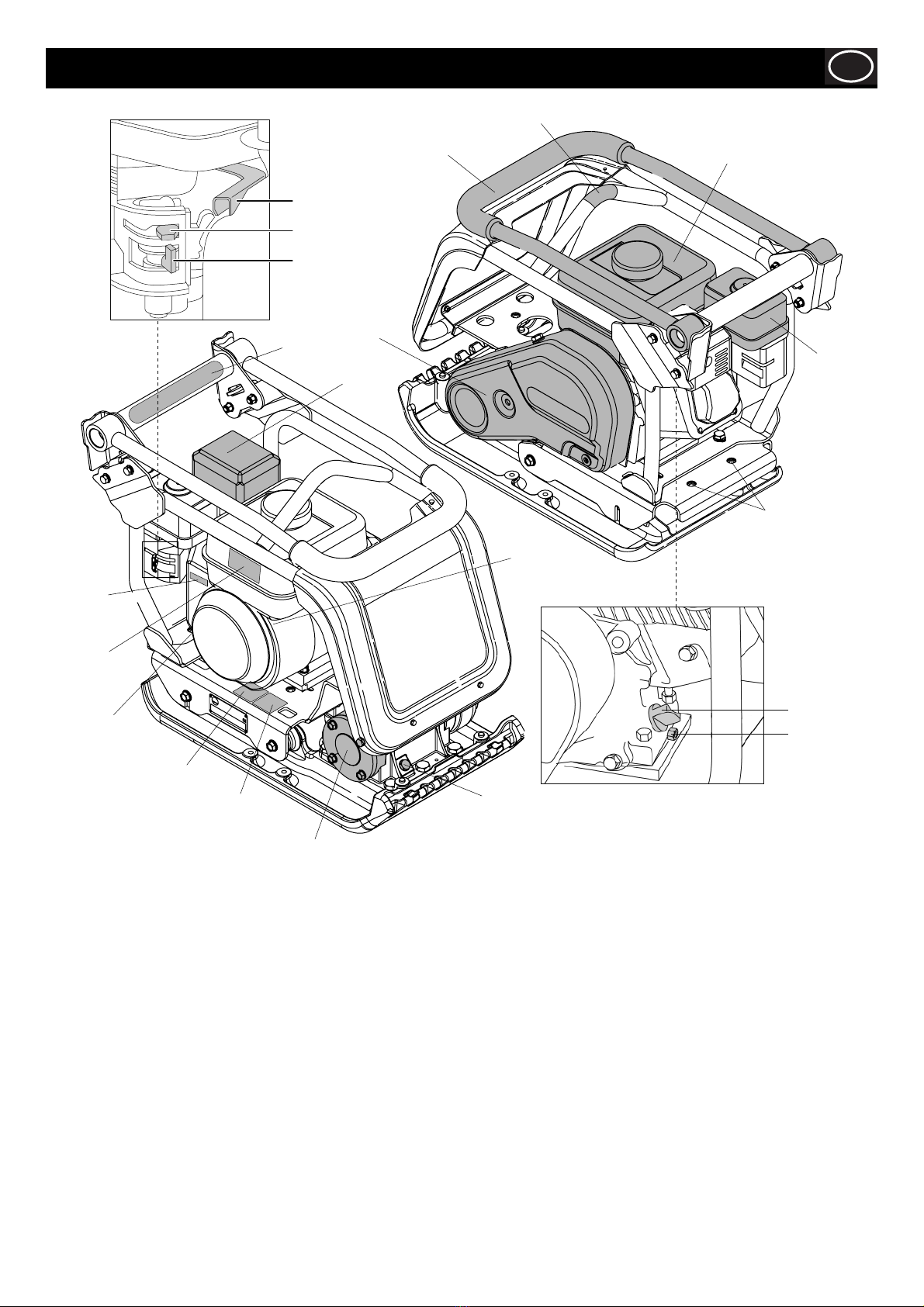

Machine Description

GB

Machine Description Decals

1. Throttle lever. A. Safety Decal

2. Choke lever. B. Noise Decals

3. Fuel ON / OFF lever. C. Engine RPM Decal

4. Engine ON / OFF switch. D. Lifting Point Decal

5. Air Filter Housing. E. Low HAV Decal

6. Fuel Tank. F. Engine Warning Decal

7. Exhaust.

8. Recoil Starter Handle.

9. Engine oil filler / dipstick.

10. Engine oil drain plug.

11. Vibrator.

12. Vibrator oil check plug.

13. Belt guard.

14. Control Handle.

15. Attachment points for Transporter Options.

Note:- Drawing based a Honda GX160 Engine. Please refer to the manufacturer’s literature for Robin Engine details.

E

D

B

A

C

F

1

2

3

75

6

8

4

9

10

11

12

13

14

15

8

Machine Description

GB

Decals

A - Safety Decal (Part No. 19.0.373)

Please Read

Operators Manual

Wear Protective

Footwear

Wear Ear

Protection

Wear Eye

Protection

B - Noise Decal (800-99942)

The Noise Level of the machine during operation is 105 dB(A)

C - Engine RPM Decal

Fast Engine Speed

Position

Slow Engine Speed

Position

D - Lifting Point Decal

Lifting Point

E - Low HAV Decal (800-99965)

The machine has a UK Patented Design which reduces HAV levels allowing a greater Usage Time.

F - Engine Warning Decal

Please Read

Engine Manual

Petrol is highly flammable. Turn off the

Engine and allow time to cool before

refuelling.

The Engine emits toxic Carbon

Monoxide. Do not run the Engine in an

enclosed area.

9

Technical Data

GB

Model PCX 12/36 PCX 13/40

A - Width (mm) 360 400

B - Height (mm) 556 556

C - Length (mm) 720 720

Weight Honda GX120 4.0hp/3kW (Kg) 81.5 83.5

Weight Honda GX160 5.5hp/4kW (Kg) - 85.5

Weight Robin EX 13 4.5hp (Kg) 81.5 83.5

Weight Robin EX 17 6hp (Kg) - 85.5

Engine RPM - Honda / Robin 3850 3850

Vibrator Force (kN) 12 13

Frequency (Hz) 101 101

Max. Travel Speed (m/min) 20 20

Static Pressure (kg/m2)586 519

Sound Power Level - GX120 & EX13 105 dB(A) 105 dB(A)

Sound Power Level - GX160 & EX17 107 dB(A) 107 dB(A)

B

AC

Environment

Safe Disposal.

Instructions for the protection of the environment.

The machine contains valuable materials. Take the discarded

apparatus and accessories to the relevant recycling facilities.

GB

Component Material.

Handle Steel

Front cover HDPE

Main frame Steel

Baseplate Steel

Hand Grips Rubber

Engine Aluminium

Flexible Mounts Steel and Rubber

Various Parts Steel and Aluminium

Water Bottle Plastic

(if fitted)

10

General Safety

For your own personal protection and for the safety of those around you, please read andensure you fully understand the following

safety information. It is the responsibility of the operator to ensure that he/she fully understands how to operatethis equipment safely.

If you are unsure about the safe and correct use of the PCX Plate Compactor, consult your supervisor or Belle Group.

• This equipment is heavy and must not be lifted single-handedly, either GET HELP or use suitable lifting equipment. A special

transport assembly is available for the compactor (see options).

• Cordon off the work area and keep members of the public and unauthorised personnel at a safe distance.

• Personal Protective Equipment (PPE) must be worn by the operator whenever this equipment is being used (see Health &

Safety).

• Make sure you know how to safely switch this machine OFF before you switch it ON in case you get into difficulty.

• Always switch OFF the engine before transporting, moving it around the site or servicing it.

• During use the engine becomes very hot, allow the engine to cool before touching it. Never leave the engine running and

unattended.

• Never remove or tamper with any guards fitted, they are there for your protection. Always check guards for condition and

security, if any are damaged or missing, DO NOT USE THE COMPACTOR until the guard has been replaced or repaired.

• Do not operate the Compactor when you are ill, feeling tired, or when under the influence of alcohol or drugs.

Fuel Safety

• Before refuelling, switch off the engine and allow it to cool.

• When refuelling, DO NOT smoke or allow naked flames in the area.

• Spilt fuel must be made safe immediately, using sand. If fuel is spilt on your clothes, change them.

• Store fuel in an approved, purpose made container away from heat and ignition sources.

GB

Fuel is flammable. It may cause injury and property damage. Shut down the engine, extinguish all open

flames and do not smoke while filling the fuel tank. Always wipe up any spilled fuel.

CAUTION

Improper maintenance or use can be hazardous. Read and Understand this section before you perform

any maintenance, service or repairs.

CAUTION

The exhaust fumes produced by this equipment are highly toxic and can kill!

CAUTION

Health and Safety

Vibration

Some vibration from the compaction operation is transmitted through the handle to the

operator’s hands. The Belle Group Plate Compactor range has been specifically designed to reduce hand/arm vibration levels. Refer

to specifications & technical data for vibration levels and usage times (recommended maximum daily exposure time). DO NOT exceed

the maximum usage times.

PPE (Personal Protective Equipment).

Suitable PPE must be worn when using this equipment i.e. Safety Goggles, Gloves, Ear Defenders, Dust Mask and Steel Toe capped

footwear. Wear clothing suitable for the work you are doing. Tie back long hair and remove any jewellery which may catch in the

equipment’s moving parts.

Dust.

The compacting process will occasionally produce dust, which may be hazardous to your health. Always wear a mask that is suited to

the type of dust being produced.

Fuel.

Do not ingest fuel or inhale fuel vapours and avoid contact with your skin. Wash fuel splashes immediately.

If you get fuel in your eyes, irrigate with copious amounts of water and seek medical attention as soon as possible.

Exhaust Fumes

Do not operate the compactor indoors or in a confined space, make sure the work area is adequately ventilated.

GB

11

Pre start-up inspection

The following Pre-start-up inspection must be performed before the start of each work session or after every four hours of use,

whichever is first. Please refer to the service section for detailed guidance. If any fault is discovered, the compactor must not be used

until the fault is rectified.

1. Thoroughly inspect the compactor for signs of damage. Check componenents are present and secure. Pay special attention

to the belt drive safety guard fitted between the engine and the vibrator unit.

2. Check the engine oil level and top up as necessary.

3. Check the engine fuel level and top up as necessary.

4. Check for fuel and oil leaks.

Pre-Start Checks

GB

Reasons For Compaction

Soil, which has been disturbed or new infill, subbase and blacktop, will have small voids or air pockets which, if not compacted, will

lead to one or more problems occurring.

1. As traffic crosses the surface of an uncompacted area, the material is compressed. This leads to subsidence of the top

surface as the material fills the voids.

2. A similar situation occurs with static loads on uncompacted ground. The load (e.g. a building) will sink.

3. Materials with voids are more susceptible to water seepage, leading to erosion. Water ingress may also cause the soil

to expand during freezing temperatures and contract during dry spells. Expansion and contraction is a major cause of

damage to building foundations and normally leads to the structure requiring underpinning.

Compaction increases the density of the material and therefore increases its load bearing capacity. Reduces air voids

and therefore reduces the risk of subsidence, expansion and contraction, due to ingress of water.

GB

Applications

Applications/materials fall into three categories:

1. Cohesive materials (less than 20% granular) e.g clay, silt & heavy soils.

2. Granular materials (more than 20% granular) e.g hard core, sand & light soils.

3. Bituminous materials e.g asphalt (tarmac), cold lay (bitumin emulsion products).

The chart shows the HAUC specifications for layer depth and number of passes for Dual Force’ plates. If standard machines are used,

optimum compaction can not be guaranteed, however, if layer depths are reduced and number of passes increased, results can be

improved.

Moisture content of cohesive & granular materials is critical to effective compaction. If granular material is too dry it will flow around the

plate instead of compacting. If the moisture content is too high the material may dry out after compaction and shrinkage will occur.

GB

1400 -1800 kg/m2

COMPACTION PASSESS REQUIRED PER LAYER OF COMPACTED THICKNESS UP TO.

40MM 60MM 80MM 100MM 150MM

Cohesive Materials** 2** 4** 5** 6** Reduce Layer Thickness

Granular Materials 2* 3* 4* 5 9

Bituminous 6 10 12 Reduce Layer Thickness

* Usually placed in 100mm minimum layer so not specified by HAUC.

** The nature of cohesive materials makes plate compaction difficult. Optimum compaction is not guaranteed and not

recommended by HAUC.

12

Start and Stop Procedure

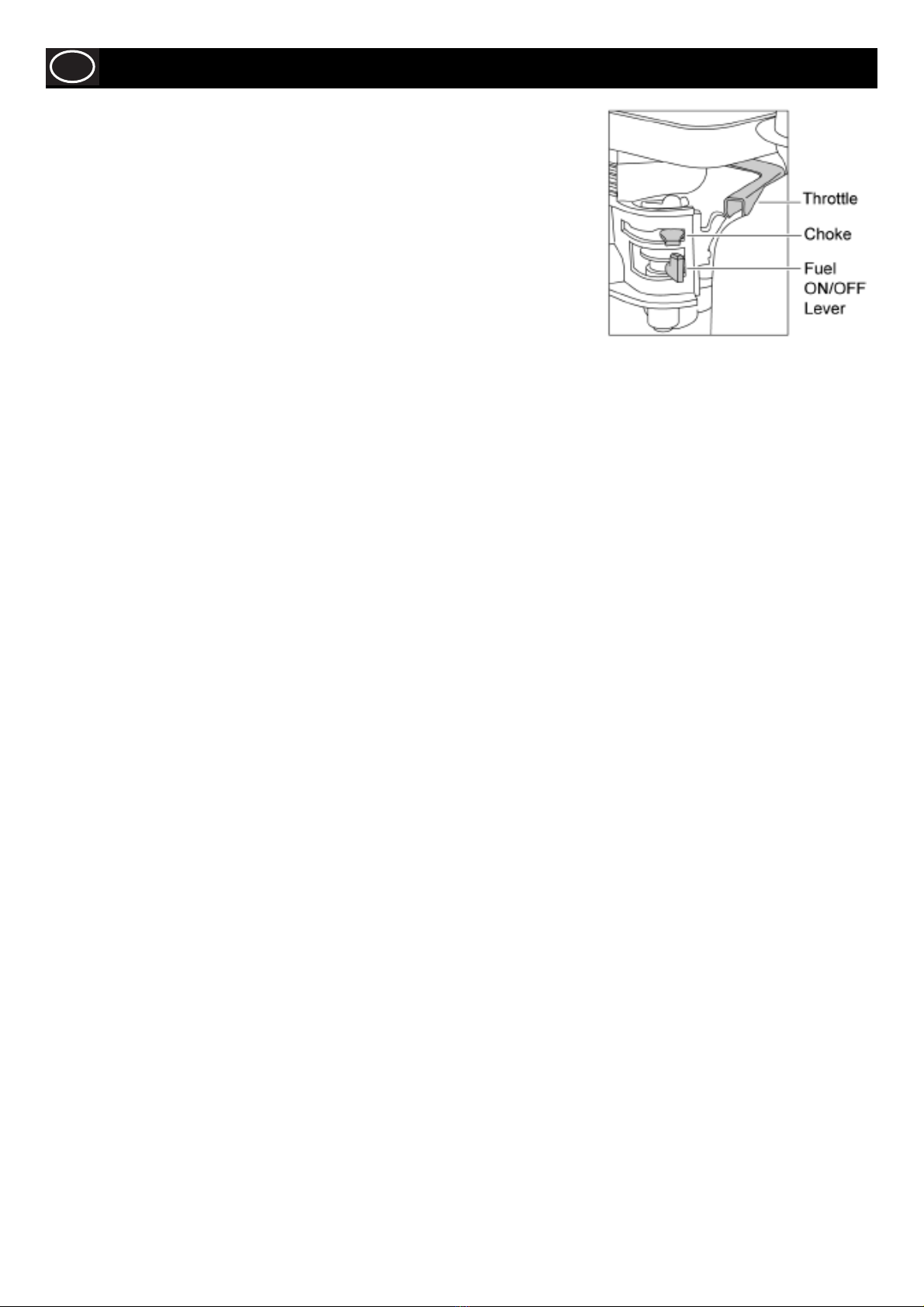

Honda GX120 & GX160

1. Open the fuel tap by moving the fuel ON / OFF lever fully to the right.

2. If starting the engine from cold, set the choke ON by moving the choke lever fully

to the left. If restarting a warm engine, the choke is usually not required, however,

if the engine has cooled to a degree, partial choke may be required.

3. Turn the engine ON / OFF switch clockwise to the ‘I’ position.

4. Set the throttle to the idle position by moving the throttle lever fully to the right. Do

not start the engine on full throttle, as the compactor will vibrate as soon as the

engine starts.

5. Taking a firm hold of the control handle with one hand, grasp the recoil starter

handle with the other. Pull the recoil starter until engine resistance is felt, then

let starter return.

6. Taking care not to pull the starter’s rope fully out, pull the starter handle briskly.

7. Repeat until the engine fires.

8. Once the engine fires gradually set the choke lever to the OFF position by moving it to the right.

9. If the engine fails to fire after several attempts, follow the trouble-shooting guide on page 8.

10. To stop the engine, set the throttle to idle and turn the engine ON / OFF switch anticlockwise to the ‘0’ position.

11. Turn the fuel off.

Robin EX13 & EX17 Petrol Engine

1. Open the fuel cock.

2. Turn the STOP SWITCH to the position ‘I’ (ON)

3. Set the speed control lever 1/3 of the way towards the high speed position.

4. Close the choke lever.

- If the engine is cold or the ambient temperature is low, close the choke lever fully.

- If the engine is warm or the ambient temperature is high, open the choke lever half way, or keep it fully open.

5. Pull the starter handle slowly until resistence is felt. This is the ‘compression’ point. return the handle to its original position

and pull swiftly. Do not pull out the rope all the way. After starting the engine, allow the starter handle to return to its original

position while still holding the handle.

6. After starting the engine, gradually open the choke by turning the choke lever and finally keep it fully opened. Do not fully open

the choke lever immediately when the engine is cold or the ambient temperature is low, because the engine may stop.

7. To stop the engine, Set the speed control lever at the low speed position and allow the engine to runat low speed for 1 to 2

minutes before stopping.

8. Turn the STOP SWITCH counter-clockwise to the position ‘0’ (OFF)

9. Close the fuel cock.

10. Pull the starter handle slowly and return the handle to its original position when resistance is felt. This operation is

necessary to prevent outside moist air from intruding into the combustion chamber.

GB

13

• Take the compactor to where it is required.

If using the ‘Detachable’ transport attachment to wheel the unit, tilt the compactor forward to raise the transport wheels off the

ground. Swing the transporter frame back, then across to disconnect it from the rear of the compactor. Place the transporter

frame somewhere safe until next required. For machines with the ‘Fixed’ transporter tilt the machine forward, pull the

transporter rearwards and upwards, lower the machine to the floor and latch the transporter into the ‘up’ position.

Where it is necessary to use lifting equipment to position the compactor, make sure the lifting equipment has a WLL (Working

Load Limit) suitable for the compactors weight (see specification chart on page 4 or the machine numberplate). Attach

suitable chains or slings ONLY to the lifting point on the top of the compactor.

• If the compactor is fitted with the water spray system and the application requires its use, check that the water outlet valve is

closed, then fill the water bottle with clean water.

• Having carried out the checks listed in the ‘pre start’ section, you may start the engine.

The Belle Group ‘PCx’ range of compactors are fitted with a centrifugal clutch, this allows the engine to run at idle without

driving the vibrator.

As the engine speed is increased the clutch will engage and will drive the vibrator.

For correct operation, the engine speed should be set to maximum.

• Set the throttle to maximum and use the control handle to steer or turn the compactor.

The vibrator will not only cause the baseplate to vibrate but will also cause it to travel forward. During normal operation you

should not have to push the compactor but allow it to travel at its own pace. The speed of travel will be determined by the

condition of the surface being compacted.

If the surface to be compacted is on a slope, great care must be taken when controlling the compactor’s direction of travel. If

necessary, use a suitable rope attached to the compactor at a low point on the chassis, to allow a helper to take part of the

compactor’s weight. Work up and down a slope not across.

• Work the compactor over the surface in an organised pattern until the required compaction has been achieved.

Where there are a number of different layers to be compacted on top of each other, compact each layer individually.

• To stop the compactor vibrating, set the throttle to idle.

Operating The Compactor

GB

Troubleshooting Guide

GB

Problem Cause Remedy

Engine will not start. No fuel. Open fuel tap.

Fill fuel tank.

Engine switched off. Switch engine on.

Spark plug fouled. Clean and reset plug gap.

Engine cold. Close choke.

Engine flooded. Honda, open choke, fully open throttle, pull recoil starter

until engine fires.

Engine still will not start. Major Fault Contact Agent or Belle Group.

Unit will not vibrate. Engine speed too slow. Set engine speed control to fast.

Drive belt tension loose. Adjust belt tension.

Air filter blocked. Clean or renew air filter.

Drive failure. Contact Agent or Belle Group.

Vibrator failure. Contact Agent or Belle Group.

Asphalt adhering to plate. Lack of lubrication. Use a water spray system.

Paving blocks damaged. Plate in direct contact with material. Use a paving pad.

Bituminous surface Over compaction. Remove and relay.

flaking (laminating).

Low travel speed Layer thickness too deep. Remove some of the material.

(plate sinking). Moisture content too high or too low. Remove material and adjust.

14

Servicing

Maintenance

The Belle Group PCX Plate Compactors are designed to give many years of trouble free operation. It is, however, important that the

simple regular maintenance listed in this section is carried out.

It is recommended that an approved Belle Group dealer carries out all major maintenance and repairs. Always use genuine Belle

Group replacement parts, the use of spurious parts may void your warranty.

Before any maintenance is carried out on the machine, switch off the engine. If working on a petrol engined machine, disconnect

the HT lead from the sparkplug. If working on a diesel engine, make sure that the stop switch is in the stop position. Always set the

compactor on level ground to ensure any fluid levels will be correctly read. Only use recommended oils (see chart below).

Running In Period

When the compactor is first used from new, the engine oil must be changed after the initial running in period (see engine manual for

full detail). The vibrator shaft case oil must be replaced after the first 100 hours use, then after every 500 working hours. For detail on

vibrator shaft case oil replacement, see ‘Vibrator unit’. The belt tension should be checked after 4 hours use.

Drive Belt

Remove the belt guard then check the belt tension by placing light finger pressure on the top of the belt, as near central between the

engine drive and vibrator pulley. The belt should deflect by between 5mm and 10mm. If the belt tension requires adjustment, loosen

the four engine mount bolts enough to allow the engine to be moved. Once set, retighten the engine mount bolts and check the belt

tension a second time. If the Belt remains loose, replace the Belt. Finally, replace the belt guard ensuring it is correctly and securely

fitted.

GB

Routine Maintenance First 4 First month / 3 Months 6 months

hours 20Hours 50 Hours 100 Hours

Engine Oil Check Level 9

Change 99

Air Filter Check Condition/Clean 99

Spark Plug Change 9

Drive Belt Tension 999

Replace when necessary / Every 12 months

Oil / Fuel Type & Quantity - Spark Plug Type

Oil type Quantity Fuel Type Capacity Spark Plug Electrode

(Litre) (Litre) Type Gap (mm)

Petrol Honda GX120 S.A.E. 10W 30 0.6 Unleaded 2.5 BM6ES or 0.7 - 0.8

BPR6ES

Petrol Honda GX160 S.A.E. 10W 30 0.6 Unleaded 3.6 BM6ES or 0.6 - 0.7

BPR6ES

Petrol Robin EX13 S.A.E. 10W 30 0.6 Unleaded 2.7 NGK BR-6HS

Petrol Robin EX17 S.A.E. 10W 30 1.1 Unleaded 3.6 NGK BR-6HS

Vibrator Turbine Oil 32 0.4 N/A N/A N/A N/A

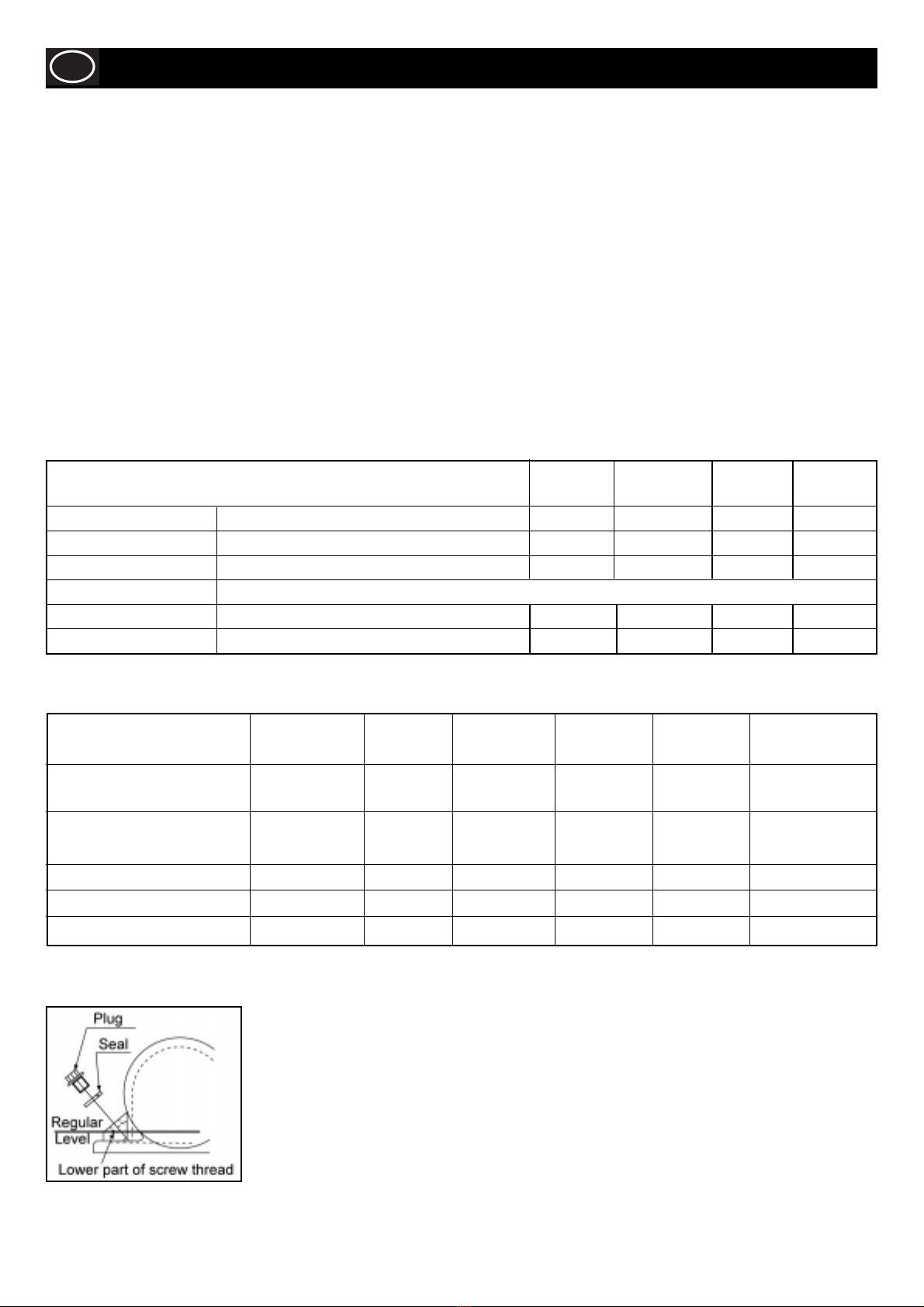

Vibrator Unit.

Remove the plug complete with seal, check that the oil level reaches the bottom thread on the oil

plug hole. Top up as necessary with the correct oil (see chart).

276

Belle Group Head Office

Sheen, nr. Buxton

Derbyshire. SK17 OEU GB.

Tel: +44 (0)1298 84000

Fax: +44 (0)1298 84722

email: [email protected]

Belle Group France

70, av du Général de Gaulle

94022 Creteil, Cedex.

FRANCE

Tel: +33 (0) 1 49 81 68 32

Fax: +33 (0) 1 43 39 94 40

Ventes : 0800 902 461

SAV : 0800 905 336

SAV Fax : 0800 909 895

Belle Equipos SL

Calle Doctor Calero Cial 19,

Local 22, 28220 Majadahonda

Madrid, Spain

Tel: +34 (0) 91 636 2043

Fax: +34 (0) 91 634 1535

email:[email protected]

Belle Group Deutschland

Husumer Straße 45 a,

D-33729,

Bielefield

Deutschland

Tel : +49(0) 5217 707505

Fax : +49 (0) 5217 707506

Sales: 0800 1808069

Spares: 0800 1816673

Belle Group (GB), Shanghai Office

Room 213, Zhonghuang Building,

1007 Zhongshan Nan Er Road,

Xuhui, Shanghai 200030 China

Tel: 00 - 86 - 21 - 5461 5228

Mobile: 00 - 86 - 133 8172 2653

Fax: 00 - 86 - 21 - 5461 5369

email: [email protected]

Belle Group Inc

3959 Electric Rd

Roanoake

Suite 360

VA 24018. USA.

Tel: +1.540.345.5090

Fax: +1.540.345.5091

Toll free 866 540 5090

e-mail: [email protected]

Belle Group World Parts Centre

Unit 5, Bode Business Park

Ball Haye Green,

Leek,

Staffordshire,

ST13 8BW

Tel: 44+ 1538 380000

Fax: 44+ 1538 380038

Belle Poland sp. z.o.o.

96-200 Rawa Mazowiecka

Ul. Mszczonowska 36,

Polska

Tel: +48 (0) 46 8144091

Fax: +48 (0) 46 8144700

Belle Group Portugal

Rua Laura Alves, 225, 2°F

2775-116 Parede

Portugal

Tel: +35 1 (21) 453 59 91

Fax: +35 1 (21) 453 59 91

Belle Group Netherlands

Tel: 0800 249861

Belle Group Belguim

Tel: 0800 80295

Belle Group Austria

Tel: 0800 291544

Belle Group Russia

64 Nevsky pr.

St, Petersburg

Russia

Tel : +7(812)314-81-34

Moscow : +7(495)589-64-32

Belle Group South East Asia

21, Jalan Ara AD 7/3B,

Pandar Sri Damansara

S2200 Kuala Lumpar, Malaysia

Tel: +60 (0) 3 62721678

+60 (0) 3 6272 9308

Fax: +60 (0) 3 6272 9528

No.1 for Light Construction Equipment

www.BelleGroup.com

COMPACTING... MIXING... CONCRETING... CUTTING... BREAKING... MOVING

No.1 for Light Construction Equipment

www.BelleGroup.com

Other manuals for PCX 12/36

1

This manual suits for next models

1

Table of contents

Other Belle Group Power Tools manuals