Belle Group RT60 User manual

1

Operators Manual 4

GB

870-10013-0

01/10

60

2

Signed by: Managing Director - On behalf of BELLE GROUP (SHEEN) UK.

Signature: Le Directeur Général - Pour le compte de la SOCIETE BELLE GROUP (SHEEN) UK.

Medido por: Director Gerente - En nombre de BELLE GROUP (SHEEN) UK.

Assinado por: Director-Geral - Em nome de BELLE GROUP (SHEEN) UK.

Getekend door: Algemeen Directeur - Namens BELLE GROUP (SHEEN) UK.

Uunderskrevetaf: Administrerende direktør – På vegne af BELLE GROUP (SHEEN) UK.

PRODUCT TYPE ................. TYPE DE PRODUIT.............. TIPO DE PRODUCTO.......... TIPO DE PRODUCTO .........

MODEL................................. MODELE............................... MODELO .............................. MODELO..............................

SERIAL No........................... N° DE SERIE........................ N° DE SERIE........................ NO. DE SÉRIE .....................

DATE OF MANUFACTURE. DATE DE FABRICATION ..... FECHA DE FABRICACIÓN.. DATA DE FABRIC

SOUND POWER LEVEL NIVEAU DE PUISSANCE NIVEL DE POTENCIA NIVEL DE POTÊNCIA

MEASURED......................... SONORE MESUREE............ ACÚSTICA MEDIDO............ DE SOM MEDIDO................

(GUARANTEED).................. (GARANTIE)......................... (GARANTIZADO) ................. (GARANTIDO) .....................

WEIGHT............................... POIDS................................... PESO.................................... PESO ...................................

We, Belle Group Sheen UK, Sheen, Nr. Buxton, Derbyshire, SK17 0EU, GB, hereby certify that if the product described within this certificate is bought from an

authorised Belle Group dealer within the EEC, it conforms to the following EEC directives: 98/37/EC (This directive is a consolidation of the original machinery directive

89/392/EEC), Electromagnetic Compatibility Directive 89/336/EEC (as amended by 92/31/EEC & 93/68 EEC). The low voltage directive 73/23/EEC, BS EN ISO

12100-1:2003 Safety of machinery and associated harmonised standards, where applicable. Noise emissions conform to directive 2000/14/EC Annex VI, for machines

under article 12 the notified body is AV Technology Limited, AVTECH house, Birdhall Lane, Cheadle Heath, Stockport, Cheshire, SK3 0XU, GB.

Noise Technical Files are held at the Belle Group Head Office address which is stated above.

Nous soussignés, Belle Group Sheen UK, Sheen, Nr Buxton, Derbyshire, SK17 0EU, GB, certifions que si le produit décrit dans ce certificat est acheté chez un

distributeur autorisé Belle Group au sein de la CEE, il est conforme aux normes CEE ci-après: 98/37/CE (Cette norme est une codification des normes de la machine

d'origine 89/392/CEE), Norme compatible pour l'électromagnisme 89/336/CEE (modifié par 92/31/CEE et 93/68/CEE). Caractéristiques basse tension 73/23/CEE, BS EN

ISO 12100-1:2003, Norme de sécurité des machines et des critères associés et configurés, si applicable. Les émissions de bruit sont conformes à la directive

2000/14/EC Annexe VI pour machines , article 12, l’objet mentionné est AV Technology Limited, AVTECH House, Birhall Lane, Cheadle Heath, Stockport, Cheshire,

SK3 0XU, GB.

Les dossiers techniques sur les émissions sonores des machines sont détenus au siège social de BELLE GROUP à l’adresse ci-dessus.

La Sociedad, Belle Group Sheen UK, Sheen, Nr. Buxton, Derbyshire, SK 17 OEU, GB, por el presente documento certifica que si el producto descrito en este

certificado es comprado a un distribuidor autorizado de Belle Group en la CEE, este es conforme a las siguientes directivas: 98/37/CE de la CEE (Esta directiva

consolida la directiva inicial sobre maquinaria 89/392/CEE), Directiva 89/336 CEE sobre Compatibilidad Electromagnética (según enmiendas 92/31/CEE y 93/68 CEE),

Directiva sobre Bajo Voltaje 73/23/CEE, BS EN ISO 12100-1:2003 de Seguridad de Maquinaria y Niveles armonizados estándares asociados donde sean aplicables.

Emisión de Ruídos conforme a la Directiva 2000/14/CE Anexo VI para máquinas bajo artículo 12 la mencionada unidad está AV Technology Limited, AVTECH House,

Birdhall Lane, Cheadle Heath, Stockport, Cheshire, SK3 OXU, GB.

En La Sede Central de Belle Group existen Archivos Técnicos con contenido referente a Niveles de Ruido.

O signatário, Belle Group Sheen UK, Sheen, Nr Buxton, Derbyshire, SK 0EU, GB, pelo presente, declara que se o produto descrito neste certificado foi adquirido a

um distribuidor autorizado do Belle Group em qualquer país da UE, está em conformidade com o estabelecido nas seguintes directivas comunitárias: 98/37/EC (esta

directiva é uma consolidação da directiva de maquinaria original 89/392/EEC), Directiva de Compatibilidade Electromagnética 89/336/EEC (conforme corrigido pelas

92/31/EEC & 93/68 EEC). A directiva de baixa voltagem 73/23/EEC, BS EN ISO 12100-1:2003 Segurança da maquinaria e às normas harmonizadas afins se aplicáveis.

As emissões de ruído respeitam e estão dentro das directivas para máquinas 2000/14/EC Anexo VI, artigo 12, sendo o organismo notificado AV Technology Limited,

AVTECH house, Birdhall Lane, Cheadle Heath, Stockport, Cheshire, SK3 0XU, GB.

A informação técnica sobre níveis sonoros está disponivel na Sede da Belle Group na morada acima mencionada.

Ondergetekende, Belle Group Sheen UK, Sheen, Nr. Buxton, Derbyshire, SK17 OEU, GB, verklaren hierbij dat als het product zoals beschreven in dit certificaat is

gekocht van een erkende Belle Group dealer binnen de EEG, het voldoet aan de volgende EEG richtlijnen: 98/37/EC (Deze richtlijn is een opvolger van de orginele

Machinerichtlijn 89/392/EEG), Electromagnetische Compatability Richtlijn 89/336/EEG ( geamendeerd door 92/31/EEG & 93/68 EEG). De Laagspannings Richtlijn

72/23/EEG, BS EN ISO 12100-1:2003 Veiligheid van Machines en hieraan gekoppelde geharmoniseerde Standaarden, waar deze van toepassing is. Rumoer emissions

passen voor richtlijn EC Zijgebouw VI , voor toestel onder stuk 12 naar de notified troep zit AV Technology Limited, AVTECH house, Birdhall Lane, Cheadle Heath,

Stockport, Cheshire, SK3 OXU, GB

Worden de Technische Dossiers van het lawaai gehouden op het adres van het Hoofdkantoor van de Groep Belle dat hierboven ' wordt verklaard.

Vi, Belle Group Sheen UK, Sheen, Nr. Buxton, Derbyshire, SK17 0EU, GB, erklærer hermed, at hvis det i dette certifikat beskrevne produkt er købt hos en autoriseret

Belle Group forhandler i EU, er det i overensstemmelse med følgende EØF-direktiver: 98/37/EF, 73/23/EØF (som ændret ved 93/68/EØF), 89/336/EØF (som ændret ved

92/31/EØF), 93/68/EØF og tilknyttede, harmoniserede standarder, hvor relevant. Støjniveauet er i overensstemmelse med direktiv 2000/14/EF, bilag VI gældende for

maskiner under paragraf 12. Det bemyndigede organ er AV Technology Limited, AVTECH house, Birdhall Lane, Cheadle Heath, Stockport, Cheshire, SK3 0XU,

Storbritanien.

De tekniske støjspecifikationer forefindes på Belle Group´s hovedkontor, adressen er skrevet ovenfor.

EC DECLARATION OF CONFORMITY / DECLARATION CE DE CONFORMITE /

DECLARACIÓN DE CONFORMIDAD CE / DECLARAÇÃO CE DE CONFORMIDADE /

EG-VERKLARING VAN OVEREENSTEMMING / EF

OVERENSSTEMMELSESERKLÆRING

Ray Neilson

PRODUCTTYPE .................. PRODUKTTYPE...................

MODEL................................. MODEL .................................

SERIENUMMER................... SERIENR. .............................

FABRICAGEDATUM............ FREMSTILLINGSDATO .......

GEMETEN LYDEFFEKTNIVEAU

GELUIDSSTERKTENIVEAU MÅLT....................................

(GEGARANDEERD) ............ (GARANTERET)...................

GEWICHT............................. VÆGT...................................

GB

F

E

P

NL

DK

3

Unterzeichnet vo: Generaldirektor – Im auftrag von BELLE GROUP (SHEEN) UK.

Firmato da: Amministratore Delegato – Per conto di BELLE GROUP (SHEEN) UK.

Undertecknat: V.D. – På vägnar av BELLE GROUP (SHEEN) UK.

Signatur: Managing Director - På vegne av SOCIETE BELLE GROUP (SHEEN) UK.

Allekirjoitus: Toimitusjohtaja - BELLE GROUP (SHEEN) UK: n puolesta.

Podpisa³: Dyrektor Zarządzający – w imieniu BELLE GROUP (SHEEN) UK

PRODUKTTYP..................... TIPO PRODOTTO ................ PRODUKTTYP..................... PRODUKTTYP.....................

MODELL .............................. MODELLO ............................ MODELL............................... MODELL ..............................

SERIENNR........................... SERIE N°.............................. SERIE NR. ........................... SERIE NR. ..........................

HERSTELLUNGSDATU ...... DATA DI FABBRICAZIONE.. TILLVERKNINGSDATUM..... PRODUKSJONSDATO........

SCHALLLEISTUNGSPEGEL LIVELLO POTENZA LJUDSTYRKA LYDKRAFTNIVÅ

GEMESSEN ......................... SONORA MISURATA ........... UPPMÄTT............................. MÅLT ...................................

(GARANTIERT).................... (GARANTITA)....................... (GARANTERAD) .................. (GARANTERT) ....................

GEWICHT............................. PESO.................................... VIKT...................................... VEKT....................................

Wir, Belle Group Sheen UK, Sheen, Nr. Buxton, Derbyshire, SK17 0EU, Großbritannien, bestätigen hiermit, dass das in diesem Zertifikat beschriebene Produkt,

wenn es von einem autorisierten Belle Group Händler innerhalb der europäischen Gemeinschaft gekauft wurde, folgenden EG-Richtlinien entspricht: 98/37/EG, 73/23/EG

(geändert durch 93/68/EG), 89/336/EG (geändert durch 92/31/EG), 93/68/EG und, wenn zutreffend, den harmonisierten Normen. Geräuschemissionen entsprechen der

Richtlinie 2000/14/EG, Anhang VI, für Maschinen unter Artikel 12: die benannte Stelle ist AV Technology Limited, AVTECH House, Birdhall Lane, Cheadle Heath,

Stockport, Cheshire, SK3 0XU, GB.

Geräuschtechnische Dokumente stehen in unserer Zentrale unter obig angegebener Adresse zur Verfügung.

Il Gruppo Belle Sheen UK, Sheen, Nr. Buxton, Derbyshire, SK17 0EU, GB, certifica che il prodotto descritto nel presente certificato è acquistato da un concessionario

autorizzato del gruppo Belle nell'ambito CEE e che è pienamente conforme alle seguenti direttive CEE: 98/37/EC, 73/23/EEC (emendamento 93/68/CEE), 89/336/EEC

(emendamento 92/31/CEE), 93/68/CEE e relativi standard armonizzati. Livelli acustici sono in conformità con la direttiva 2000/14/EC Annex VI per macchine coperte dall’

articolo 12. L’ente di riferimento è AV Technology Limited, AVTECH house, Birdhall Lane, Cheadle Heath, Stockport, Cheshire, SK3 0XU, GB.

Dati tecnici relativi ai livelli acustici sono disponibili su richiesta dalla sede madre Belle Group al sopra citato indirizzo.

Undertecknade, Belle Group Sheen UK, Sheen, Nr Buxton, Derbyshire, SK17 0EU, Storbritannien, intygar härmed att en produkt beskriven i detta certifikat som

köps från en godkänd Belle Group återförsäljare inom EU stämmer överens med följande EG-direktiv: 98/37/EG, 73/23/EG (ändrat genom 93/68/EEC), 89/336/EG

(ändrat genom 92/31/EG), 93/68/EG och tillhörande harmoniserade standarder i tillämpliga fall. Buller nivån överensstämmer med Direktiv 2000/14/EC Bilaga VI gällande

maskiner under artikel 12, den aviserade organisationen är AV Technology Limited, AVTECH house, Birdhall Lane, Cheadle Heath, Stockport, Cheshire, SK3 0XU,

Storbritannien.

Teknisk dokumentation vad gäller test av maskiners ljud/bullernivå finns dokumenterad hos Belle-Groups huvudkontor i Sheen, England.

Vi, Belle Group Sheen UK, Sheen, Nr Buxton, Derbyshire, SK17 0EU, GB, bekrefter med dette at det produktet som står beskrevet i denne erklæringen er kjøpt fra en

autorisert Belle Group forhandler innen EØF, og at det oppfyller følgende direktiver: 98/37/CE dette direktivet er et sammendrag av det opprinnelige maskindirektivet

89/392/EØF), Det elektromagnetisk kompatabiltets-direktivet 89/336/EØF (som endret av 92/31/EØF og 93/68/EØF). Lavspenningsdirektivet 73/23/EØF, BS EN ISO

12100-1:2003, Sikkerhet til maskineri og tilhørende harmoniserte standarder, hvor atuelt. Støyemisjon er i samsvar med direktiv 2000/14/EC, vedlegg VI, for maskiner.

Organet som skal informeres under artikkel 12 er

AV Technology Limited, AVTECH House, Birhall Lane, Cheadle Heath, Stockport, Cheshire, SK3 0XU, GB.

Lydtekniske filer er arkivert hos Bell Group Hovedkontor med adresse som nevnt ovenfor.

Me, Belle Group Sheen UK, Sheen, Nr. Buxton, Derbyshire, SK17 0EU, GB, ilmoitamme täten, että jos tässä todistuksessa kuvattu tuote on ostettu valtuutetulta Belle

Groupin myyjältä ETY:n alueella, se on yhdenmukainen seuraavien ETY-direktiivien kanssa: 98(37/EY (Tämä direktiivi on yhdistelmä alkuperäisestä konedirektiivistä

89/392/ETY, sähkömagneettisen yhteensopivuuden direktiivistä 89/336/ETY, korjauksineen 92/31/ETY ja 93/68/ETY), matalajännitedirektiivistä 73/23/ETY,

koneturvallisuusstandardista BS EN ISO 12100-1:2003 ja siihen liittyvistä yhdenmukaistetuista standardeista, tapauksen mukaan. Melumittaus mittaus on laadittu

direktiivin 2000/14/EC Kohdan VI artiklan 12 mukaisille koneille mukaan. Mittauksen suorittaja on AV Technology Limited, AVTECH House, Birdhall Lane, Cheadle

Heath, Stockport, Cheshire, SK3 0XU, GB.

Melumittausten teknilliset arvot ovat saatavana Belle Group pääkonttorin ylläolevasta osoitteesta.

My, Belle Group Sheen UK, Sheen, Nr. Buxton, Derbyshire, SK17 0EU, Wielka Brytania, niniejszym poświadczamy, iż produkt opisany w tym świadectwie został

zakupiony od autoryzowanej Belle Group w UE i jest zgodny z następującymi dyrektywami EU: 98/37/EC (ta dyrektywa to konsolidacja oryginalnej dyrektywy na temat

maszyn 89/392/EEC), Dyrektywą zgodności elektromagnetycznej 89/336/EEC (z poprawkami wniesionymi przez 92/31/EEC oraz 93/68/EEC), Dyrektywą w sprawie

niskich napięć 73/23/EEC, BS EN ISO 12100-1:2003 Bezpieczeństwo maszyn i związane normy harmonizacyjne, tam gdzie to ma zastosowanie. Poziom hałasu jest

zgodny z Dyrektywą 2000/14/EC Zalącznik VI, organizacja zawiadamiana (odnośnie zgodności) to AV Technology Limited, AVTECH house, Birdhall Lane, Cheadle

Heath, Stockport, Cheshire, SK3 0XU, Wielka Brytania.

Informacje Techniczne dotyczące poziomu hałasu są przechowywane w Belle Group – adres powyżej.

EGKONFORMITÄTSERKLÄRUNG / DICHIARAZIONE CE DI CONFORMITÁ /

EG-VERKLARING VAN OVEREENSTEMMING /

EC SAMSVARSERKLÆRING / EY-YHDENMUKAISUUSILMOITUS / DEKLARACJA

ZGODNOSCI Z PRZEPISAMI UE

Ray Neilson

TUOTETYYPPI..................... TYP PRODUKTO..................

MALLI................................... MODEL .................................

VALMISTUSNRO................. Nr SERII................................

VALMISTUSPÄIVÄ.............. DATAPRODUKCJI ...............

ÄÄNENVOIMAKKUUDEN POZIOM MOCY

TASO MITATTU...................

DŹ

WI

Ę

KU ZMIERZONY ......

(TAATTU) ............................. (GWARANTOWANY)............

MASSA................................. WAGA...................................

D

I

S

NO

SF

PL

4

How To Use This Manual

GB

This manual has been written to help you operate and service the RT60 Rammer safely. This manual is intended for dealers and

operators of the RT60 Rammer.

Foreword

The ‘Machine Description’ section helps you to familiarise yourself with the machine’s layout and controls.

The ‘Environment’ section gives instructions on how to handle the recycling of discarded apparatus in an environmentally friendly way.

The ‘General Safety’ and ‘Health and Safety’ sections explain how to use the machine to ensure your safety and the safety of the

general public.

The ‘Start and Stop Procedure’ helps you with starting and stopping the machine.

The ‘Trouble Shooting Guide’ helps you if you have a problem with your machine.

The ‘Service & Maintenance’ section is to help you with the general maintenance and servicing of your machine.

The ‘Warranty’ Section details the nature of the warranty cover and the claims procedure.

The ‘Declaration of Conformity’ section shows the standards that the machine has been built to.

Directives with regard to the notations.

Text in this manual to which special attention must be paid are shown in the following way:

Before you operate or carry out any maintenance on this machine YOU MUST READ and STUDY

this manual.

WARNING

The product can be at risk. The machine or yourself can be damaged or injured if procedures are not carried

out in the correct way.

CAUTION

The life of the operator can be at risk.

WARNING

WARNING

GB

Contents

KNOW how to safely use the unit’s controls and what you must do for safe maintenance. (NB Be sure that you know how to switch the

machine off before you switch on, in case you get into difficulty.)

ALWAYS wear or use the proper safety items required for your personal protection. If you have ANY QUESTIONS about the safe use

or maintenance of this unit, ASK YOUR SUPERVISOR OR CONTACT: BELLE GROUP (UK): +44 (0) 1298 84606

GB

How to use this manual..............................................................................................................................................................................4

Warning......................................................................................................................................................................................................4

Decals.........................................................................................................................................................................................................5

Machine Description...................................................................................................................................................................................6

Environment ...............................................................................................................................................................................................6

Technical Data...................................................................................................................................................................................... 6 - 7

General Safety ...........................................................................................................................................................................................7

Health and Safety.......................................................................................................................................................................................8

Intended Use..............................................................................................................................................................................................8

Pre-Start Safety Checks.............................................................................................................................................................................8

Start & Stop Procedure..............................................................................................................................................................................9

Operation..................................................................................................................................................................................................10

Trouble Shooting Guide ...........................................................................................................................................................................10

Service & Maintenance ............................................................................................................................................................................11

Long Term Storage...................................................................................................................................................................................11

Warranty...................................................................................................................................................................................................12

Declaration of Conformity...........................................................................................................................................................................2

Belle Group reserves the right to change machine specification without prior notice or obligation.

5

Decals

GB

A. Fuel and Transport Decal

B. Safety Decal

C. Fuel Valve Decal

D. Throttle Lever Decal

E. RT60 Decal

A - Fuel and Transport Decal (Part No. 800-99895)

Only use ‘SP95 Unleaded Petrol’.

On Site Transport

The rammer may be moved vertically by 2 people, or laid only on the Transport Rollers.

Road Transport

The rammer must be transported as far as possible standing up, strapped to the body side board of the truck, or strapped inside a lorry

(panel truck). If not possible, it may be laid down only on the Transport Rollers, in stable position and strongly strapped down to guard

against rolling or sliding.

B - Safety Decal (800-99840)

Please Read

Operators Manual Wear Protective

Footwear Wear Ear

Protection Wear Eye

Protection

C - Fuel Valve Decal (800-99873)

Fuel Valve ‘ON’ and ‘OFF’ positions.

- To START the machine, the Fuel Valve must be in the ‘ON’ position.

- To STOP the machine, the Fuel Valve must be in the ‘OFF’ position.

D - Fuel Valve Decal (800-99843)

Max. RPM

Position ‘OFF’ Position

A.

D

B

D

E

6

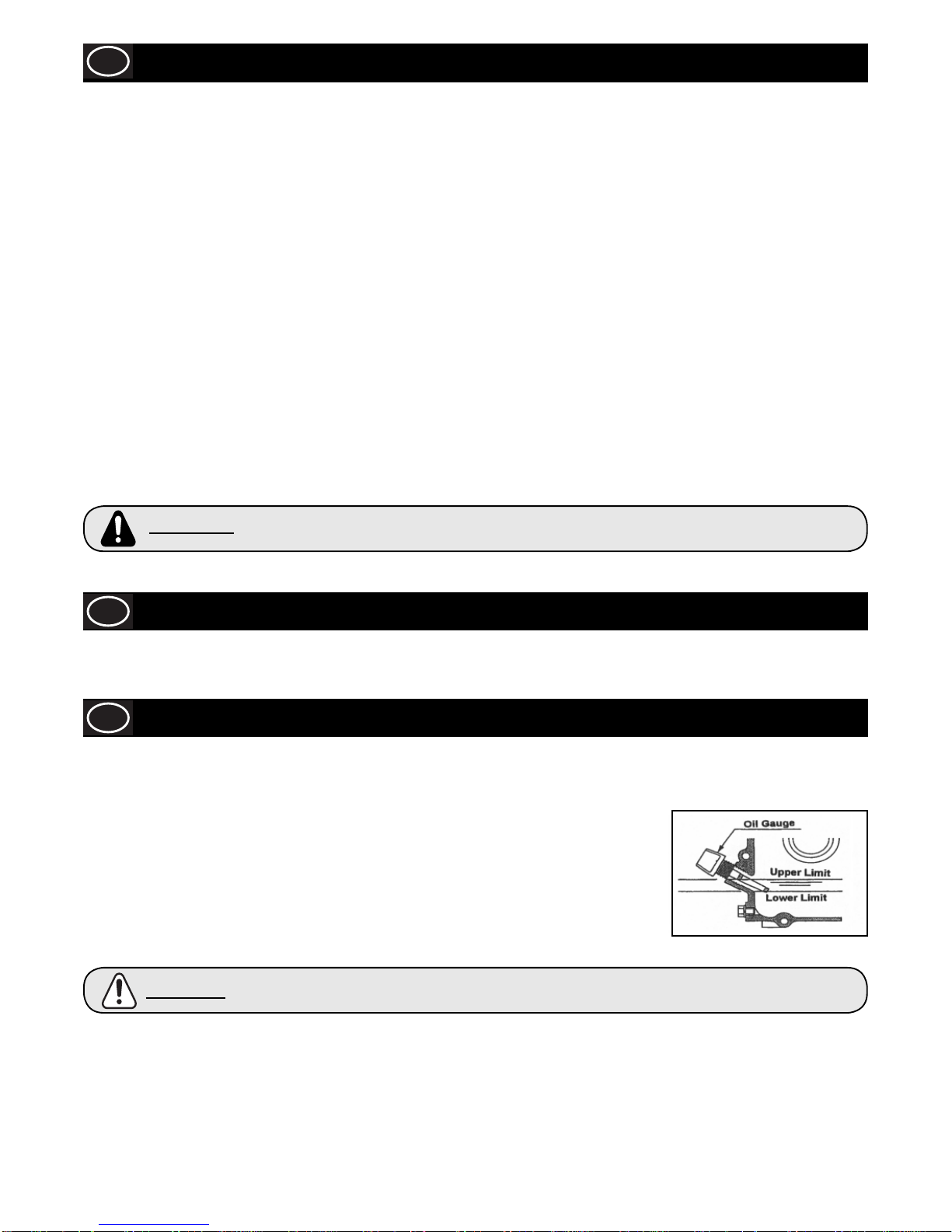

Machine Description

GB

1. Fuel Tank.

2. Throttle Lever.

3. Fuel ON / OFF lever.

4. Engine.

5. Engine ON / OFF Switch.

6. Crankcase.

7. Bellows.

8. Lifting Point.

9. Oil Plug.

10. Ramming Shoe.

11. Operating Handle.

Environment

Safe Disposal

Instructions for the protection of the environment.

The machine contains valuable materials. Take

the discarded apparatus and accessories to the

relevant recycling facilities.

Component Material

Handle Steel

Ramming Shoe Plywood and Steel

Rubber Isolators Rubber and Steel

Bellows Urethane

Crankcase Aluminium

Crankcase Cover Aluminium

Gears Steel

Engine Steel and Aluminium

Various Parts Steel and Aluminium

GB

Technical Data

GB

Model RT60

Engine Models Honda GX100

Engine Type 4 Stroke, OHC, Air Cooled

Maximum Output 2.3 kW

Fuel Type Unleaded Petrol

Fuel Tank Capacity 2.0 Litres

Starting Mechanism Recoil Starter

Operational Weight 60Kg

Overall Dimensions (LxWxH) 705 x 380 x 990mm

Ramming Shoe Size (WxL) 250 x 332mm

Vibration Frequency 570-635 v.p.m

Noise Level 104 dB(A)

3 Axis Vibration 13.82 m/sec2

Usage Time (Mins)

- EAV 2.5m/s230.55

- ELV 5.0m/s2122.19

Vibration Level: Minimum Level - EN500 Part 4.

8

1010

67

10

9

311

1

5

3

4

7

General Safety

GB

• This machine must only be used for its intended purpose. This machine must be operated only by well trained personnel.

• The owner of this machine must observe, and train the user of the machine to observe, the effective Labour Protection

Regulation in the country of application.

• This equipment is heavy and must not be lifted single-handedly, either GET HELP or use suitable lifting equipment.

• This machine must be operated on ground where stability is guaranteed. When working near the rim of excavated trenches, use the

machine properly so that the machine may not collapse or fall down.

• Cordon off the work area and keep members of the public and unauthorised personnel at a safe distance.

• Personal Protective Equipment (PPE) must be worn by the operator whenever this equipment is being used (See Health & Safety

Section).

• Make sure you know how to safely switch this machine OFF before you switch it ON in case you get into difficulty.

• Always switch OFF the engine before transporting, moving it around the site or servicing it.

• During use the engine becomes very hot, allow the engine to cool before touching it.

• Never leave the engine running and unattended.

• Never remove or tamper with any guards fitted, they are there for your protection.Always check guards for condition and security, if

any are damaged or missing, DO NOT USE THE RT until the guard has been replaced or repaired.

• Do not operate the RT60 when you are ill, feeling tired, or when under the influence of alcohol or drugs.

• This machine is designed to eliminate the possible risks arising from its use. However, risks DO reside, and these residual risks are

not clearly recognisable and may cause personal injury, property damage and possible death. If such unpredictable and unrecogni-

sable risks become apparent, the machine must be stopped immediately, and the operator or his supervisor must take the appro-

priate measures to eliminate such risks. It is sometimes necessary for the manufacturer to be informed of such an event for future

counter measuring.

For your own personal protection and for the safety of those around you, please read and ensure you fully understand the following

safety information. It is the responsibility of the operator to ensure that he/she fully understands how to operate this equipment safely.

If you are unsure about the safe and correct use of your RT60, consult your supervisor or Belle Group of companies.

Improper maintenance or use can be hazardous. Read and Understand this section before you perform any

maintenance, service or repairs.

CAUTION

Fuel is flammable. It may cause injury and property damage. Shut down the engine, extinguish all open

flames and do not smoke while filling the fuel tank. Always wipe up any spilled fuel.

WARNING

• Before refuelling, switch off the engine and allow it to cool.

• When refuelling, DO NOT smoke or allow naked flames in the area.

• When refuelling, use a proper funnel, and avoid spilling fuel over the engine.

• Spilt fuel must be made safe immediately, using sand. If fuel is spilt on your clothes, change them.

• Store fuel in an approved, purpose made container away from heat and ignition sources.

8

Pre start-up inspection

The following Pre-start-up inspection must be performed before the start of each work session or after every four hours of use, which-

ever is first. Please refer to the service section for detailed guidance. If any fault is discovered, the RT60 must not be used until the fault

is rectified.

1. Thoroughly inspect the RT60 for signs of damage.

2. Check hoses, filler openings, drain plugs and any other areas for signs of leakage. Fix any

leaks before operating.

3. Check the engine oil level and top up as necessary.

3.1 Place the machine on a level surface, and check the oil level in the engine.

3.2 Remove the oil guage, and observe that the oil is up to the rim of the filler port.

Use proper engine oil with the proper viscosity. (SAE 10W-30 recommended)

4. Check the engine fuel level and top up as necessary. Use clean fuel. Use of contaminated

fuel may damage the fuel system.

Health & Safety

Vibration

Some vibration from the machines operation is transmitted through the handle to the operator’s hands. The Belle Group RT60 has

been specifically designed to reduce hand/arm vibration levels. Refer to specifications & technical data for vibration levels and usage

times (recommended maximum daily exposure time). DO NOT exceed the maximum usage times.

PPE (Personal Protective Equipment)

Personal injury or property damage may be caused by knocks, crushing, slipping, tripping, falling, or by flying chips due mainly to the

improper or careless handling of the machine, or working in a confined area.

Suitable PPE must be worn when using this equipment i.e. Safety Goggles, Gloves, Ear Defenders, Dust Mask and Steel Toe capped

footwear. Wear clothing suitable for the work you are doing. Tie back long hair and remove any jewellery which may catch in the

equipment’s moving parts.

Dust

The compaction process can produce dust, which may be hazardous to your health. Always wear a mask that is suited to the type of

dust being produced.

Fuel

Oil and fuel used in this machine may cause the following hazards.

• Poisoning if the fuel or oil vapour is inhaled.

• Allergies if the fuel or oil spills on the skin.

• Fire and explosion if the fuel and oil is handled near smoking or open fires.

• Do not ingest fuel or inhale fuel vapours and avoid contact with your skin. Wash fuel splashes immediately. If you get fuel in your

eyes, irrigate with copious amounts of water and seek medical attention as soon as possible.

Exhaust Fumes

GB

The exhaust fumes produced by this equipment are highly toxic and can kill!

WARNING

Do not operate your RT60 indoors or in a confined space, make sure the work area is adequately ventilated.

Intended Use

GB

NOTICE: This machine uses Unleaded Gasoline/Petrol.

NEVER fill the fuel tank with a mixture of Oil and Gasoline/Petrol.

CAUTION

This machine is intended for base preperation, driveways, foundations, curbs, and footings. It can also be used for repair work on

streets, highways and/or sidewalks/pavements.

Pre-Start Checks

GB

5. Check that the air filter is clean. Excessive dust/dirt accumulation within the filter element will cause erratic engine operation.

Clean the air filter element when it is contaminated (See Maintenance section).

9

GB

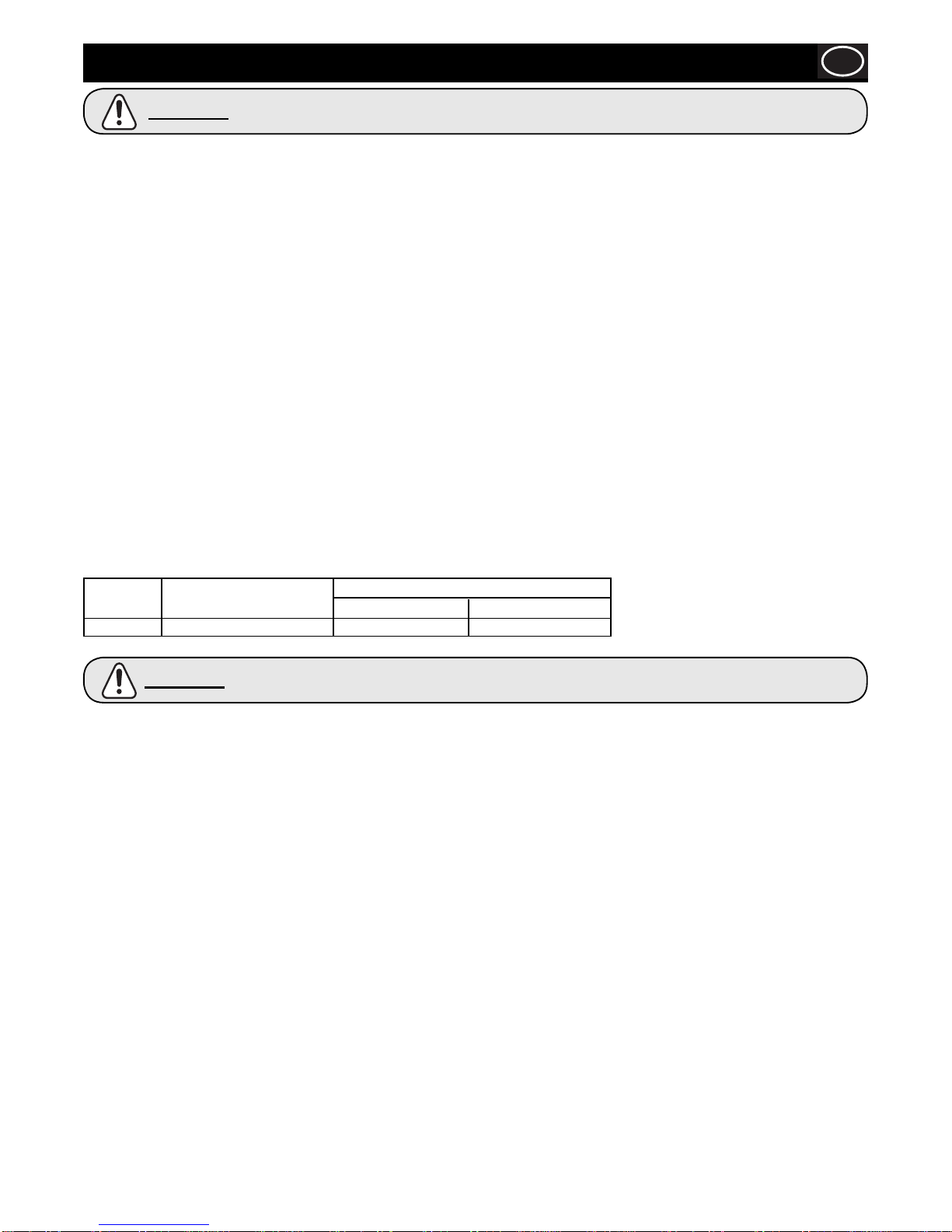

Start & Stop Procedure

1. Open the fuel cock.

2. Set the engine switch to the ON position.

3. Set the speed control lever to the STARTING position (Halfway between HIGH and LOW position).

4. Move the choke lever to the CLOSED position.

5. Taking a firm hold of the Operating handle with one hand, grasp the recoil starter handle with the other, Pull the recoil starter

handle until engine resistance is felt, then let starter return.

6. Taking care not to pull the starters rope fully out, pull the starter handle briskly.

7. Repeat until the engine fires.

8. Once the engine fires gradually set the choke lever to the OPEN position.

9. Let the engine run at idle for a few minutes to warm up.

10. After the engine has warmed up, the machine is ready for operation.

11. Move the throttle lever to the high speed ‘H’ position quickly to prevent damage from occuring to the clutch. The ‘Full

Throttle’ position of this machine has been preset at the factory to achieve optimum machine performance.

12. With the engine running in the full throttle position, the machine will move forward and compact loose ‘lifts’

13. In preparation for stopping the engine, move the throttle lever to the LOW position.

14. Allow the engine to idle for 1-3 minutes.

15. Set the engine switch to the OFF position. Do not touch the HOT engine part at this time.

16. Close the fuel cock.

17. Pull the recoil starter slowly until you feel resistance. Then release your hand from the starter knob to set it back to its

original position. This will prevent any air or humidity from entering into the cylinder.

Improper operation can be hazardous. Read and understand this section before you start the machine.

CAUTION

NOTICE: The optimum maximum engine revolution has been set at the factory as follows:

Model Engine Maximum RPM

Optimum Upper Limit

RT60 Honda GX100 3,800 +/- 50 4,000

GB

DO NOT alter this setting since irregular vibration or damage to the gear transmission mechanism can

result, and both engine and machine warranties will be automatically voided.

CAUTION

10

Operation

GB

Lifting

Where it is necessary to use lifting equipemnt to position the RT60, check and confirm that the rubber isolators on the operation handle

is not damaged or cracked. If they are cracked or damaged, replace the rubber isolators before attempting to lift the machine. Also

make sure that the lifting equipment has a WLL (Working Load Limit) suitable for the RT60’s weight (See specification chart or the

machine number plate). Attach suitable chains or slings ONLY to the lifting point on top of the RT60’s operating handle.

• NEVER leave the engine running whilst transporting or moving the RT60, even if it is only a short distance.

• The height of the operating handle can be adjusted within the range of 850 ~ 880 mm. Loosen three bolts at each side of the

operating handles base, and retighten them at the desired handle height. Note, that when the handle is set too high,

excessive vibration may be transmitted through the handle.

Having carried out the checks listed in the ‘pre-start’ section, you may start the engine.

The Belle Group RT60 range of tampers are fitted with a centrifugal clutch, thisallows the engine to run at idle without driving the crank

mechanism. As the engine speed is increased the clutch will engage and the engine will drive the crank mechanism.

• To avoid damage to the centrifugal clutch, move the throttle lever quickly from the L to H position. For correct operation, the

engine speed should be set to maximum.

• Avoid operating the machine on a fully compacted, hard, or non-yielding surface. Otherwise, the gear transmission mechanism

will be damaged, and the life of the machine will be greatly reduced.

• When working in a narrow trench, if the ramming shoe should get caught between the walls of the trench, the rammer may miss-

strike and can be severly damaged. The ramming shoe may especially be damaged severely.

• Make certain that the rammer is steered only by using the handle grip. It should only be pushed. The rammer must not be

pressed into the materials being compacted. Excessive pressure on the operating handle will lead to the unsatisfactory

compaction due to the fact that the jumping action is hindered.

Transportation.

When transporting or storing the machine, place the machine in an upright position if at all possible. Should the machine be required to

be laid down, NEVER attempt to lay the machine in a manner that the air cleaner faces downwards. Otherwise, the oil in the cylinder

may get into the combustion chamber or in the air cleaner, which may result in starting difficulties. Laying the machine forwards (The

crankcase cover of the rammer facing downwards) may not cause any spill of the engine oil into the cylinder or air cleaner of the en-

gine. However, if the engine is still hot, spilt fuel on the engine may cause fire. Lay the machine after the machine is completely cooled.

The machine fitted with the transporting roller on the operating handle may be easily loaded to and unloaded from a vehicle. Tilt the

machine forwards until the transporting roller touches the floor of the vehicle. Lift the lower part of the machine using the grab handle

provided at the ramming shoe, and push forward to load the machine. During transportation, the machine should be tied firmly, and

placed in an upright position if at all possible. To unload the machine, tilt the machine forward, until the roller touches the floor. Slightly

lift the lower part of the machine, and pull the machine out.

Operation at High Altitude

For continuous High-Altitude operation above 1,000m (3,000FT), it will be necessary to change the engine main jet to a type that will allow

for correct fueling of the engine. Otherwise, the unit will suffer from a lack of engine power and not work correctly.

Please contact BELLE group companies for details.

Trouble Shooting Guide

GB

Problem Cause Remedy

Engine will not start No fuel Fill Fuel Tank

Fuel Tap has been closed Open fuel tap.

Engine turned OFF Turn engine ON

Spark Plug contaminated Replace spark plug.

or damaged.

Faulty Carburettor Service the Carburettor

Engine stops suddenly, or stops when the See Above See Above

engine rpm is increased Main jet of the Carburettor Take out the main jet of the Carburettor and

clogged with dirt clean with Compressed air.

Air filter element dirty Clean the element.

Spark plug cap is loose Tightly fit cap to plug.

Engine runs, but machine does not produce impact. Lack of engine power See above.

Clutch is slipping Dismantle clutch assembly, Clean shoe

and drum with proper solvent. Replace

clutch shoe if necessary.

Crank mechanism is damaged Contact Dealer.

11

Maintenance

The Belle Group RT60 is designed to give many years of trouble free operation. It is, however, important that the simple regular

maintenance listed in this section is carried out.

It is recommended that an approved Belle Group dealer carries out all major maintenance and repairs. Always use genuine Belle Group

replacement parts, the use of spurious parts may void your warranty.

Before any maintenance is carried out on the machine, switch off the engine. If working on a petrol engined machine, disconnect the

HT lead from the sparkplug.

Always set the RT60 on level ground to ensure any fluid levels will be correctly read. Only use recommended oils (see chart).

Servicing the Engine

Service the engine according to the engine manufacturer’s specifications. Refer to the engine operation and maintenance manual.

Maintenance : Every 8 hours or daily.

1. Check for loose bolt and nuts, retighten if necessary.

2. Check and clean air filter element, re-lube the element

according to the engine manufacturer’s recommendations. If

operating conditions are unusually dusty and severe, filter

element cleaning should be done more frequently.

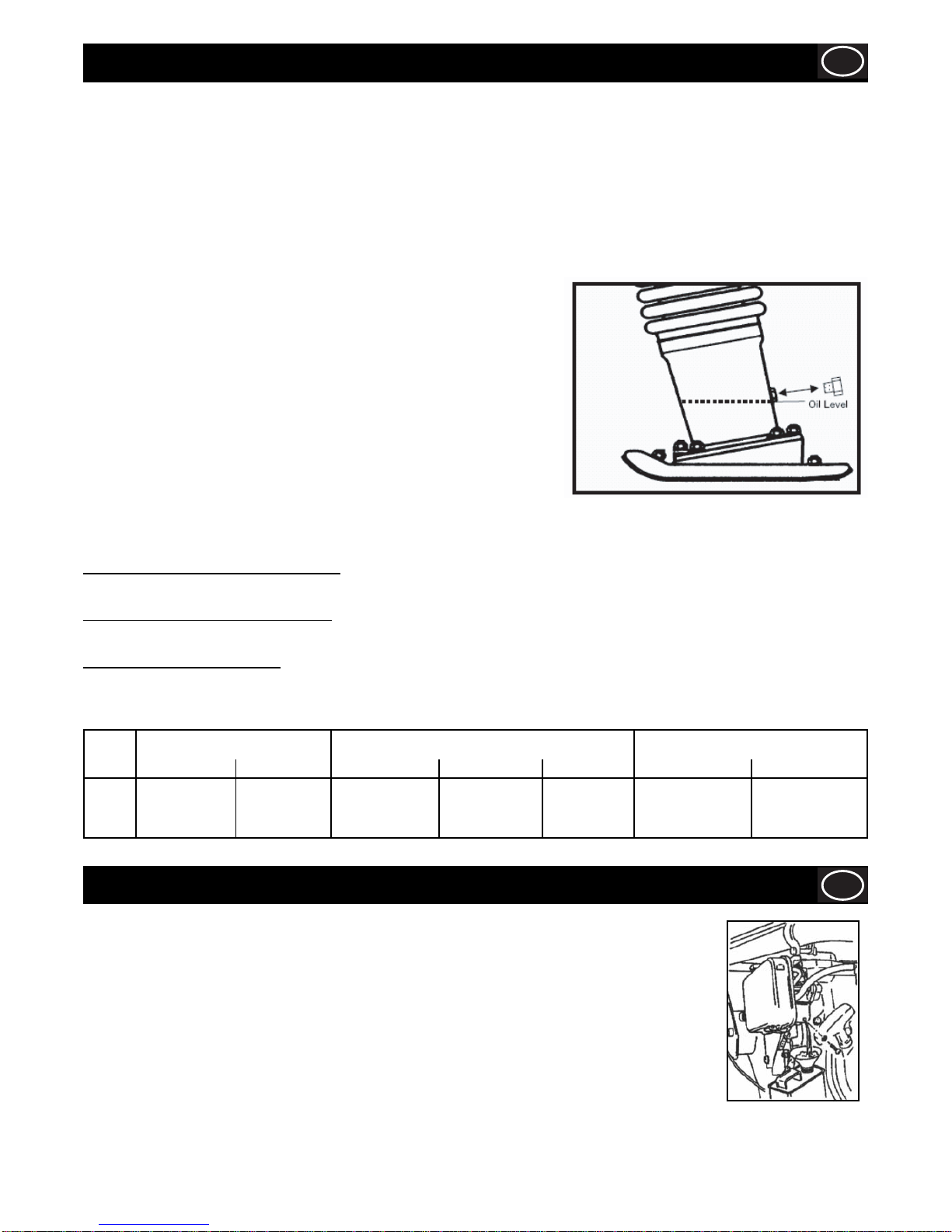

3. Check oil level in crankcase of engine and replenish as

necessary. Check oil level in the ramming cylinder as per

following procedures.

- Make sure that the machine has not been run in the last 10

minutes.

- Set the machine on a level surface and remove the oil plug.

- The top surface of the oil must be seen just below the lower rim of

the hole for oil plug. Replenish as necessary.

NOTICE: Care should be taken not to overfill the ramming cylinder with oil. Overfilling will cause excessive load on the engine, which

may result in poor or irregular vibration.

Maintenance : First 20 hours of operation

1. Replace the Oil in the Ramming Cylinder

Maintenance : Every 50 hours or weekly

2. Check for loose bolts and nuts. Retighten if necessary.

Maintenance : Every 200 Hours.

3. Change the ramming cylinder oil. Do not overfill.

Fuel and Lubricant

Service & Maintenance

GB

Long Term Storage

For long term storage, empty the fuel in the carburettor by running the engine with the fuel tap being closed.

The chemical composition of fuel will deteriorate after prolonged storage. When the machine needs to be

stored for a long time, remove all fuel from the fuel tank. Also remove the fuel from the float chamber of the

carburettor by draining the fuel out from the drain plug (see diagram).

Clean up oil and dust accumulation on rubber parts.

Clean the base plate and apply a light coating of oil to prevent rust formation.

Cover the machine and store in a dry place.

GB

Model

Type of Oil Capacity Type Of Oil Engine Capacity Type Of Oil Capacity

SAE 10W-30, SAE 10W-30,

RT60 Unleaded 2.0 Litres API, SG, GX 100 0.6 Litres API, SG, 0.7 Litres

SF/CC, CD SF/CC, CD

Fuel Ramming Cylinder

Engine Crankcase

12

Warranty

GB

Your new Belle Group RT60 is warranted to the original purchaser for a period of one-year (12 months) from the original date of

purchase. The Belle Group warranty is against defects in design, materials an workmanship.

The following are not covered under the Belle Group warranty:

1. Damage caused by abuse, misuse, dropping or other similar damage caused by or as a result of failure to follow assembly,

operation or user maintenance instructions.

2. Alterations, additions or repairs carried out by persons other than Belle Group or their recognised agents.

3. Transportation or shipment costs to and from Belle Group or their recognised agents, for repair or assessment against a

warranty claim, on any machine.

4. Materials and/or labour costs to renew, repair or replace components due to fair wear and tear.

The following components are not covered by warranty.

· Engine air filter

· Engine spark plug

Belle Group and/or their recognised agents, directors, employees or insurers will not be held liable for consequential or other damages,

losses or expenses in connection with or by reason of or the inability to use the machine for any purpose.

Warranty Claims

All warranty claims should firstly be directed to Belle Group, either by telephone, by Fax, by Email, or in writing.

For warranty claims:

or Write to:

Belle Group Warranty Department,

Sheen, Nr. Buxton

Derbyshire,

SK17 0EU

England

13

14

Belle Group Head Office

Sheen, Nr. Buxton

Derbyshire.

SK17 OEU

GB.

Tel: +44 (0)1298 84606

Fax: +44 (0)1298 84722

email: [email protected]

Belle France SARL

1 rue de l'Equerre

ZI de Béthunes

BP 20541

95005 Cergy Pontoise Cedex

FRANCE

Tel: +33 (0) 1 34 21 45 83

Tel: +33 (0) 1 34 21 45 84

Fax: +33 (0) 1 30 37 31 28

Belle Equipos SL

Calle Doctor Calero Cial 19,

Local 22, 28220 Majadahonda

Madrid, Spain

Tel: +34 (0) 91 636 2043

Fax: +34 (0) 91 634 1535

email:[email protected]

Belle Group Deutschland

Husumer Straße 45 a,

D-33729,

Bielefield

Deutschland

Tel : +49(0) 5217 707505

Fax : +49 (0) 5217 707506

Sales: 0800 1808069

Spares: 0800 1816673

Belle Group (GB), Shanghai Office

Room 213, Zhonghuang Building,

1007 Zhongshan Nan Er Road,

Xuhui, Shanghai 200030 China

Tel: 00 - 86 - 21 - 5461 5228

Mobile: 00 - 86 - 133 8172 2653

Fax: 00 - 86 - 21 - 5461 5369

email: [email protected]

Belle Group Inc

3959 Electric Rd

Roanoake

Suite 360

VA 24018. USA.

Tel: +1.540.345.5090

Fax: +1.540.345.5091

Toll free 866 540 5090

e-mail: [email protected]

Belle Group World Parts Centre

Sheen, Nr. Buxton

Derbyshire.

SK17 OEU

GB.

Tel: +44 (0)1298 84606

Fax: +44 (0)1298 84722

email: [email protected]

Belle Poland sp. z.o.o.

96-200 Rawa Mazowiecka

Ul. Mszczonowska 36,

Polska

Tel: +48 (0) 46 8144091

Fax: +48 (0) 46 8144700

Belle Group Portugal

Rua Laura Alves, 225, 2° F

2775-116 Parede

Portugal

Tel: +35 1 (21) 453 59 91

Fax: +35 1 (21) 453 59 91

Belle Group Netherlands

Tel: 0800 249861

Belle Group Belguim

Tel: 0800 80295

Belle Group Austria

Tel: 0800 291544

Belle Group Russia

64 Nevsky pr.

St, Petersburg

Russia

Tel : +7(812)314-81-34

Moscow : +7(495)589-64-32

Belle Group South East Asia

21, Jalan Ara AD 7/3B,

Pandar Sri Damansara

S2200 Kuala Lumpar, Malaysia

Tel: +60 (0) 3 62721678

+60 (0) 3 6272 9308

Fax: +60 (0) 3 6272 9528

www.BelleGroup.com

www.Altrad.com

COMPACTING... MIXING... CONCRETING... CUTTING... BREAKING... MOVING

No.1 for Light Construction Equipment

Table of contents

Other Belle Group Power Tools manuals

Popular Power Tools manuals by other brands

Metabo HPT

Metabo HPT KM 12VC Safety instructions and instruction manual

Stihl

Stihl BG-KM instruction manual

Beta

Beta BETA 599DGT-AN 10 Operation manual and instructions

Hitachi

Hitachi H 60MR Handling instructions

PEUGEOT

PEUGEOT ENERGYGrind 100A instruction manual

Powerfix Profi

Powerfix Profi Z29621 Operation and safety notes