2

Signed by: Managing Director - On behalf of BELLE GROUP (SHEEN) UK.

Signature: Le Directeur Général - Pour le compte de la SOCIETE BELLE GROUP (SHEEN) UK.

Medido por: Director Gerente - En nombre de BELLE GROUP (SHEEN) UK.

Assinado por: Director-Geral - Em nome de BELLE GROUP (SHEEN) UK.

Getekend door: Algemeen Directeur - Namens BELLE GROUP (SHEEN) UK.

Uunderskrevetaf: Administrerende direktør – På vegne af BELLE GROUP (SHEEN) UK.

unterzeichnet vo: Generaldirektor – Im auftrag von BELLE GROUP (SHEEN) UK.

Firmato da: Amministratore Delegato – Per conto di BELLE GROUP (SHEEN) UK.

Undertecknat: V.D. – På vägnar av BELLE GROUP (SHEEN) UK.

852/10004/2

Ray Neilson

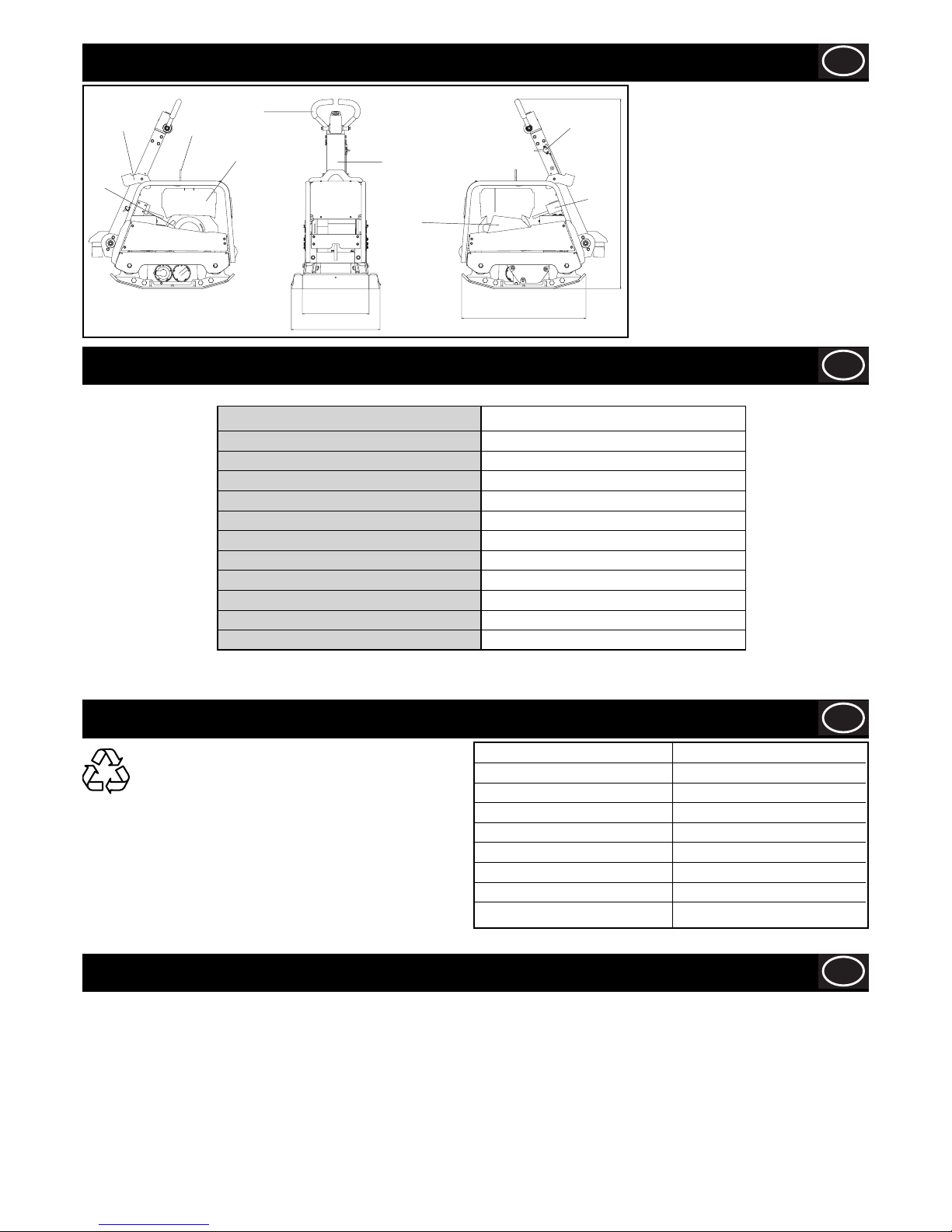

PRODUCT TYPE ..................

MODEL .................................

SERIAL No............................

DATE OF MANUFACTURE...

SOUND POWER LEVEL.......

MEASURED

(GUARANTEED):

TYPE DE PRODUIT ..............

MODELE................................

N° DE SERIE ........................

DATE DE FABRICATION.......

NIVEAU DE ..........................

PUISSANCE SONORE

MESUREE (GARANTIE)

TIPO DE PRODUCTO ............

MODELO ................................

Nº DE SERIE ..........................

FECHA DE FABRICACIÓN....

NIVEL DE ...............................

POTENCIA ACÚSTICA

MEDIDO (GARANTIZADO)

TIPO DE PRODUTO: ...........

MODELO:.............................

NO. DE SÉRIE: ....................

DATA DE FABRIC................

NIVEL DE .............................

POTÊNCIA DE SOM

MEDIDO (GARANTIDO)

PRODUCTTYPE.....................

MODEL ..................................

SERIENUMMER ....................

FABRICAGEDATUM .............

GEMETEN ..............................

GELUIDSSTERKTENIVEAU

(GEGARANDEERD)

We, Belle Group Sheen UK, Sheen, Nr. Buxton, Derbyshire, SK17 0EU, GB, hereby certify that if the product described within this certificate is bought from an authorised Belle Group dealer

within the EEC, it conforms to the following EEC directives: 98/37/EC (This directive is a consolidation of the original machinery directive 89/392/EEC), Electromagnetic Compatability Directive

89/336/EEC (as amended by 92/31/EEC & 93/68 EEC). The low voltage directive 73/23/EEC, EN 292 Safety of machinery and associated harmonised standards, where applicable. Noise emissions

conform to directive 2000/14/EC Annex VI, the notified body being AV Technology Limited, AVTECH house, Birdhall Lane, Cheadle Heath, Stockport, Cheshire, SK3 0XU, GB.

O signatário, Belle Group Sheen UK, Sheen, Nr Buxton, Derbyshire, SK 0EU, GB, pelo presente, declara que se o produto descrito neste certificado foi adquirido a um distribuidor autorizado do

Belle Group em qualquer país da UE, está em conformidade com o estabelecido nas seguintes directivas comunitárias: 98/37/EC (esta directiva é uma consolidação da directiva de maquinaria

original 89/392/EEC), Directiva de Compatibilidade Electromagnética 89/336/EEC (conforme corrigido pelas 92/31/EEC & 93/68 EEC). A directiva de baixa voltagem 73/23/EEC, EN 292 Segurança

da maquinaria e às normas harmonizadas afins se aplicáveis. As emissões acústicas estão em conformidade com a directiva 2000/14/EC Anexo VI, sendo o organismo notificador a AV Technology

Limited, AVTECH house, Birdhall Lane, Cheadle Heath, Stockport, Cheshire, SK3 0XU, GB.

Ondergetekende, Belle Group Sheen UK, Sheen, Nr. Buxton, Derbyshire, SK17 OEU, GB,verklaren hierbij dat als het product zoals beschreven in dit certificaat is gekocht van een erkende Belle

Group dealer binnen de EEG, het voldoet aan de volgende EEG richtlijnen: 98/37/EC (Deze richtlijn is een opvolger van de orginele Machinerichtlijn 89/392/EEG), Electromagnetische Compatability

Richtlijn 89/336/EEG ( geamendeerd door 92/31/EEG & 93/68 EEG). De Laagspannings Richtlijn 72/23/EEG, EN 292 Veiligheid van Machines en hieraan gekoppelde geharmoniseerde

Standaarden, waar deze van toepassing is. Geluidsemissies volgens richtlijn 2000/14/EC Bijlage Vl. Het contactorgaan is AV Technology Limited, AVTECH house, Birdhall Lane, Cheadle Heath,

Stockport, Cheshire, SK3 OXU, GB

La Sociedad, Belle Group Sheen UK, Sheen, Nr. Buxton, Derbyshire, SK 17 OEU, GB, por el presente documento certifica que si el producto descrito en este certificado es comprado a un

distribuidor autorizado de Belle Group en la CEE, este es conforme a las siguientes directivas: 98/37/CE de la CEE (Esta directiva consolida la directiva inicial sobre maquinaria 89/392/CEE),

Directiva 89/336 CEE sobre Compatibilidad Electromagnética (según enmiendas 92/31/CEE y 93/68 CEE), Directiva sobre Bajo Voltaje 73/23/CEE, EN 292 de Seguridad de Maquinaria y Niveles

armonizados estándares asociados donde sean aplicables. Emisiones Acústicas conformes a la Directiva 2000/14/EC Apéndice VI, siendo notificado el organismo AV Technology Limited, AVTECH

House, Birdhall Lane, Cheadle Heath, Stockport, Cheshire, SK3 OXU, GB.

Nous soussignons, Belle Group Sheen UK, Sheen, Nr Buxton, Derbyshire, SK17 0EU, GB, certifions que si le produit décrit dans ce certificat est acheté chez un distributeur autorisé Belle Group

au sein de la CEE, il est conforme aux normes CEE ci-après: 98/37/CE (Cette norme est une codification des normes de la machine d'origine 89/392/CEE), Norme compatible pour

l'électromagnisme 89/336/CEE (modifié par 92/31/CEE et 93/68/CEE). Caractéristiques basse tension 73/23/CEE, EN 292, Norme de sécurité des machines et des critères associés et configurés,

si applicable. Niveau sonnore conforme à la norme 2000/14/CE Annex VI, l'état avisé étant

AV Technology Mimited, AVTECH House, Birhall Lane, Cheadle Heath, Stockport, Cheshire, SK3 0XU, GB.

EC DECLARATION OF CONFORMITY / DECLARATION CE DE CONFORMITE / DECLARACIÓN DE

CONFORMIDAD CE / DECLARAÇÃO CE DE CONFORMIDADE / EG-VERKLARING VAN

OVEREENSTEMMING / EF OVERENSSTEMMELSESERKLÆRING /

EGKONFORMITÄTSERKLÄRUNG / DICHIARAZIONE CE DI CONFORMITÁ / EG-VERKLARING VAN

OVEREENSTEMMING / EC SAMSVARSERKLÆRING / EY-YHDENMUKAISUUSILMOITUS

Vi, Belle Group Sheen UK, Sheen, Nr. Buxton, Derbyshire, SK17 0EU, GB, erklærer hermed, at hvis det i dette certifikat beskrevne produkt er købt hos en autoriseret Belle Group forhandler i EU, er

det i overensstemmelse med følgende EØF-direktiver: 98/37/EF, 73/23/EØF (som ændret ved 93/68/EØF), 89/336/EØF (som ændret ved 92/31/EØF), 93/68/EØF og tilknyttede, harmoniserede

standarder, hvor relevant. Støjemissioner er i overensstemmelse med direktiv 2000/14/EF, Bilag VI, og det bemyndigede organ er AV Technology Limited, AVTECH House, Birdhall Lane, Cheadle

Heath, Stockport, Cheshire, SK3 0XU, GB.

Wir, Belle Group Sheen UK, Sheen, Nr. Buxton, Derbyshire, SK17 0EU, Großbritannien, bestätigen hiermit, dass das in diesem Zertifikat beschriebene Produkt, wenn es von einem autorisierten

Belle Group Händler innerhalb der europäischen Gemeinschaft gekauft wurde, folgenden EG-Richtlinien entspricht: 98/37/EG, 73/23/EG (geändert durch 93/68/EG), 89/336/EG (geändert durch

92/31/EG), 93/68/EG und, wenn zutreffend, den harmonisierten Normen. Die Geräuschemissionen entsprechen der Richtlinie 2000/14/EG Anhang VI - für die Bestätigung zuständig ist AV

Technology Limited, AVTECH House, Birdhall Lane, Cheadle Heath, Stockport, Cheshire, SK3 0XU, Großbritannien.

Il Gruppo Belle Sheen UK, Sheen, Nr. Buxton, Derbyshire, SK17 0EU, GB, certifica che il prodotto descritto nel presente certificato è acquistato da un concessionario autorizzato del gruppo Belle

nell'ambito CEE e che è pienamente conforme alle seguenti direttive CEE: 98/37/EC, 73/23/EEC (emendamento 93/68/CEE), 89/336/EEC (emendamento 92/31/CEE), 93/68/CEE e relativi standard

armonizzati. Emissioni acustiche conformi alla direttiva 2000/14/EC Allegato VI con relativa notifica all'ente AV Technology Limited, AVTECH house, Birdhall Lane, Cheadle Heath, Stockport,

Cheshire, SK3 0XU, GB.

Undertecknade, Belle Group Sheen UK, Sheen, Nr Buxton, Derbyshire, SK17 0EU, Storbritannien, intygar härmed att en produkt beskriven i detta certifikat som köps från en godkänd Belle Group

återförsäljare inom EU stämmer överens med följande EG-direktiv: 98/37/EG, 73/23/EG (ändrat genom 93/68/EEC), 89/336/EG (ändrat genom 92/31/EG), 93/68/EG och tillhörande harmoniserade

standarder i tillämpliga fall. Bullernivåerna överensstämmer med direktiv 2000/14/EG Bilaga VI, och anmälningsorgan är AV Technology Limited, AVTECH house, Birdhall Lane, Cheadle Heath,

Stockport, Cheshire, SK3 0XU, Storbritannien.

Vi, Belle Group Sheen UK, Sheen, Nr Buxton, Derbyshire, SK17 0EU, GB, bekrefter med dette at det produktet som står beskrevet i denne erklæringen er kjøpt fra en autorisert Belle Group

forhandler innen EØF, og at det oppfyller følgende direktiver: 98/37/CE dette direktivet er et sammendrag av det opprinnelige maskindirektivet 89/392/EØF), Det elektromagnetisk

kompatabiltets-direktivet 89/336/EØF (som endret av 92/31/EØF og 93/68/EØF). Lavspenningsdirektivet 73/23/EØF, EN 292, Sikkerhet til maskineri og tilhørende harmoniserte standarder, hvor

atuelt. Støynivået oppfyller kravene til direktiv 2000/14/EC, Tillegg VI, aktuelt organ er

AV Technology Limited, AVTECH House, Birhall Lane, Cheadle Heath, Stockport, Cheshire, SK3 0XU, GB.

NO

Me, Belle Group Sheen UK, Sheen, Nr. Buxton, Derbyshire, SK17 0EU, GB, ilmoitamme täten, että jos tässä todistuksessa kuvattu tuote on ostettu valtuutetulta Belle Groupin myyjältä ETY:n

alueella, se on yhdenmukainen seuraavien ETY-direktiivien kanssa: 98(37/EY (Tämä direktiivi on yhdistelmä alkuperäisestä konedirektiivistä 89/392/ETY, sähkömagneettisen yhteensopivuuden

direktiivistä 89/336/ETY, korjauksineen 92/31/ETY ja 93/68/ETY), matalajännitedirektiivistä 73/23/ETY, koneturvallisuusstandardista EN 292 ja siihen liittyvistä yhdenmukaistetuista standardeista,

tapauksen mukaan. Melupäästöt ovat yhdenmukaisia direktiivin 2000/14/EY liitteen VI kanssa, asianomaisen elimen ollessa AV Technology Limited, AVTECH House, Birdhall Lane, Cheadle

Heath, Stockport, Cheshire, SK3 0XU, GB.

SF

PRODUKTTYPE..................

MODEL ...............................

SERIENR. ...........................

FREMSTILLINGSDATO......

LYDEFFEKTNIVEAU .........

MÅLT (GARANTERET)

PRODUKTTYP ..........................

MODELL....................................

SERIENNR.................................

HERSTELLUNGSDATU............

SCHALLLEISTUNGSPEGEL ...

GEMESSEN (GARANTIERT)

TIPO PRODOTTO......................

MODELLO.................................

SERIE N° ..................................

DATA DI FABBRICAZIONE......

LIVELLO....................................

POTENZA SONORA

MISURATA (GARANTITA)

PRODUKTTYP ..........................

MODELL....................................

SERIENR. .................................

TILLVERKNINGSDATUM.........

LJUDSTYRKA...........................

UPPMÄTT

(GARANTERAD)

PRODUKTTYPE........................

MODELL....................................

SERIENR ..................................

PRODUKSJONSDATO.............

LYDKRAFTNIVÅ........................

MÅLT (GARANTERT)

TUOTETYYPPI....................

MALLI..................................

VALMISTUSNRO................

VALMISTUSPÄIVÄ.............

ÄÄNENVOIMAKKUUDEN

TASO...................

MITATTU (TAATTU)