Henan Master Machinery Co., Ltd

Tel:(+86)17737606271 www.mastermachinerys.com

◎Avoid operation errors.

Focus on operation, and pay attention to bystanders.

◎Be careful of bystanders and barriers when forward and back

the machine.

◎Repair the machine at once when meeting shortcomings.

◎Attentions to park the machine.

The machine should be parked on level surface. If must be parked

on slope, block should be put in the front of drum.

Push the forward and back control lever to middle position, and

push the lock lever to lock position, then turn off the engine, and

pull out the key.

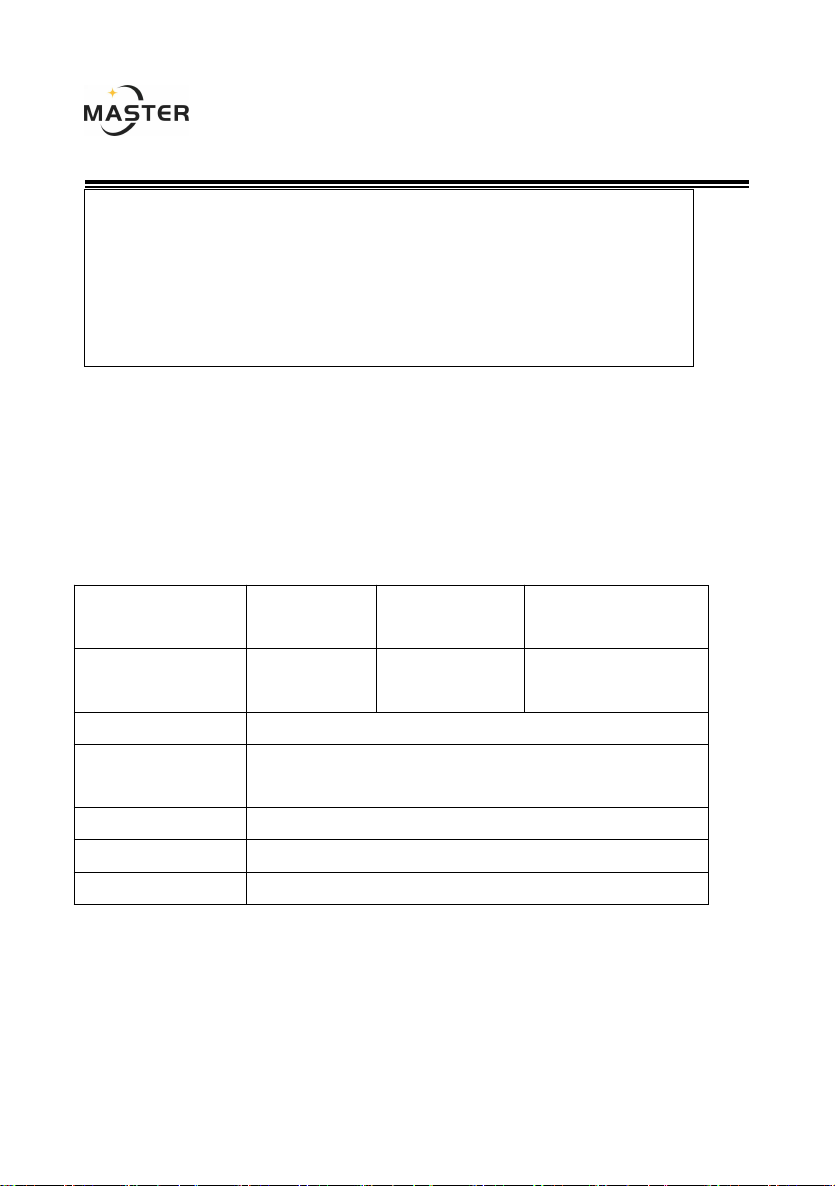

4.6 Attention of loading and unloading the machine

◎Use the hard climbing board with appropriate width, length

and thickness for safe loading and unloading

◎Don’t use redirector on the climbing board.

◎Use the rope with the adequate strength to lifting the machine

◎Please vertical lifting the machine

◎After loading, the machine firmly fixed. Then inset the block

under the double side of drums

4.7 The correct usage of the battery (note: For the battery needing to

maintain, maintenance-free except)

◎The battery will produce flammable gas, may cause an

explosion. Do not smoke around the battery, so that the battery can be

far away from fire, sparks and fire

Battery electrolyte contains sulfuric acid; it will destroy the clothing

and skin. If it exposed to clothes and skin, rinse with plenty of