Benchmark PRE420 User manual

Benchmark PRE420

Instruction Manual

4-Channel Microphone Preamplifier/Mixer

Safety Information

Voltage Selection

CAUTION: THE FUSE DRAWER INCLUDES

A VOLTAGE SELECTION SWITCH WITH

TWO SETTINGS: “110” AND “220”.

CHECK TO SEE THAT IT IS PROPERLY

CONFIGURED FOR YOUR LOCATION

BEFORE CONNECTING AC POWER.

Incorrect configuration may blow fuses or

cause erratic operation.

Repairs

CAUTION: DO NOT SERVICE OR REPAIR

THIS PRODUCT UNLESS PROPERLY

QUALIFIED. ONLY A QUALIFIED

TECHNICIAN SHOULD PERFORM

REPAIRS.

Fuses

CAUTION: FOR CONTINUED FIRE

HA ARD PROTECTION ALWAYS REPLACE

THE FUSES WITH THE CORRECT SI E

AND TYPE (0.5A 250 V SLO-BLO

®

5 X 20

MM – LITTELFUSE® HXP218.500 OR

EQUIVALENT).

Modifications

CAUTION: DO NOT SUBSTITUTE PARTS

OR MAKE ANY MODIFICATIONS

WITHOUT THE WRITTEN APPROVAL OF

BENCHMARK MEDIA SYSTEMS, INC.

MODIFICATION MAY CREATE SAFETY

HA ARDS AND VOID THE WARRANTY.

NOTICE: CHANGES OR MODIFICATIONS

NOT EXPRESSLY APPROVED BY

BENCHMARK MEDIA SYSTEMS COULD

VOID THE USER'S AUTHORITY TO

OPERATE THE EQUIPMENT UNDER FCC

REGULATIONS.

Contents

Safety Information

Voltage Selection 2

Repairs 2

Fuses 2

Modifications 2

Contents 3

Overview 4

Features 6

Connections 7

Microphone Inputs (1 4) 7

Balanced Outputs – Overview 7

Driving Unbalanced Loads 8

Output Signal Levels 8

Direct Outputs (1 4) 8

Control Room Outputs (L&R) 8

Main Outputs (L&R) 8

AC Power Entry Connector 8

Fuse Holder 8

Preamp Section 9

Preamp Overview 9

Input Topology 9

Microphone Gain Controls 9

Blocking RF, EMI, and Noise 9

Phantom Power Switches 9

Input Protection 9

MirrorPan™ Pan Controls 11

20 dB Pads 11

Terminating Unused Inputs 11

40 Hz High Pass Filters 11

LED Meters – Direct Outputs 11

Solo Bus 1

Solo Switches 12

Stereo/Mono Solo Switch 12

Control Room Outputs 13

Control Room Mute Switch 13

Driving Unbalanced Loads 13

Monitor Fader 13

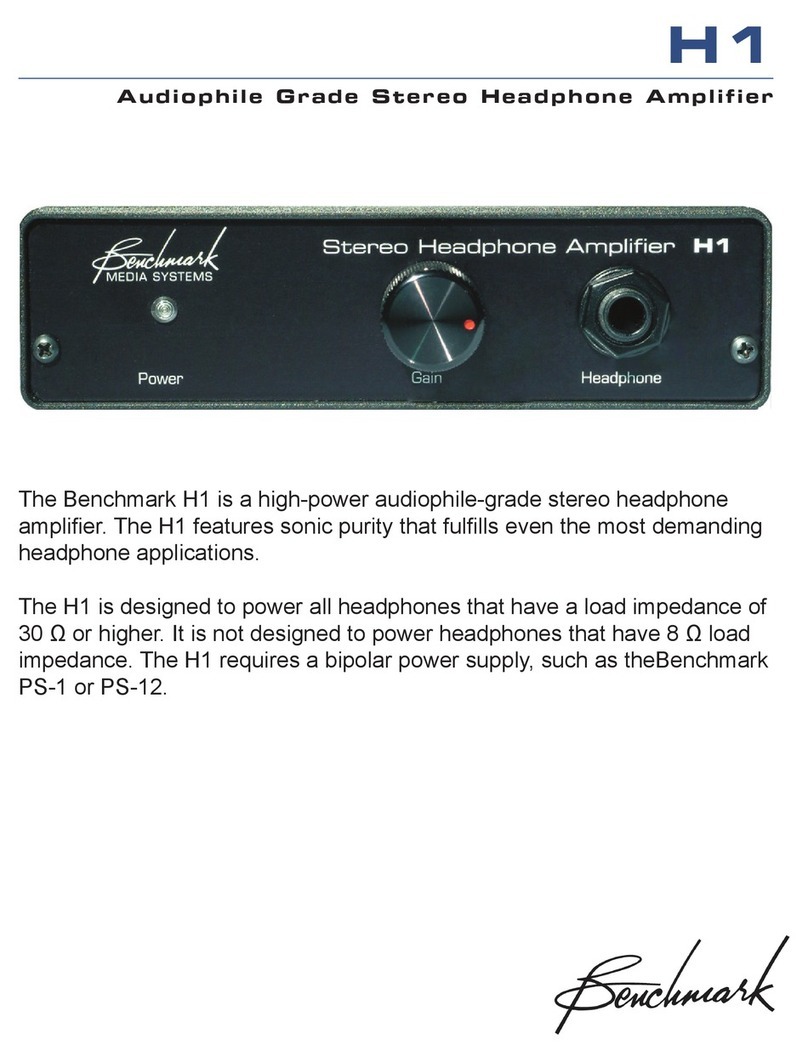

HPA ™ Headphone Output 14

“0 Ohm” Output Impedance 14

Headphone Performance 14

Mix Outputs 15

Driving Unbalanced Loads 15

Main Fader 15

LED Meters – Mix Outputs 15

Rack Mounting 16

Mounting Near Other Equipment 16

Performance Graphs 17

Frequency Response 17

High Pass Filter Frequency Response 18

Inter Channel Phase Response 19

THD+N vs. Frequency 20

Wideband THD+N vs. Frequency 21

Equivalent Input Noise vs. Gain 22

Noise Spectrum 23

THD Spectrum at 1 KHz 24

THD Spectrum at 10 KHz 25

Specifications 6

Microphone Preamps 26

Direct Outputs 27

Control Room and Main Outputs 27

MirrorPan™ Constant Power Pan Circuit 28

HPA2™ Headphone Amplifier 28

LED Status Indicators and Meters 29

AC Power Requirements 29

Dimensions 30

Weight 30

Regulatory Compliance 31

FCC Notice 31

RoHS Compliant Information 31

CE Certificate of Conformity 32

Warranty Information 33

Benchmark Extended Warranty 34

Calibration 35

Required Equipment 35

+48V Adjustment 35

Microphone Gain and Metering 35

Monitor Gain Balance 35

Microphone Pan Balance 35

Main Gain Balance 36

Peak LED Adjust – Main Outputs 36

PRE420 Instruction Manual – rev. E Page 4

Overview

The PRE420 is a 4 channel microphone

preamplifier/mixer and is designed to achieve

the highest performance available in a

microphone preamplifier. The PRE420 is

designed for maximum transparency, wide

bandwidth, low noise, low distortion, and

superior RF immunity. It is well suited for the

most demanding applications in studios and

live venues.

The PRE420 is the next evolution of

Benchmark’s legendary MPS 420 microphone

preamplifier. We have improved the

performance while adding meters, a mix bus,

a solo bus, and an internal power supply. The

added features do not compromise the

performance of the classic Benchmark design.

In all respects, the PRE420 meets or exceeds

the performance of the MPS series preamps.

The PRE420 features an astonishingly low

noise stereo mix bus driven by Benchmark's

proprietary MirrorPan™ circuitry to achieve

precise, distortion free, constant power

panning. The mix bus allows pristine direct

to stereo recording from up to 4

microphones. The balanced stereo outputs

are equipped with meters and a master level

control.

A solo bus allows monitoring of individual

microphones as well as any stereo or mono

mix of microphones. The solo bus is routed

to the balanced control room outputs and to

the headphone amplifier. The control room

outputs have a switch that enables mute on

headphone insertion.

The PRE420 includes the HPA2™

Benchmark's signature high current, 0 Ohm

headphone amplifier. The HPA2™ is capable

of delivering the full performance of the

PRE420 into the difficult loading presented by

many headphones.

Each of the PRE420's four microphone inputs

includes switches for +48V Phantom power, a

20dB pad, and a 40Hz high pass filter. The

PRE420 achieves outstanding performance

over a wide range of input levels. Gain is

controlled by matched 41 detent pots and is

adjustable over a range of 22dB to 60dB

(without pad), or 2dB to 40dB (with pad

enabled). The mix bus can provide an

additional gain of up to 6 dB.

The PRE420 has four direct outputs, two

control room outputs, and two stereo outputs.

All outputs feature low distortion, high

current drivers that easily handle long cables

and other less than ideal loads.

A rugged 1 RU enclosure includes an internal

power supply that supports all international

voltages and has generous margins for over

voltage and under voltage conditions. It

features a core banded toroidal transformer

in a shielded enclosure.

The entire signal path of the PRE420 has a

generously wide bandwidth: 500 kHz. This

creates a significant demand for exceptional

RF filtering and shielding – a demand

Benchmark fulfills.

All signal paths in the PRE420 are

aggressively protected from RF and magnetic

interference. For example, a special

construction technique is employed with the

multi layer printed circuit board to create a 3

PRE420 Instruction Manual – rev. E Page 5

dimensional shield surrounding the

microphone level signal traces to block RF

interference. Also, the microphone level

traces are arranged in a star quad layout to

prevent magnetic interference. Benchmark's

innovative shielding and filtering techniques

have given Benchmark microphone preamps

a proven track record for exceptional

performance in difficult, RF intensive

locations.

This RF immunity is coupled with ultra low

distortion performance at high frequencies,

beyond that of most mic preamps, giving

your audio remarkable realism. With an

amazingly low THD+N of 0.00024% (see

specs), we encourage you to compare the

PRE420's performance specifications and

sonic performance with any other mic

preamp.

Microphone pre amplifier circuits usually

suffer from non linear performance at ultra

sonic frequencies. This non linearity causes

inter modulation distortion (IMD) components

that fold down to audible frequencies. Unlike

harmonic distortion (THD), IMD produces

distortion tones that are very un natural and

non musical. IMD also masks and alters the

subtle details of delicate high frequency

transients such as those produced by bells.

Benchmark MPS series preamps have always

had outstanding high frequency performance

as well as freedom from IMD. The PRE420

takes the Benchmark design one step further,

and achieves the lowest IMD that we have

ever measured in a microphone preamplifier.

We believe that you will enjoy the sonic

performance and features of the PRE420.

PRE420 Instruction Manual – rev. E Page 6

eatures

• Four Transformerless Microphone Inputs

• Four Balanced Direct Outputs (XLR)

• Balanced Left and Right Main Outputs (XLR)

• Balanced Left and Right Control Room Outputs (XLR)

• HPA2™ “0 Ohm” 1/4” TRS Headphone Output

• Precision Matched Monolithic Low Noise Transistor Quads on Each Microphone Input

• High Current High Speed Low Capacitance Phantom Protection Circuits

• Fully Protected Against Phantom Hot Plug and Cable Shorting Scenarios

• Balanced Transformerless Inputs and Outputs

• +48v Phantom Power Switch on Every Microphone Input

• 40 Hz High Pass Filter Switch on Every Microphone Input (12 dB/octave)

• 20 dB Pad Switch on Every Microphone Input

• Matched 41 Detent First Stage Gain Controls on Every Microphone Input

• 60 dB Maximum First Stage Gain, Adjustable to 70 dB

• 22 to 60 dB Gain (pad off), 2 to 40 dB (pad on)

• +27 dBu Maximum Input Level (with pad), +7 dBu (without pad)

• +29.5 dBu Maximum Output Level on all Balanced Outputs

• + 23.5 dBu Maximum Headphone Output Level

• MirrorPan™ Low Distortion Constant Power Pan Controls (1 per input channel)

• Solo Switches (1 per input channel)

• Mono/Stereo Solo Switch for Flexible Monitoring

• 41 Detent Control Room/Headphone Level Control

• 41 Detent Main Output Level Control

• Control Room “Mute on Headphone Insertion” Mode Switch (rear panel)

• Intensity Modulated Signal Presence LEDs (Green 4 on direct outputs plus 2 on main outputs)

• +24 dBu Warning LED (Red – 4 on direct outputs plus 2 on main outputs)

• Solo Warning LED (Yellow)

• +48V Phantom Warning Indicators (Yellow 1 per input channel)

• Power LED (Blue)

• Ultra Quiet Linear Power Supply with Rear Panel Input Voltage Selector

• Complies with FCC and CE Regulations

• RoHS Compliant

PRE420 Instruction Manual – rev. E Page 7

Connections

Microphone Inputs (1-4)

The balanced transformerless microphone

inputs use locking Neutrik™ gold pin female

XLR jacks with both pin 1 (Ground) and the

XLR shell directly bonded to the chassis. This

direct bonding is important for maximum RF

shielding and for immunity to hum due to

shield currents.

• XLR pin 2 = + Audio In

• XLR pin 3 = Audio In

• XLR pin 1 = Cable Shield – bonded to

chassis

• XLR shell – bonded to chassis

The microphone inputs have a wide operating

range. With the pad enabled, maximum input

level is +28 dBu. With the pad off, maximum

input level is +8 dBu.

All inputs are equipped with +48V phantom

power, and each input has its own phantom

power switch. Under certain circumstances,

phantom power can cause large voltage

transients. The PRE420 is equipped with

high current input protection circuits that

protect the sensitive low noise input

transistors from the worst case phantom

induced transients. Large transients are

produced when a microphone is connected or

disconnected while phantom power is on. The

worst possible transients occur when a

microphone cable has an intermittent short to

ground from either pin 2 or pin 3. The

PRE420 is very well protected against both of

the above. For the protection of your

microphones (and your ears), we strongly

recommend shutting off phantom power

several seconds before connecting or

disconnecting a microphone.

The first generation of PRE420’s (with five

digit serial numbers) featured a common

mode choke for RF immunity. These choke

filters were designed for balanced microphone

or balanced line level inputs. When using the

PRE420 with unbalanced sources, the user

should insert the internal jumpers that bypass

the choke (J5 J12). The frequency response

of the PRE420’s is 500 kHz, but the choke will

limit the frequency response of an un

balanced input to 26 kHz if the choke is not

bypassed. This difference is because of the

nature of common mode chokes. RF

interference signals tend to be common mode

signals, and the choke filter has excellent

common mode rejection at ultrasonic and RF

frequencies. The common mode rejection of

the choke filter is 60 dB at 1 MHz.

The second generation (with eight or nine

digit serial numbers) features a new RF and

EMI filtering mechanism (the same used in

the Benchmark MPA1 microphone

preamplifier). The RF performance of the

second generation is nearly identical to the

first generation PRE420, with the added

advantage that the new design is compatible

with unbalanced sources without the need to

use jumpers. The newer design works

equally with balanced and unbalanced

sources. It features star quad signal

distribution between the microphone input

jacks and the preamplifier circuit. This star

quad signal path is immune to magnetic

interference that may be caused by adjacent

equipment in a tightly packed rack.

Balanced Outputs ---- Overview

The PRE420 has 8 balanced outputs including

four direct outputs, two control room outputs,

and two main outputs. All outputs use gold

PRE420 Instruction Manual – rev. E Page 8

pin Neutrik™ male XLR connectors with direct

chassis bonding of both pin 1 and the

connector shell. This direct bonding is

important for maximum RF shielding and for

immunity to hum due to shield currents.

All outputs are transformerless and have an

impedance of 60 Ohms balanced or 30 Ohms

unbalanced. All outputs are equipped with

high performance drivers that can drive high

signal levels into load impedances as low as

300 Ohms without an increase in distortion.

These outputs are well suited for driving long

lines.

• XLR pin 2 = + Audio Out

• XLR pin 3 = Audio Out

• XLR pin 1 = Cable Shield – bonded to

chassis

• XLR shell – bonded to chassis

Driving Unbalanced Loads

Special cables are required for driving

unbalanced loads:

• Connect XLR pin 2 to audio in

• Connect XLR pin 1 to shield

• Make no connection to XLR pin 3 – this pin

must be left floating when driving

unbalanced loads

Output Signal Levels

The maximum output level on all balanced

outputs is 29.5 dBu. The four direct outputs

and the two main outputs are equipped with

two segment LED meters. The green LED

shows signal presence with varying intensity

based on signal level over a range of 8 dBu

to +24 dBu. The green LED reaches half

brightness at an output level of about +4

dBu, and is near full brightness at +24 dBu.

The red LED is factory preset to illuminate at

an output level of precisely +24 dBu, but may

be adjusted to other levels between 20 dBu

and 29 dBu. The red LED is driven by a peak

detection and stretching circuit so that very

short transients can be observed. The red

LED is a warning indicator; it is not a clip

indicator.

Direct Outputs (1-4)

Each microphone preamp has its own direct

output. Each output has a dual segment LED

meter.

Control Room Outputs (L&R)

The solo bus is routed post fader to the

Control Room Outputs. A rear panel switch

allows these outputs to mute upon headphone

insertion if desired.

Main Outputs (L&R)

The mix bus is routed post fader to the main

outputs. Both outputs have a dual segment

LED meter.

AC Power Entry Connector

The AC power input uses a standard IEC type

connector and includes a power switch.

Factory configured 110V units ship with a

power cord. 220V units ship without a power

cord, as they are location specific and may be

purchased from a local source.

Fuse Holder

The fuse holder is built into a drawer next to

the IEC power connector. The drawer requires

two 5 x 20 mm 250 V Slo Blo

®

Type fuses.

The drawer includes a voltage selection switch

with two settings: “110” and “220”. Both

settings use a 0.5 Amp fuse.

The AC input has a very wide input voltage

range and can operate over a frequency

range of 50 to 60 Hz. At the “110” setting,

the PRE420 will operate normally over a

range of 105 to 140 VAC. At the “220”

setting, the PRE420 will operate normally

over a range of 200 to 285 VAC.

CAUTION: FOR CONTINUED FIRE

HA ARD PROTECTION ALWAYS REPLACE

THE FUSES WITH THE CORRECT SI E

AND TYPE (0.5A 250 V SLO-BLO

®

5 X 20

MM – LITTELFUSE® HXP218.500 OR

EQUIVALENT).

PRE420 Instruction Manual – rev. E Page 9

Preamp Section

Preamp Overview

Each preamp channel includes switches for

phantom power, a 20 dB pad, and a 40 Hz

high pass filter. Each channel also has a

center detent MirrorPan™ control, a 41

detent gain control, a Phantom warning LED,

and a 2 segment output level meter. Inputs

are fully protected against overloads and

phantom power transients.

Input Topology

The first gain stage on each microphone input

is built around precision matched monolithic

low noise transistor quads. Bandwidth is 500

kHz, IMD and THD are virtually non existent.

The PRE420 is designed to achieve faithful

and transparent microphone amplification.

Microphone Gain Controls

These controls are a 41 detent pots that

accurately set the first stage gain of each

preamplifier. These controls are calibrated for

precise minimum and maximum gain. This

calibration provides accurate channel to

channel matching, and allows precise control

of stereo microphone pairs.

Maximum gain is calibrated for exactly 60 dB,

but may be adjusted to any value between 50

and 70 dB using the calibration procedure in

this manual. Minimum gain is 22 dB without

the pad, and 2 dB with the pad enabled.

TIP: ENGAGE THE PAD ON ANY UNUSED

INPUT AND TURN THE MICROPHONE

GAIN CONTROL TO MINIMUM TO REDUCE

NOISE AT THE MIXER OUTPUTS.

Blocking RF, EMI, and Noise

The entire signal path of the PRE420 has a

generously wide bandwidth: 500 kHz. This

creates a significant demand for exceptional

RF filtering and shielding – a demand

Benchmark fulfills.

All signal paths in the PRE420 are

aggressively protected from RF and EMI

(electro magnetic interference). For example,

the multi layer printed circuit board uses a

special construction technique that creates a

3 dimensional shield surrounding each mic

level signal trace to block RF interference.

Star quad trace layouts prevent magnetic

interference. Benchmark's innovative

shielding and filtering techniques have given

Benchmark mic preamps a proven track

record for exceptional performance even in

the most difficult environments.

Common mode signals in the audio band are

removed with a precisely trimmed differential

amplifier. The PRE420 even includes a

subsonic common mode trim adjustment on

each microphone input that eliminates

sensitivity to +48V ripple caused by power

supply noise and/or the loading of

microphone electronics.

Phantom Power Switches

• In = Phantom On

• Out = Phantom Off

Each channel has a +48V warning LED that

will illuminate when +48V is present on the

microphone inputs.

CAUTION: ALWAYS TURN OFF PHANTOM

POWER AND WAIT FOR THE +48V LED TO

GO OUT BEFORE CONNECTING OR

DISCONNECTING MICROPHONES.

Input Protection

Under certain circumstances, phantom power

can cause large voltage transients. The

PRE420 is equipped with high speed high

PRE420 Instruction Manual – rev. E Page 10

current low capacitance input protection

circuits that protect the sensitive low noise

input transistors from the worst case

phantom induced transients.

Large transients are produced when a

microphone is connected or disconnected

while phantom power is on. The worst

possible transients occur when a microphone

cable has an intermittent short to ground

from either pin 2 or pin 3. The PRE420 is

very well protected against both of the above.

For the protection of your microphones (and

your ears), we strongly recommend shutting

off phantom power several seconds before

connecting or disconnecting a microphone.

PRE420 Instruction Manual – rev. E Page 11

MirrorPan™ Pan Controls

The PRE420 incorporates Benchmark’s new

MirrorPan™ constant power pan control. The

advantages of MirrorPan™ include:

• Accurate 3 dB constant power pan law

• Accurate balance at center detent

• Excellent channel separation when fully

panned

• Ultra low distortion

• Ultra low noise

Benchmark’s MirrorPan circuit eliminates the

distortion and pan law errors caused by pan

pot wiper current. The center detent is

precisely calibrated for an accurate center

pan, and channel separation is excellent when

fully panned.

0 dB Pads

• In = Pad Enabled

• Out = Pad Off

The 20 dB Pad allows the connection of line

level signals as high as 27 dBu. Without the

pad, the maximum input level is 7 dBu. The

input impedance of the PRE420 is 1.37k

Ohms with the pad enabled and 8.13k Ohms

when the pad is off. The pad is constructed

from two 750 Ohm series resistors plus one

150 Ohm shunt resistor.

Terminating Unused Inputs

The pad should be used to apply a 150 Ohm

termination to an unused microphone input.

Microphone preamplifiers will amplify the

Johnson noise from the source resistance

connected to the input. Most microphones

have a source resistance of about 150 Ohms.

But, an un terminated preamplifier sees only

its own input impedance. The input

impedance of the PRE420 is 8.13k Ohms.

The Johnson noise of a 150 Ohm resistor is

130.8 dBu while the Johnson noise from an

8.13k Ohm resistor is 113.5 dBu. An un

terminated microphone input will be about 17

dB noisier than an input that is properly

terminated.

The 20dB pad applies a 150 Ohm resistor

across the inputs of the preamplifier.

Engaging the pad on an unused input

terminates the preamplifier with

approximately the same resistance as a

typical microphone, and drops the EIN of the

preamplifier to its specified value. If a

microphone is not connected, engage the pad

to terminate the input.

TIP: ENGAGE THE PAD ON ANY UNUSED

INPUT AND TURN THE MICROPHONE

GAIN CONTROL TO MINIMUM TO REDUCE

NOISE AT THE MIXER OUTPUTS.

40 Hz High-Pass Filters

• In = Filter Enabled

• Out = Filter Off

The 40 Hz high pass filter is a second order

filter with a slope of 12 dB per octave. This

filter is intended to remove unwanted

subsonic noise and rumble caused by sources

such as HVAC, air currents, and vibration.

LED Meters ---- Direct Outputs

Each preamp channel has a direct output.

Each direct output is equipped with a two

segment LED meter.

The green LED shows signal presence. The

intensity of the green LED varies with signal

level over a range of 8 dBu to +24 dBu. The

green LED reaches half brightness at an

output level of about +4 dBu, and is near full

brightness at +24 dBu.

The red LED is factory preset to illuminate at

an output level of precisely +24 dBu, but may

be adjusted to other levels between 20 dBu

and 29 dBu. The red LED is driven by a peak

detection and stretching circuit so that very

short transients can be observed.

The red LED is a warning indicator not a clip

indicator. The direct outputs have 5.5 dB of

remaining headroom when the red LED is just

illuminated. The mix amps have a minimum

of 2 dB of headroom when all channels are

just illuminating the red LEDs.

PRE420 Instruction Manual – rev. E Page 12

Solo Bus

The PRE420 has a flexible solo bus that

allows:

• Mono monitoring of any mix of

microphones

• Stereo (post pan) monitoring of any

combination of microphones

• Stereo monitoring of the main mix bus

• Mono monitoring of the main mix bus

The output of the solo bus is directed to the

“monitor” fader and then to the headphone

and “control room” outputs.

Solo Switches

The solo bus has one solo button for each of

the 4 channels. These can be pressed in any

combination to create a mix of microphones.

If any microphone solo button is pressed, the

“Solo” indicator will illuminate.

Stereo/Mono Solo Switch

Microphones may be monitored before the

pan control (mono) or after the pan control

(stereo). Press the “Mono/Stereo” switch for

stereo solo. Stereo monitoring can be used

to check the pan position of a single

microphone or any combination of

microphones.

If none of the 4 microphone solo buttons are

pressed, the main stereo mix is directed to

the solo bus.

NOTE: The “Mono/Stereo” switch is only

functional when one or more microphone solo

buttons are pressed. This makes it easy to

toggle between the main stereo mix and a

mono solo of a single microphone.

TIP: TO CHECK A MIX FOR MONO-

COMPATIBILITY, PRESS ALL 4

MICROPHONE SOLO BUTTONS. THEN,

USE THE “MONO/STEREO” BUTTON TO

TOGGLE BETWEEN THE MONO MIX AND

THE MAIN STEREO MIX.

PRE420 Instruction Manual – rev. E Page 13

Control Room

Outputs

The output of the solo bus is directed to the

“monitor” fader and then to the headphone

and “control room” outputs.

Maximum output level is 29.5 dBu. All drivers

are high current low distortion amplifiers.

These are capable of driving loads as low as

300 Ohms without an increase in distortion.

Control Room Mute Switch

TIP: THE “CONTROL ROOM” OUTPUTS

CAN BE SET TO AUTOMATICALLY MUTE

WHENEVER A HEADPHONE IS INSERTED.

PRESS THE REAR-PANEL BUTTON TO

ENABLE THE AUTO-MUTE FUNCTION.

Driving Unbalanced Loads

CAUTION: ALWAYS LEAVE XLR PIN 3

FLOATING WHEN DRIVING UNBALANCED

LOADS.

XLR to RCA Wiring:

1. Connect XLR pin 2 (+) to RCA center pin.

2. Connect XLR pin 1 (GND) to RCA shield.

3. Make no connection to XLR pin 3 ( ).

XLR to ¼” TS Wiring:

1. Connect XLR pin 2 (+) to Tip.

2. Connect XLR pin 1 (GND) to Sleeve.

3. Make no connection to XLR pin 3 ( ).

Monitor Fader

The “monitor” fader is located to the right of

the solo buttons. It controls the output level

of the headphone jack and the balanced

control room outputs.

This stereo fader has factory adjusted

balance trim circuitry to provide accurate L/R

balance.

PRE420 Instruction Manual – rev. E Page 14

HPA2™ Headphone

Output

The output of the solo bus is directed to the

“monitor” fader and then to the headphone

and “control room” outputs.

The headphone output is driven by

Benchmark’s signature HPA2™ headphone

amplifier. This high current, high output

amplifier has an output impedance of 0

Ohms. It is designed to drive loads as low as

30 Ohms without any increase in distortion.

It also has sufficient amplitude to drive low

sensitivity 600 Ohm headphones.

The HPA2™ includes current limiting circuits

that fully protect against damage from short

circuits. This is important because the right

channel of a headphone amplifier will

experience a short whenever a mono phone

plug is inserted into the stereo headphone

jack. Shorts may also occur when a plug is

partially inserted.

‘‘0-Ohm’’ Output Impedance

Most headphone amplifiers use series

resistors to maintain stability and protect

against short circuit conditions. These

resistors are usually at least 30 Ohms, and

have a negative impact on performance. A

headphone amplifier with series resistors may

measure very well when driving resistive

loads. However, the same amplifier will

measure very poorly when driving a

headphone load. Unfortunately most

manufacturers do not specify headphone

amplifier performance with anything other

than ideal resistive loads. Our measurements

show that headphones do not behave like

resistive loads.

Headphone Performance

In our tests we have measured substantial

distortion across resistors that are wired in

series with headphones. We conducted

measurements with a variety of headphones.

In general, distortion increases as headphone

impedance decreases. This distortion can be

eliminated with a properly designed 0 Ohm

headphone amplifier.

The performance of the HPA2™ does not

change when headphones are driven. THD+N

measurements for no load, 30 Ohm resistive

load, and 30 Ohm headphone load, and 600

Ohm headphone load are virtually identical.

The HPA2™ will substantially improve the

sound of 30 and 60 Ohm headphones. It will

make very noticeable improvements with

600 Ohm headphones.

PRE420 Instruction Manual – rev. E Page 15

Mix Outputs

The output of the mix bus is directed to the

“Main” fader and then to the “Main” outputs.

Maximum output level is 29.5 dBu. All drivers

are high current low distortion amplifiers.

These are capable of driving loads as low as

300 Ohms without an increase in distortion.

TIP: ENGAGE THE PAD ON ANY UNUSED

INPUT AND TURN THE MICROPHONE

GAIN CONTROL TO MINIMUM TO REDUCE

NOISE AT THE MIXER OUTPUTS.

Driving Unbalanced Loads

CAUTION: ALWAYS LEAVE XLR PIN 3

FLOATING WHEN DRIVING UNBALANCED

LOADS.

XLR to RCA Wiring:

1. Connect XLR pin 2 (+) to RCA center pin.

2. Connect XLR pin 1 (GND) to RCA shield.

3. Make no connection to XLR pin 3 ( ).

XLR to ¼” TS Wiring:

1. Connect XLR pin 2 (+) to Tip.

2. Connect XLR pin 1 (GND) to Sleeve.

3. Make no connection to XLR pin 3 ( ).

Main Fader

The “main” fader is located at the far right of

the front panel. This stereo fader has factory

adjusted balance trim circuitry to provide

accurate L/R balance.

LED Meters ---- Mix Outputs

The left and right mix outputs are equipped

with two segment LED meters located to the

left of the main fader.

The green LED shows signal presence. The

intensity of the green LED varies with signal

level over a range of 8 dBu to +24 dBu. The

green LED reaches half brightness at an

output level of about +4 dBu, and is near full

brightness at +24 dBu.

The red LED is factory preset to illuminate at

an output level of precisely +24 dBu, but may

be adjusted to other levels between 20 dBu

and 29 dBu. The red LED is driven by a peak

detection and stretching circuit so that very

short transients can be observed.

The red LED is a warning indicator not a clip

indicator. The direct outputs have 5.5 dB of

remaining headroom when the red LED is just

illuminated.

.

PRE420 Instruction Manual – rev. E Page 16

Rack Mounting

To enable rack mounting, the front panel of

the PRE420 has rack mount holes that are

machined to conform to standard rack mount

dimensions. The PRE420 ships with rubber

feet that should be removed whenever

another device will be mounted directly below

the PRE420.

Mounting Near Other

Equipment

CAUTION: STRAY MAGNETIC FIELDS

FROM ADJACENT EQUIPMENT MAY

CAUSE MAGNETICALLY INDUCED HUM IN

THE SENSITIVE HIGH-GAIN PREAMP

CIRCUITS.

The PRE420 may be mounted directly above

or below other PRE420 preamps. It may also

be mounted directly above or below

Benchmark DAC1 and ADC1 converters. The

Pre420 is well shielded but we cannot

guarantee that unknown pieces of equipment

will not cause interference if mounted too

close to the PRE420. Follow the procedure

below when mounting near other equipment:

TIP: TO CHECK FOR MAGNETIC

INTERFERENCE FROM ADJACENT

EQUIPMENT:

• Disconnect all microphones

• Turn on all pads (to back terminate

microphone inputs)

• Set all preamp gain controls at maximum

• Listen to headphone output

• Unplug adjacent equipment to determine

if there is any magnetic interference

TIP: IN MANY CASES, POWER SWITCHES

DO NOT TURN OFF ALL OF THE

MAGNETIC COMPONENTS IN AN

ELECTRONIC DEVICE. THEREFORE, WHEN

PERFORMING MAGNETIC INTERFERENCE

TESTS, IT IS IMPORTANT TO UNPLUG

THE ADJACENT EQUIPMENT TO INSURE

THAT THESE DEVICES ARE TRULY OFF.

PRE420 Instruction Manual – rev. E Page 17

Performance Graphs

Frequency Response

Audio Precision

02/19/07 11:33:00PRE420 - Frequency Response

ColorS eep Trace Line Style Thick Data Axis Comment

1 1 Red Solid 4 Anlr.Level A Left HP Filter Off

-3

+3

-2.8

-2.6

-2.4

-2.2

-2

-1.8

-1.6

-1.4

-1.2

-1

-0.8

-0.6

-0.4

-0.2

+0

+0.2

+0.4

+0.6

+0.8

+1

+1.2

+1.4

+1.6

+1.8

+2

+2.2

+2.4

+2.6

+2.8

d

B

r

A

10 200k20 50 100 200 500 1k 2k 5k 10k 20k 50k 100k

Hz

The above graph shows the frequency response of the PRE420 with the 40 Hz high pass filter off.

The amplitude response measures 0.020 dB at 10 Hz and 0.165 dB at 200 kHz. The bass

response extends well below the 10 Hz limitation of the test equipment, and the high frequency

response extends well above the 200 kHz limit of the test equipment.

PRE420 Instruction Manual – rev. E Page 18

High-Pass Filter - Frequency Response

Audio Precision

02/19/07 11:33:00PRE420 - Frequency Response

ColorS eep Trace Line Style Thick Data Axis Comment

2 1 Red Solid 4 Anlr.Level A Left HP Filter On

-3

+3

-2.8

-2.6

-2.4

-2.2

-2

-1.8

-1.6

-1.4

-1.2

-1

-0.8

-0.6

-0.4

-0.2

+0

+0.2

+0.4

+0.6

+0.8

+1

+1.2

+1.4

+1.6

+1.8

+2

+2.2

+2.4

+2.6

+2.8

d

B

r

A

10 200k20 50 100 200 500 1k 2k 5k 10k 20k 50k 100k

Hz

The above graph shows the response of the 40 Hz high pass filter. Response is 3 dB at 40 Hz with

a slope of 12 dB/octave.

PRE420 Instruction Manual – rev. E Page 19

Inter-Channel Phase Response

Audio Precision

02/19/07 11:35:37PRE420 - Inter-Channel Phase Response

-1

+1

-0.9

-0.8

-0.7

-0.6

-0.5

-0.4

-0.3

-0.2

-0.1

+0

+0.1

+0.2

+0.3

+0.4

+0.5

+0.6

+0.7

+0.8

+0.9

d

e

g

10 100k20 50 100 200 500 1k 2k 5k 10k 20k 50k

Hz

This graph shows that the differential phase is significantly better than ± 0.05 degrees from 10 Hz

to 20 kHz.

PRE420 Instruction Manual – rev. E Page 20

THD+N vs. Frequency

Measurement Bandwidth = 10Hz to 80 kHz, Gain = 30 to 60 dB, Output Leve = +4 dBu

Audio Precision

02/21/07 09:56:41PRE420 - THD+N vs Frequency at 60 dB Gain, BW=80 kHz

ColorS eep Trace Line Style Thick Data Axis Com ment

1 1 Red Solid 4 Anlr.THD+N Ratio Left 60 dB Gain (top trace)

2 1 Magenta Solid 4 Anlr.THD+N Ratio Left 50 dB Gain

3 1 Blue Solid 4 Anlr.THD+N Ratio Left 40 dB Gain

4 1 Green Solid 4 Anlr.THD+N Ratio Left 30 dB Gain (bottom trace)

0.0001

0.01

0.0002

0.0005

0.001

0.002

0.005

%

-120

-80

-118

-116

-114

-112

-110

-108

-106

-104

-102

-100

-98

-96

-94

-92

-90

-88

-86

-84

-82

d

B

20 80k50 100 200 500 1k 2k 5k 10k 20k 50k

Hz

This graph shows that THD+N does not rise with frequency – even at maximum gain.

Table of contents

Other Benchmark Amplifier manuals

Benchmark

Benchmark HPA4 User manual

Benchmark

Benchmark DAC2 HGC User manual

Benchmark

Benchmark DAC2 HGC User manual

Benchmark

Benchmark DA-101 User manual

Benchmark

Benchmark HPA4 Quick start guide

Benchmark

Benchmark DAC1 HDR User manual

Benchmark

Benchmark DAC2 HGC User manual

Benchmark

Benchmark DAC3 HGC User manual

Benchmark

Benchmark AHB2 User manual

Benchmark

Benchmark DAC2 D User manual