Bend-Pak RS7580V-601 User manual

1645 Lemonwood Dr.

Santa Paula, CA, 93060 USA

Toll Free: (800) 253-2363

Telephone: (805) 933-9970

bendpak.com

Rotary-Screw Air Compressor

Installation and Operation Manual

Manual P/N 5900090 — Manual Revision A — September 2019

Model:

• RS7580V-601

Engineered by BendPak Inc. in Southern California, USA. Made in China.

⚠DANGER

Read the

entire

contents of this manual

before

using this

product. Failure to follow the instructions and safety precautions in

this manual can result in serious injury or death. Make sure all other

operators also read this manual. Keep the manual near the product

for future reference. By proceeding with setup and operation, you

agree that you fully understand the contents of this manual.

Manual. RS7580V-601 Rotary-Screw Air Compressor, Installation and Operation Manual, Manual Part Number

5900090, Manual Revision A, Released September 2019.

Copyright. Copyright © 2019 by BendPak Inc. All rights reserved. You may make copies of this document if you

agree that: you will give full attribution to BendPak Inc., you will not make changes to the content, you do not gain

any rights to this content, and you will not use the copies for commercial purposes.

Trademarks. BendPak and the BendPak logo are registered trademarks of BendPak Inc. All other company,

product, and service names are used for identification only. All trademarks and registered trademarks mentioned

in this manual are the property of their respective owners.

Limitations. Every effort has been made to ensure complete and accurate instructions are included in this

manual. However, product updates, revisions, and/or changes may have occurred since this manual was

published. BendPak reserves the right to change any information in this manual without incurring any obligation for

equipment previously or subsequently sold. BendPak is not responsible for typographical errors in this manual.

The latest version of the manual for this product is available on the BendPak website.

Warranty. The BendPak warranty is more than a commitment to you: it is also a commitment to the value of

your new product. Contact your nearest BendPak dealer or visit www.bendpak.com/support/warranty for

full warranty details. Go to bendpak.com/support/register-your-product/ and fill out the online form to

register your product (be sure to click Submit).

Safety.Your product was designed and manufactured with safety in mind. However, your safety also depends

on proper training and thoughtful operation. Do not install, operate, maintain, or repair the unit without reading and

understanding this manual and the labels on the unit;

do not use your unit unless you can do so safely!

Owner Responsibility. In order to ensure operator safety and maintain your product properly, it is the

responsibility of the product owner to read and follow these instructions:

• Follow all installation, operation, and maintenance instructions.

• Make sure product setup and use conforms to all applicable local, state, and federal codes, rules, and

regulations, such as state and federal OSHA regulations and electrical codes.

• Read and follow all safety instructions. Keep them readily available for operators.

• Make sure all operators are properly trained, know how to safely operate the unit, and are properly supervised.

• Do not operate the product until you are certain all parts are in place and operating correctly.

• Carefully inspect the product on a regular basis and perform all maintenance as specified.

• Service and maintain the unit only with approved replacement parts.

• Keep all instructions permanently with the product and make sure all labels are clean and visible.

•Only use the unit if it can be used safely!

Unit Information.

Enter the Model Number, Serial

Number

, and the Date of Manufacture from the label on

your unit

. This information is required for part or

warranty issues.

Model:

Serial:

Date of

Manufacture:

RS7580V-601 Rotary-Screw Air Compressor 3P/N 5900090 — Rev. A — Sept. 2019

Table of Contents

Introduction 3 Installation 13

Shipping Information 4 Operation 23

Safety Considerations 4 Maintenance 32

Components 6 Troubleshooting 36

FAQs 8 Wiring Diagram 37

Specifications 9 Labels 38

Important Electrical 10 Parts Diagram 41

Installation Checklist 12 Maintenance Log 43

Introduction

This manual describes the Hush-Quiet RS7580V-601 Rotary-Screw Air Compressor, which efficiently

and reliably creates, stores, and distributes pressurized air for your facility. Pressurized air can be used

to power pneumatic tools, operate spray equipment, inflate tires, and many other things.

More information about the full line of BendPak products is available at bendpak.com.

This manual is mandatory reading for all RS7580V-601 users, including anyone who sets up, operates,

maintains, or repairs it.

⚠DANGER Be very careful when setting up, operating, maintaining, or repairing this equipment;

failure to do so could result in property damage, product damage, injury, or (in very

rare cases) death. Make sure only authorized personnel operate this equipment. All

repairs must be performed by an authorized technician. Do not make modifications

to the unit; this voids the warranty and increases the chances of injury or property

damage. Make sure to read and follow the instructions on the labels on the unit.

Keep this manual on or near the equipment so that anyone who uses or services it can read it.

If you are having issues, refer to the Troubleshooting section of this manual for assistance.

Technical support and service is available from your dealer, on the Web at bendpak.com/support,

by email at techsupport@bendpak.com, or by phone at (800) 253-2363, extension 196.

You may also contact BendPak for parts replacement information (please have the model and serial

number of your unit available) at (800) 253-2363, extension 191.

RS7580V-601 Rotary-Screw Air Compressor 4P/N 5900090 — Rev. A — Sept. 2019

Shipping Information

Your equipment was carefully checked before shipping. Nevertheless, you should thoroughly inspect

the shipment

before

you sign to acknowledge that you received it.

When you sign the bill of lading, it tells the carrier that the items on the invoice were received in good

condition.

Do not sign the bill of lading until

after

you have inspected the shipment.

If any of the

items listed on the bill of lading are missing or damaged, do not accept the shipment until the carrier

makes a notation on the bill of lading that lists the missing and/or damaged goods.

If you discover missing or damaged goods

after

you receive the shipment and have signed the bill of

lading, notify the carrier at once and request the carrier to make an inspection. If the carrier will not

make an inspection, prepare a signed statement to the effect that you have notified the carrier (on a

specific date) and that the carrier has failed to comply with your request.

It is difficult to collect for loss or damage after you have given the carrier a signed bill of lading. If this

happens to you, file a claim with the carrier promptly. Support your claim with copies of the bill of

lading, freight bill, invoice, and photographs. Our willingness to assist in helping you process your claim

does not make us responsible for collection of claims or replacement of lost or damaged materials.

Safety Considerations

Read this manual carefully before using your new product.

Do not set up or operate

the product until you are familiar with

all

operating instructions and warnings. Do not allow anyone

else to operate the product until they are also familiar with all operating instructions and warnings.

⚠DANGER When you even hear the words “air compressor,” you need to remember that being

in close proximity to one is a serious endeavor with potentially life-threatening risks.

The Compressor can start without warning. An accidental quarter turn on a ball

valve can unleash pressurized air at potentially dangerous levels. Only allow trained

personnel anywhere near the Compressor.

Do not assume you are going to

be safe this time just because nothing happened last time

.

General Safety Information

•The product is a Rotary-Screw Air Compressor. Use it only for its intended purpose.

•Do not make any modifications to the Compressor. If you do, you void your warranty.

•Do not override, remove, or disable Compressor safety features or components; they are there for

your safety. Do not use the Compressor if safety features or components have been overridden,

removed, disabled, or damaged.

•The Compressor must

only

be operated by authorized personnel. Take

active measures

to

keep untrained personnel away from the unit.

•You

must

wear OSHA-approved (publication 3151) personal protective equipment at all times

when installing, using, maintaining, or repairing the Compressor: leather gloves, steel-toed work

boots, eye protection, back belts, and hearing protection.

•When the product is in use, keep away from it. Only the Operator should be within 30 feet.

•Make sure all Operators read and understand the Installation and Operation Manual. Keep the

manual near the device at all times.

•Make a visual inspection of the unit on a

daily

basis. Check for damaged or missing parts. Do not

use the product if you find any issues. Instead, take it out of service, then contact your dealer,

email techsupport@bendpak.com, visit bendpak.com/support, or call (800) 253-2363.

RS7580V-601 Rotary-Screw Air Compressor 5P/N 5900090 — Rev. A — Sept. 2019

•Make a

thorough

inspection of the unit at least once a year. Replace any damaged or severely

worn parts, decals, or warning labels.

•If you are using the Compressor to paint, keep the paint far away from the Compressor.

⚠DANGER The pressurized air generated by the Compressor is

not

human breathable when it

leaves the Compressor. If you want it to be human breathable, additional equipment is

required. Refer to the current version of the Compressed Gas Association (CGA, an

ANSI-approved standards developing organization) for information about what is

required for human breathable air. CGA G-7.1-2018 was the current version at the

time of this writing.

Symbols

Following are the symbols used in this manual:

⚠DANGER Calls attention to an immediate hazard that will result in injury or death.

⚠WARNING Calls attention to a hazard or unsafe practice that could result in injury or death.

⚠CAUTION Calls attention to a hazard or unsafe practice that could result in minor personal

injury, product, or property damage.

NOTICE Calls attention to a situation that, if not avoided, could result in product or property

damage.

Tip Calls attention to information that can help you use your product better.

Liability Information

BendPak Inc. assumes no liability for damages resulting from:

• Use of the product for purposes other than those described in this manual.

• Modifications to the equipment without prior, written permission from BendPak Inc.

• Damage to the equipment from external influences.

• Incorrect operation of the equipment.

RS7580V-601 Rotary-Screw Air Compressor 6P/N 5900090 — Rev. A — Sept. 2019

Components

Not all components clearly visible.

Compressor components include:

•Air Intake. Where outside air comes in, on its way to the Compressor.

•Compressor. Compresses the air and then sends it to the Tank.

•Motor. Powers the Compressor.

•Controls. Configure the Compressor.

•Electrical Box. Holds the Compressor’s electrical components.

•Hole for Power. Have your Electrician wire the Compressor to a power source via the hole on

the underside of the Electrical Box.

•Emergency Stop Button. Immediately stops the Compressor.

•Water Drain. Drains water from the Tank.

•Tank. Stores the pressurized air created by the Compressor.

•Tank Shutoff Valve. Allows or prevents pressurized air from leaving the Tank.

•Discharge Port. Where pressurized air leaves the Tank. If better for your location, the Discharge

Port can be switched from the higher location to the lower location.

RS7580V-601 Rotary-Screw Air Compressor 7P/N 5900090 — Rev. A — Sept. 2019

•Pressure Relief Valve. Releases air pressure from the Tank if it exceeds 175 psi. ASME

certified. Do

not

remove or adjust the Valve; if you do, you put people in danger and void the

warranty. Do

not

open the Valve while there is air pressure in the Tank.

•Air Pressure Gauge. Shows the Air Pressure in the Tank. Located on the top of the Tank.

•Oil Separator Tank. Where the combined air/oil is separated into the component parts.

•Pressure Gauge. Shows the Pressure in the Oil Separator Tank.

The following drawing shows the Oil Separator Tank.

Not necessarily to scale. Not all components shown.

•Oil Level Gauge. Shows the oil level in the Oil Separator Tank. Oil level is very high when you

receive the Compressor; this is normal. It moves down into the area between the two red lines

during normal operation.

•Oil Fill Hole. Use to add oil.

•Oil Drain. Use to drain oil out of the Oil Separator Tank, when necessary.

RS7580V-601 Rotary-Screw Air Compressor 8P/N 5900090 — Rev. A — Sept. 2019

Frequently Asked Questions

Question: What does an Air Compressor do?

Answer: An Air Compressor compresses air, making it into a power source: pressurized air. That

pressurized air can then be used to power pneumatic tools and other things.

⚠DANGER The pressurized air generated by the Compressor is

not human breathable

when it leaves the Compressor. If you want it to be human breathable, additional

equipment is

required

. Refer to the current version of the Compressed Gas

Association (CGA, an ANSI-approved standards developing organization) for

information about what is required for human breathable air.

Q: Can the Compressor be installed outside?

A: Technically yes, but we advise against it. Air compressors are designed to be installed indoors. If

your Compressor is outside, the intake air will be dirtier (a significant issue), the electrical

components will be subject to extra moisture (including water), and all of the components will be

subjected to a harsher environment (cold, wind, rain, humidity, and so on). You will need special

protections and accommodations for the unit if you install it outside.

Q: What psi/bar does the Compressor provide?

A: The maximum pressure is regulated to 175 psi / 12 bar. The automatic turn-on pressure is

120 psi / 8.3 bar, the automatic shut-off pressure is 175 psi / 12 bar.

Q: What cfm does the Compressor provide?

A: 25 cfm at 90 psi / 6.2 bar, 21.3 cfm at 175 psi / 12 bar.

Q: What are cfm and psi?

A: cfm is the volume (the amount) of air being delivered. psi is the force at which that air is being

delivered. cfm stands for cubic feet per minute, psi stands for pounds per square inch.

Q: What are the motor specifications for the Compressor?

A: 7.5 horsepower, 208-240 VAC, 1 phase. Recommended breaker is 80 amps and 6 AWG wire

gauge.

60 Hz: 1,740 rpm 1/min, amps 32.8-30 A, SF amps 38-34.7 A

50 Hz: 1,445 rpm 1/min, amps 34.3-32.63 A, SF amps 34.3-32.63 A

RS7580V-601 Rotary-Screw Air Compressor 9P/N 5900090 — Rev. A — Sept. 2019

Specifications

Model RS7580V-601

Motor Horsepower 7.5 HP

RPM 1,740 RPM at 60 Hz, 1,445 at 50 Hz

Voltage 208–240 VAC

Phase 1 Ph

Hertz 50 or 60 Hz

Amps at 60 Hz 32.8-30 A, SF amps 38-34.7 A

Amps at 50 Hz 34.3-32.63 A, SF amps 34.3-32.63 A

Recommended Breaker 80 Amp

Wire Gauge 6 AWG

Noise ≤70 dB

Pump Style Rotary Screw

Lubrication Forced Oil

Duty Cycle Continuous

CFM @ 90 psi 25 CFM

CFM @ Maximum (175) psi 21.3 CFM

Auto Turn-On Pressure 120 psi / 8.3 bar

Auto Shut-Off pressure 175 psi / 12 bar

Maximum psi 175 psi / 12 bar

Tank Orientation Vertical

Tank Size 80 gallon / 302.8 liter

Tank Outlet 1.5 in / 38 mm fitting

Tank Certification ASME

Dimensions 39 in wide by 32 in deep by 73 in high

991 mm wide by 813 mm deep by 1,854 mm high

Weight 630 lb / 286 kg

Specifications subject to change without notice.

RS7580V-601 Rotary-Screw Air Compressor 10 P/N 5900090 — Rev. A — Sept. 2019

Important Electrical Information

⚠WARNING Electrical installation, service, and all electrical connections

must

be done by a

qualified, licensed Electrician who is familiar with all applicable electrical codes.

General. The motor rating, as shown on the motor nameplate, and power supply must have

compatible voltage, phase, and hertz characteristics. Make sure to have your Electrician

check all wiring connections when they are connecting the Compressor to power;

sometimes wiring becomes loose during transportation.

Wire Size. The electrical wiring between the power supply and electric motor varies according to

motor horsepower and other factors. Install adequately sized power leads to protect against excessive

voltage drop during pressure loaded start-up. Refer to the applicable electric codes in your area for

information on selecting the proper wire size and securing electrical connections. If you connect

additional electrical equipment to the same circuit, consider the total electrical load when selecting the

proper wire size.

Do not use undersize wire

.

Minimum Wire Size. (Use 75°C copper wire). Make sure voltage is correct with the motor wiring.

Refer to the motor label for the running HP rating. This will determine the wire size needed.

Recommended wire sizes may be larger than the minimum set up by local ordinances. If so, the larger

wire size should be used to prevent excessive line voltage drop.

The additional wire cost is very small compared with the cost of repairing or replacing a motor

electrically “starved” by the use of supply wires that are too small. Also, if a lead wire longer than 10

feet is needed, consult a local Electrician for alternative wiring options.

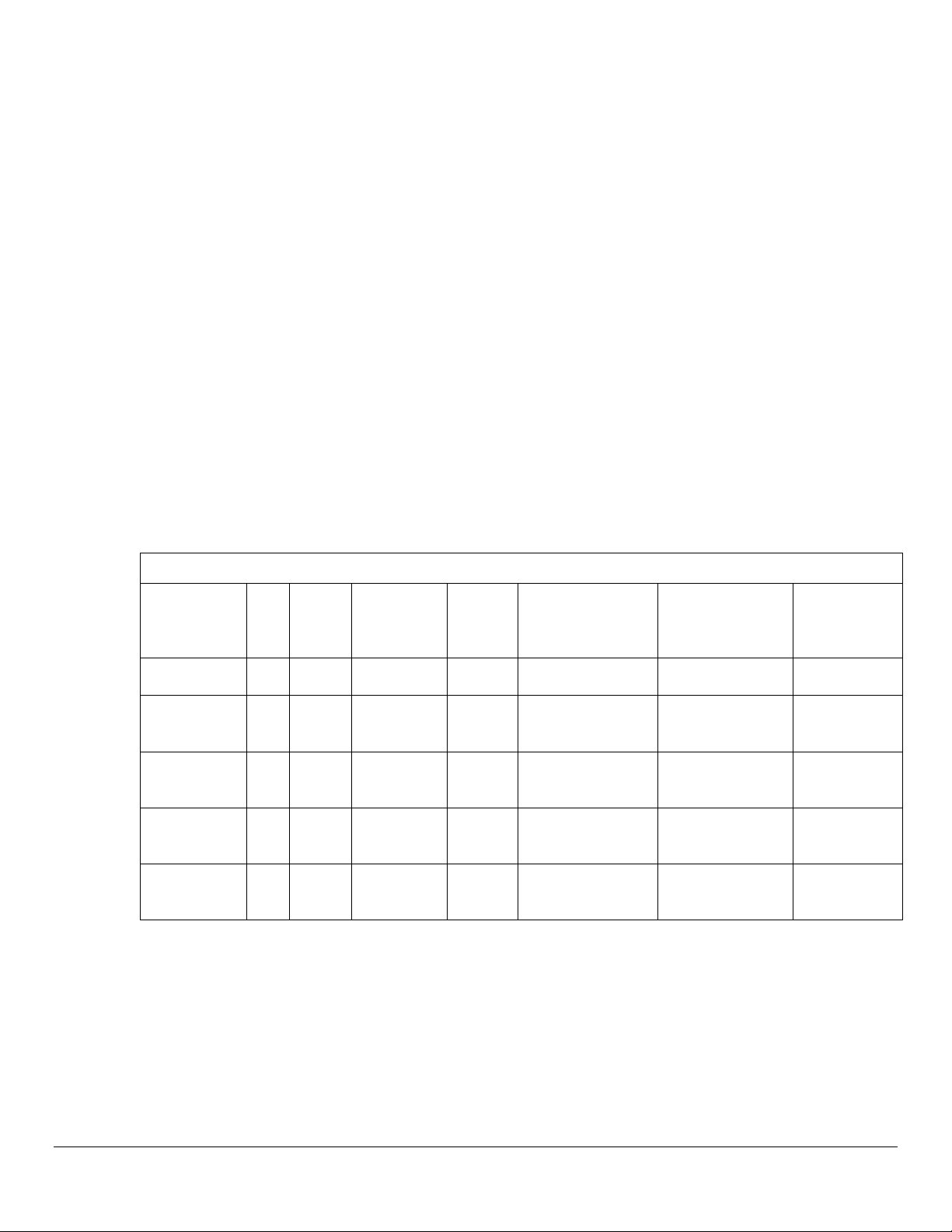

Minimum Wire Size and Branch-Circuit, Short-Circuit, and Ground-Fault Protection Devices

Model HP Phase Voltage Full

Load

Ampere

Inverse Time

Breaker Maximum

Allowable Size (A)

Dual Element

Fuse Maximum

Allowable Size (A)

Min. Wire

Size (copper

wire at 75°C)

TS580V-601 5 1 208-230 V 22.5-20 70 50 8 AWG

VMX7580V-

601

7.5 1 208-230 V 32.8-30 100 70 6 AWG

VMX7580V-

603

7.5 3 208-230 V 24.2-22 60 40 10 AWG

VMX10120V-

603

10 3 208-230 V 28-25.3 70 50 8 AWG

RS7580V-

601

7.5 1 208-230 V 32.8-30 100 70 6 AWG

Note 1: Table provides branch-circuit, short-circuit, and ground fault protection device sizes and

required copper wire size at 75°C and up to 10 feet long. For longer distances, proper

(larger) wire size must be determined and installed by local, licensed Electrician to prevent

excessive voltage drop. Refer to motor label for motor HP, voltage, and phase to determine

minimum wire size;

do not use undersized wire

.

Note 2: Smaller inverse time-trip breakers and dual element fuses may be used when recommended

by a licensed Electrician. However, using an improper (too small) breaker may cause

nuisance breaker tripping, which interferes with normal operation of the Compressor and

could cause damage to the Compressor’s electric motor and other electrical components.

RS7580V-601 Rotary-Screw Air Compressor 11 P/N 5900090 — Rev. A — Sept. 2019

Fuses / Circuit Breakers. Refer to applicable local codes to determine the proper fuse or circuit

breaker rating required. When selecting fuses, remember the momentary starting current of an electric

motor is greater than its full load current. Time delay or “slow-blow” fuses are recommended.

Grounding. In the event of an electrical short circuit, grounding reduces the risk of electric shock by

providing an escape wire for the electric current. Ground terminals are identified with a ground symbol

and/or the letters “G”, “GR” or “PE” (Potential Earth).

Ground must be established with a grounding wire size according to the voltage and minimum branch

circuit requirements printed on the compressor specifications decal. Ensure good bare metal contact

at all grounding connection points, and ensure all connections are clean and tight.

⚠WARNING Improper grounding can result in electrical shock and can cause severe injury or

death. This product must be connected to a grounded, metallic, permanent wiring

system or an equipment-grounding terminal or lead. All grounding must be

performed by a qualified, licensed Electrician and must comply with all applicable

electric codes.

RS7580V-601 Rotary-Screw Air Compressor 12 P/N 5900090 — Rev. A — Sept. 2019

Installation Checklist

Following are the steps needed to install the Compressor. Perform them in the order shown.

☐1. Review the installation Safety Rules.

☐2. Make sure you have the necessary Tools.

☐3. Select the Installation site.

☐4. Move the Compressor into position.

☐5. Remove the Stabilizing Bars.

☐6. Make sure there is adequate Clearance on all sides and above.

☐7. Anchor the Feet.

☐8. Connect to a Power Source.

☐9. Check the Oil Level.

☐10. Connect the Discharge Port.

☐11. Perform an Operational Test.

☐12. Review the Final Checklist.

RS7580V-601 Rotary-Screw Air Compressor 13 P/N 5900090 — Rev. A — Sept. 2019

Installation

This section describes how to install your Compressor. Perform the steps in the order listed.

⚠WARNING Use only the factory-supplied parts that came with your unit. If you use parts from a

different source, you void your warranty and compromise the safety of everyone

who installs or uses the Compressor. If you are missing parts, visit

bendpak.com/support or call (800) 253-2363, extension 191.

Safety Rules

When installing the Compressor, your safety depends on proper training and thoughtful operation.

⚠WARNING Do not install this equipment unless you have installation training. Always use

proper tools, such as a Forklift, to move heavy components. Do not install the unit

without reading and understanding this manual and the safety labels on the unit.

Only fully trained personnel should be involved in installing this equipment.

Pay attention at all

times.

Use appropriate tools and equipment. Stay clear of moving parts.

⚠WARNING You must wear OSHA-approved (publication 3151) personal protective equipment

at all times

when installing the Compressor: leather gloves, steel-toed work

boots, eye protection, back belts, and hearing protection.

Tools

You may need some or all of the following tools:

•Two adjustable wrenches, one pipe wrench

•Socket and ratchet set

•Medium slot and Philips screwdriver

•Forklift

•Rotary hammer drill or similar

•Masonry bits

The Electrician may require additional tools.

RS7580V-601 Rotary-Screw Air Compressor 14 P/N 5900090 — Rev. A — Sept. 2019

Select a Location

Keep the following in mind when selecting a location:

•Clearance. You must have adequate space on all sides and above. See Clearance for more

information. Make sure the Compressor is at least 3.3 feet / 1 meter from a wall or corner, with at

least 3.3 feet / 1 meter of open space

above

the unit (for good air circulation).

•Floor. Install your Compressor on a flat, dry concrete floor.

•Power. You will need a 208–240 VAC power source available near the Compressor. Use a 60

amp or greater fuse and 6 AWG wire.

•Operating temperature. The Compressor is designed to be used between temperatures of

41º to 104ºF (5º to 40ºC).

•Second floor installs. Do not install the Compressor on a second floor or elevated floor without

first consulting the building architect and getting their permission.

•Indoor installation. Your Compressor works best with clean, dry air, which is found indoors. If

you install the Compressor outdoors, the air is wetter and dirtier; outside air

must

be filtered

before it can be used with the Compressor.

•Ventilation. Install the Compressor in a well-ventilated area, away from sources of contamination

such as dirt or dust. You do not want the Compressor pulling in the same air that just came out of

it; that air is hot and dirty, not suitable for air intake. Installing the Compressor in a dust-filled

environment is not acceptable; it will damage the Compressor and it voids your warranty.

⚠DANGER The pressurized air generated by the Compressor is

not

human breathable when it

leaves the Compressor. If you want it to be human breathable, additional

equipment is

required

. Refer to the current version of the Compressed Gas

Association (CGA, an ANSI-approved standards developing organization) for

information about what is required for human breathable air.

RS7580V-601 Rotary-Screw Air Compressor 15 P/N 5900090 — Rev. A — Sept. 2019

Moving the Compressor

There are two appropriate ways to move the Compressor:

•Move the Pallet the Compressor is on using a Forklift. One way to move your

Compressor to the desired location is to use a Forklift from underneath while the Compressor is

still on its pallet. Make sure the Compressor is firmly secured to the Pallet before moving it.

•Move the Compressor from Above using the Two Eye Bolts. The Compressor comes

with two heavy-duty, silver Eye Bolts, which can be used—together—to lift the Compressor from

above. Use great care if you decide to lift the Compressor from above using the Eye Bolts. Make

sure the Eye Bolts are securely in place before lifting the Compressor using them.

⚠WARNING You

must

use

both

Eye Bolts; do not lift the Compressor from above using only

one of the Eye Bolts.

RS7580V-601 Rotary-Screw Air Compressor 16 P/N 5900090 — Rev. A — Sept. 2019

Remove the Stabilizing Bars

The Compressor ships with two Stabilizing Bars in place to help keep it secure during transport.

You can remove them when the Compressor has been moved to its permanent location.

⚠CAUTION If you wish, you can leave the Stabilizing Bars in place. If you do, avoid hitting them;

they have sharp corners and you could be injured.

One Stabilizing Bar is between the Electrical Box and the Motor; the other is below the Oil Separation

Tank.

Note: The Stabilizing Bars are in different locations on some older models of the RS7580V-601.

To remove a Stabilizing Bar, remove the Nuts and Bolts holding the Stabilizing Bar in place, then

remove the Bar.

RS7580V-601 Rotary-Screw Air Compressor 17 P/N 5900090 — Rev. A — Sept. 2019

Clearance

The Compressor has two clearance zones:

•Ventilation/Maintenance. Always keep at least 3.3 feet / 1 meter completely clear around the

Compressor, even if it is in a corner or against a wall. This ensures an unobstructed flow of air to

the Compressor and allows adequate space for maintenance.

Required

.

•Safety Exclusion Zone. BendPak strongly recommends keeping 6.6 feet / 2 meters clear

around the Compressor for safety purposes. Only trained personnel should be allowed in the

Safety Exclusion Zone; nothing else—no half-finished projects, no wires or cables, no storage,

no chemicals, no things you’re going to get to next week.

Strongly recommended

.

⚠DANGER When you even hear the words “air compressor,” you need to remember that being

in close proximity to one is a serious endeavor with potentially life-threatening risks.

The Compressor can start without warning. An accidental quarter turn on a ball

valve can unleash pressurized air at potentially dangerous levels. Only allow trained

personnel near the Compressor.

Do not assume you are going to be safe

this time just because nothing happened last time

.

Top view. Not necessarily to scale. Not all components shown.

The Safety Supervisor at the facility should implement appropriate written policies and physical

safeguards including, if possible, a physical barrier around the Safety Exclusion Zone.

RS7580V-601 Rotary-Screw Air Compressor 18 P/N 5900090 — Rev. A — Sept. 2019

Anchor the Feet

If desired, you can anchor each of the four feet on the Compressor. This provides extra stability for the

unit. Anchoring the feet is optional; anchor bolts are not provided.

Important: Whether you decide to anchor your Compressor or not, remember to use the supplied

Anti-Vibration Pads between the Compressor feet and the ground.

Recommended Anchor Bolt specifications: wedge anchors; 3/8 in wide by 3.5 in deep; torque to 55

pound feet.

To anchor the Compressor feet:

1. Make sure the Compressor is in the desired location.

Once anchor bolts are torqued into position, they are not easily removed. BendPak strongly

recommends making sure the Compressor is in the desired location

before

anchoring it into

place.

2. Put the Anti-Vibration Pads under the feet of the Compressor.

3. Using the holes in the feet as guides, drill the holes for the Anchor Bolts through the Anti-Vibration

Pads and into the concrete.

Go in straight; do not let the drill wobble.

Use a carbide bit (conforming to ANSI B212.15).

The diameter of the drill bit

must

be the same as the diameter of the Anchor Bolt. So if you are

using a 3/8 inch diameter Anchor Bolt, for example, use a 3/8 inch diameter drill bit.

4. Use a vacuum to thoroughly clean each hole.

If a vacuum is not available, use a wire brush, hand pump, or compressed air.

Do

not

ream the hole. Do

not

make the hole any wider than the drill bit made it.

5. Put the washer and nut into place, make sure the top of the nut is flush with the top of the Anchor

Bolt, then insert the Anchor Bolt into the hole.

6. Hammer or mallet the Anchor Bolt down into the hole.

Stop hammering when the washer is snug against the top of the foot.

7. Wrench each Nut

clockwise

to the recommended installation torque, 55 pound feet, using a

torque wrench.

Important: Do

not

use an impact wrench to torque the Anchor Bolts.

Wrenching the nut forces the wedge up, pushing out the expansion sleeve and pressing it tightly

against the concrete.

RS7580V-601 Rotary-Screw Air Compressor 19 P/N 5900090 — Rev. A — Sept. 2019

Connect to a Power Source

The Compressor must be connected to an appropriate power source.

⚠DANGER All electrical work

must be done by a licensed, certified Electrician

in

accordance with all applicable local electrical codes. Damage caused by improper

electrical installation may void your warranty.

All electrical work

must

conform to applicable local, state, and federal codes, rules, and regulations,

such as state and federal OSHA regulations and electrical codes. The Compressor

must

be

grounded.

Important: BendPak recommends having your Electrician check all wire connections inside the

Electrical Box; sometimes they can become loose during transport.

Based on what’s best for your specific location, most customers have their Electrician:

•Wire the Compressor directly into the facility’s electrical system, or

•Add a power cord with appropriate plug to the Compressor, which is then plugged in to an

appropriate power source.

The Electrician will need to provide these components; they are

not

supplied with the Compressor.

There is a hole in the bottom of the Electrical Box (labelled Power In on the inside) specifically for

wiring the Compressor to a power source.

Important: The Compressor uses electrical energy and creates pneumatic energy; if your

organization has Lockout/Tagout policies, make sure to implement them after

connecting the Compressor to a power source.

The Compressor’s motor is 7.5 horsepower, 208-240 VAC, 50 or 60 Hz, 1 phase. BendPak

recommends using a 60 Amp breaker and 6 AWG (if the 60 Amp breaker trips frequently, switch to a

higher breaker until the tripping stops) .

Check the ID plate for additional information

.

This drawing on the next page uses the United States color codes for the three wires that need to be

connected inside the Compressor’s Electrical Box:

•Black: Live

•White: Live

•Green: Ground

If you are using the Compressor in Europe, the Black – White – Green colors correspond to:

•Brown: Live

•Blue: Neutral

•Green/Yellow: Ground

Information about color code conventions in other regions and countries is available online.

To connect the Compressor to a power source:

1. Work with the Electrician to decide whether you are going to wire the Compressor into the facility’s

electrical system or connect a power cord with appropriate plug.

2. Have your Electrician get the necessary components.

3. Route the wiring through the hole in the bottom of the Electrical Box.

The wiring needs to have three wires, Black-White-Green in the United States.

RS7580V-601 Rotary-Screw Air Compressor 20 P/N 5900090 — Rev. A — Sept. 2019

5. Open the Electrical Box and connect the wiring as shown below.

The Green (ground) wire attaches to one of the Ground connectors on the left.

The Black and White (live) wires attach to the two Live connectors.

Note: The unused area to the right of the Live connectors is for 3-phase configurations, which

is not available for the RS7580V-601.

Not necessarily to scale. Not all components shown.

6. Close the Electrical Box.

7. If your Electrician wired a power cord with plug, plug it in.

The Display Screen on the Electrical Box displays a greeting.

If the Display Screen does

not

display a greeting, refer to Troubleshooting.

⚠WARNING The Compressor uses electrical energy and creates pneumatic energy; if your

organization has Lockout/Tagout policies, implement them after connecting the

Power Unit to a power source.

8. After a moment, the greeting goes away and normal operating information appears.

Table of contents

Other Bend-Pak Air Compressor manuals