Operating Manual

Your Bambi Air Compressor is a precision engineered product. By following these simple steps you will ensure years of trouble

free use.

Parts & Service are available from your Bambi dealer.

It is important to quote Model, Type & Serial Number in all communications.

The substitution of parts not manufactured nor approved by Bambi can impair performance, service life and create potential

mechanical or personnel hazards and will invalidate your warranty.

Bambi reserves the right to modify the contents of this operating booklet without notice and the information is in no way binding

on the company.

Warranty

Provided the operating instructions have been followed and the compressor has been properly maintained, Bambi compressors

are guaranteed against faulty workmanship for a period of 1 year.

The air receiver is guaranteed for 3 years.

The guarantee does not cover damage by misuse, incorrect parts or service.

Contact Bambi Air Compressors or your retailer for further information.

Safety Precautions

What you must do:

• Read these instructions before using your air compressor

• Ensure the compressor has been installed, electrically connected and piped in by a properly qualified

person

• Ensure the compressor is kept upright at all times

What you must not do:

• Do not attempt any maintenance on the compressor until it has been isolated from the power supply

• Do not attempt any work on the compressor until the air receiver and pipe work systems are

depressurised.

• Compressed air is dangerous if misused and can prove fatal. Avoid any bodily contact with compressed air

• During operation the motor will become quite hot to the touch. Avoid contact to prevent burns. At no

time must the oil temperature be allowed to exceed 100°C

• Never tamper with the pressure relief valve

• Never change the oil when the compressor is still warm. Take necessary precautions to avoid contact with the

skin

Bambi BPB1110S compressor oil does not contain hazardous components and is not required to be labelled dangerous

according to the Classification, Packaging and Labelling of dangerous substances regulation (CPL) Regulation 1984.

Siting The Compressor

What you must do:

• Provide adequate protection from the weather

• Site the compressor level in both plains

• Larger models are heavy, ensure the surface has sufficient load bearing capacity

• Allow access for maintenance all around the compressor

• Site in a dry area, avoiding damp or humid conditions. The site must be dust free, well ventilated and

have a cool ambient temperature. 35°C should be allowable ambient. Protect from frost, minimum

What you must not do:

• Enclose the compressor or allow hot air generated by the motor to re-

c

irculate around the compressor

Electrical Connections

All 220/240 volt compressors are supplied with a moulded plug in accordance with national standards. Never remove the moulded

plug.

Wired in accordance with European Standard –

Blue = neutral Brown = live Yellow & Green Stripe = earth

Operation

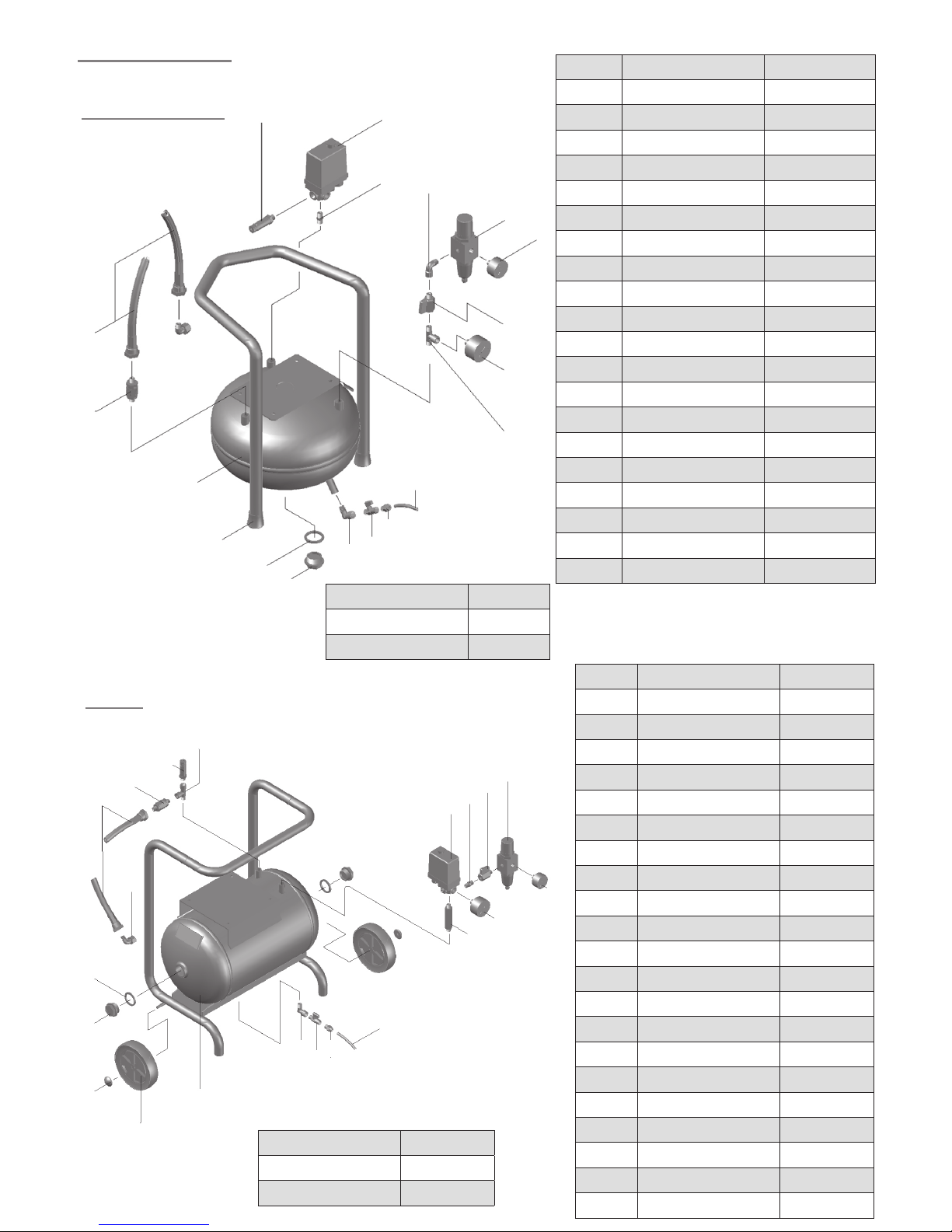

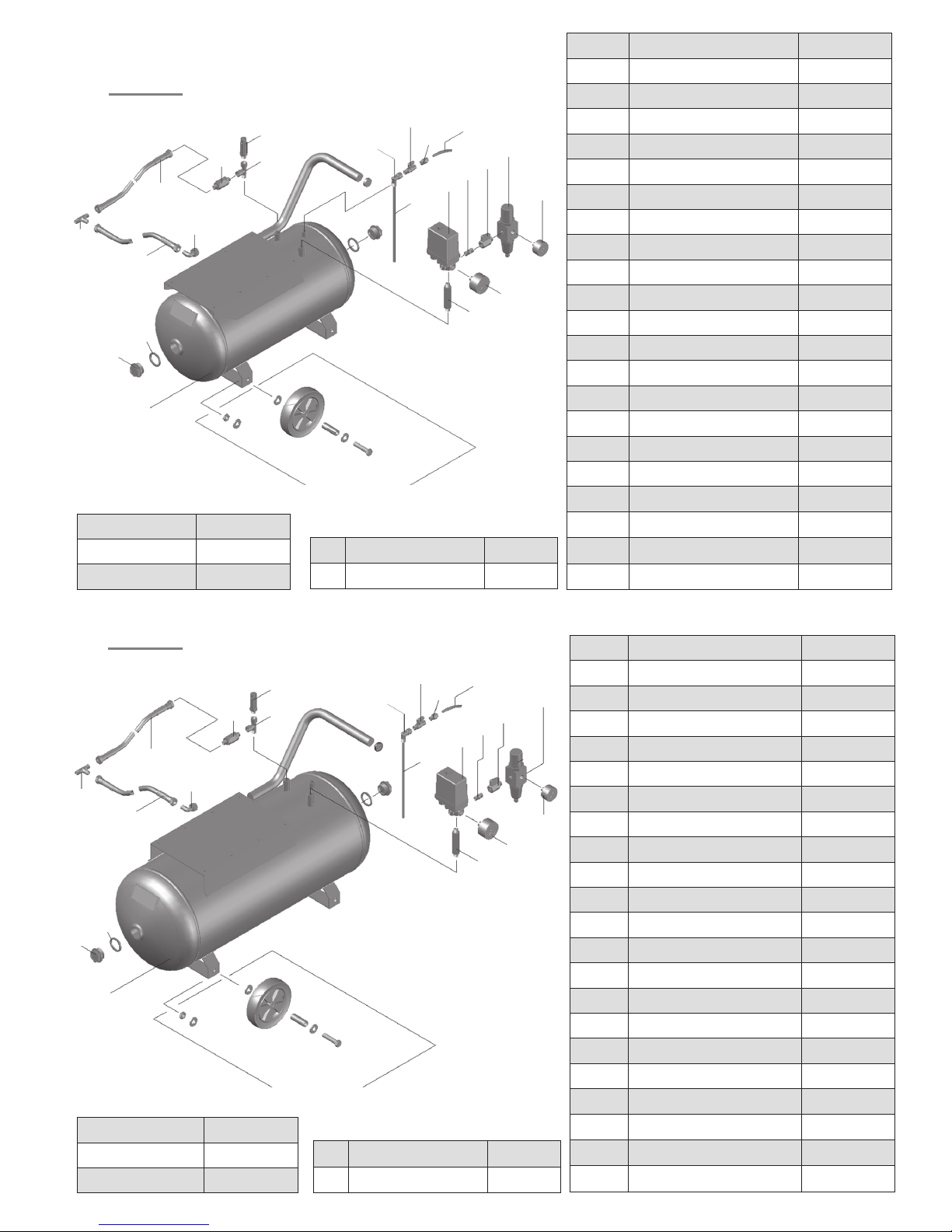

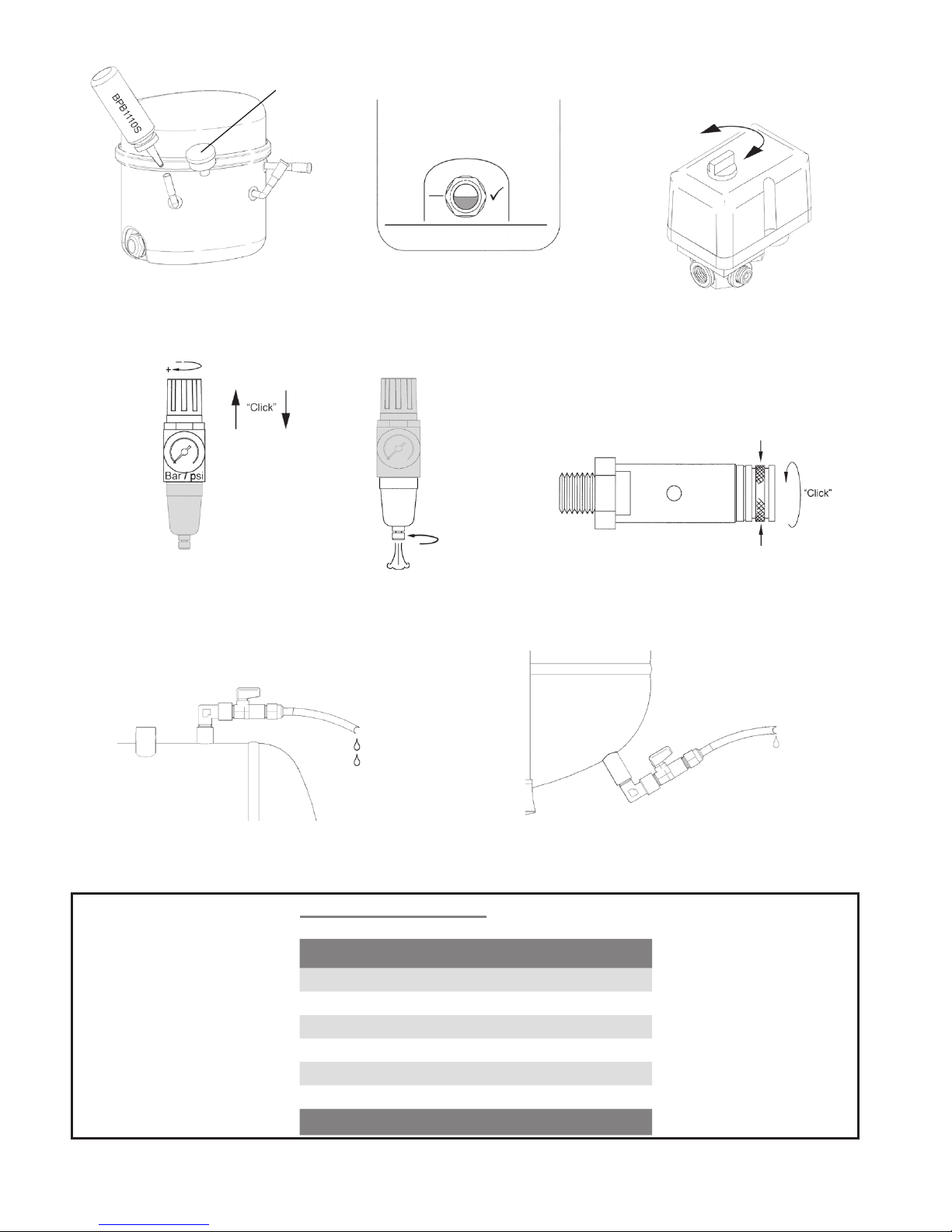

Refer to exploded parts diagrams and illustrations when reading this section.

operating temperature 0°C

Oil Level

Your Bambi Compressor is shipped pre-lled with oil for your convenience. Before use, please let the compressor stand for 20-30

minutes to let the oil settle in the sump. The bottle of oil supplied is to be used for topping up the compressor as and when required

- see g.1 for more detail.

Air Filter

The plug on the air lter intake must be removed and the air lter tted before use - see g. 9 and g. 10 on the card attached to

compressor.

Your airline should be tted to the outlet of the lter regulator.

Always use Bambi BPB1110S compressor oil. Failure to do so will invalidate your warranty.