Bend-Tech Dragon A400 User manual

A400

Part 1 of 1

Cooling System Assembly Manual

Version 3.1 | English ©2020 Bend-Tech LLC

ii Bend-Tech Dragon A400

Cooling System Assembly Manual

©2020 Bend-Tech LLC

All rights reserved. The information in this manual is subject to change without notice. Bend-

Tech LLC strives to produce the most complete and accurate information regarding its

products. We are constantly working to advance our products to improve product performance,

user satisfaction and experience. Bend-Tech LLC assumes no responsibility for errors or

omissions regarding this manual. Bend-Tech LLC assumes no liability for damages resulting

from the use of the information contained in this publication.

iiiBend-Tech Dragon A400 Cooling System Assembly Manual

Dragon A400

Cooling System Assembly Manual

Version 3.1

English

Original Instructions

February 2020

Bend-Tech, LLC

729 Prospect Ave.

Osceola, WI 54020 USA

(651) 257-8715

www.bend-tech.com

iv Bend-Tech Dragon A400

Cooling System Assembly Manual

Covering Bend-Tech Dragon

Bend-Tech, LLC provides a limited warranty on all new Dragon machines that are

manufactured directly or under license by Bend-Tech, LLC, and sold by Bend-Tech, LLC or its

approved distributors.

Warranty Coverage

Each Bend-Tech Dragon machine is warrantied by the manufacturer against defects in material

workmanship for 12-months. The warranty period commences upon delivery of the Dragon

machine to the customer’s facility.

Repair or Replacement Only

The Manufacturer’s sole liability, and the Customer’s exclusive remedy under this warranty

shall be limited to repairing or replacing the defective part. Repair or replacement of parts

is at the sole discretion of the manufacturer. The Customer is responsible for warranty parts

installation. Bend-Tech does not provide warranty service labor.

Limits

This warranty does not cover components subject to wear due to normal use of the machine

such as belts, lights, tooling etc. This warranty is void if Bend-Tech, LLC has determined any

failure is the result of mishandling, abuse, misuse, improper installation, improper storage,

Software

Dragon software is covered by a 2-year maintenance plan from the purchase date of the

Dragon A400 machine. After the 2-year maintenance plan is expired, the Customer can

purchase a maintenance plan. A maintenance plan will ensure the customer always has

the newest version of Dragon software. The maintenance plan is critical to keeping Dragon

software updated with the newest capabilities possible, and is critical to the servicing of the

machine. Bend-Tech, LLC will contact the Customer regarding updates to the maintenance

plan within 1-month of expiration. Contact Bend-Tech Support to ensure software is up to date:

Limited Warranty

vBend-Tech Dragon A400 Cooling System Assembly Manual

Any questions or concerns regarding this manual can be directed to Bend-Tech, LLC

representatives via the Dragon website, www.bend-tech.com. Click Contact in the menu bar for

communication options and send your comments to the Dragon Customer Service department.

Online Resources

• https://www.youtube.com/user/bendtech2020

• http://www.bend-tech.com/wiki7

• http://www.bend-tech.com

• https://www.facebook.com/2020ssi

• https://www.instagram.com/bend_tech

Customer Service

Congratulations on your purchase of the world’s best CNC plasma tube and pipe cutting

machine, the Dragon A400. Bend-Tech, LLC places great pride in customer satisfaction and it

our support is a key factor in your success.

Contact Us

You can contact Bend-Tech, LLC customer service at 651-257-8715. Our support hours are

mailing address is: Bend-Tech LLC, 729 Prospect Ave., Osceola, WI 54020, U.S.A..

Customer Satisfaction Commitment

vi Bend-Tech Dragon A400

Cooling System Assembly Manual

This manual contains important statements that are called out from the regular text with an

associated signal word: “Danger,” “Warning,” “Caution,” or “Note.” Each of these signal words

is accompanied by its own icon. These signal words and icons indicate the severity of the

condition and the warning. The machine operator should familiarize themselves with these

warnings and read the statements before operating the machine.

Denitions & Examples

Danger

Danger indicates a serious condition that could cause severe injury or death to the operator or

bystanders if the instructions are not followed.

Warning

A Warning indicates there is a possibility for minor injury if the instructions are not followed

correctly.

! Danger !

Exceeding the material weight limit of the Dragon A400 can result in serious injury

to the operator and/or bystanders.

! Warning !

Due to the extreme temperatures that result from the plasma cutting process, parts

cooled in water in the parts catcher can still be extremely hot. Always use caution

when handling newly-cut parts.

Warnings

Example

Example

viiBend-Tech Dragon A400 Cooling System Assembly Manual

Caution

Caution warns the operator that minor injury or machine damage could occur if instructions are

being performed.

Note

! Caution !

the Dragon A400.

Water Cooling system greatly reduces smoke and vapor emitted by the machine.

Bend-Tech recommends use of the Water Cooling system whenever possible.

Example

Example

viii Bend-Tech Dragon A400

Glossary

Cooling System Assembly Manual

Glossary

A400

Indicates machine with 400-lb weight limit.

Axis

Bend-Tech 7X

Machine design software - CAD.

BOB

Breakout Board.

Material Support Lifter

The Material Support Lifter supports

material to reduce sag.

Chuck

Located on the Trolley, the Chuck holds the material

so it can be moved forward, backward and rotated.

Control Box

Connects Dragon Software Suite to the Dragon A400.

Coolant Tray

Cools cut parts as they are produced.

Drive Belt

The X Motor uses the Drive Belt to power the

Trolley along the Rail. The Drive Belt is mounted

stationary along the length of the machine.

Drive Belt Pulley

The X motor uses the Drive Belt Pulley to engage

the Drive Belt and power the Trolley along the Rail.

E-Stop

Emergency stop.

ESS

Ethernet Smooth Stepper (Control Board).

Ethernet

System for connecting multiple computers

via a Local Area Network.

Front Gate

The Gate supports the material at the

front of the machine. It consists of two

sets of self-centering roller jaws.

Gate Lead Screw

Controls operation and adjustment of the Gate.

Interface

Any particular screen display generated

by Bend-Tech software.

Mach3

Machine driver software.

Parts Catcher

The parts catcher is placed at the front of the

machine to catch parts as they are cut.

Rail

The Rail is the main structure of the Dragon

A400. The Trolley rides on the Rail.

Tail

The Tail is located at the opposite end of the Head

of the machine. The Tail arrives pre-assembled. The

X Axis homing sensor, Drive Belt Adjustment Block

and E-Stop are located at the Tail of the machine.

Toolhead

Operates the Marker, Engraver and Torch.

Trolley

The Trolley rides on the Rail, and carries

the Chuck forward and backward along

the length of the Rail Support Beam.

ixBend-Tech Dragon A400 Cooling System Assembly Manual

Contents

Limited Warranty ............................ iv

Customer Service............................ v

Customer Satisfaction

Commitment .................................... v

Warnings ......................................... vi

Glossary......................................... viii

Contents.......................................... ix

01

Parts and Equipment ............. 11

1.1 Parts List ......................11

1.2 Tools and Equipment ............ 12

02

Cooling System Assembly .... 13

2.1 Overview ..................... 13

2.1.1 Cooling System Assembly

Tools ......................... 13

2.2 Water Tray System Components ... 14

2.2.1 Parts Catcher and Support Leg

Removal ...................... 14

2.2.2 Support Leg Gusset......... 14

2.2.3 Leveling Feet .............. 15

2.2.4 Parts Catcher.............. 15

2.2.5 Attach Water Tray to Parts

Catcher ....................... 16

2.2.6 Water Tray System Assembly . 17

2.2.7 C Bracket................. 18

Contents

2.2.8 Aluminum Support Leg

Braces. . . . . . . . . . . . . . . . . . . . . . . . 18

2.2.9 Finishing the Tray System

Assembly ..................... 19

2.3 Water Tray Drain System ......... 19

2.3.1 Bung Installation ........... 19

2.3.2 PVC Drain Installation ....... 20

2.3.3 Tray System Drain Diagram. . . 20

2.3.4 Placing the Cooling System

Reservoir ..................... 20

2.4 Water Pump ................... 20

2.4.1 Water Pump Requirements ... 21

... 21

2.5 Hose System .................. 21

2.6 Connect the Pump .............. 21

2.7 Install the Water Pump........... 21

2.8 Attaching the Hose to the Rail

Beam ........................... 22

2.9 Hose Reel Mount ............... 22

2.10 Hose Reel ................... 22

2.11 Trolley Hose Mount ............ 23

2.12 Connect the Hose ............. 24

2.13 Leveling the Aluminum Tray

System .......................... 24

2.14 Sealing the Aluminum Tray

System .......................... 24

2.15 Control Box Cover ............. 25

2.16 Fill the Reservoir .............. 25

2.17 Male Plug Coupler ............. 25

xBend-Tech Dragon A400

Contents

Cooling System Assembly Manual

11Bend-Tech Dragon A400

Parts and Equipment

01

Cooling System Assembly Manual

01

Parts and Equipment

1.1 Parts List

Cooling System

• Plug Kit

• Aluminum Trays (3)

• Aluminum Support Legs (3)

• Parts Catcher/Control Box Cover Box

• Reservoir

• Hose Reel

• Hose Reel Mount

Cooling System Hardware (shipped

inside water reservoir)

• Hardware Bag

• Material Rollers (3)

• Clear Silicone (1)

• PVC Cement (1)

• Cushion Clamps (6)

• Leveling Feet (6)

• Disposable Mesh Bags (2)

• 8 in. zip ties (8)

Fastener Bag

• Nuts (54)

• Washers (54)

• ¾ in. Button Head Hex Screws (40)

• 1 in. Button Head Hex Screws (14)

PVC Components

• Coupling (5)

• Union (3)

• Bung (4)

• Tee (2)

• Elbow (2)

• Pipe (11)

Reel and Hose Hardware

• ¼-20 T-nuts (6)

• ¼-20 ½ in. Hex head screws

• Flanged hex head screws (8)

•

• ¾ in. FGHT x ½ in. FIP + Male Coupler

12 Bend-Tech Dragon A400

Parts and Equipment

01

Cooling System Assembly Manual

1.2 Tools and Equipment

• ¾ in. FGHT x 1/8 in. FIP + Male Coupler

• ¾ in. Barb x ¾ in. FGHT w/rubber

grommet

• Hose Clamps (2)

Cooling System Tools List

•

• Rubber Mallet

•

•

•

•

adapter

•

• ½ in. wrench

• Flat head screwdriver

13Bend-Tech Dragon A400

Cooling System Assembly

02

Cooling System Assembly Manual

02

Cooling System

Assembly

2.1 Overview

The Dragon A400 Cooling System enables the machine to achieve cleaner cuts with less

burr and slag. The Cooling System also reduces plasma dust and toxic gas during the cutting

process. While the Cooling System will help the Dragon A400 achieve cleaner cuts on any

2.1.1 Cooling System Assembly Tools

Before assembling the Cooling System the Installer should ensure the required tools are

available. The following tools are required to assemble the Cooling System:

Tools Needed

•

•

•

•

•

•

•

• Slotted or Flat blade

screwdriver

• Punch or small Phillips

screwdriver

• Utility knife

• Rubber mallet or plastic dead

blow hammer

• Large channel lock pliers

14 Bend-Tech Dragon A400

Cooling System Assembly

02

Cooling System Assembly Manual

2.2 Water Tray System Components

The Water Tray System is placed at the Head of the machine. The Water Tray System serves

as both parts catcher and water drainback system for the Cooling System. Before beginning

assembly, assure that all components of the Water Tray System are present. The Water Tray

System consists of:

• Aluminum Trays (3)

• Aluminum Support Legs (3)

• Parts Catcher (1)

• Support Leg Braces (6)

• Parts Rollers (3)

• Leveling Feet (6)

• C Bracket (1)

2.2.1 Parts Catcher and Support Leg Removal

If the Installer is adding a Cooling System to a Dragon A400 machine that has already been

assembled and run without a Cooling System, it will be necessary to remove the Parts Catcher,

the four screws that hold the Parts Catcher at the front and back end of the Beak. Remove the

eight screws that hold the Parts Tray where the Beak mounts to the Head of the machine. Use

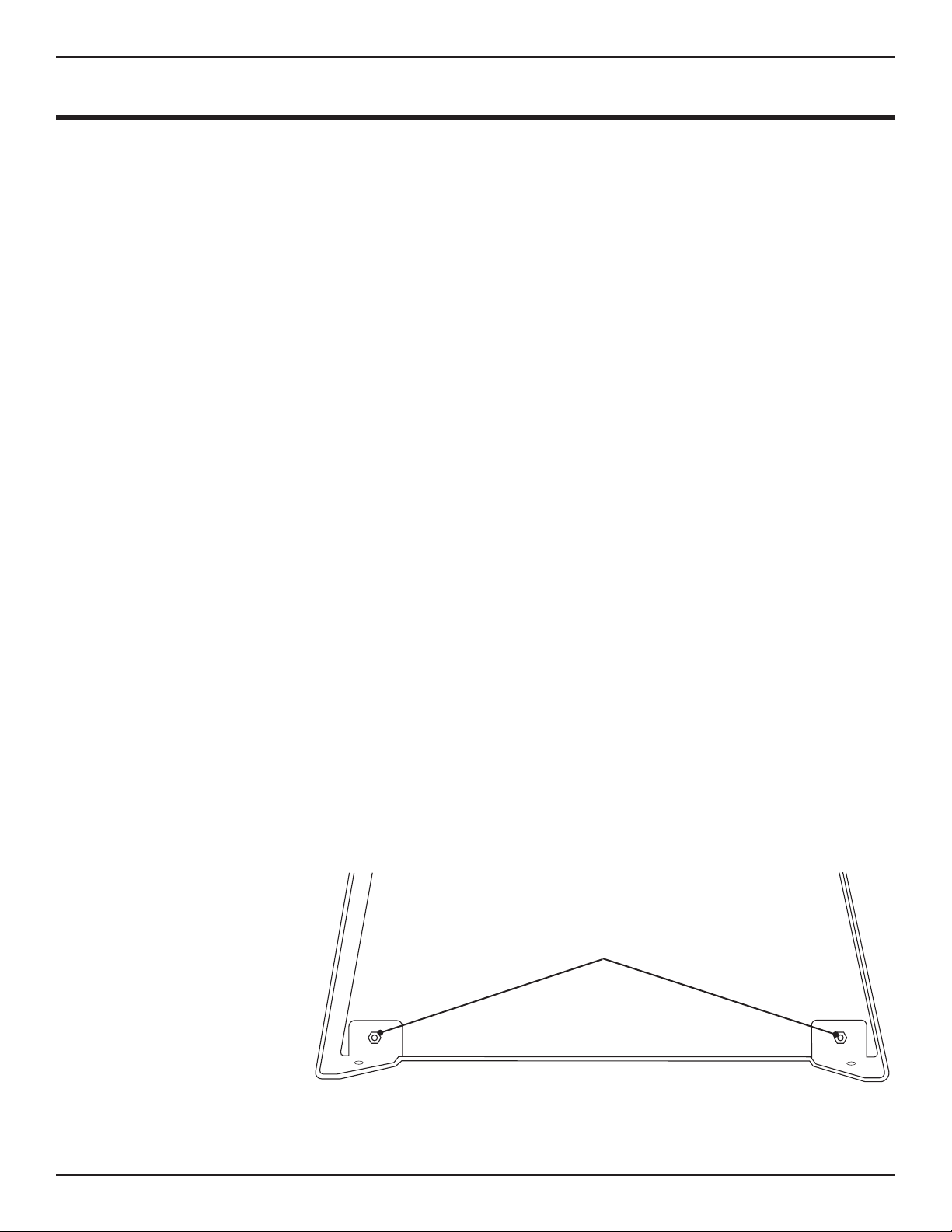

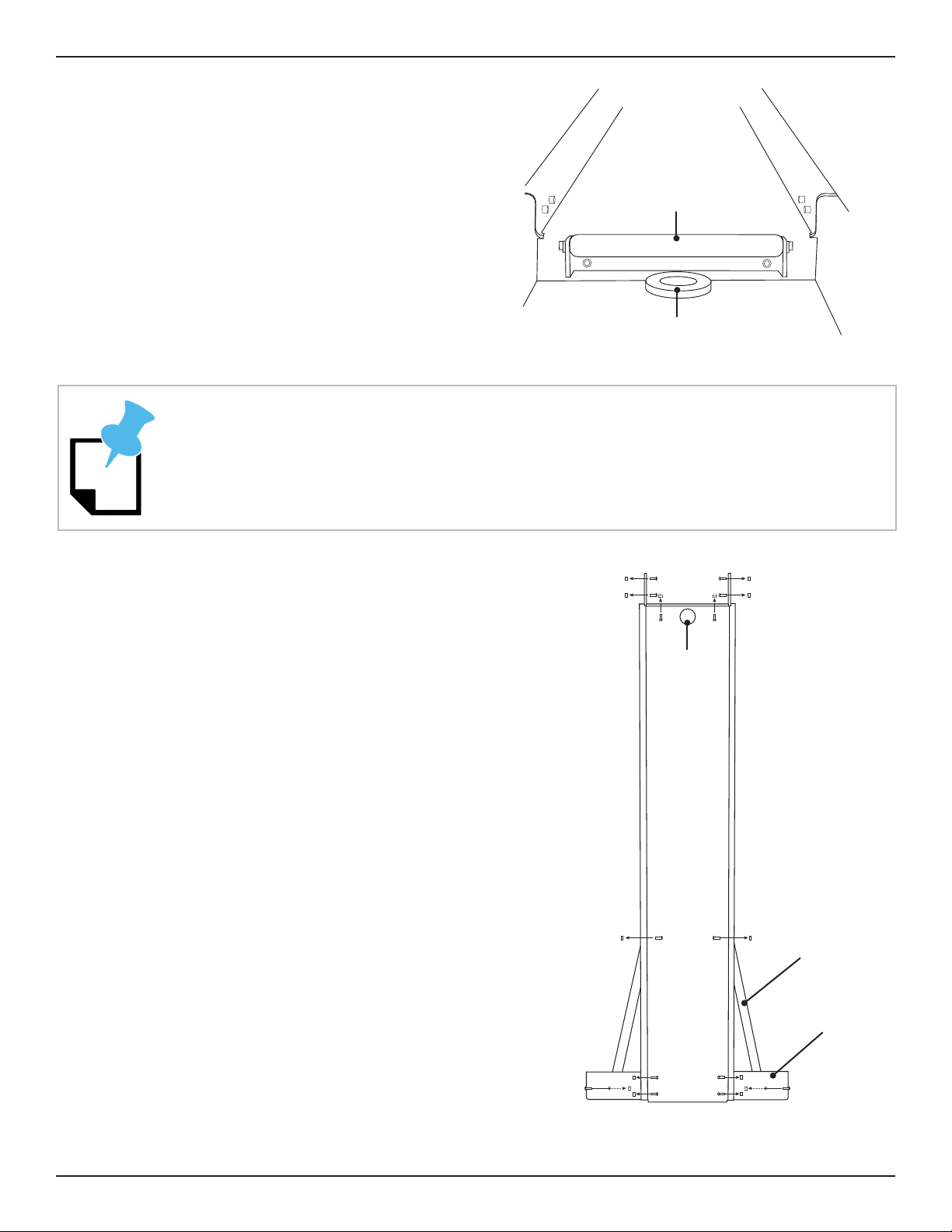

2.2.2 Support Leg Gusset

The bottom of each support leg is constructed with an integrated gusset design. In each

corner, the Installer will be required to secure the gusset using a 1 in. Button Head Hex Screw,

washers and nut. Place a washer on the 1 in. Button Head Cap Screw and insert into the hole

in the Support Leg and gusset. Place a washer on the inside and thread a nut onto the Button

Head Cap Screw. Use

socket and ratchet

to tighten the nut,

securing the gusset.

1 in. Button Head

Cap Screw

15Bend-Tech Dragon A400

Cooling System Assembly

02

Cooling System Assembly Manual

2.2.3 Leveling Feet

Locate the Leveling Feet in the hardware bag. Thread a nut onto each leveling foot, leaving

about an inch between the base of the foot and the nut. Insert a Leveling Foot into the hole at

the bottom of each Aluminum Support Leg.

Thread a second nut

onto the Leveling

Foot after inserting it

in the mounting hole

on the bottom of the

Aluminum Support

Leg. Do not tighten.

Leave space for

adjustment of the

Aluminum Support

Leg.

2.2.4 Parts Catcher

Place the Parts Catcher on the Beak at

the Head of the machine, just in front

of and under the Gate opening.

Locate eight ¾ in. button head screws,

nuts and washers from the hardware

bag. Insert the eight fasteners through

the slotted opening in the Parts

Catcher, aligning them with the holes in

the Beak.

Ensure the screw heads are on the

outside of the assembly and the nuts

and washers are on the inside. Thread

the nuts on and snug them down. Do

not tighten the nuts at this time.

2.2.5 Attach Water Tray to Parts

Bend-Tech recommends enlisting a helper when assembling the Water Tray System.

Head of Machine

Parts Catcher

4 Bolts

per side

Leveling Feet

16 Bend-Tech Dragon A400

Cooling System Assembly

02

Cooling System Assembly Manual

Catcher

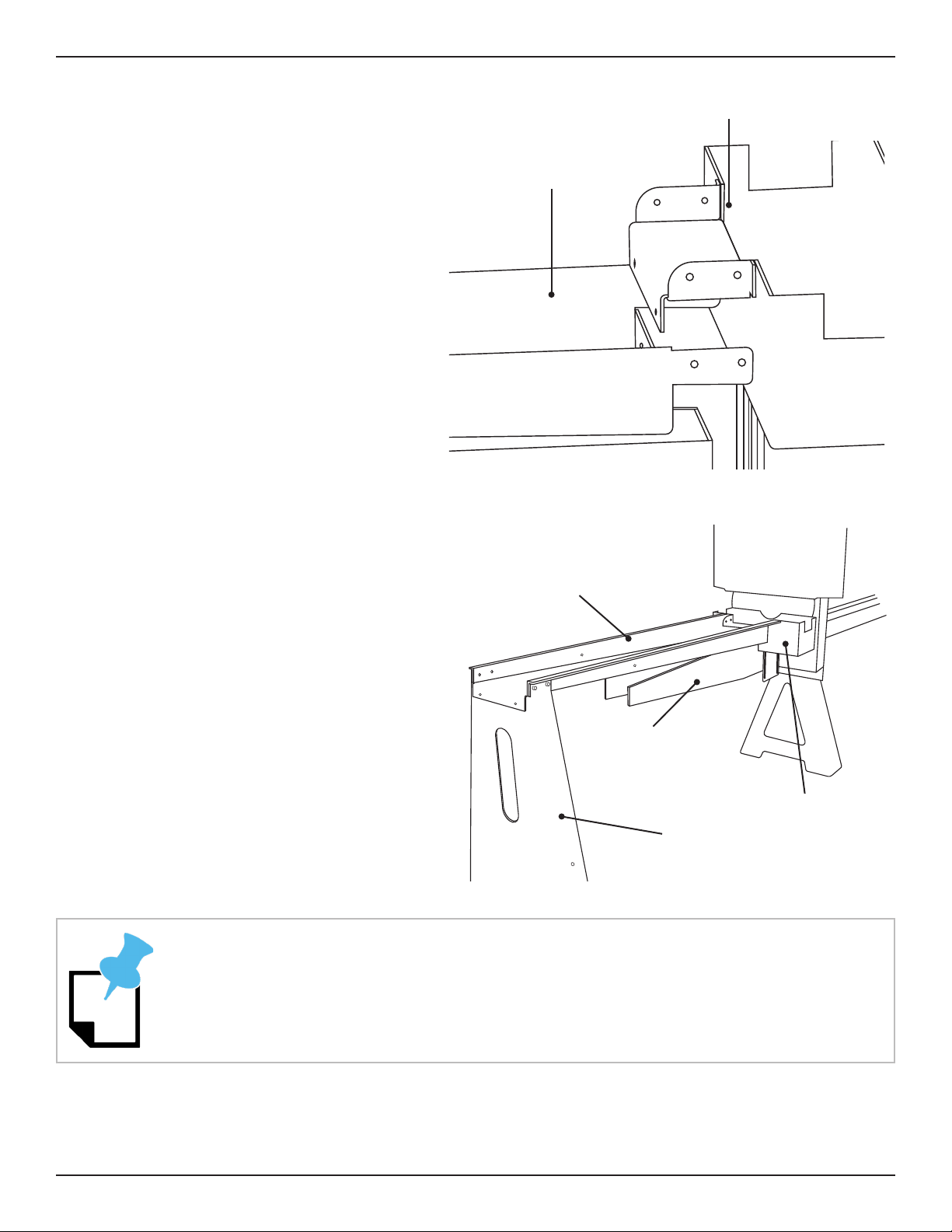

When assembling the Water Tray

System, the face of the Water Tray

Tray will connect to the Parts Catcher

Water Tray behind the lip of the Parts

Catcher.

Use one of the Aluminum Support Legs

to support the free end of the Water

Tray. Use four ¾ in. button head screws,

nuts and washers to attach the side tabs

on the Water Tray to the Parts Catcher.

Feed the screws through the side of the

Water Tray so the head of the screw is

inside the Water Tray and the nut and

washer are on the outside.

Use a punch or small Phillips head screwdriver to help align the mounting holes in the

Water Tray system.

Head of Machine

Tray 1

Support Leg

Beak

Parts Catcher

Parts Catcher

Tray 1

17Bend-Tech Dragon A400

Cooling System Assembly

02

Cooling System Assembly Manual

Locate one of the rollers from the parts

bag. Using two 1 in. button head screws,

nuts and washers, attach the roller on

the inside face of the Water Tray where it

connects to the Parts Catcher. Feed the

button head screw through the roller and

through the mounting holes in the Water

Tray and the Parts Catcher. Ensure the

roller is placed as far up as possible.

2.2.6 Water Tray System Assembly

Position the second Water Tray behind the

Aluminum Support Leg to support the free

end of the second Water Tray. Position

mounting surface is on the outside of both

water trays. Align the four mounting holes

in the Aluminum Support Leg with the

and the side tabs on the second Water

Tray.

Fasten the sides of the Water Trays and

Aluminum Support Leg together using

four 1 in. button head screws, nuts and

washers. Ensure the heads of the screws

are on the inside of the water tray and the

nuts and washers are on the outside. Do

not tighten.

Top View

Drain

Support Leg Brace

Support Leg

Tray or Parts

Catcher

Drain

Roller

Do not tighten any fasteners on the Tray System Assembly until all components of the

Tray System Assembly are connected.

18 Bend-Tech Dragon A400

Cooling System Assembly

02

Cooling System Assembly Manual

Repeat this process with the third Water Tray.

2.2.7 C Bracket

Place the C Bracket at the front end of

Aluminum Tray No. 3. Align the mounting

holes of the third Aluminum Support Leg

with the holes in the Water Tray and C

Bracket.

with the heads on the inside of the Water

Tray and the nuts and washers on the

outside of the Aluminum Support Leg.

Below the C Bracket, insert two ¾ in.

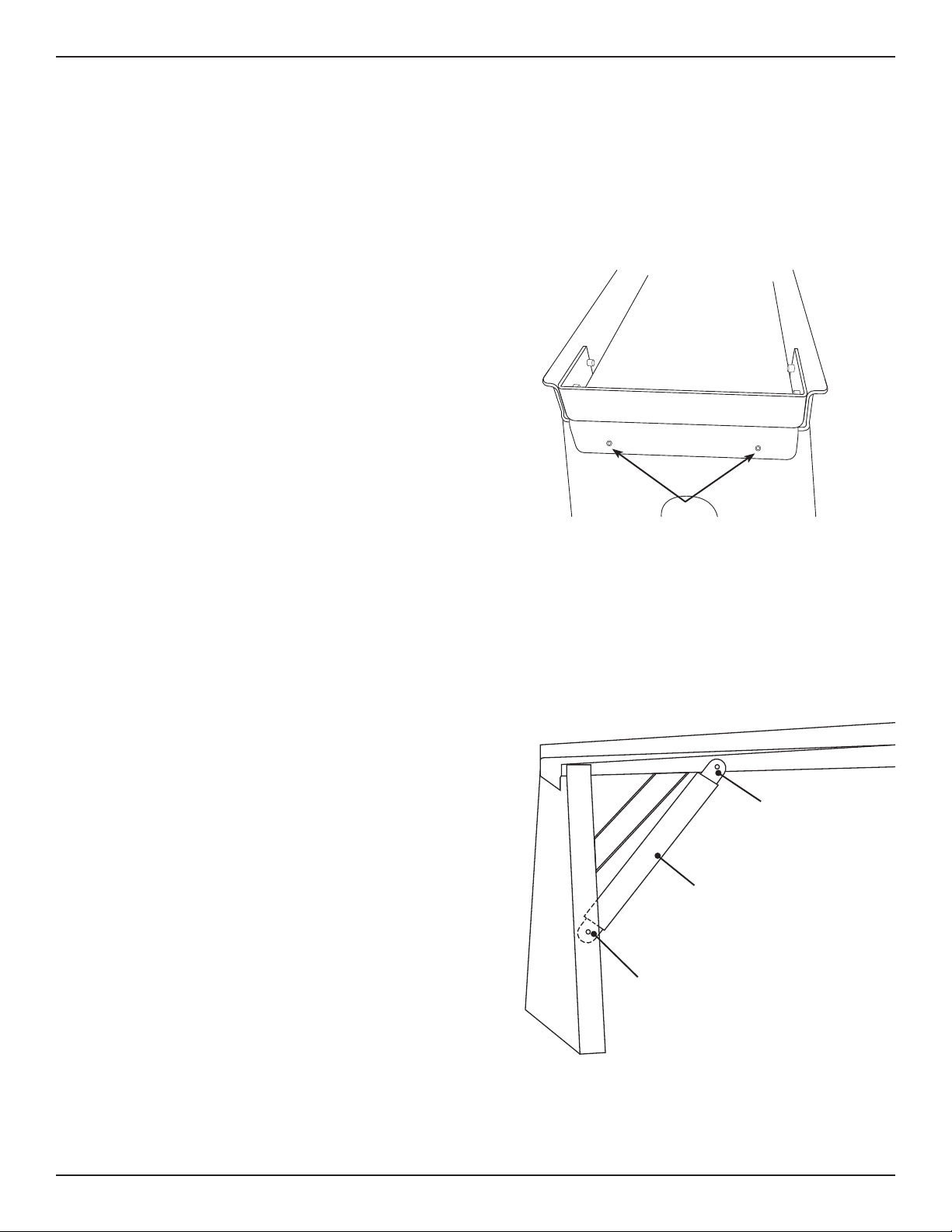

2.2.8 Aluminum Support Leg Braces

Starting at the front of the system, use (12)

¾ in. button head screws, washers and nuts

to attach the Aluminum Support Leg Braces

to the Aluminum Support Legs and the

Water Trays.

Support Leg Brace to the inside the of the

Aluminum Support Leg, inserting the button

head screws so the head is on the outside

of the Aluminum Support Leg and nut and

washer are on the inside.

Attach the bent end of the Aluminum

Support Leg Brace to the outside of the

Water Tray, feeding the button head screw

from the inside of the Water Tray and the

nut and washer are on the outside.

Outside of Tray

(Bent End)

Support Leg Brace

Inside of Support

Leg (Flat End)

Tray 3

C-Bracket

fasteners

19Bend-Tech Dragon A400

Cooling System Assembly

02

Cooling System Assembly Manual

2.2.9 Finishing the Tray System Assembly

Braces. Tighten securely. Take care to position the rollers so they sit above the surface of the

Tray System, adjusted as high as possible.

2.3 Water Tray Drain System

The Cooling System’s Water Tray Drain

System collects water from the Tray

System, holds it in the Cooling System

Reservoir and recirculates it back through

the material.

2.3.1 Bung Installation

Locate the four drain bungs in the PVC

parts bag. Remove the coupling nuts from

each drain bung. Insert a bung into the

drain hole in each Aluminum Tray and in

the Parts Catcher. Thread the nuts back

onto each bung underneath the Aluminum Tray and tighten securely using a large channel lock

pliers. Locate the male/female couplers in the PVC parts bag. Thread one PVC male/female

coupler into each drain bung.

Also thread one PVC coupler into the bung inside the parts catcher. This will allow the Parts

Catcher to hold water to help cool parts.

Teon tape or plumber’s tape can help seal the male/female coupler in the drain bung.

Drain Bung

Male/Female

Coupler

When in use, the rollers should keep parts from resting on the bottom of the Tray

System.

20 Bend-Tech Dragon A400

Cooling System Assembly

02

Cooling System Assembly Manual

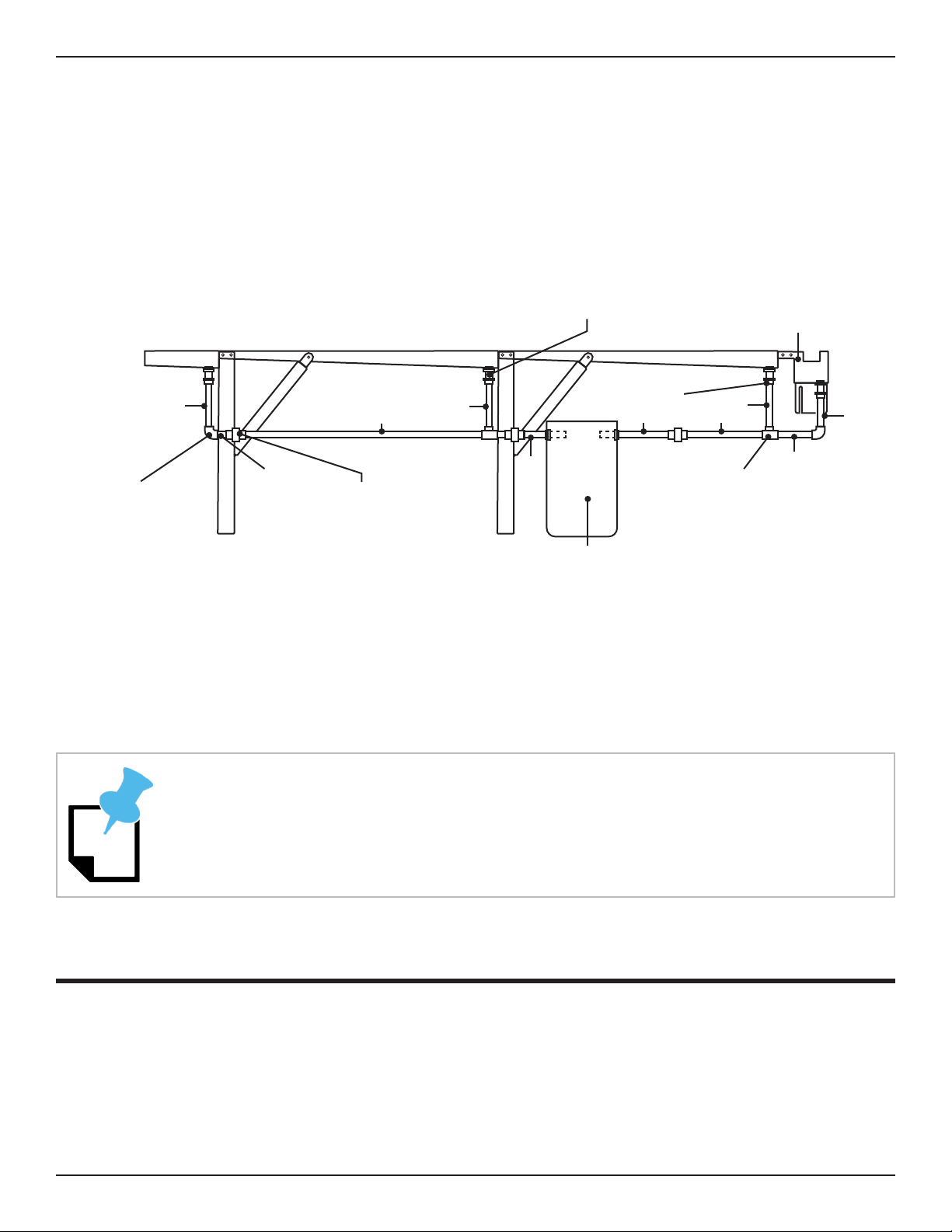

2.3.2 PVC Drain Installation

The PVC drain system is installed beginning at the Parts Catcher and then working to the end

of the Tray System. The PVC Parts are numbered in order of installation. During this process

the Installer will also place and connect the Cooling System Reservoir. Using PVC cement,

install the parts per diagram 2.3.3.

2.3.3 Tray System Drain Diagram

2.3.4 Placing the Cooling System Reservoir

Place the Cooling System Reservoir according the diagram in section 2.3.3. Install the screens

on the drains feeding into the Cooling System Reservoir. Secure using zip ties.

Fit the No. 5 and No. 6 PVC pieces through the grommets in the reservoir.

2.4 Water Pump

The Cooling System requires the addition of a water pump to be operational. Because

customer needs can vary, Bend-Tech does not supply a water pump with the Cooling System.

The Customer will be required to supply a water pump to complete the Cooling System. Refer

Drain Bung

Coupler

Parts Catcher

Union Fitting

Elbow Fitting T Fitting

Cooling System

Reservoir

1

2

3

45

8

9

10

11

6

Depending on the size of the the water pump used, the pump may need to be placed

into the reservoir prior to connecting the reservoir to the rest of the PVC drain system.

Other manuals for Dragon A400

14

Table of contents

Popular Accessories manuals by other brands

Visonic

Visonic DUO 200 installation instructions

Rice Lake

Rice Lake IQ plus 310A Technical and service manual

ISYGLT

ISYGLT LS-05-HF-WH Technical Data/Instruction Manual

Garmin

Garmin TruSwing Quick start manual

Gin Gliders

Gin Gliders Safari Pilot 2 user manual

Omega Engineering

Omega Engineering Series Micro Flow Sensor FP-5060 user guide