2

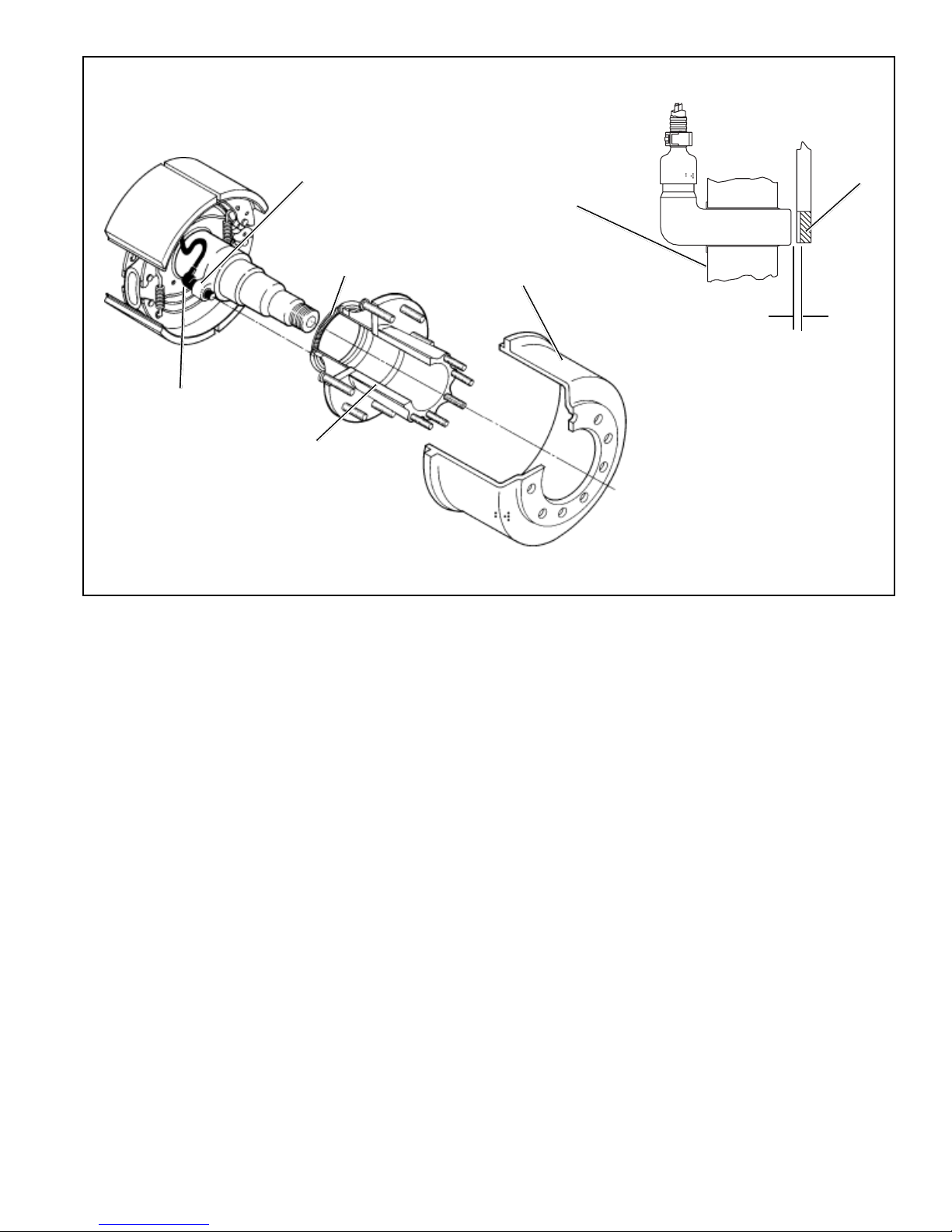

ANTILOCK CONTROLLER

& RELAY

WS-20™SPEED SENSORS

EXCITERS

FRONT WHEEL REAR WHEELS

feature allows the WS-20™sensor to "self adjust" after it

has been installed in the mounting block and the wheel is

installed.

When the WS-20™sensor is inserted all the way into the

mounting block and the wheel is installed on the axle, the

hub exciter contacts the sensor, which pushes the sensor

back.Also,normalbearing play will "bump" thesensoraway

from the exciter. The combination of these two actions will

establisharunning clearance or air gap between the sensor

andexciter.

FIGURE 2 - SPEED SENSOR VOLTAGE CYCLE OUTPUT

PEAKTO PEAK

PEAKTO PEAK

HIGHSPEED

LOWSPEED

TECHNICAL INFORMATION

ElectricalConnector- 2 Pin.

OutputVoltage- With a 3,000 Ohm resistor across

thetwosensorleads,outputvoltage

measured on a VOM = .800 VAC

Minimum at 42 Hz, or

approximately5 mph.

SensorGap- 0 to .015 inch.

SensorBody- FormulatedEpoxy;.628" Diameter.

NormalResistance

RangeatRoomTemp- 2000-2500ohms

PREVENTIVE MAINTENANCE

1. Every 3 months; 25,000 miles; 900 operating hours; or

duringthevehiclechassis lubrication interval, makethe

visual inspections noted in "SERVICE CHECKS"

below.

2. Every12months;100,000miles;or3600operatinghours,

performtheOPERATIONALTESTinthis manual.

SERVICE CHECKS

Check all wiring and connectors. Make sure connections

arefreefromvisibledamage.

Examine the sensor. Make sure the sensor, mounting

bracket,andfoundationbrakecomponentsarenotdamaged.

Repair/replaceas necessary.

WARNING! PLEASE READ AND FOLLOW

THESE INSTRUCTIONS TO AVOID

PERSONAL INJURYOR DEATH:

When working on or around a vehicle, the following

general precautions should be observed at all times.

1. Park the vehicle on a level surface, apply the

parking brakes, and always block the wheels.

Always wear safety glasses.

2. Stop the engine and remove ignition key when

working under or around the vehicle. When

working in the engine compartment, the engine

should be shut off and the ignition key should be

removed. Where circumstances require that the

enginebe in operation, EXTREME CAUTION should

be used to prevent personal injury resulting from

contact with moving, rotating, leaking, heated or

electrically charged components.

3. Do not attempt to install, remove, disassemble or

assemble a component until you have read and

thoroughly understand the recommended

procedures. Useonlythepropertoolsandobserve

all precautions pertaining to use of those tools.

4. If the work is being performed on the vehicle’s air

brake system, or any auxiliary pressurized air

systems,make certain todrain the air pressurefrom

FIGURE 3 - TYPICAL ANTILOCK SYSTEM