Senect Oxygen Sensor O2S User manual

Oxygen Sensor O2S

Manual

Product type

2

Product type

Name of product:

SENECT®Oxygen Sensor O2S

Type:

O2S-20-SC

Art.-No.:

2100

Producer:

SENECT GmbH & Co. KG

An 44 –No. 11

76829 Landau / Germany

Important note:

Please read this manual carefully and store it so that you can use

it later. Read the warning and safety notes attentive.

Further information and latest software releases or documents

can be downloaded from:

www.senect.de

© SENECT GmbH & Co. KG - FW 01.10

Table of contents

3

Table of contents

Product type.................................................................................. 2

Table of contents........................................................................... 3

General Security Notes.................................................................. 5

Intended use.................................................................................. 7

Getting started .............................................................................. 8

Getting started –Short version................................................... 11

Maintenance and cleaning .......................................................... 12

Cleaning................................................................................... 12

Sensor disinfection .................................................................. 12

Recalibration ........................................................................... 13

Oxygen signal: 1-Point-calibration .......................................... 15

Short-version: Oxygen signal: 1-Point-calibration................... 17

Oxygen signal: 2-Point-Calibration.......................................... 17

Temperature: 2-Point-Calibration........................................... 18

Sensor Error............................................................................. 19

Salinity / Conductivity correction............................................ 20

Technical data ............................................................................. 22

Information about the correct disposal ...................................... 23

Guarantee.................................................................................... 24

Table of contents

4

Used symbols and wording

DANGER!

Warning of life threatening

dangers.

WARNING!

Warning of possible life

threatening and / or severe

irreversible injuries.

ATTENTION!

Warning of possible medium

or slight injury.

ATTENTION!

Follow the notes to avoid

damage of equipment.

NOTE!

Further information for the

use of the device.

NOTE!

Further information for the

use of the device.

General Security Notes

5

General Security Notes

The oxygen sensor O2S is an electronic unit for the

measurement of the concentration of dissolved oxygen in

water and must be used in combination with SENECT control

units.

Since it is an electronic product the common prerequisites

for a safe instrument usage must be fulfilled. The

corresponding control unit must be operatated

with 230 V AC (~50 Hz). Ensure that all cables are

installed safely so that no obstacles for persons are

built and all. Mount all cables and electric devices

protected against direct environmental impacts

like overheating by direct sunlight and water.

Even if the products are protected against spray

water, the product´s lifetime will be elongated, if it is

mounted on a protected place. The oxygen sensor O2S uses

24 V DC supply voltage which is therefore not of danger for

persons.

For many applications a ground fault circuit interruper

(interrupting current <= 30 mA) is required by law. Inform

yourself about the valid legislation.

General Security Notes

6

The operating temperature of the device must be between

0°C and +40°C. It is not allowed to modify the sensor, to open

the housing or to insert anything into the housing.

The oxygen sensor O2S is designed to be operated by

professional users. However, it can be operated by children

of the age of at least 8 years and persons with limited

physical, sensorial or cognitive ability, if they are supervised

and trained in the usage of the instrument, so that no

dangers or threats can result of the operation.

Please store this manual. We suggest the storage a copy of

the manual in the vicinity of the device.

Technical and optical changes of this manual are subject to

alterations.

Warning: Before starting any maintenance work,

unplug all electrical devices in the water.

Intended use

7

Intended use

The oxygens sensor O2S can be used to measure the

concentration and saturation of dissolved oxygen (O2) in

water in aquaculture applications. It has a measurement

range from 0 to 200% air saturation (a. s.) or 0 to 20 mg O2/

l at temperatures between 0°C and +40°C.

The sensor measures the saturation concentration based on

the principle of luminescence quenching with a resolution of

1% a.s. or 0.1 mg / l and the temperature with a resolution

of 0.1°C. Based on these two measurements, the absolute

concentration of dissolved oxygen in mg O2/ l is calculated.

The sensor is intended to be used in industrial aquaculture

farms in freshwater.

Getting started

8

Getting started

Scope of delivery

o1 x Oxygen sensor O2S

o1 x Manual

Note

Please check directly after delivery, that the

package is not destroyed or damaged or was

opened before. Please check also, that all parts as

listed above are included. If anything is missing or broken,

please contact us as soon as possible within 14 days.

Unfortunately, we cannot accept later information of

damage, which happened during the transport.

Installation and start-up

Choose a place for the electronic interface of the

O2S which is clean, dry and protected from direct

sunlight. Ensure that all cables are placed safely

and all regulations are fulfilled.

Remove the blue protection cap from the sensor and mount

the sensor so that the sensor is submerged.

It is also possible to mount the sensor so that only the lower

sensing part is submerged. Please ensure that the sensor is

Getting started

9

at least to 80% submerged, since the temperature is

measured on the sensor housing.

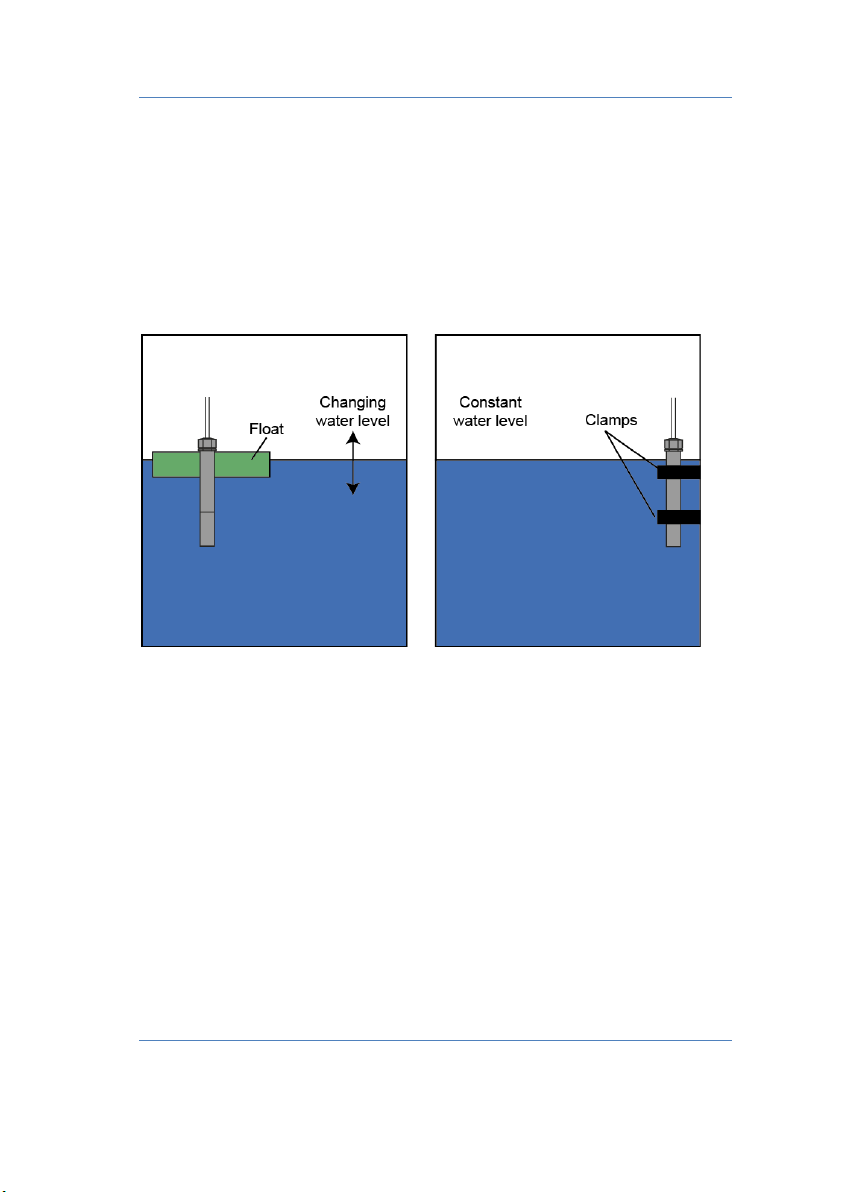

When the sensor will be installed at a location with a

changing water level, it can be mounted free swimming on a

float or completely submerged.

Fig. 1: Mounting possibilities of the sensor.

Please consider when selecting the mounting location that in

surface waters like fish ponds the solar radiation can lead to

a thermal stratification of the water body, associated with

strong gradients in dissolved oxygen.

Ensure to install the sensor at a location, where no rising gas

bubbles can be caught under the sensor.

Getting started

10

Fig. 2: Stainless steel holder Art. No. 2102.

Protect your sensor from fish biting on the sensor

membrane! SENECT offers protection cages.

Connect the blue marked plug of the sensor with a sensor

input port (also blue marked) of your control unit.

The SENECT control units recognize the sensor itself and start

automatically the measurements.

Take into account that the measurement interval is set to

30 s to elongate the lifetime of the sensing cap.

Getting started –Short version

11

The oxygen sensor O2S is factory calibrated and need to be

recalibrated –under for aquaculture typical environmental

conditions –after 6 months.

Getting started –Short version

1. Mount the sensor submerged.

2. Mount the black electronic interface at a protected

location.

3. Connect the sensor cable with a control unit (plug

„SENSOR“).

4. The control unit recognizes the sensor and starts the

measurements.

Maintenance and cleaning

12

Maintenance and cleaning

The O2S oxygen sensor measures the oxygen concentration

optically. This principle enables long-term stable

measurements with a high precision. However, dirt can

influence the measurements. For example, a biofilm on the

sensing membrane can lead to measurements of the oxygen

concentration of the biofilm and not of the surrounding

water.

Cleaning

The sensor should be cleaned regularly by wiping with a soft

water-dipped paper towel or a cotton swab without cleaning

agents.

Avoid the contact with organic solvents like for

example toluol, acetone or chloroform. These

solvents damage the sensing membrane. Also do

not steam-sterilize the sensor.

Sensor disinfection

The sensor can be disinfected with peracetic acid (max. 5

mg / l), methanol, ethanol, isopropanol or 3% H2O2 solution.

Rinse the sensor afterwards with tap water.

Maintenance and cleaning

13

Recalibration

The recalibration is recommended for typical applications

every 6 months. However, a regular weekly check of the

oxygen reading in humid air (should be ~ 100% a.s.) can be

used to check if the sensor needs calibration.

In some applications, e.g. under harsh environmental

conditions, the sensor must be recalibrated more frequently

to guarantee precise measurements. Please check regularly

the oxygen reading of the sensor when it is placed in humid

air.

Since the florescent membrane is prone to photobleaching

effects during the measurement and is therefore an

expendable part, it can be changed by replacing the sensor

cap (Art.-No.: 2101, Type: O2S-ATK). Please note, that the

sensor must be always recalibrated, if the sensing cap is

exchanged. A typical lifetime of the sensor cap is > 2 years.

Maintenance and cleaning

14

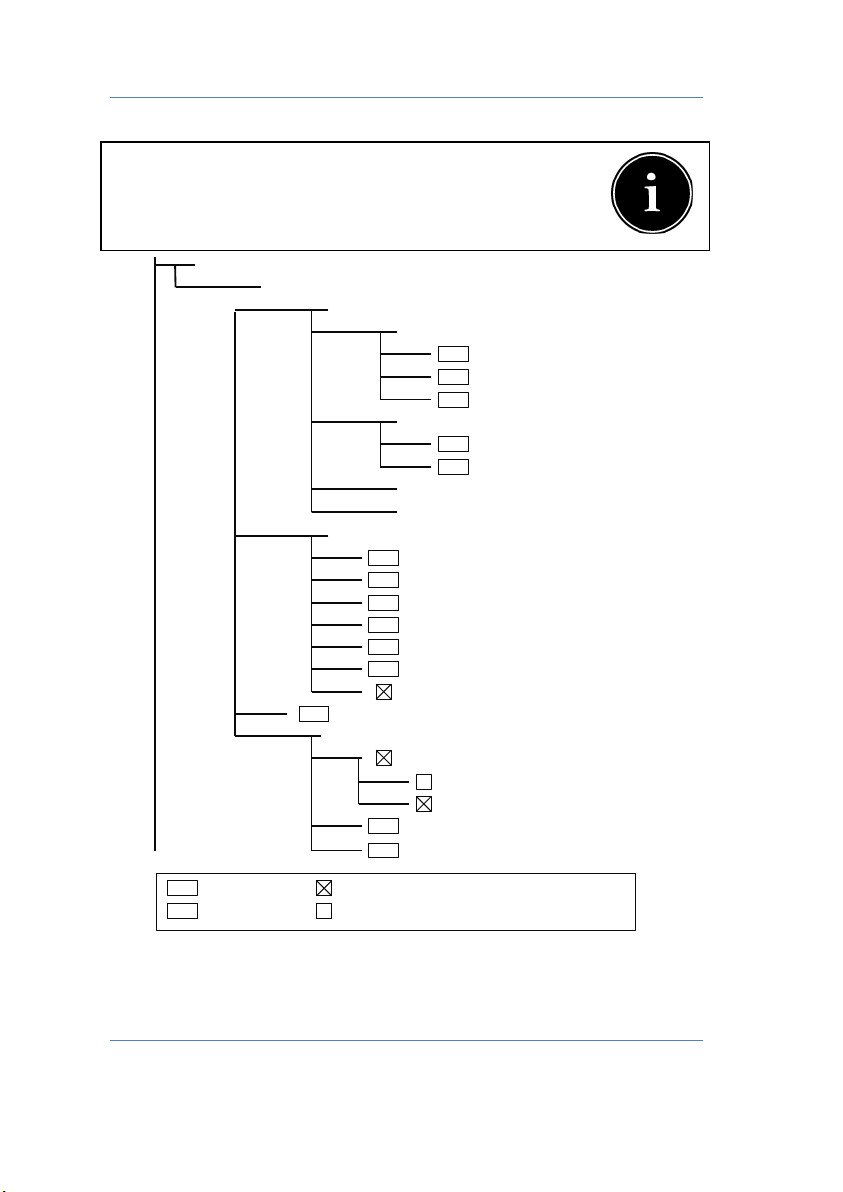

Depending on the actual software version, the

menu can be different. You find the latest

manuals at www.senect.de.

OK

123

123

123

123

123

123

123

123

123

123

abc

Sensors

S1: O2S Name

Sensor Calibration

O2 % a. s.

0% a.s.

100% a.s.

Factory settings

Temperature

Calibration Point 1

Calibration Point 2

Information

Info to SENECT

Alarm Threshold

Lower Threshold (O2)

Upper Threshold (O2)

Hysteresis (O2)

Lower Threshold (°C)

Upper Threshold (°C)

Hysteresis (°C)

Alarm On / Off

Plug Name

Salinity Correction

Mode

From sensor cor.

From fix value cor.

Correction Value

With plug

Selection set (default)

Selection not set

Numerical

Confirmation

123

OK FW01.10

123

123

Maintenance and cleaning

15

Oxygen signal: 1-Point-calibration

Place the sensor for several minutes at humid (100% water

vapour saturated) air and ensure, that there are no water

drops on the membrane.

Select in the menu „Sensors“ the oxygen sensor (O2S) and

choose „Sensor calibration/ O2 % a.s.“.

Select 100% a.s. (Calibration Point 2) to take up the 100%

a.s. calibration point. Wait the displayed 120 s and save this

point with OK.

Fig. 1: Calibration diagram with 2 calibration points.

Maintenance and cleaning

16

Alternatively, you can use air saturated water to create a

100% a.s. oxygen solution. Aerate therefore water with an

air pump and diffusor stone. After several minutes, the water

should be equilibrated with the air. This equilibrated water

has by definition an oxygen concentration of 100% air

saturation.

Attention! By using this method, inaccuracies can

be created by:

The air is injected with a pressure

exceeding atmospheric pressure. Therefore, the

partial pressure of O2can also be slightly increased.

The exact timing, when 100% saturation is achieved

is hard to determine, since oversaturation due to the

injection with overpressure can occur.

Oxygen depleting substances in the water can be

present so that 100% a.s. may not be achieved.

Due to these risks, we recommend the calibration on water-

saturated air.

The calibration should be carried out at the same

temperature like in the measured water.

Maintenance and cleaning

17

Short-version: Oxygen signal: 1-Point-calibration

1. Place the sensor in air

2. Menu / Sensors / O2S / Sensor calibration / O2 %

a.s. / 100% a.s.

3. Wait 120 s.

4. Press OK. Finished!

Oxygen signal: 2-Point-Calibration

For the 2-Point-Calibration perform at first the previous step

(calibration of calibration point 2, e.g. in air). Additionally,

perform the same procedure when the sensor is submerged

in oxygen-free water.

You can create an oxygen-free solution by adding 1 tea

spoon of sodium sulphite in 100 ml water (concentration 2

mol / l). Please wait 15 minutes until all oxygen is reduced.

Dip now the sensor in the solution, wait until the

measurement value is stabilized and select in the menu:

0% a.s. (calibration point 1). Save this calibration point.

More background information about the calibration of

oxygen sensors can be found in the DIN EN 25814.

Maintenance and cleaning

18

Temperature: 2-Point-Calibration

To calibrate the temperature signal of the O2S, two

calibration points are necessary. The calibration point 1 must

have a lower temperature (e.g. 0°C) than calibration point 2.

This temperature must be lower than 20°C.

The calibration point 2 (higher temperature) must be

between 30°C and 50°C.

Submerge the sensor in a water bath with the lower

temperature (calibration point 1) and wait, until the sensor

has the same temperature as the water. Select in the menu

“Sensors / O2S / Sensor Calibration / Temperature /

Calibration point 1”. Measure the water temperature with a

reference thermometer and enter this temperature with the

cursor keypad. Confirm the calibration point with OK.

Repeat this procedure for the upper calibration point 2 with

a temperature between 30°C and 50°C.

Tipp: You find the calibration information in the menu under

“Sensors / O2S / Sensor Calibration / Info”.

Maintenance and cleaning

19

Abbr.

Description

SN

Serial number

C0

Raw signal O2 at lower calibration point 1

(0% a.s.)

C1

Raw signal O2 at upper calibration point 2

(100% a.s.)

T0

Raw signal temperature at lower

calibration point 1 (e.g. 0°C)

T1

Raw signal temperature at upper

calibration point 2 (e.g. 0°C)

The SENECT control units measure the

atmospheric pressure and use this value for an

automatic pressure compensation.

Sensor Error

In case the sensor or the sensing membrane is damaged, the

control unit shows an error code. This information (together

with more internal sensor data) can be sent directly to

SENECT for troubleshooting service. Select in the Menu

“Sensors / O2S / Calibration / Info to SENECT”to send the

data via email to SENECT GmbH & Co. KG.

Maintenance and cleaning

20

Salinity / Conductivity correction

By connecting an SENECT conductivity sensor CON to the

SENECT control unit, an automatic salinity correction based

on conductivity measurements for the oxygen measurement

can be made (“Sensors / O2S / Salinity correction” – Mode:

From sensor cor.).

In case there is no conductivity sensor connected, the

conductivity can be entered manually under “Sensors / O2S

/ Salinity correction / Correction value”. Select also as

Mode: From fix value cor.

This manual suits for next models

1

Table of contents

Other Senect Accessories manuals

Popular Accessories manuals by other brands

Ascon tecnologic

Ascon tecnologic TRH 11 manual

Honeywell

Honeywell TRADELINE Y594 user manual

SOMFY

SOMFY Sunis WireFree RTS Light Sensor installation guide

Johnson

Johnson Relax Model Double Instructions for use

Lippert Components

Lippert Components Solera owner's manual

Learning Resources

Learning Resources Eclipse RGB user manual