Benner-Nawman BN Products JMB-25H User manual

| 1 |

BN Products-USA www.bnproducts.com

PRODUCT: JMB-25H

REBAR BENDER

OPERATIONS MANUAL

3450 Sabin Brown Road • Wickenburg, AZ 85390

JMB-25H 2023 HALF LETTER Operations Manual.indd REV | 0522023

| 2 |

BN Products-USA www.bnproducts.com

Thank you for choosing our JMB-25H Rebar Bender

This manual covers the proper operation and maintenance.

Before operating, please read this manual carefully for im-

portant procedures and safety.

All technical data and drawings in this manual are consistent

with the information on this product. As a result of revisions

and other on going updates, the contents of this manual

may be slightly dierent from the actual product. BN Prod-

ucts reserves the right to make changes at any time, without

notice and without incurring any obligation, please under-

stand.

The copyright of this instruction manual belongs to us. No

reproduction is allowed without the written consent from BN

Products-USA. All rights are reserved.

This manual is a permanent part of this rebar bender and

should accompany the rebar bender if it is resold.

| 3 |

BN Products-USA www.bnproducts.com

Please read this manual carefully to ensure the safe use of this bender.

Failure to comply with the instructions in this manual may lead to acci-

dents and injuries. Therefore, make sure to operate the machine in com-

pliance with these instructions. We are not liable for any damage caused to

the machine or injury to the operator resulting from unauthorized modi-

cation of the device or the use of parts that are not genuine.

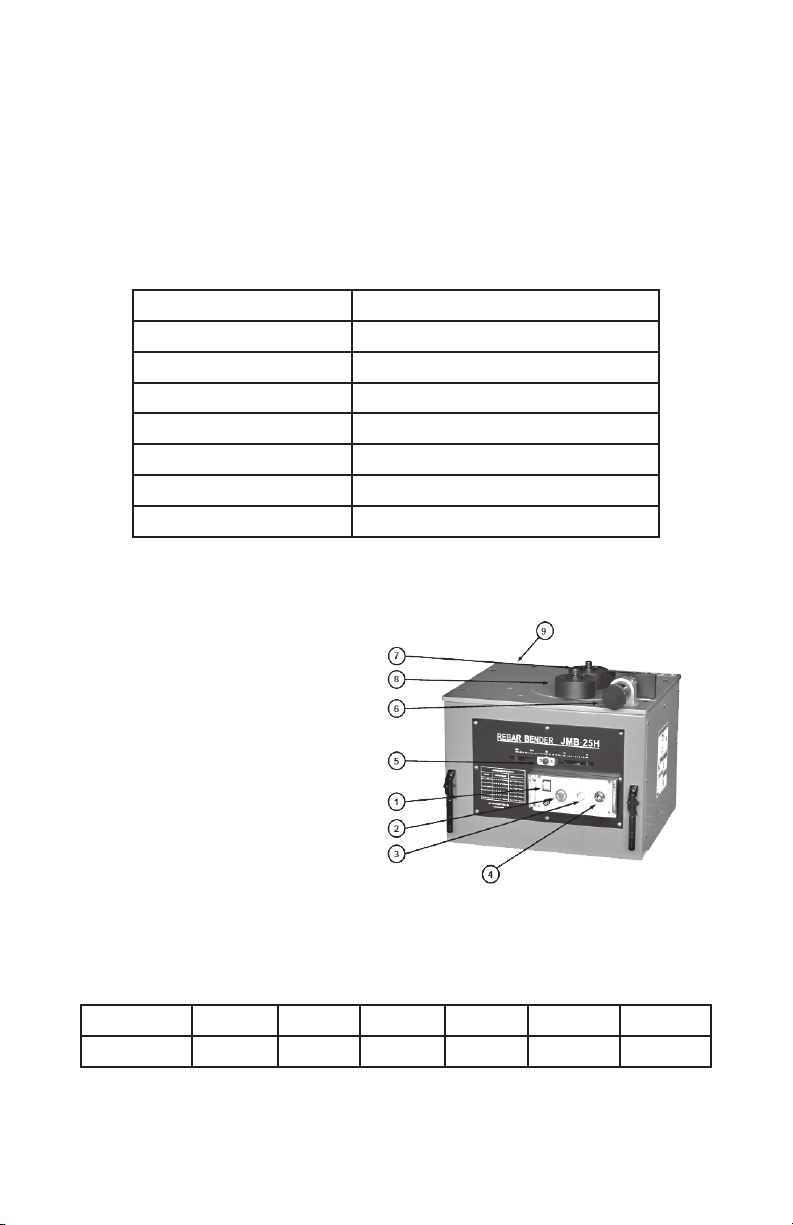

Basic Specications and Performance

Specications

Classication JMB-25H

Power Supply Single Phase 115V / 60HZ

Current 12 Amp

Motor 2.2 kW

Bending Capacity 25mm ( #8)

Bending Angle 1~180

Bending Time 180 / 7sec.

Weight 132kg

Feature Identication

1. Power Switch

2. Emergency Switch

3. Operation Switch

4. Footing Switch

5. Angle Adjustment Handle

6. Bar Adjustment Stopper

7. Center Roller

8. Moving Roller

9. Spring Tension Bolt

Simultaneous Bending Capacity and Number of Bars

(refer to the front panel of the machine)

Rebar No. No. 3 No. 4 No. 5 No. 6 No. 7 No. 8

JMB-22 4 3 2 2 1 1

| 4 |

BN Products-USA www.bnproducts.com

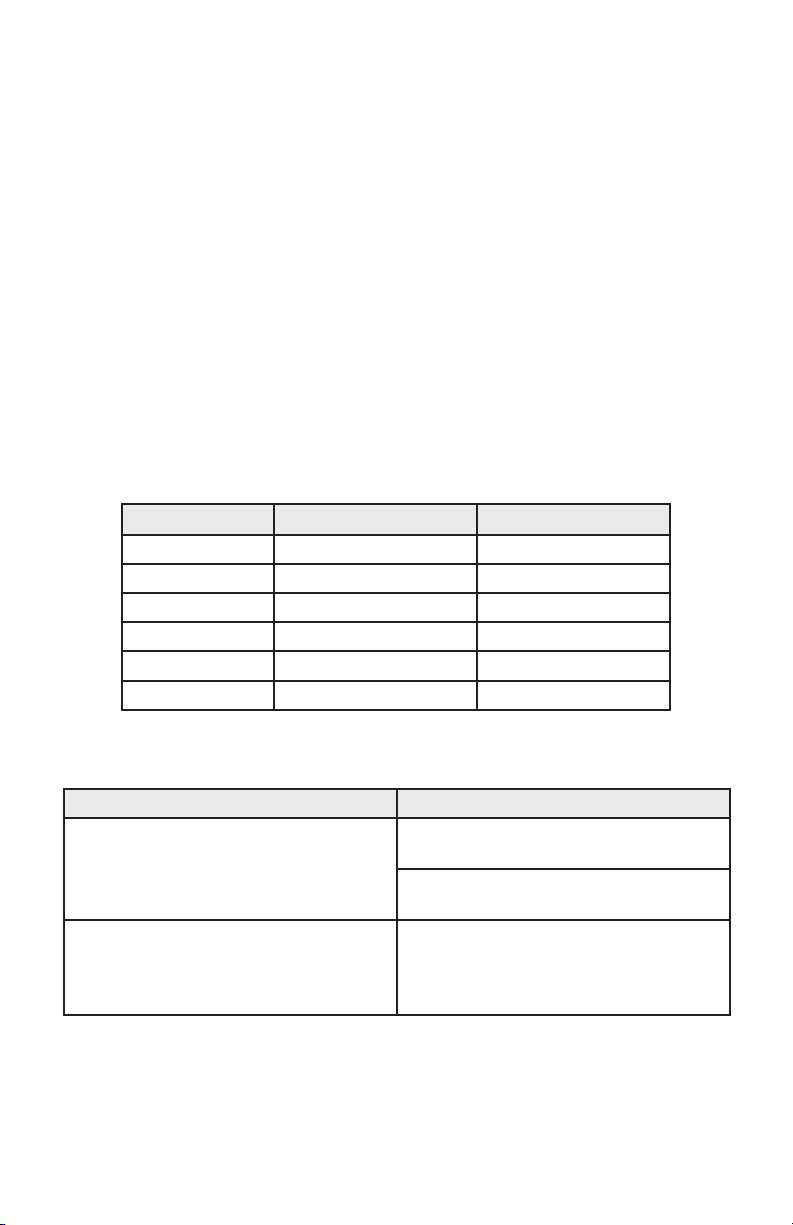

Installation and Work Preparation

Installation

• Install the machine on a level, even surface.

• If the ground is not level, use an auxiliary base capable of supporting

the bender rigidly.

Power Connection

• Power cable conductor must be at least 5.5mm2.

• Power cable length must not exceed 50m.

(If it exceeds 50m, use a cable of 8mm2 minimum.)

Work Preparation

• Turn on the power switch. Set the Angle Adjustment at about 135, and

let the machine run idly for at least 3 minutes.

• (Warming up should be at least 5 minutes in winter.)

• Once warmed up, set the desired angle for bending.

• Select the roller according to the thickness of the steel bar.

Bar Diameter Center Roller Moving Roller

#8 1” (25mm) No. 7 - 5.97” (153mm) No. 1 - 2.54” (65mm)

#7 7/8” (22mm) No. 6 - 5.15” (132mm) No. 3 - 3.63” (93mm)

#6 3/4” (19mm) No. 4 - 4.45” (114mm) No. 5 - 4.45” (114mm)

#5 5/8” (16mm) No. 3 - 3.63” (93mm) No. 6 - 5.15” (132mm)

#4 1/2” (13mm) No. 2 - 3.09” (79mm) No. 8 - 6.48” (166mm)

#3 3/8” (10mm) No. 1 - 2.54” (65mm) No. 9 - 7.14” (183mm)

Periodic Check and Maintenance

Trouble Inspection and Maintenance

Excessive noise Check the precision of the reducing

gear.

Check for wear or damage of the gears

in the gearbox.

Bar angle cannot be adjusted Remove foreign matter from the Angle

Adjustment Slide.

Check switch for ease of operation.

Repair or replace as appropriate.

| 5 |

BN Products-USA www.bnproducts.com

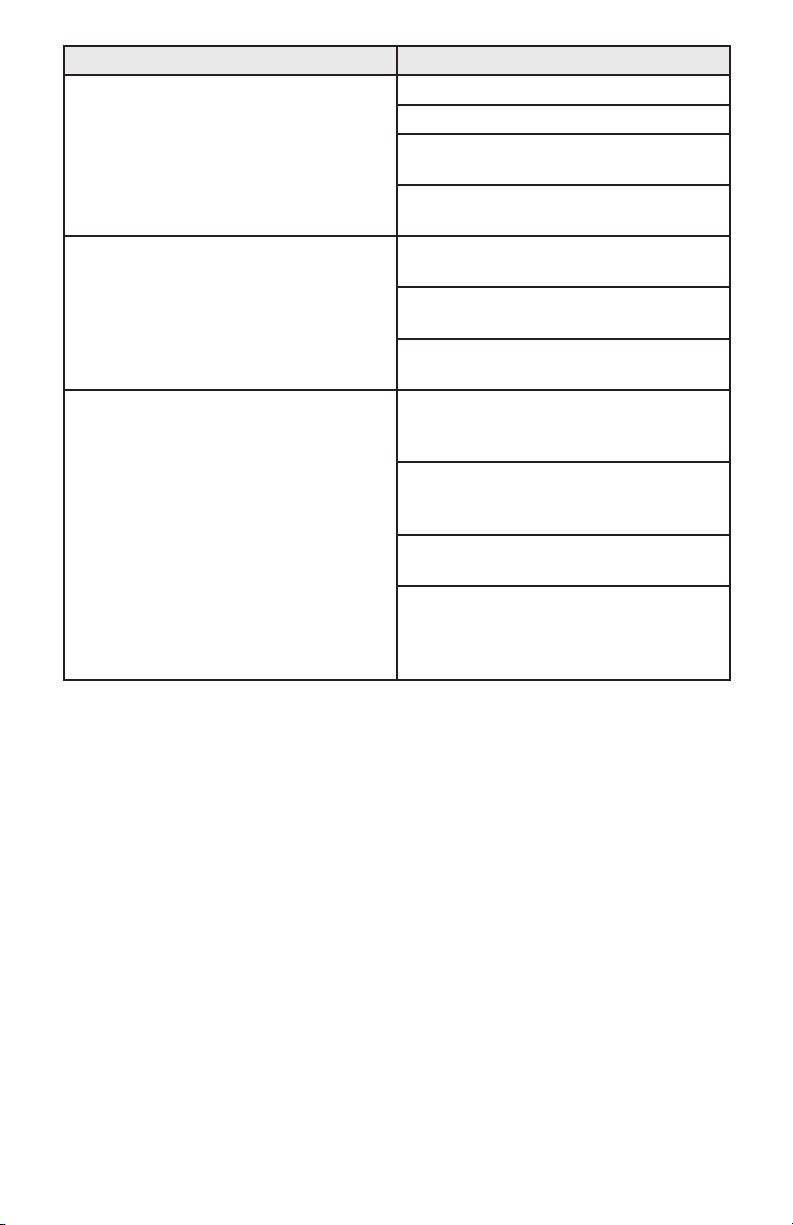

Trouble Inspection and Maintenance

Does not rotate Check Foot Switch connection.

Check if Emergency Switch is pressed.

Check gear connection. Take measures

as necessary.

If motor output power is reduced, re-

place carbon brush of motor.

Electric devices and wiring connection Check connections from time to time.

Fix wiring when necessary.

Check switch operation. Remove for-

eign matter if necessary.

Check wiring connections. Correct bro-

ken or damaged lines.

Clean-up Clean the machine of dust and bar

chips with a brush (do not use com-

pressed air).

Check for cracks or damage in mechan-

ical parts. Replace or request after-ser-

vice as necessary

After the rainy season or after rain, pull

o cover and dry machine completely.

When soaked in water or exposed to

rain, there is a danger of electric shock.

Do not try to use the machine. Call for

service.

Precautions

• Do not exceed the machine’s capacity for simultaneous bending. If

exceeded, machine failure may result.

• When bending rebars while holding them, watch out for your ngers

and prevent accidents.

• Depending on the rebar material, it may fracture during bending, re-

sulting in an accident. Therefore, keep your attention fully focused on

the bending work.

• Ensure that no persons or objects are within the radius of the bending

rebar.

• Since this machine uses electric power, rain or water may cause an

electricity leak. Keep in a dry place or cover with a waterproof lm.

• When moving the machine, check that the transportation handle is

rmly xed.

| 6 |

BN Products-USA www.bnproducts.com

Repairs and Security

• Replacing the carbon brush - Be sure to isolate the power plug from

the power source. Check the carbon brush for wear when the machine

is not in operation. If the carbon brush in the motor, which is subject

to wear and tear, is worn, the motor will lose power or even stop until

the power is next turned on. In such cases, the carbon brush(es) must

be replaced.

• On the motor inside the machine, unscrew the brush cap with a

straight tip screwdriver, and remove the brush together with the spring

(replace both of the brushes.)

• When replacing the rotating roller or xed roller, clean up with a brush.

• Inspection and Security. Check that bolts and nuts are fully tightened

from time to time.

• Dry the machine suciently after the rainy season or rainfall before

operation

• If the rotating roller jolts when returning to its original position, adjust

it by unscrewing the spring tension adjustment bolt. If it returns too

slowly, tighten the adjustment bolt.

• The machine is ready for operation when the power indicator lamp

lights up after power input and power switch. If the lamp is not lit,

check the power cable connection.

• If the machine does not start up when the power lamp is lit, check the

fuse or check the carbon brush in the motor for wear.

• In the event of other troubles, please call (800) 992-3833

Table of contents