Berchtold Podo-Q User manual

DE/RU/EN/JP/IT/ES/CZE

OPERATING INSTRUCTIONS

Podo-Q

Technical Data 4

Safety Instructions 4

Operation 4

Control Unit 5

Touchpad operation 6

Display operation 7

Changing the dust bag 8 - 9

Hand piece maintenance and cleaning 10-11

Motor and motor hand piece 12-13

Settings 14

Fault diagnosis control unit 15

Fault diagnosis motor hand piece 16

Contents

5

EN

4

EN

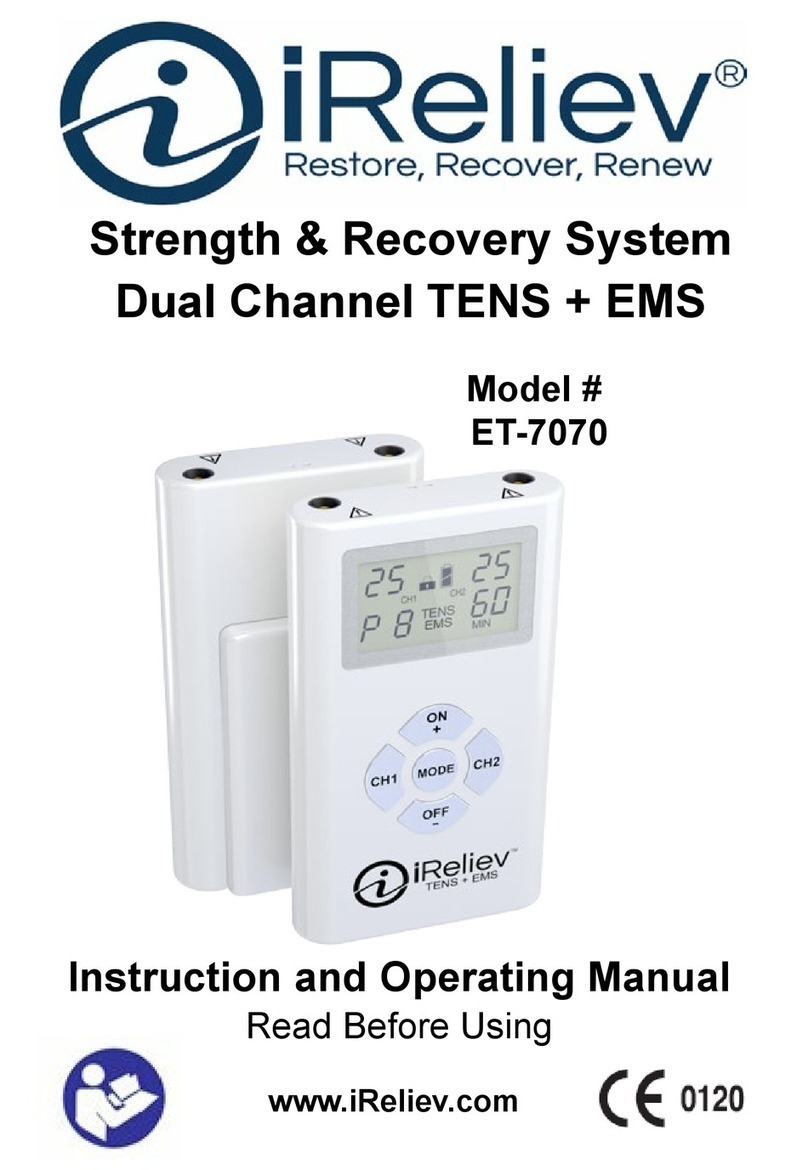

Control UnitTechnical Data

Dimensions W x H x D: 290 x 80 x 250mm

Equipment: Control unit, micro motor hand piece,

dust bag, power cord, instruction

manual

Weight: 2300g

Voltage: 95-265V 50/60Hz

Warranty: 24 months

12 months for hand piece

• To prevent overheating, at least

30mm clearance must be kept on

all sides of the device. The venting

slots in the device must not be

blocked under any circumstances.

• Protect the device from moisture

• The device must not be used to

draw liquids

• Only authorized experts are allowed

to open the device

• Unauthorized opening renders the

warranty void

• The plastic housing must not be

cleaned with petrol or chemical

detergents. Only use a slightly

moistened towel for cleaning.

(Unplug device first)

• Disinfect the surface of the hand

piece with a surface disinfectant.

Make sure no liquid enters the

handpiece.

• Press suction cover with dust bag

into dust bag compartment. (see

pages 8/9) Insert the hand piece

cable‘s plug into socket (bracket

pointing downwards).

• Plug the device into a properly

installed 95-265 V / 50-60 Hz AC

power socket and turn on power

switch. (Display lights up)

• On the touch sliding strip you can

adjust the burr/mandrel rotation to

the desired value. Lightly touching

the suction level symbols lets you

set the suction level (see page 6).

The device is put into operation via

the start/stop switch or the switch

on the hand piece. Other functions

can be operated via the touch pad,

as described below.

• Insert burr/mandrel into hand

piece as far as possible. The burr/

mandrel in this hand piece is

automatically powered as soon as

the motor starts. The burr/mandrel

may be removed again after the

hand piece has come to a stop.

• Never remove burr/mandel when

the device is running to avoid risk

of injury! Please do not ever use

burrs/mandrels with damaged or

bent shafts! Shaft diameter must

be 2.35 mm. Please also mind

permissible maximum speeds

allowed for the respective burr/

mandrel attachment.

Touchpad

Display

Hand piece connector socket

Fuse

external lamp

IEC connector

Power switch

Dust bag compartment

Safety Instructions

Operation

7

EN

6

EN

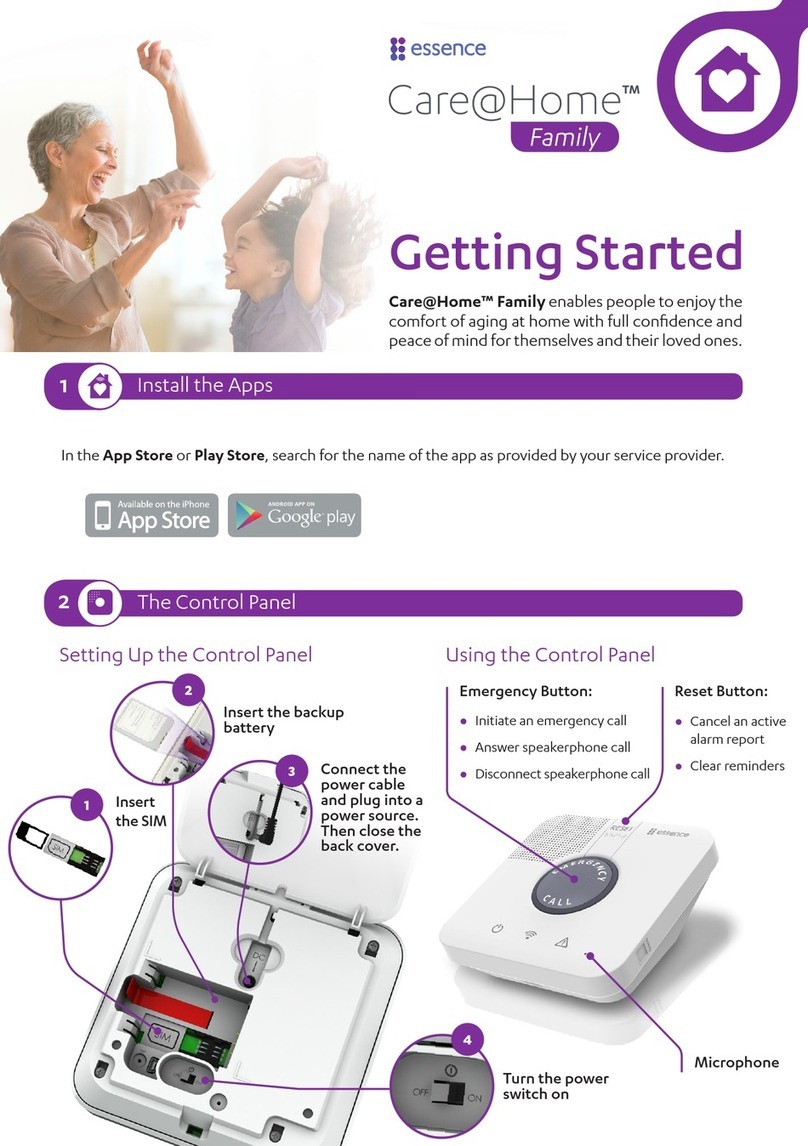

Touchpad & Display

Suction stop and standby button

If pressed for 4 seconds, the device goes

to standby mode.

Device is automatically put into standby

mode if not operated for

more than 2 hours.

Start/Stop button

Hand piece with

suction

Slider to adjust burr speed

Suction level button

low, medium, high

Memory function

Burr speed indicator

Rotations per minute

Suction strength indicator

low, medium, high

Press and hold „Start/Stop“ and press

the desired „Memory button“ to save

current burr speed, rotational direction

and suction level.

Memory buttons

Rotational direction button

left/right

Burr default and rotation

direction indicator

small, medium, large and left/right

Notice high milling speed

external light

ON / OFF

optional:

Chose your favourite settings burr speed,

burr direction and suction strenght

1.

2.

9

EN

8

EN

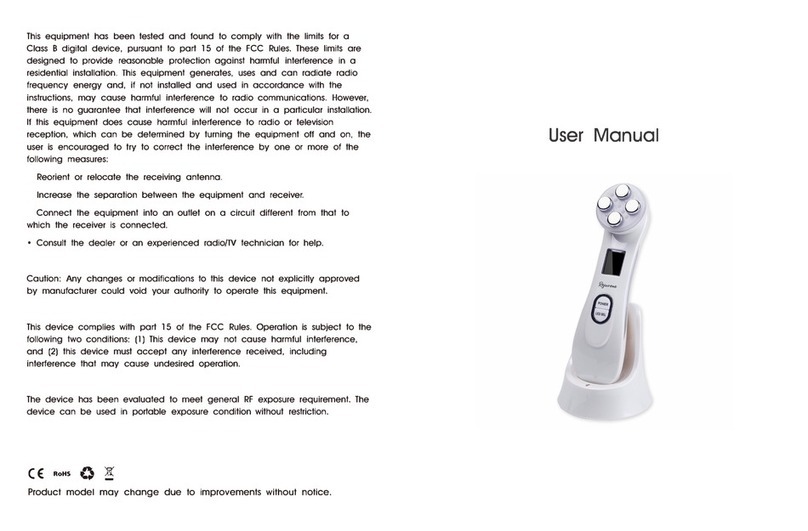

Changing the dust bag

Pull hand piece connector from socket

Dust Bag

Remove suction cover and bag

Separate bag from suction cover

Put suction cover on bag

and reassemble unit by following these steps in reverse order

Dust Bag

11

EN

10

EN

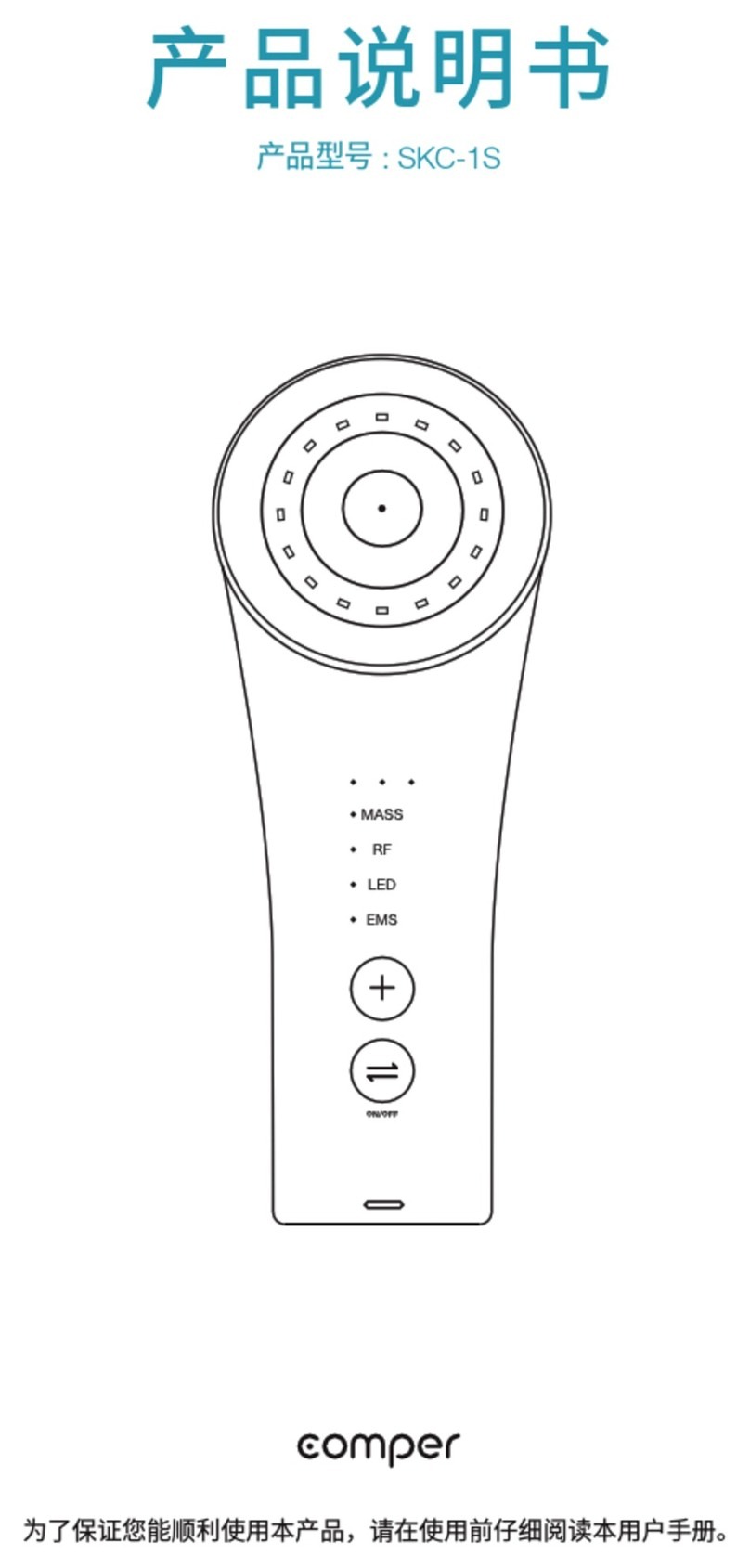

Hand piece maintenance and cleaning

Regular hand piece maintenance ensures a secure fit of the burr/mandrel

Maintenance

• Press polygon sleeve with

burr out of bearing bushing

Maintenance

• Insert burr into collet chuck, thus

pulling collet chuck and clamping

rollers out of polygon sleeve

• Clean collet chuck, clamping rollers

and polygon sleeve

• Assemble following these steps

in reverse order

Do not use oils or fats

• Remove burr/mandrel from

hand piece

• Unscrew handle sleeve

• Unscrew bearing bushing

and pull forward

13

EN

12

EN

Removing the micro motor

Disassembling the hand piece

• Loosen knurled nut by turning left

• Caution! Do not turn the plastic lid

Incorrect opening may damage connector pins on the micro

motor

Caution: Please mind the micro motor‘s connection pins

Disassembling the hand piece

• Pull motor with hand piece cover out of motor sleeve

• The motor may now be pulled from the hand piece cover

Regular hand piece maintenance ensures a reliable clamping of the burr/mandrel

• Remove burr/mandrel from

hand piece

• Unscrew handle sleeve

• Unscrew bearing bushing

and pull forward

15

EN

14

EN

Error Symbol Cause Solution

Dust bag

Dust bag full Exchange dust bag and confirm

(see page 8/9)

Hand piece

Hand piece not

inserted Hand

piece faulty

Check plug

Replace hand piece motor (see page

13)

Suction

Problem with

dust suction Turn device off using the power switch

and turn on again. Contact service

partner if problem persists.

Hardware

Hardware error

Processor error Turn device off using the power switch

and turn on again. Contact service

partner if problem persists.

Settings

Version info menu

Pressing the „Suction stop“ button when turning on the

device (while the logo is displayed) opens the version info

menu. This menu displays information on the software

versions and component run times.

VERSIONINFO

MAIN PCB V1.9H

TURBINE 005

TOUCH 028

T-H 00001 013

T-B 00001 011

T-L 00000 010

Software version control panel

Software version turbine

Software version touch panel

Runtime hand piece

Runtime turbine

Runtime lamp

Display Error Analysis

User setup menu

Pressing the following buttons in the version info menu

opens the user setup menu. In the user setup menu, you can

set display brightness and the hand piece‘s maximum speed.

Use arrow keys to select the desired setting. Pressing the „SET“ button activates

the selected field. When activated (#), setting can be changed using the arrow keys.

Pressing „SET“ again saves the setting.

To exit version info or user setup menus, restart device using the power switch on

the back.

USER SETUP

BRIGHTNESS >080

RPM-MAX 030

SCREEN SAVE 030

Display brightness

Max. Rpm Hand piece (x 1000)

Time to screensaver

Fixing smaller issues

Error: Error:

Burrs do not clamp properly: Burrs do not run smoothly:

Cause: Cause:

Dirty collet chuck Bent burr shaft

Burr shaft diameter too small

Solution: Solution:

• Clean collet chuck & polygon

sleeve

• Replace the burr/mandrel

• Replace the burr/mandrel

16

EN

Service record & dealer contact details

09/11/2017

Year Service Date Date Complete Service Stamp

1

2

3

4

5

6

7

8

9

10

Other manuals for Podo-Q

1

This manual suits for next models

1

Table of contents