Berg Hortimotive BeNomic Star 300 User manual

Translated user manual (EN-V1) BeNomic Star 300 2 / 50

Machine type plate

The BeNomic Star 300 carries a machine type plate which contains the following data:

Berg Hortimotive address details, CE marking, serial number and the year of manufacture.

If you would like to contact the Berg Hortimotive dealer with respect to the BeNomic Star

300, please ensure that this information is always readily available.

The machine is manufactured by:

Berg Hortimotive

Burg. Crezeelaan 42a

2678 KZ De Lier

The Netherlands

Tel: +31 (0) 174- 517 700

Email: info@berghortimotive.com

Internet: www.berghortimotive.com

Translated user manual (EN-V1) BeNomic Star 300 3 / 50

1. Declarations

1.1 Copyright

Berg Hortimotive

De Lier, 2022

No part of this documentation may be reproduced and/or made public by means of print,

photocopy, film or any other means without prior written permission from Berg Hortimotive

in De Lier, the Netherlands –Except parts intended to be reproduced for the purpose of

using this documentation such as abbreviated instructions and indications on the

machine.

1.2 Liability

Berg Hortimotive is not liable for unsafe situations, accidents and damages resulting from

the failure to observe warnings or regulations, as shown on the BENOMIC 290 and/or in

this documentation, for example:

- inexpert or improper use or maintenance;

- use for applications or under conditions other than those specified in this

documentation;

- use of parts other than those specified;

- repairs without permission from Berg Hortimotive and/or a certified dealer;

- modifications to the BeNomic Star 300. This includes:

- changes to the controls;

- welding, mechanical operations, etc.;

- extensions or additions to the BeNomic Star 300 or the controls.

Berg Hortimotive is also not liable in the following cases:

- if the customer has not fulfilled all his obligations toward Berg Hortimotive (financial

or otherwise);

- for consequential damage caused by faults or defects on the BeNomic Star 300

(e.g. business interruption, delays, etc.).

Translated user manual (EN-V1) BeNomic Star 300 4 / 50

1.3 Guarantee

Berg Hortimotive guarantee is valid for six(6) months after delivery, and offers the customer

warranty on material and manufacturing defects, which arise during normal use. This

guarantee shall not apply if the fault(s) is/are due to improper use or causes other than

material and manufacture faults, or if Berg Hortimotive supplies materials or used goods

after consultation with the client or if the cause of the fault(s) cannot be clearly

demonstrated.

The guarantee conditions are described in the Dutch “METAALUNIE”CONDITIONS, as

recorded in the most recently deposited text. The terms of delivery will be sent on request.

For all goods and materials that Berg Hortimotive does not manufacture itself, Berg

Hortimotive does not, at any time, offer lengthier guarantee than that provided to it by its

supplier. Warranty is “ex-factory”; faulty machines and/or parts need to be delivered

freight-paid.

If machines or installations cannot be delivered, the travel and accommodation costs

incurred will be borne by the client.

Goods sold and delivered with factory, importer's or wholesale guarantees shall be subject

to the warranty provisions laid down by the suppliers.

The hydraulic pump is subject to manufacturer's warranty only if it has an undamaged

supplier's safety seal.

Berg Hortimotive takes responsibility for the availability of replacement parts provided that

they are available from its suppliers under reasonable conditions.

2. Foreword

This manual describes the BeNomic Star 300 .

This manual provides you with additional information on safety aspects, a description of

the working principle of the entire setup, as well as maintenance instructions for the

BeNomic Star 300.

It will draw attention to potential hazards and directions for avoiding them.

It is very important to read this manual carefully to learn how to operate and maintain the

BeNomic Star 300. By reading and following this manual when using the BeNomic Star

300, you and others will be helped to properly use the BeNomic Star 300, and to prevent

personal injury and damage to the machine.

Berg Hortimotive produces safe machines. These machines are designed to the latest

standards, according to the CE marking. The user is responsible for the proper use and

maintenance of the machine.

Translated user manual (EN-V1) BeNomic Star 300 5 / 50

Table of contents

1. DECLARATIONS....................................................................................................................... 3

1.1 COPYRIGHT.......................................................................................................................... 3

1.2 LIABILITY.............................................................................................................................. 3

1.3 GUARANTEE......................................................................................................................... 4

2. FOREWORD .............................................................................................................................. 4

3. INTRODUCTION........................................................................................................................ 7

3.1 GENERAL:............................................................................................................................ 7

3.2 SUPPLIERS INFORMATION...................................................................................................... 7

4. SAFETY ..................................................................................................................................... 8

4.1 DECLARATION OF SAFETY TERMS........................................................................................... 8

4.2 SAFETY INSTRUCTIONS ......................................................................................................... 8

4.3 SAFETY ICONS.................................................................................................................... 11

4.4 OTHER RISKS...................................................................................................................... 12

5. INTENDED USE....................................................................................................................... 13

5.1 SCOPE OF USE.................................................................................................................... 13

5.1.1 Physical operating conditions................................................................................... 13

5.2 SAFETY SYSTEMS ............................................................................................................... 14

5.3 SIGNALLING SYSTEMS ......................................................................................................... 15

5.3.1 The battery status indicator (12)............................................................................... 15

5.3.2 The buzzer................................................................................................................ 15

5.4 BENOMIC STAR 300 DESCRIPTION....................................................................................... 16

6. TRANSPORT ........................................................................................................................... 18

6.1 EXTERNAL TRANSPORT ....................................................................................................... 18

6.2 INTERNAL TRANSPORT......................................................................................................... 18

7. COMMISSIONING.................................................................................................................... 19

7.1 INSPECTION BEFORE TAKING INTO SERVICE .......................................................................... 19

7.2 PIPE-RAIL SYSTEM IN HORTICULTURE................................................................................... 19

7.3 MINIMUM REQUIREMENTS FOR THE PIPE-RAIL SYSTEM........................................................... 20

7.4 MOUNTING THE FENCE,DOOR AND CONTROL CONSOLE......................................................... 20

7.4.1 Transport frames ...................................................................................................... 20

7.4.2 Assembly.................................................................................................................. 22

7.5 TILT INDICATION.................................................................................................................. 24

7.6 LOAD-HOLDING FUNCTION ................................................................................................... 25

7.7 SCISSOR-LOCKING DEVICE .................................................................................................. 25

7.8 EMERGENCY LOWERING VALVE............................................................................................ 25

7.9 PIPE -CONCRETE PATH TRANSITION..................................................................................... 26

8. OPERATION ............................................................................................................................ 26

8.1 OPERATION........................................................................................................................ 27

8.1.1 Undercarriage controls............................................................................................. 27

8.1.2 Controls on the platform........................................................................................... 28

8.2 MOVING THE BENOMIC STAR 300 ONTO THE MAIN PATH ....................................................... 30

8.3 MOVING THE BENOMIC STAR 300 ON THE HARVESTING PATH................................................ 30

8.3.1 Driving into the harvesting path................................................................................ 30

8.3.2 Driving out of the harvesting path............................................................................. 30

8.4 OUT OF SERVICE................................................................................................................. 31

8.5 CLEANING .......................................................................................................................... 31

8.6 PROBLEMS,CAUSES AND SOLUTIONS................................................................................... 32

8.7 DISASSEMBLY..................................................................................................................... 34

9. MAINTENANCE AND REPAIRS............................................................................................. 35

9.1 SPECIALIST MAINTENANCE................................................................................................... 35

Translated user manual (EN-V1) BeNomic Star 300 6 / 50

9.2 MAINTENANCE ON,IN OR UNDER THE SCISSOR-UNIT ............................................................. 36

9.3 PIPE-RAIL SYSTEM MAINTENANCE......................................................................................... 37

9.4 CHAIN TIGHTENING.............................................................................................................. 38

9.5 CHECK PIPE-RAIL WHEEL WEAR ........................................................................................... 39

10. TECHNICAL SPECIFICATIONS ......................................................................................... 40

10.1 *EXPLANATION OF THE TECHNICAL SPECIFICATIONS............................................................. 41

11. EC DECLARATION OF CONFORMITY.............................................................................. 42

APPENDIX 1: MAINTENANCE LOGBOOK .............................................................................. 43

APPENDIX 2: TECHNICAL DRAWINGS................................................................................... 44

APPENDIX 3: BATTERY SAFETY SHEET ............................................................................... 45

APPENDIX 4: CLEANING THE POWDER COAT FINISH........................................................ 50

Translated user manual (EN-V1) BeNomic Star 300 7 / 50

3. Introduction

3.1 General:

You have made a good choice in purchasing the Berg Hortimotive BeNomic Star 300. You

have an excellent tool, which has been carefully constructed and manufactured. This

investment will benefit you most if you carefully follow the safety, use, and maintenance

instructions detailed in this user manual.

Before commissioning the BeNomic Star 300, please make yourself familiar with this user

manual. The safety precautions, instructions and directions given should be observed at

all times.

Berg Hortimotive is not liable for damage or indirect damage resulting from failure to follow

the instructions and safety precautions set out in this user manual.

The liability of Berg Hortimotive shall also lapse as soon as you or third parties make any

modifications to the pipe-rail trolley or accessories without our written permission.

The BeNomic Star 300 has been delivered under the "METAALUNIE" (The Dutch METAL-

ASSOCIATION) CONDITIONS, as filed at the court of Rotterdam, as they are in

accordance with the last text set out there. The terms of delivery will be sent on request.

You can also contact the Koninklijke Metaalunie, Postbus 2600, 3430 GA Nieuwegein,

The Netherlands.

3.2 Suppliers information

In the event of breakdowns or defects occurring on the BeNomic Star 300 please contact

your Berg Hortimotive dealer.

Translated user manual (EN-V1) BeNomic Star 300 8 / 50

4. Safety

4.1 Declaration of safety terms

Safety terms:

Danger: Indicates serious injury or risk of fatality when ignoring the

instructions set out in the user manual.

Warning: Indicates risk of injury when ignoring the instructions set out in the

user manual.

Caution: Indicates risk of damage to the machine when ignoring the

instructions set out in the user manual.

ATTENTION: Indicates risk of injury when ignoring the instructions set out in the

user manual.

4.2 Safety Instructions

Please read the following safety precautions carefully.

After reading the safety instructions, always follow them strictly.

If the safety precautions are ignored, working with the pipe-rail trolley will be significantly

more dangerous, which can cause very serious injury.

DANGER!

-Read the user manual carefully. Follow the instructions, safety precautions,

etc. at all times.

-The BeNomic Star 300 is suitable for running on a stable pipe-rail system.

-Use the BeNomic Star 300 exclusively on the correct type of pipe-rail system.

You must check whether the centre-to-centre pipe-rail gauge corresponds

with the pipe-rail trolley, see the icon on the platform.

-Never exceed the maximum load capacity of 250 kg* (for capacities and

restrictions see 10.1!)

- One person incl. load (e.g. tools); see the pictogram on the trolley.

-Never exceed the sideways applied force of 110 N (towing capacity of 11 kg),

during crop maintenance.

-Use the BeNomic Star 300 only for crop maintenance in a greenhouse.

-It is strictly forbidden to use the BeNomic Star 300 for crop maintenance with

a tilt exceeding 2

(linearly and/or crosswise).

-It is prohibited to transport any unsecured load with the BeNomic Star 300!

Make sure that the load is placed in the middle and is no higher than 40cm

above the platform and is always properly secured.

-Only one person is allowed on the platform at all times.

Translated user manual (EN-V1) BeNomic Star 300 9 / 50

-Persons are not permitted to ride on the chassis in any way.

-It is prohibited to remove the safety fence.

-The use of the safety rail height extender is mandatory if the user is taller

than 1.80 metres. Only use an original approved Berg Hortimotive safety

guardrail raiser!

(see 5.2)

-It is strictly prohibited to increase the lifting height in whatever way.

- Always stand on the work platform.

-Keep a safe distance from fixed and/or moving parts of the greenhouse

structure, live electric wiring, and cables and ropes.

-Pulling steel or other types of rope/cord/wire and installing protective canvas

with the BeNomic Star 300 is not permitted.

-Using the BeNomic Star 300 as a crane is not permitted.

-Persons or pets are not permitted to enter the operational pathway of a

BETOMIC S290. Never use more than one pipe-rail trolley on the same path!

-All safety shields and protective caps must be fitted and closed during

operation of the BeNomic Star 300.

-Additional options, accessories and parts must be manufactured and/or

supplied by Berg Hortimotive.

Warning!

-The BeNomic Star 300 may only be operated when there are no other

persons, other than the operator, in the vicinity of the machine.

-The BeNomic Star 300 may only be operated by persons of at least 18 years

of age who have received thorough instruction on the BeNomic Star 300, are

familiarized with this user manual, fully understand it, and are aware of the

hazards.

-The BeNomic Star 300 may only be operated once it has been correctly

installed on the pipe-rail system.

-All employees working within the active radius of the BeNomic Star 300 must

be familiar with the relevant safety rules and regulations that apply to the

machine.

- Instructions must be provided by the from the employer.

-Repairs on the BeNomic Star 300 may only be carried out by personnel

instructed by Berg Hortimotive.

-When servicing the scissors, use the scissor-lock at all times (see 9.2).

-Never carry out work on the BeNomic Star 300, while someone else is

operating it. Always switch it off using the main switch, and remove the

charging plug from the trolley before carrying out maintenance.

Translated user manual (EN-V1) BeNomic Star 300 10 / 50

-Check the BeNomic Star 300 every day for defects and give it regular

maintenance, see chapter 9: Maintenance.

- Clean the controls and safety pictograms regularly.

- Operating functions and safety pictograms must be visible at all times.

-The BeNomic Star 300 must always be switched off after use, by using the

main

switch.

-Never leave the BeNomic Star 300 unattended.

- unless the key is removed from the main switch.

-It is prohibited to make any modifications/alterations to the BeNomic Star

300 without written permission from Berg Hortimotive.

-When leaving a track, first stop and check whether anybody is standing in

the direct vicinity before continuing onto the concrete path.

-Before going onto a track, ensure that there are no obstacles such as plant

remains, etc. lying on the pipe-rail system.

-Never clean the BeNomic Star 300 with a water hose, high-pressure water

gun or steam cleaner.

-When moving the BeNomic Star 300, other than on the pipe-rail, or crossing

on a concrete path, the platform has to be at its lowest position.

-The BeNomic Star 300 is besides driving on a pipe rail system, also suitable

for driving on a flat paved floor (concrete), which is rough enough to be able

to drive and stop safely. The surface condition must comply with NEN2743:

2003 Concrete floors.

-Never use the BeNomic Star 300 outdoors or on the public road.

-It is prohibited leaving a trolley that is not completely at its lowest position.

-Follow the battery safety specifications, see Appendix 3.

-Beware of feet and toes when operating the lifter on the BeNomic Star 300!

The trolley moves a few centimetres forward during the lowering process!

-It is mandatory to wear shoes with safety toecaps (minimum S1).

-Always remove the charging plug before using the BeNomic Star 300.

Translated user manual (EN-V1) BeNomic Star 300 11 / 50

Attention!

- Keep the workplace tidy.

An untidy working area leads to hazardous situations.

-Be focused.

Always maintain the appropriate level of concentration when operating the pipe-rail

trolley. Do not operate the BeNomic Star 300 when using medication that could

impair your reaction times when operating machinery or participating in traffic.

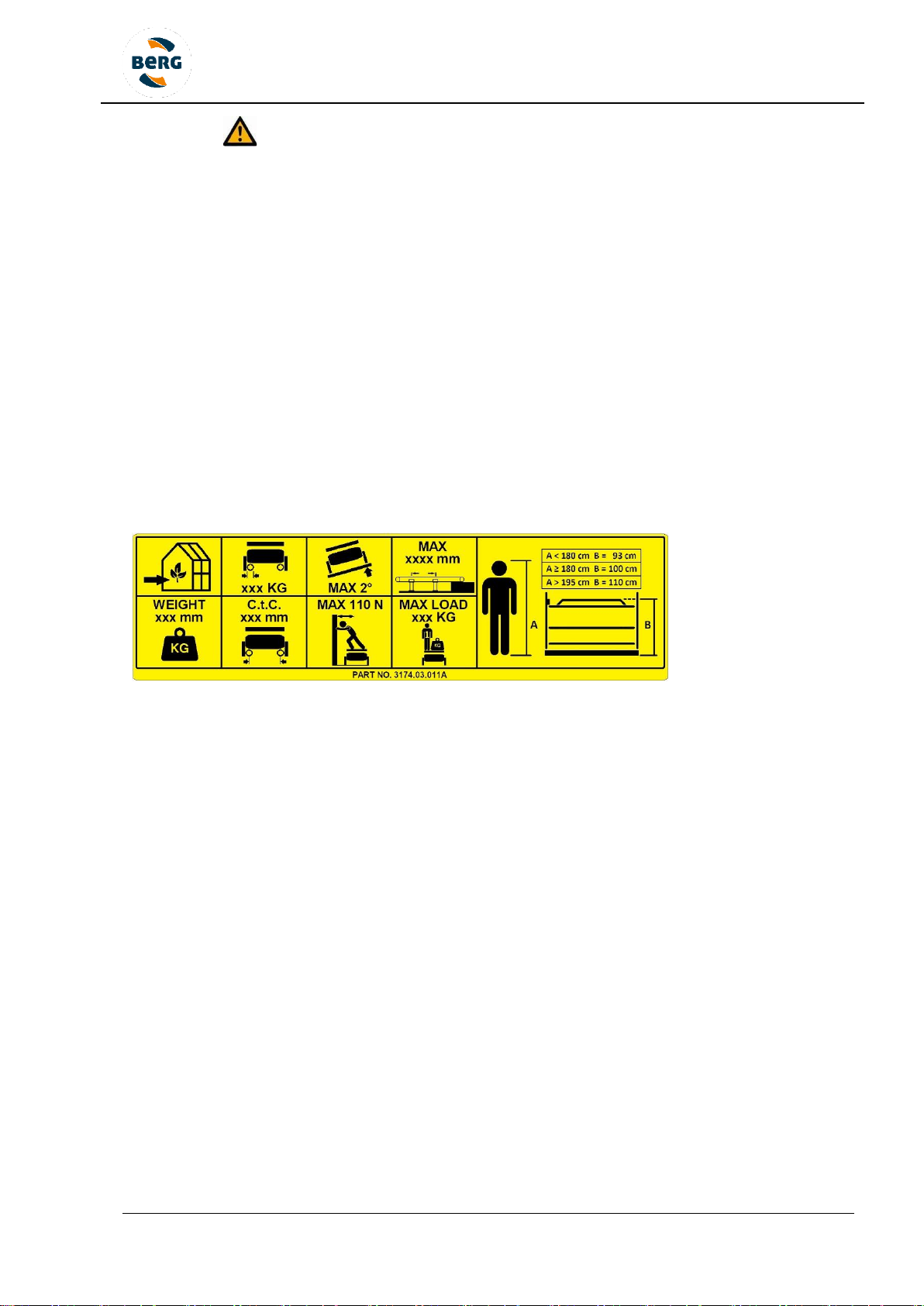

4.3 Safety icons

The BeNomic Star 300 has the following safety icons. These icons should alert the user to

potential hazards or hazardous situations. Take the warnings serious at all times and

contact your supplier if the hazard indicated on the icon seems unclear.

Always make sure the icons remain visible and undamaged!

The operator of the BeNomic Star 300 must have read and understood this manual before

using the machine. If the user does not understand the warnings in the manual or on the

machine (e.g. because he/she speaks a different language), all instructions, hazards,

warnings and functions should be explained to the user by a designated person so that

the user can clearly understand them.

Used indoors only (in the greenhouse)

Mass of the machine* in kg

Suitable for the indicated pipe diameter* with minimum wall thickness

Suitable for the indicated centre-to-centre (gauge)* pipe-rail system size

Maximum tilt 2°

Maximum lateral applied force in Newton (kg x 10)

Maximum support distance*

Maximum total load* in kg (maximum one person + secured load)

Height of the railing depends on the length of the user

*The values depend on the type of BeNomic Star 300!

Translated user manual (EN-V1) BeNomic Star 300 12 / 50

WARNING! Read the user manual before use!

WARNING! During maintenance, first isolate the power (Switch off main switch) and

consult the manual

Upwards = scissors up, Downwards = scissors down

Main switch (power): key vertical = ON, key horizontal = OFF

The key can be removed by continuing to turn in the off position.

Pay attention to the lowering platform!

Always use the scissors locking device when working under or on the scissors!

WARNING; danger of entrapment!

Keep your hands away from the scissor parts!

Warning! Dangerous chemical battery: explosive gas and corrosive battery acid!

4.4 Other risks

Despite the best possible design, dangerous situations remain or may arise when using

the BeNomic Star 300. Pay extra attention!

-The risk of crushing hands, fingers, arms and head between the scissor parts!

-The risk of crushing under the trolley when using the lifting mechanism for setting

down or lifting!

-Tipping of the trolley if used on an unsuitable pipe-rail system!

-Tipping of the trolley if the maximum weight or applied force limits are exceeded!

-Users taller than 1.80 metres can lose their balance if they do not use the obligatory

safety rail height extender!

Translated user manual (EN-V1) BeNomic Star 300 13 / 50

5. Intended Use

5.1 Scope of use

The BeNomic Star 300 is intended for professional use in the greenhouse horticulture

sector. The controls may only be operated by one person with a minimum age of 18 years

who has received thorough instruction on operation of the BeNomic Star 300. This person

must fully understand the safety instructions and this manual. The BeNomic Star 300 is a

pipe-rail trolley, which runs on a pipe-rail system that meets the minimum requirements of

paragraph 7.3 and is intended as an aid in harvesting, caring for and/or maintaining the

crops in a greenhouse. Use of the BeNomic Star 300 for any other purposes is strictly

forbidden. The maximum load may consist of one person plus a secured load, of which

the combined weight should not exceed 250 kg*. The trolley may only be operated once it

has been correctly installed on the pipe-rail system. Take extra care when the scissors

drop so that no persons or objects are trapped under or between the scissor-unit. Always

walk alongside the trolley, therefore not on the chassis when transporting it over the main

path.

* Stability tests have shown that with unfavourable combinations of pipe-rail type and the

support distance of the pipe-rail system, constraints must be applied for the maximum

permissible load. See 10.1 Explanation of the technical specifications.

5.1.1 Physical operating conditions

Ambient temperature,

Transport & Storage: 5 to +40 degrees Celsius

Working: 5 to +40 degrees Celsius

Rel. Humidity (RH): 0% to 90%, not condensing

Lighting: Normal ambient lighting.

The machine is not designed to be used outdoors.

The machine is not suitable for operating in explosive atmospheres.

Translated user manual (EN-V1) BeNomic Star 300 14 / 50

5.2 Safety systems

The BeNomic Star 300 series is equipped with the following safety systems, which will be

described in chapter 7 (Commissioning) and chapter 8.1 (Operation).

-Tilt indication (see 7.5)

-Load-holding function (see 7.6)

-Scissor-locking device (see 7.7)

-Emergency lowering control (see 7.8)

-Pipe-rail to concrete path transition (see 7.11)

-Emergency stop (see 8.1.2)

-Guardrail raisers*

The regulations for the use of certain safety devices may differ from country to country,

always consult the local safety authorities before use, these regulations are authoritative!

* The use of guardrail braces depends on the height of the user. For employees

taller than 1.80 metres, raising the standard guardrail is mandatory!

- Always work according to the local safety regulations!

- Manipulation of safety systems is strictly prohibited!

- Additional options, accessories and parts must be manufactured

and/or supplied by Berg Hortimotive.

Translated user manual (EN-V1) BeNomic Star 300 15 / 50

5.3 Signalling systems

In order to alert the user to changing status of the BeNomic Star 300 during use, a battery

status indicator (12) and buzzer are used.

5.3.1 The battery status indicator (12)

The battery status indicator (12) is located on the platform control, for this refer to chapter

8.1.2.

Safe & alert status

The battery status indicator (12) displays status off or on

Indication:

Safety status:

Solution:

Off

BeNomic Star 300

is powered off or

the emergency

stop has been

pressed

Release the emergency stop

On

BeNomic Star 300

is on

5.3.2 The buzzer

The acoustic warning gives the user feedback on the action that is being performed, or a

changing safety status.

Buzzer

signal:

Action or

Safety status:

Status or Solution:

Bleeping

Critical tilt with

raised platform

Platform lowered,

level the pipe-rail system

Translated user manual (EN-V1) BeNomic Star 300 16 / 50

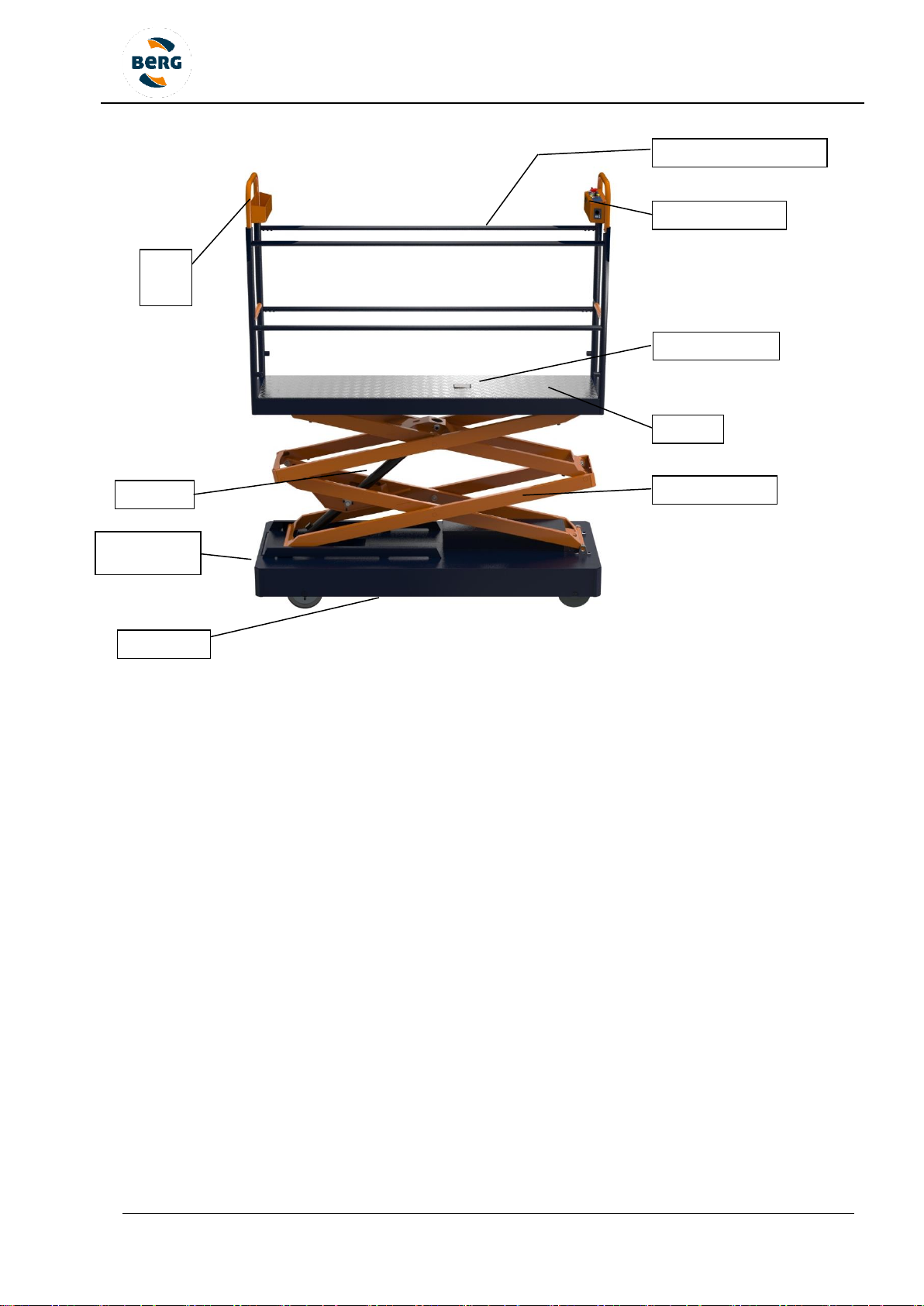

5.4 BeNomic Star 300 description

Figure 5.1; Names of the components on the upper-side of the BeNomic Star 300

Fencing/safety railing

Control panel

Foot pedal (5)

Platform

Scissor-unit

Gate

with

bin

Cylinder

Undercarriage

controls

Side cover

Translated user manual (EN-V1) BeNomic Star 300 17 / 50

Hydraulics

valve block

Hydraulic tank

Hydraulic motor

Figure 5.3; Names of the components on the inside of the BeNomic Star 300

Emergency

lowering valve

Lift-wheels

Drive roller

Trailing roller

Figure 5.2; Names of the components on the under-side of the BeNomic Star 300

Tilt sensor

Drive motor

Translated user manual (EN-V1) BeNomic Star 300 18 / 50

6. Transport

6.1 External transport

Please follow the procedure set out below if you need to transport the BeNomic Star 300:

1. Lower the platform completely.

2. Make sure the lift-wheels are retracted, so that the trolley is resting on its flange

rollers.

3. Set the direction and speed control to position 0.

4. Switch off the BeNomic Star 300 with the main switch (turn the red key to the

horizontal

position).

5. Properly secure the BeNomic Star 300 to prevent it from sliding, rolling or toppling

over.

6. Ensure that the BeNomic Star 300 remains dry and frost-free during transportation.

7. After having arrived at its destination, the BeNomic Star 300 must be started up in

accordance with the points described in chapter 7.1.

6.2 Internal transport

The BeNomic Star 300 may also be transported indoors (in the greenhouse). The

preferred method here is to drive the trolley on its lift-wheels (see 8.2), but it can also be

moved with a forklift. To move it with a forklift, proceed as follows:

1.Lower the platform fully.

2.The lift-wheels are retracted, so that the trolley is resting on the flange rollers.

3.Switch off the BeNomic Star 300 with the main switch (turn the red key to the

horizontal position).

4.Position the forklift forks as far apart as possible and insert them as far as possible

under the trolley, keeping them centred.

5.On the other side, check that the forks protrude far enough and are positioned

centrally under the BeNomic Star 300.

6.Secure the BeNomic Star 300 to the load backrest on the forklift truck, so that the

trolley cannot slide or tilt with respect to its position on the forks.

7.Lift the BeNomic Star 300 from the ground carefully, and no higher than necessary.

Attention!

- Secure the BeNomic Star 300 to the rack of the forklift truck with a suitable strap!

- Never lift higher than necessary!

- Make sure that the forklift truck is suitable for lifting at least 600 kg!

- Remove loose parts from the platform before lifting!

- Drive slowly and carefully!

Translated user manual (EN-V1) BeNomic Star 300 19 / 50

7. Commissioning

The BeNomic Star 300 has been specially designed for running on a stable pipe-rail

system (see 7.2 and 7.3). Berg Hortimotive checked the pipe-rail trolley for proper

functioning and safety before it left the factory. The items described in article 7.1 must be

inspected prior to taking the BeNomic Star 300 into service.

7.1 Inspection before taking into service

The following points must be checked before putting the BeNomic Star 300 into service:

-Mounting the fence, door and control console (7.4)

-No loose electrical connections (all the functions and buttons work properly);

-No damaged cables and/or hoses (leakage).

-The drive and trailing flange rollers and lift-wheels must be undamaged, and they

should rotate smoothly;

-The battery should be charged (see Battery indication 8.1.2 No.12).

-Ensure there is no general mechanical damage (with special attention to the

scissor components).

-No damage to or impaired visibility of the control components, pictograms and

symbols.

-Presence of safety guards and covers.

-The scissor mounting on the undercarriage and the fence on the scissor-lift

platform.

-Proper working of the lift-system.

-Battery indicator and buzzer operation as described in Signalling systems (5.3)

and Controls (8.1)

-Special attention should be paid to the periodic checks stated in the following

paragraphs of this chapter. These checks should be carried out at least monthly

or yearly, according to the stipulation!

7.2 Pipe-rail system in horticulture

The BeNomic Star 300 has been designed to run on a stable pipe-rail system. This

means that each path between the crops has a track comprising two pipes of the same

diameter with a fixed width between them (centre-to-centre (c.t.c.) size). The pipes are

often used as heating pipes and are supported with fixed spacing between them.

Translated user manual (EN-V1) BeNomic Star 300 20 / 50

7.3 Minimum requirements for the pipe-rail system

Stability tests have shown that with unfavourable combinations of pipe-rail type and

support spacing on the pipe-rail system, constraints must be applied for the maximum

permissible load. See 10.1 Explanation of the technical specifications.

The BeNomic Star 300 is based on a pipe-rail system as described in the Dutch ARBO

catalogue. Briefly, the following key principles apply:

-A pipe-rail system means that each path between the crops has a track comprising two

pipes of the same diameter and with a fixed width between them (centre-to-centre

(c.t.c.) size).

-The pipes are often used as heating pipes and are supported with fixed spacing

between them. These supports are subject to a minimum requirement of a 1.5 mm

thick steel base plate (with a stiffening profile), a minimum width of 115 mm and with

enough length to ensure that the base plate protrudes at least 70 mm from the two

upright supports that carry the pipes.

-The pipes must be steel quality (S235) with pipe diameter and wall thickness of 51/2,25

mm or 45/2 mm respectively.

-The pipes must be anchored into the concrete path. They must not be free-standing!

-Regardless of the pipe-rail system, the requirement is that a maximum support

spacing of 1 metre is applied in the last 10 meters!

-At the end of the pipes (in front of the façade), there should be a welded stop with a

height of at least 5 cm. These should be checked once for every change of season to

ensure that the stops are not flattened, bent, skewed or cracked.

-The surface under the pipe-rail system should be sufficiently load-bearing. This is

based on a top-layer cone penetration test value of more than 0.4 Mpa (62 psi). It is

important to keep the surface dry, flat and therefore hard. Soft/wet spots must be

repaired and any subsidence must be permanently resolved.

-The pipe-rail system must have a maximum tilt of 2 degrees, both lengthwise and

width. This makes it important to check the pipe-rail periodically.

7.4 Mounting the fence, door and control console

7.4.1 Transport frames

In order to reduce transport volumes, the BeNomic Star trolleys may be delivered on

special transport frames.

These transport frames are for single use only and must be taken to a

recycling company on site.

Berg Hortimotive cannot be held liable for any reuse or use for other

applications!

Table of contents