HIRD GLASS KAPPEL HYDRAULICA 2000 User manual

OPERATOR MANUAL

www.hird.co.uk

KAPPEL

HYDRAULICA 2000

www.hird.co.uk

DISCLAIMER - ALL INSTRUCTIONS ARE SUPPLIED FROM MANUFACTURER AND WHERE CORRECT AT TIME OF PRINT OM 1128-2

Northern (Head Office)

Tel: +44 (0)1482 227333

Western

Tel: +44 (0)1384 900388

Southern

Tel: +44 (0)203 174 0658

Central

Tel: +44 (0)1302 341659

www.hird.co.uk

OPERATOR MANUAL | KAPPEL HYDRAULICA 2000 www.hird.co.uk

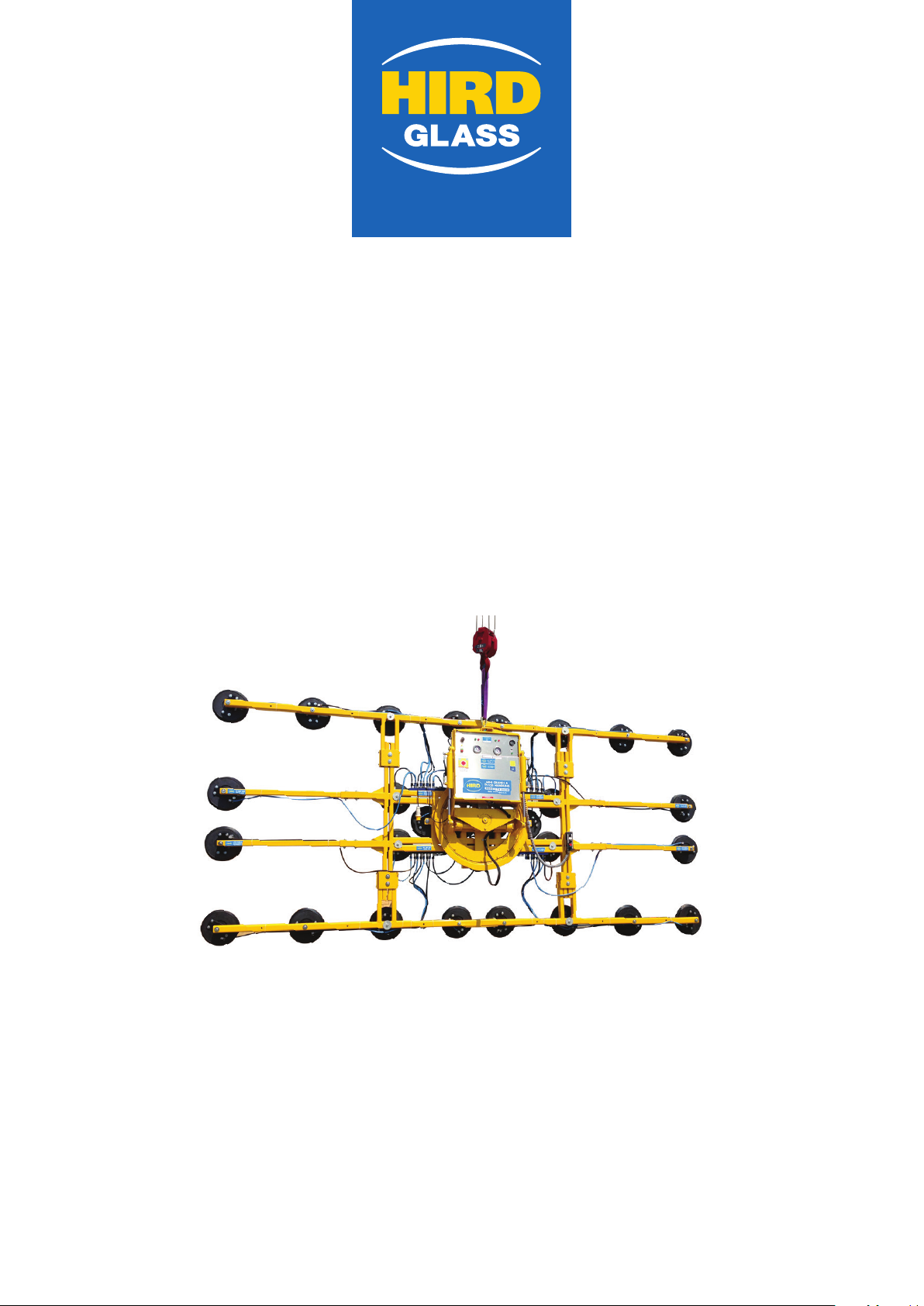

Technical Description

The dual-circuit Hydraulica 2000 multi-purpose vacuum lifter is capable of lifting non-porous loads

of up to 2000kgs. It features 210o powered rotation up to 210o and hydraulic tilt from 0 to 90o.

It is a dual powered machine which can be powered by the on board maintenance free 12V dry cell

rechargeable batteries. Or by 110V supply. The built in charger allows the operator to recharge the

battery during the mains operation or overnight before lifting commences.

Safe operation is assured by four independent systems:

Two independent vacuum systems, each with its own vacuum pumps (3 per circuit), non-

return valve, vacuum sensor, vacuum gauge and alarm system. This ensures that should

one circuit loose vacuum due to breakage, etc the other circuit will still support the load.

Either circuit is capable of supporting the safe working load (SWL). During thorough

examination both circuits are independently proof tested to 1.5 times the SWL.

N.B. This does not mean that the lifter can be used to lift greater than the SWL.

At no tome must a loan more than the SWL be lifted;

If electrical power is lost during mains operation the batteries will automatically take over

to power the lifting in all its functions;

The pumps are controlled by vacuum sensors which automatically start the pumps and

regenerates the vacuum if a low vacuum condition (below 61%) is reached on either

circuit. This is accompanied by audible and visual warnings.

Pump application is reduced by a combination of the vacuum reserve tanks and vacuum sensors,

which switch off the pump when the vacuum reaches approximately 74% and only restarts when the

61% unsafe limit is reached. This limits the drain on the battery.

The individual pads are movable on the pad frame to cater for different sizes or odd shaped loads.

Shut off valves allow individual pads to be isolated should they not be required.

N.B. Although it is possible to apply the vacuum circuits individually the lifter MUST NEVER be

operated in this manner. Both vacuum circuits must be functioning correctly and MUST ALWAYS

be operated before attempting to lif the load. Failure to do so could lead to loss of the load with

potentially fatal consequences.

KAPPEL HYDRAULICA 2000

OPERATOR MANUAL | KAPPEL HYDRAULICA 2000 www.hird.co.uk

HEALTH AND SAFTY INSTRUCTIONS

General

1) The Hydraulica 2000 is designed in accordance with the relevant European standard

(EN13155:2003). However, operating errors and misuse will result in hazards:

a) To the life of the operator and others;

b) To the lifter and materials of the company and others;

c) To the correct and efficient operation of the device.

2) All persons involved with the set-up, operation and maintenance of the machine must read

and observe the following instructions. The personal safety of yourselves and others that may

encroach upon your operation is at stake.

3) Only operate the Hydraulica 2000 under the correct environmental conditions, to do otherwise

jeopardises health and safety, and will invalidate the Report of Thorough Examination to ensure

the Safe Working Load (SWL) of the lifters current configuration is adequate for the load to be

lifted.

Intended Use

4) The Hydraulica 2000 is intended for the carriage of gastight, dry materials with a solid smooth

surface. The load may be manually rotated through 270o and hydraulically tilted from 0 to

90o.. Use of additional and sufficient manpower is strongly recommended when preforming

the rotation manoeuvre. Other operations involving the lifting of gas permeable or foil coated

materials, wet or unstable loads, loads that are heavier than the SWL or operating outside

environmental guidelines or using the machine in the rain is regarded as contrary to intended

use. The manufacturer/supplier is not liable for any damage resulting from such misuse. That

risk lies entirely with the user.

5) Care is to ne take when operating this machine in areas of high electromagnetic disturbance,

e.g. HV power generation facilities, HV transformer sub-stations as this may lead to the

inadvertent release of materials. Where this work is carried out every opportunity must be taken

to isolate equipment from HV interference by ensuring all covers to distribution boxes, control

boxes, etc are closed.

6) Unauthorised alterations to the structure or operations controls of the device is prohibited for

safety reasons.

7) Intended use also requires observance of the operating manual and adherence to the conditions

for inspection and maintenance.

KAPPEL HYDRAULICA 2000

OPERATOR MANUAL | KAPPEL HYDRAULICA 2000 www.hird.co.uk

Emissions

8) The equivalent continuous A-weighted sound pressure level (LpA) is approximately 8odbA at a

distance of one meter whilst the pump warning siren is operating. This is below the first action

level as defined in the Control of Noise at Work Regulations 2005. However in confined areas

this level may be exceeded and personnel suffer hearing disturbance and should be issued with

the appropriate personal protective equipment.

Environmental Considerations

9) The lifter must not be used in the rain or on wet loads. Failure to observe this requirement may

lead to failure of the systems with potentially fatal consequences.

10) The operating temperature range is 0 oC to +35oC. The storage temperature range is -5 oC to

+50 oC.

Sources of Hazards

11) The lifting frame works on negative pressure (vacuum) to hold the gastight load. Any failure of

vacuum system may cause the load to release with potentially fatal consequences. Therefore,

as far as is reasonably practicable, all measures must be taken to avoid lifting the load over

personnel.

Organisational Measures

12) A job specific risk assessment and method statement must be prepared by a competent person

prior to the commencement of the task.

13) Always have the Hydraulica 2000 operating manual available on site.

14) No one under the age of 18 years old may operate this machinery.

Maintenance

15) User maintenance of the device is strictly limited to:

a) Pre-use inspection;

b) Battery charging;

c) Resetting of 2A and 25A circuit breakers.

16) Other than these operations all maintenance, inspection and testing must be carried out by

authorised and competent personnel only.

17) Never clean the pads with solvent based chemicals, this will remove the plasticiser and seriously

degrade the pads shortening their life and rendering them unsafe. In the event of serious

contamination of the pads, a mild solution of soapy water should be used. Care should be taken

that no water enters the system during cleaning via the holes on the pads.

18) As a designated “accessory for lifting” the Hydraulica 2000 is subject to a thorough examination

by a competent person every 6 months in accordance with the Lifting Operations and Lifting

Equipment Regulation 1998, Redulation 9(3)(a)(i).

KAPPEL HYDRAULICA 2000

OPERATOR MANUAL | KAPPEL HYDRAULICA 2000 www.hird.co.uk

TROUBLESHOOTING

Lifter fails to achieve 65% vacuum

1) Check whether all cups are in contact with the load.

Reposition cups if necessary

2) Check that nothing is stopping the vacuum lips on the cup from forming a seal. This may be cork

spacer pads, an outer lip that has curled under, etc.

Remove lifter and check load and pads, reposition lifter

3) Check the hose clamps for security and tightness

Tighten clamps, but only where necessary

4) Check the pipes for damage

Contact Peter Hird and Sons Ltd for pipe replacement

5) If after recertification the pump will still not achieve 65% vacuum contact Peter Hird and Sons Ltd.

Pump Fails to run when power is set to on

1) Check whether 25A circuit breaker S2 has tripped

Press S2 to reset, located on top of the function panel.

If S2 coninually needs resetting there is a problem within the function panel.

There are no user serviceable parts within and the lifter must be returned to Pete Hird and Sons Ltd.

2) Check whether the battery has sufficient charge.

Wither recharge the battery or use the lifter on mains power

3) If the lifter is on mains power, check the leads (and transformer if 110V)

Replace leads and/or transformer

4) If the lifter still does not function return to Peter Hird and Sons Ltd for investigation

Mains operation not possible (POWER light does not illuminate)

1) Check cables and site supply (and transformer if 110V)

Replace cables and transformer if necessary. Contact site service electrician about

restoring of power.

2) Check whether 2A circuit breaker S1 has tripped

Press S1 to reset, located on top of the function panel.

If S1 coninually needs resetting there is a problem within the function panel.

There are no user serviceable parts within and the lifter must be returned to

Pete Hird and Sons Ltd.

3) If the lifter still does not function return to Peter Hird and Sons Ltd for investigation

KAPPEL HYDRAULICA 2000

OPERATOR MANUAL | KAPPEL HYDRAULICA 2000 www.hird.co.uk

LIFTING AND POSITONING

1) Carry out pre-use check.

2) Position lifter on load within 40mm of center of gravity

3) Ensure all pads are in contact with unit surface and all relevant pad shut off taps are ON (in-line)

and quick release fitting are correctly connected (extension arms only)

4) Turn the power ‘ON’.

5) Press both vacuum actuation buttons on the remote control box until they click.

6) Ensure vacuum gauge reaches at least 65% and all warnings cease.

7) Carry out 50mm lift whilst observing vacuum gauge. Vacuum levels should not suddenly drop

under load.

8) Check stability of load, lower and adjust if necessary.

9) When confident of stability of load and vacuum, the load is raise and if required may now be

rotated and tilted to desired angle.

Always ensure that there is sufficient space to rotate and tilt the load.

10) The load may now be banked into position and final adjustments to tilt and/or rotation carried

out by fixers.

11) If mains power is being used it is essential that the cable has an unobstructed pathway both on

the ground and in the air to prevent snagging which could lead to a violent arresting of the lifter

and potentially loss of the load.

12) To release the load, both remote control buttons are lifted to release the vacuum then press the

red power switch and ensure all lights are off and vacuum gauge drop to ‘0’.

13) It is VERY IMPORTANT that the power switched to ‘OFF”. If the switch is left ‘ON” the operating

solenoids will burn out.

14) The Vacuum takes a few seconds to release, so it is vital that all the pads are free before the

crane or hoisted is raised. This prevent any residual vacuum in the system from lifting the load

whilst no power is applied to the pump.

KAPPEL HYDRAULICA 2000

OPERATOR MANUAL | KAPPEL HYDRAULICA 2000 www.hird.co.uk

LIMITED WARRANTY AND LIABILITIES

1) In principle, dependent upon type of supply our ‘Hire Terms and Conditions” or “Sales Terms

and Conditions’ are valid and apply.

2) Warranties and liability claims for injury to persons or material damage are limited to where it

can be proven that aforesaid injury or damage is due to negligence on the part of

Kappel or their authorised representative.

3) In particular the following conditions are strictly excluded from warranty or liability claims:

a) Device being used for lifting materials other than those covered by the intended use section

of the health and safety instructions;

b) Improper mounting, installation, operation or maintenance of the device;

c) Use of the device with safety or protective devices that are not operating correctly;

d) Device being transported, operated, mounted, installed, maintained or prepared in

contradiction of the advice as described in the health and safety instructions;

e) Unauthorised modification or alteration to the device;

f) Use of the device by personnel with inadequate knowledge of the operation of vacuum

devices.

g) Improper repair;

h) Natural catastrophe or force majeure.

KAPPEL HYDRAULICA 2000

OPERATOR MANUAL | KAPPEL HYDRAULICA 2000 www.hird.co.uk

OPERATION

KAPPEL HYDRAULICA 2000

CHARGING THE BATTERY

1) Ensure that the mains supply voltage corresponds with the charger

voltage

i.e. 110 volts.

2) Unwind the supply able and any extension leads fully.

3) Plug the lad receptacle onto the plug fitted on the lifter prior to

inserting any other plugs. Failure to do so may cause the 2A witch S1

to trip.

4) Once the lead is firmly secured to the lifter, the other end may be

plugged into the mains or transformer.

5) The green POWER light should now illuminate and the battery

will begin to charge. Charging is fully automatic and will take

approximately 8 hours.

6) To check the amount of charge in the battery, press the Battery Test

button and the gauge will illuminate and indicate the percentage of

charge.

N.B. Never attempt to lift if the battery charge is indicating

below 20%.

7) If the Power light fails to illuminate, check the 2A trip S1 and reset if

required.

OPERATOR MANUAL | KAPPEL HYDRAULICA 2000 www.hird.co.uk

PRE-USE INSPECTION

KAPPEL HYDRAULICA 2000

Prior to starting any operations, the Provision and Use of Work Equipment

Regulations 1998 stated that the lifter must be inspected. Please note the

approved Vacuum Lifter Pre-Use Inspection Check List is available for free

download at TO ADD LINK HERE IF REQUIRED

1) Check the lifter for damage and distortion, particularly in the area of

the vacuum tanks and any welds.

2) Check the vacuum pads afor rips or tears that may affect the vacuum

lips. Check also for perishing of evidence of hardening, and for

cleanliness of the pads.

3) Check the vacuum pipes for any damage and security. Where the

extension arms are fitted pay particular attention to the security of the

quick release fixings.

4) Check the electrical cabling for any damage. Inspect the battery

connections for security.

5) Check battery has sufficient charge. Where the lifter is to be mains

powered, ensure the mains voltage matches that of the lifter

6) Check the test plate of the lifter for:

a) Safe Working Load (SWL), this will always show the maximum SWL.

The current Report of Thorough Examination must be consulted to

confirm the SWL in the configuration being used.

b) Serial number of lifter, and that if it matches the serial number of

the accompanying Report of Thorough Examination.

c) The last examination date matches that on the Report of Thorough

Examination and that the current date is within 6 months of the last

thorough examination.

7) Ensure all pad shut off valves are in the ‘OFF’ position, i.e. not in line

with the pipe.

8) Press both vacuum activation buttons on the remote control

9) Turn the pumps in using green button indicated

10) Ensure that all warning lights and sirens are on during the vacuum

build up.

11) Ensure vacuum reaches correct level on both circuits before pump

turns off

OPERATOR MANUAL | KAPPEL HYDRAULICA 2000 www.hird.co.uk

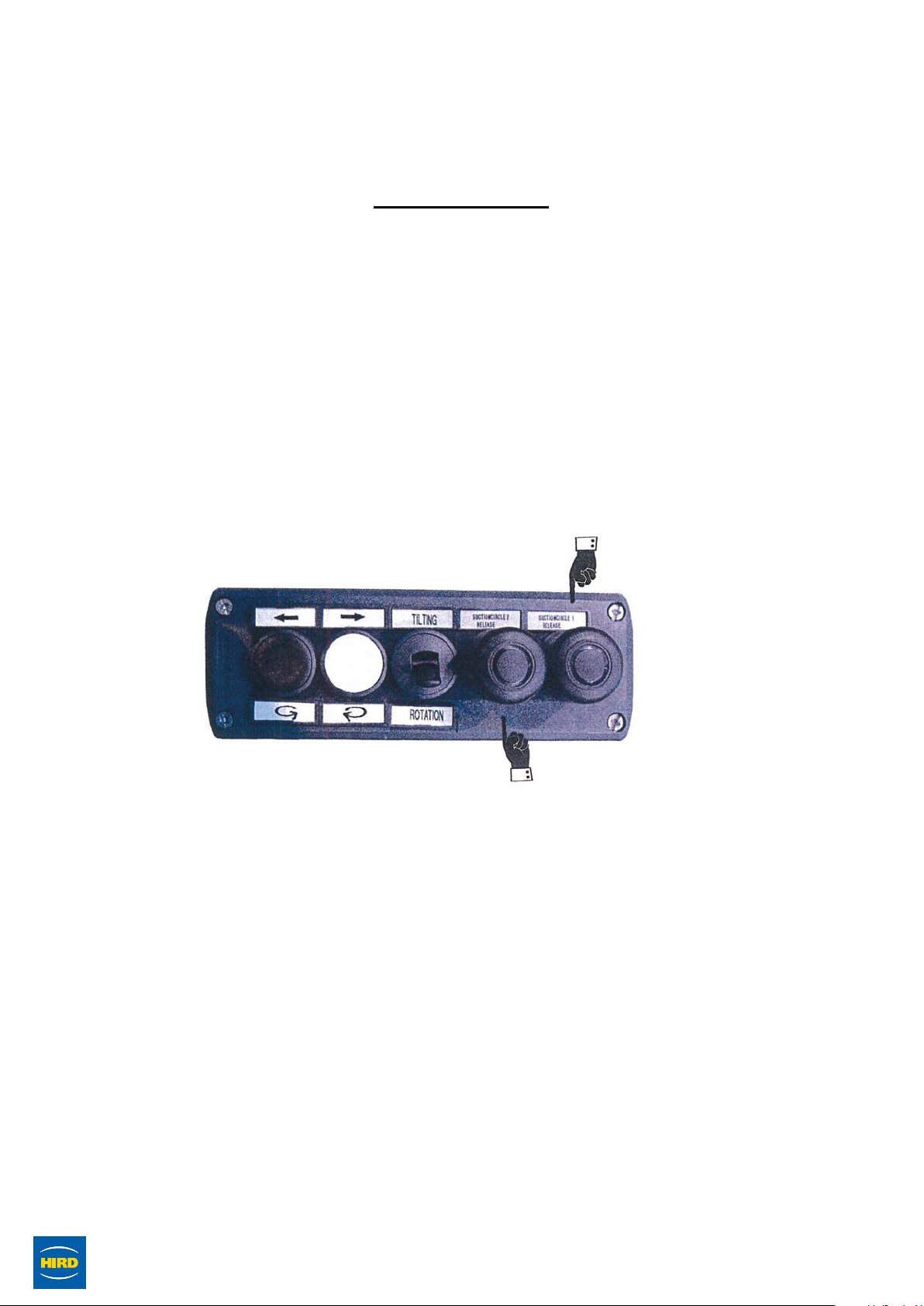

12) Select ‘TILTING’ on the remote control and using the

remote control buttons, check that the lifter tilts from 0 to

KAPPEL HYDRAULICA 2000

90oand back again freely.

13) Select ‘ROTATION’ on the remote control and using

the remote control buttons, check that the lifter rotates

clockwise and anti-clockwise freely.

14) Turn the power switch to ‘OFF: and pull both vacuum

actuation valves to release the vacuum and ensure the

vacuum gauge drops to 0.

15) Ensure all pad isolation valves are turned on

i.e. in line with the pipes.

16) Apply the lifter to a glass unit, turn the power on using

the green button, press both the vacuum application

buttons until they click. When the correct vacuum levels

are reached and all warnings are extinguished, record

the vacuum levels, leave the lifter applied and wait for a

period of 10 minutes. Inspect the gauges again and check

whether the levels have dropped 5% or more from the

recorded values. If so DO NOT USE go to step 17.

17) Remove the lifter clean the load and pads thoroughly. Repeat step

15. If the lifter is still loosing more than 5% over the 10 minute period

from either circuit, remove the lifter from service and label it “Out of

Service” and ring Peter Hird and Sons Ltd for more advice.

Safety Note 1

When using the extension arms it is imperative that the pipes from

the pads are correctly connected to the quick release fitting prior to

vacuum being applied. Failure to do so will isolate the relevant pad

from the vacuum system.

If the above condition is seen, return load to safe position before

trying to rectify, as any attempt to connect the pipe after the vacuum is

applied mat lead to loss of load, particularly if the pad is not in correct

contact with the load surface.

OPERATOR MANUAL | KAPPEL HYDRAULICA 2000 www.hird.co.uk

TRANSPORT & STORE

1) Do not set down the suction cups, nor try to apply them on a surface that is likely to

damage the sealing lips, such as: rough stone or concrete, sharp edges. The resulting

damage to the lips could impair the cups ability to seal when required and may lead to

the loss of the load.

2) Likewise, never place the cups down on a dusty or sandy area or one that is covered with

grit. This may lead to sharp grains becoming embedded in the pads. This may lead to

the pad not sealing correctly or damage to the surface being lifted.

3) Never lean the lifter against a surface for storage as the lips may become distorted or

the lifter may be knocked over and damaged. If it is necessary to lean the machine

against a surface ensure the pads are supported clear of the floor and the lifter is

adequately secured against falling.

4) The lifter should be transported and stored either on a smooth clean surface or by being

freely suspended.

5) Always ensure that the lifter is stored away from areas that are subject to rain, snow

or heavy condensation as the moisture may penetrate the electrical or vacuum system

causing severe damage and creating an electric shock risk and/or impairment of the

vacuum system.

6) Temperatures of -5oC should be avoided for storage as this may cause premature

perishing of the pads and render them unsafe and unusable.

7) Preferably the lifter should be stored on its own stand or transport frame in a warm,

dry atmosphere.

KAPPEL HYDRAULICA 2000

OPERATOR MANUAL | KAPPEL HYDRAULICA 2000 www.hird.co.uk

SAFETY DEVICES

The Hydraulica 2000 has several safety devices to prevent the loss of vacuum.

1) The non-return valves in the vacuum pumps prevent loss of vacuum when the pumps

guts off or fails.

2) The vacuum tanks create a vacuum to hold the load in the event of a vacuum pump

failure, It also prevents the pump switching on to often during normal operation, helping

preserve battery.

3) Vacuum gauges give a direct indication of the percentage of the vacuum in both circuits.

4) Vacuum sensors with in-line warning lights and siren to indicate when vacuum has

dropped to an unsafe level in either circuit

5) The remote control has a “press to apply and lock – pull to release” control knob for

each circuit to prevent the inadvertent release of vacuum.

KAPPEL HYDRAULICA 2000

PRE1125-2

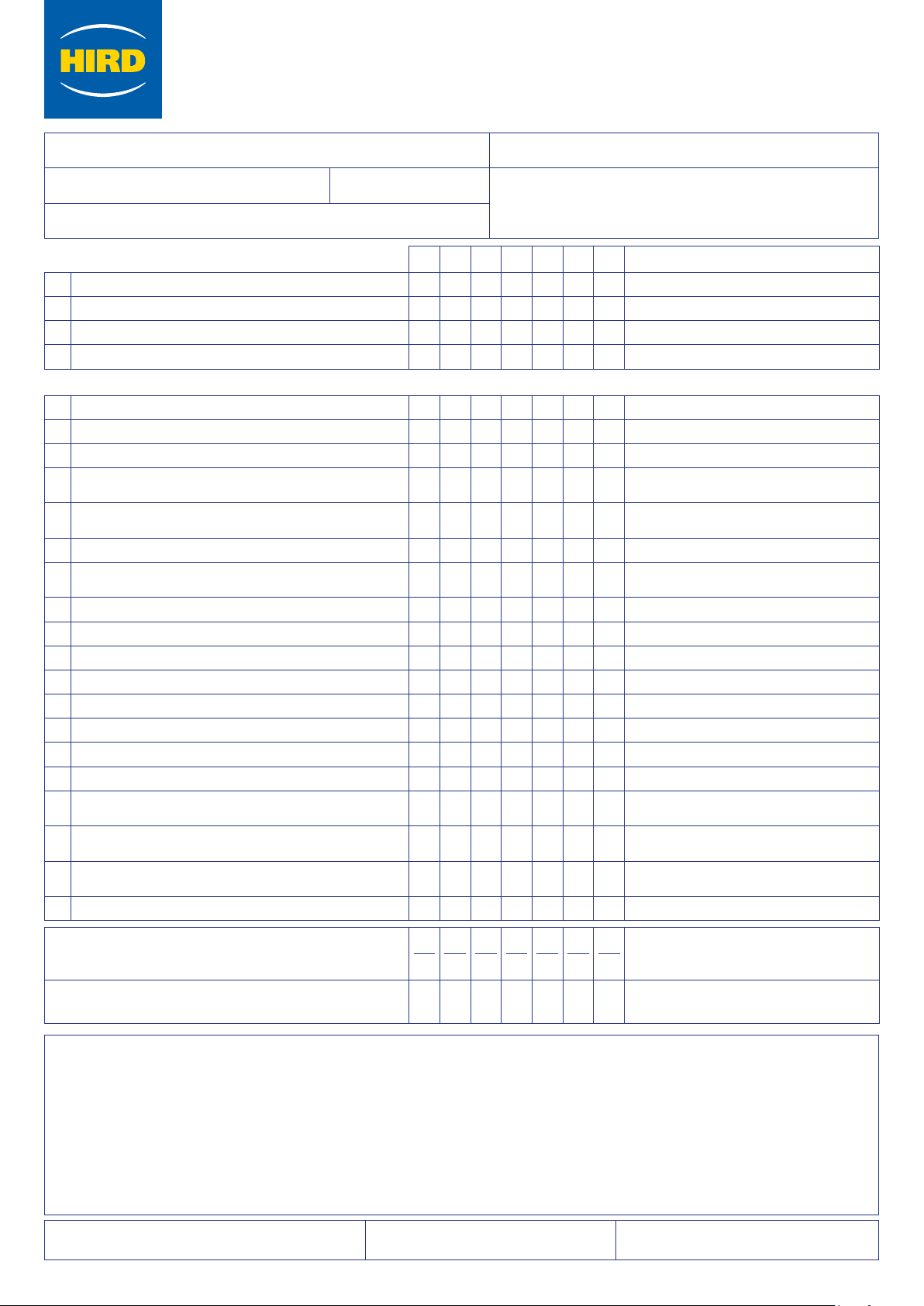

Daily Pre-Use Checklist

Vacuum Lifter

Machine Model: Site Name:

Date Week Commencing: Fleet No: Address:

Inspected by:

Northern (Head Office) Tel: +44 (0)1482 227333

Central Tel: +44 (0)1302 341659

Western Tel: +44 (0)1384 900388

Southern Tel: +44 (0)203 174 0658

www.hird.co.uk

PRE1125 Kappel Hydraulica 2000

Kappel Hydraulica 2000

Result of Inspections: List defects or state “No Defects”

Signature: Name: Date:

Daily Pre-use Checks M T W T F S S COMMENTS

1Are all operators manuals present and readable

2Is the Report of Thorough Examination (LOLER) in date

3Complete a visual walk around / Inspection for any noticeable defects

4Are all safety information decals present and readable

Check the following components or areas for damage, or missing parts & unauthorised modifications:

5Is the lifting attachment free from defects and safe to use

6Vacuum pads for rips, tears, quality and cleanliness

7Vacuum pipes and connections (in particular quick release fittings)

8All extension arms are present and free from defects

(where applicable)

9Make sure all individual pad shut off valves are open

(where applicable)

10 Electrical components, wiring, connectors,

11 Check input mains voltage corresponds with charger voltage

(110v or 240v)

12 Charger

13 Check battery has sufficient charge

14 Are rotation and tilting movements functional

15 Check handles security

16 Check remote for any damage or defects (where applicable)

17 Check operation buttons / switches are working and free from defects

18 Energise vacuum on non porus surface

19 Are lights and audible alarms on during vacuum process

20 Does the vacuum reach sufficient level, before switching off

(see gauges)

21 Does battery gauge illuminate when pump switches off

If NO - DO NOT USE

22 Check Safe Working load of vacuum - is it suitable for

the proposed load

23 Carry out full function test

Is the machine safe to use? (please circle)

YES YES YES YES YES YES YES

NO NO NO NO NO NO NO

Operator’s Initials

Table of contents

Other HIRD GLASS Lifting System manuals

Popular Lifting System manuals by other brands

BLUM

BLUM SERVO-DRIVE uno installation instructions

Valx

Valx Landing leg S Installation and operation instructions

Ravaglioli

Ravaglioli RAV232 NL manual

Ravaglioli

Ravaglioli RAV8065.1.65MB Translation of the original instructions

Nussbaum

Nussbaum 2.30 SPL Operating Instruction and Documentation

Terex

Terex Genie GR -12 Service manual

EKKO

EKKO EB12E Series user manual

Powerbuilt

Powerbuilt 941877GCF instruction manual

Aqua Creek

Aqua Creek PORTABLE PRO POOL-AT LIFT Installation and operating instructions

CRESTO

CRESTO RESQ RED Pro III Instructions for use

Kleton

Kleton MP007 instruction manual

AMGO Hydraulics

AMGO Hydraulics 409-DP Installation and service manual