3

Table of contents

1. Information concerning the document............................................................................................................4

1.1. Scope and intended use of the manual.......................................................................................................4

1.2. Intended use of the compressor and conditions of safe use ......................................................................4

1.3. Qualification requirements for operation of the compressor.....................................................................5

1.4. Operation ....................................................................................................................................................5

1.5. Other remarks and instructions ..................................................................................................................6

1.6. Warranty .....................................................................................................................................................6

2. Operating safety rules......................................................................................................................................6

2.1. Basic requirements for safe transport and positioning of the screw compressor ......................................7

2.2. Operating safety requirements ...................................................................................................................7

2.3. Other hazards..............................................................................................................................................8

2.4. Meaning of pictograms ...............................................................................................................................8

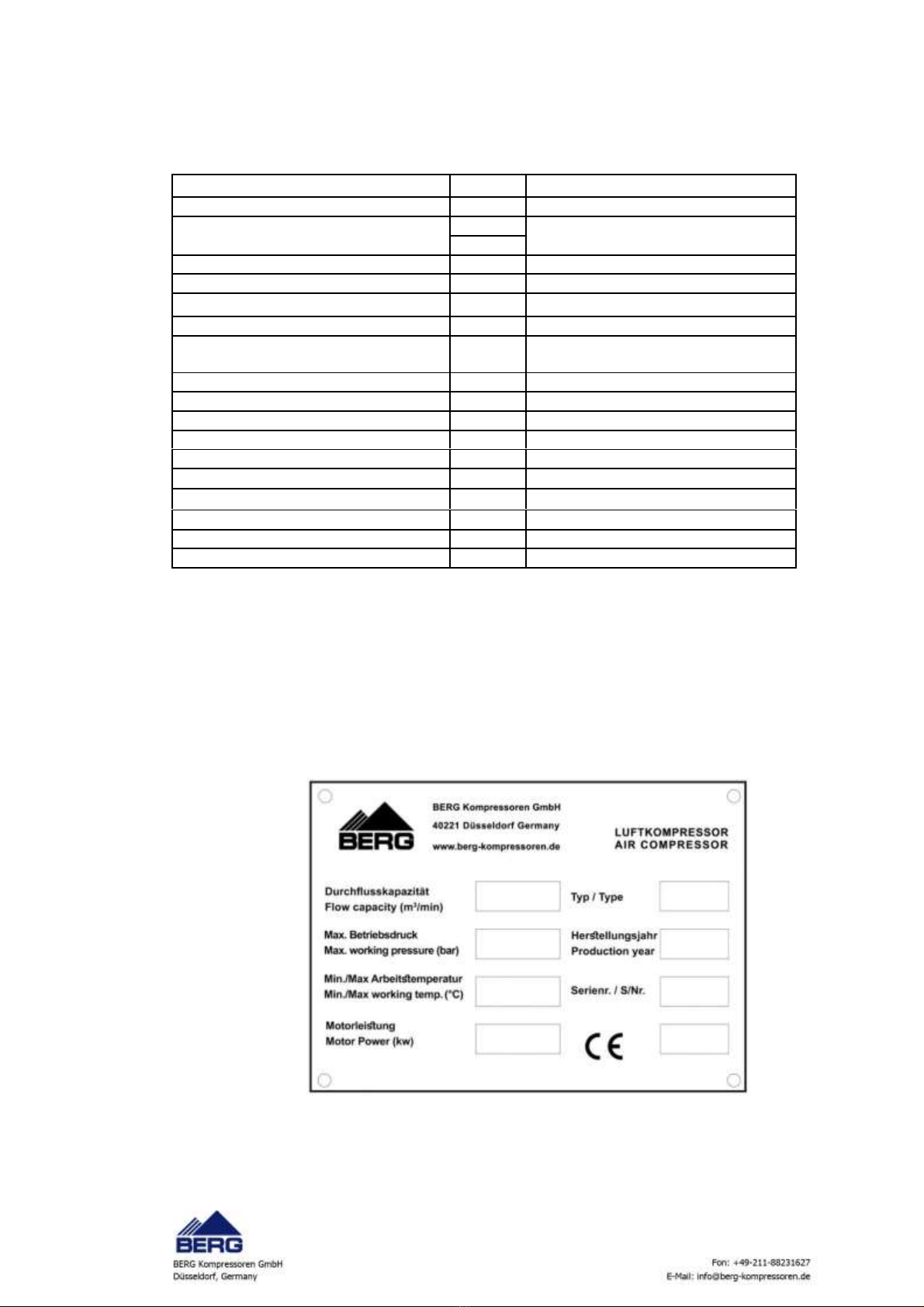

3. Technical data ................................................................................................................................................9

3.1. Identification plate ......................................................................................................................................9

4. Setting........................................................................................................................................................... 10

4.1. Room requirements ................................................................................................................................. 10

4.2. Requirements concerning electrical system ............................................................................................ 11

4.3. Compressed air connection...................................................................................................................... 11

5. Screw compressor operating description and drawings............................................................................... 12

Technological diagram .................................................................................................................................... 19

6. Start-up ......................................................................................................................................................... 22

6.1. Start-up preparation................................................................................................................................. 22

6.2. Restart (after longer downtime) .............................................................................................................. 23

7. Maintenance ................................................................................................................................................. 23

7.1 General requirements ............................................................................................................................... 23

7.2. Maintenance and checks.......................................................................................................................... 24

7.2.1 Maintenance at the beginning of use, after oil and drive belts (if present) change ..........................24

7.2.2 Daily maintenance..............................................................................................................................24

7.2.3 Periodic maintenance ........................................................................................................................24

7.2.4 Warranty and post-warranty checks..................................................................................................25

7.3. Basic components requiring maintenance. Maintenance operations............................................... 25

7.3.1. Air filter cartridge .............................................................................................................................25

7.3.2 Cleaning or replacing the filter mats..................................................................................................26

7.3.3. Oil filter .............................................................................................................................................26

7.3.4. Oil level..............................................................................................................................................27

7.3.5 Changing oil........................................................................................................................................27

7.3.6. Handling wastes produced while operating the compressor ...........................................................28

7.3.7 Oil cooler (exchanger) / interstage / final air .....................................................................................28

7.3.8. . Electric motor..................................................................................................................................29

7.3.9 Safety valve ........................................................................................................................................30

8. Troubleshooting............................................................................................................................................ 30

9. Consumables for one year guarantee........................................................................................................... 33

10. Electrical scheme ........................................................................................................................................ 33