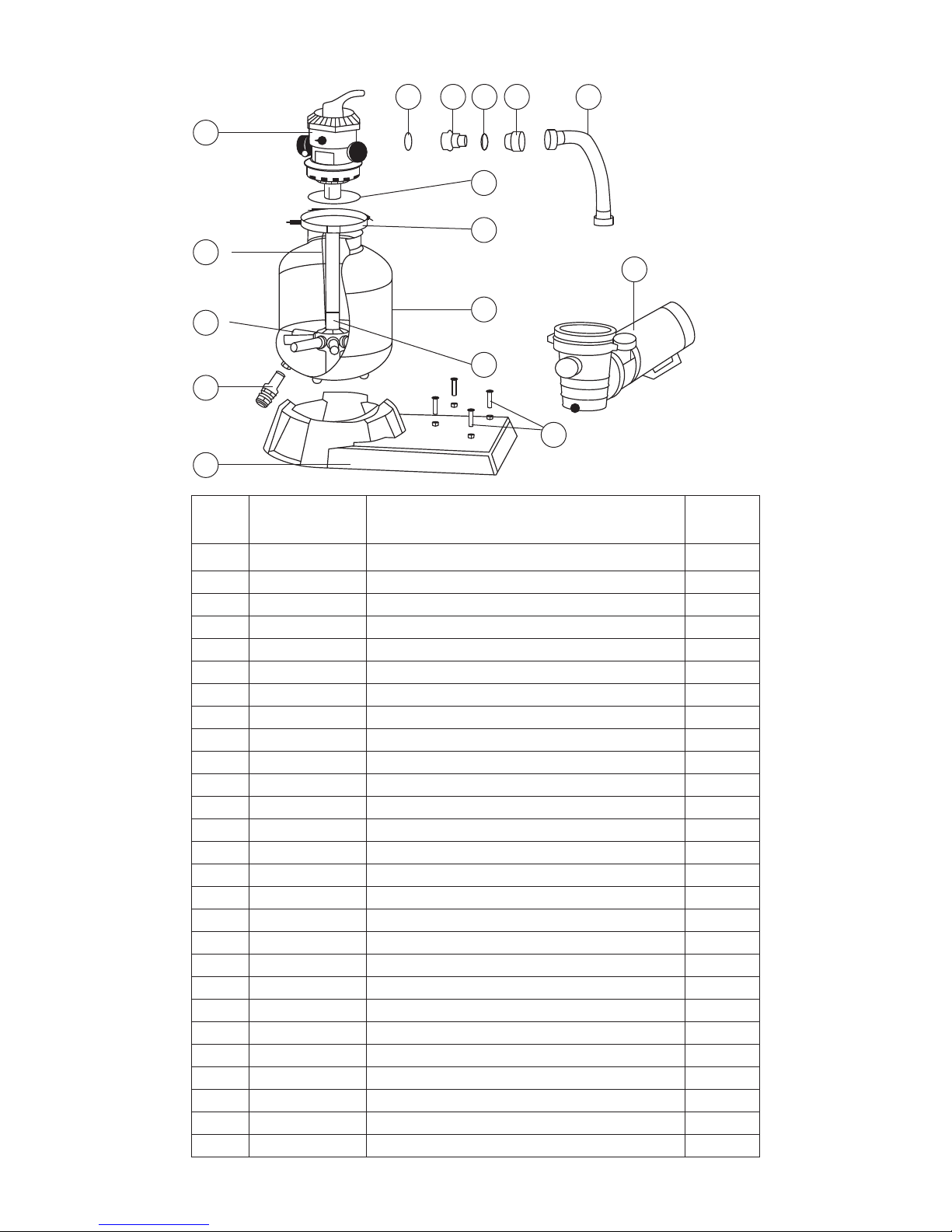

5718 52nd Street Kenosha WI 53144|Orders and Customer Care: 1-866-616-1270|Fax: 1-866-616-1271|HarrisPoolProducts.com

9. To connect the pump to the base, use the screws

from the pump hardware pack. Use the pump

manual to install the and operate the pump.

10. Adjust the valve position. The white pressure hose

connects to the pump output/input valve.

11. The other two connection ends of the valve connect

to the swimming pool and the drain outlet hose.

Installation Notes

1. Make sure the lter is worked under the work

pressure and using a pressure control valve when

the system is using a booster pump.

2. If the pump position is higher than the water level,

it requires to install the back water control valve.

3. If the pump position is lower than the water level,

it requires installing an isolation valve.

4. Minimize the length of pipe and the number of

ttings to minimize friction loss to ensure maximum

efciency.

5. Connect all plumbing to the Multiport Valve taking

care that all joints are glued or tightened securely

to prevent leaking.

6. To prevent breakage and damage to the pump and

Multiport Valve, use only pipe sealants specically

formulated for plastics.

7. Ensure solvents are not excessively applied to

ttings as this could run into O-Rings and create

sealing problems.

8. Do not over tighten ttings or adapters.

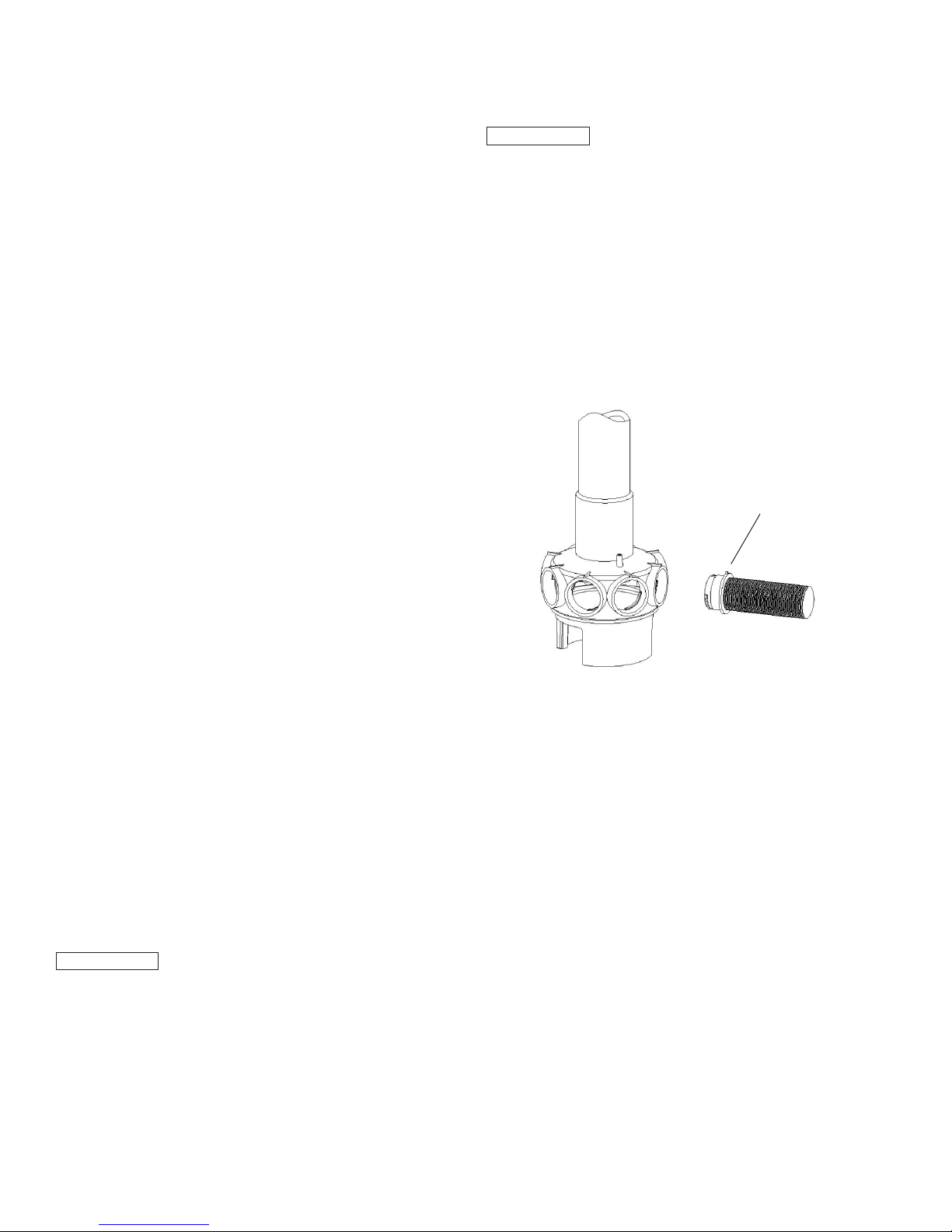

InstallationoftheMultiportValve

Top Mount Sand Filters are supplied with a screw

down

Multiport Valve. Supplied with the Multiport Valve are

Flange clamp, screws and O-Ring.

1. Screw the barrel unions onto the threaded ports on

the Multiport Valve.

2. When rotating the Multiport Valve into position

on a Top Mount Filter, leave some leeway for better

alignment of plumbing.

3. Once the Multiport Valve is in position and the

plumbing is aligned, apply the thread tape to the

barrel union thread.

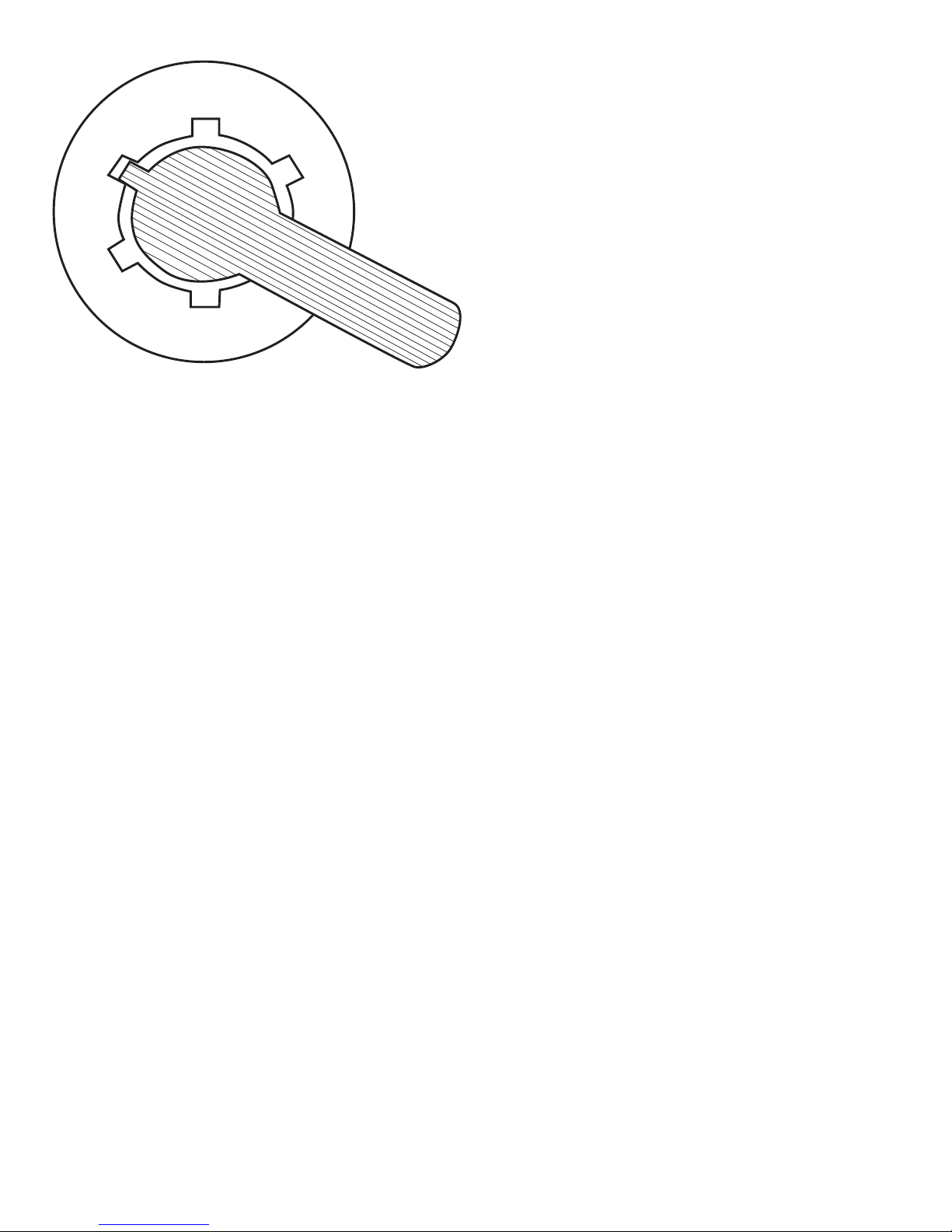

4. Using the roll of Teon tape wrap the Teon tape

around the thread (tail) of the barrel union in a clock

wise direction.

5. Screw the barrel union into the thread of the

Multiport Valve and hand tighten. The barrel union

should be rmly threaded into the Multiport Valve

and there should be no play between the thread.

6. Once you have done this tighten the barrel union

with an appropriate tool until it is tight.

7. Repeat steps until all barrel unions are rmly onto

the Multiport Valve.

8. Glue the plumbing to the Barrel unions and allow

24 hours for glue (solvent) to set before starting

the lter.

9. Test the lter and check for leaks around the

threads. If leaking occurs disconnect plumbing and

repeat the steps 2 to 6 until the leak has stopped.

CHAPTER 4: INITIAL STARTUP OF FILTER

Be sure correct amount of lter media is in tank and

that all connections have been made and are secure.

1. Depress Multiport Valve handle and rotate to the

BACKWASH position. NOTE: To prevent damage

to control valve seal, always depress handle

before turning.

2. Switch on the Pump. Open the Inlet Valve allowing

the lter tank to ll with water. CAUTION: All

suction and discharge valves must be open

when starting the pump. Failure to do so could

cause severe personal injury and/ or property

damage. NOTE: If a pump is installed, switch the

pump on and off, instead of closing and opening

the Inlet Valve.

3. Once water ow is steady out the waste line, run

the pump for at least one minute. The initial

backwashing of the lter is recommended to

remove any impurities or ne sand particles in the

lter media.

4. Turn the pump off. Set the Multiport Valve to the

RINSE position. Switch on the Pump. Open the

Inlet Valve until water in sight glass is clear -

approximately 10 to 15 seconds.

5. Switch off the Pump. Close the Inlet Valve, set the

Multiport Valve to the FILTER position and Switch

on the Pump. Open the Inlet. Your lter is now

operating in the normal lter mode.

6. Adjust pool suction and return valves to achieve

desired ow. Check the plumbing and lter for water

leaks and tighten connections, bolts, and nuts, as

required. NOTE: During initial clean-up of the

pool water, it may be necessary to backwash

frequently due to the unusually heavy initial dirt

load in the water.

7. Record the pressure gauge reading (start up

pressure) during initial operation. After a period

of time, the accumulated dirt and debris in the lter

causes a resistance to ow, and the ow diminishes.

The pressure will start to rise and the ow of

water will start diminishing. When the pressure

gauge reading is 8-10 PSI higher than the

initial “Start up” pressure, it is time to backwash

(clean) the lter (see Backwashing). NOTE: To

prevent unnecessary strain on piping system

and valving, always shut off the pump before

switching lter control valve position. To

prevent damage to the pump and lter and

for proper operation of they system, clean

pump strainer and skimmer baskets regularly.