10

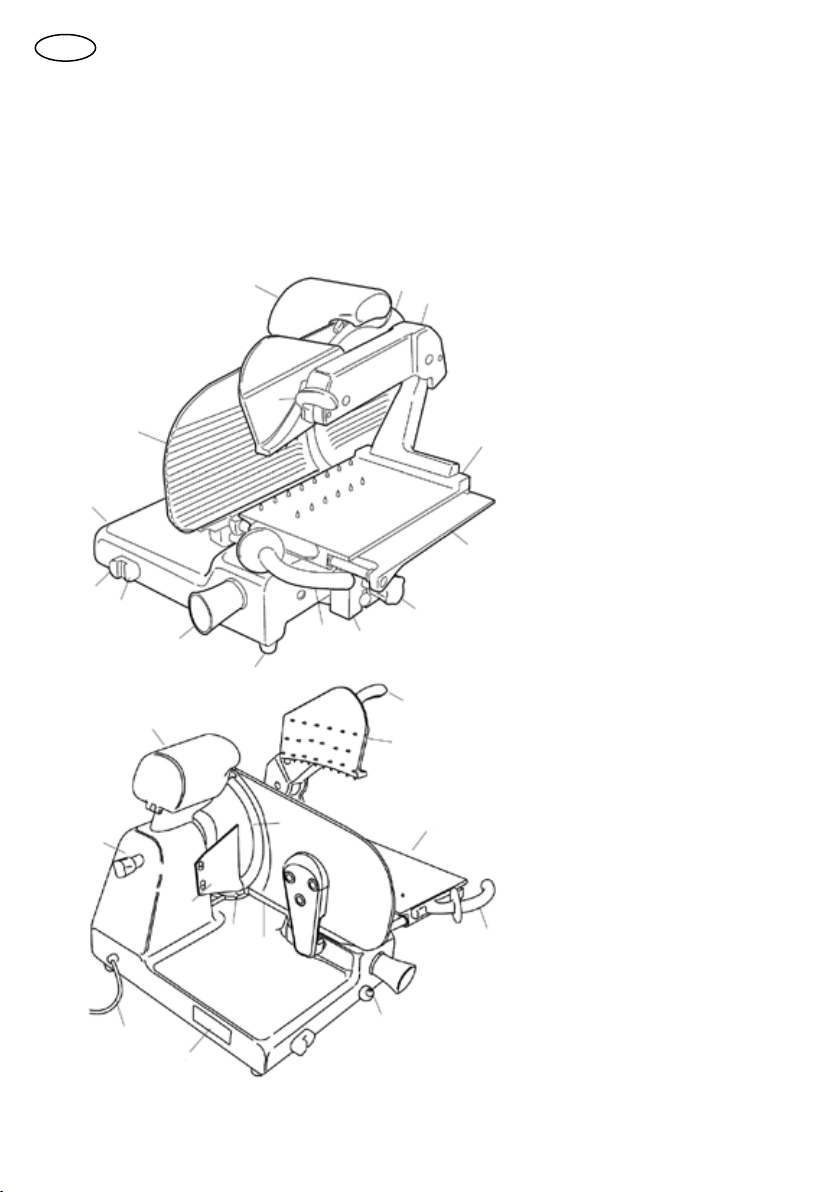

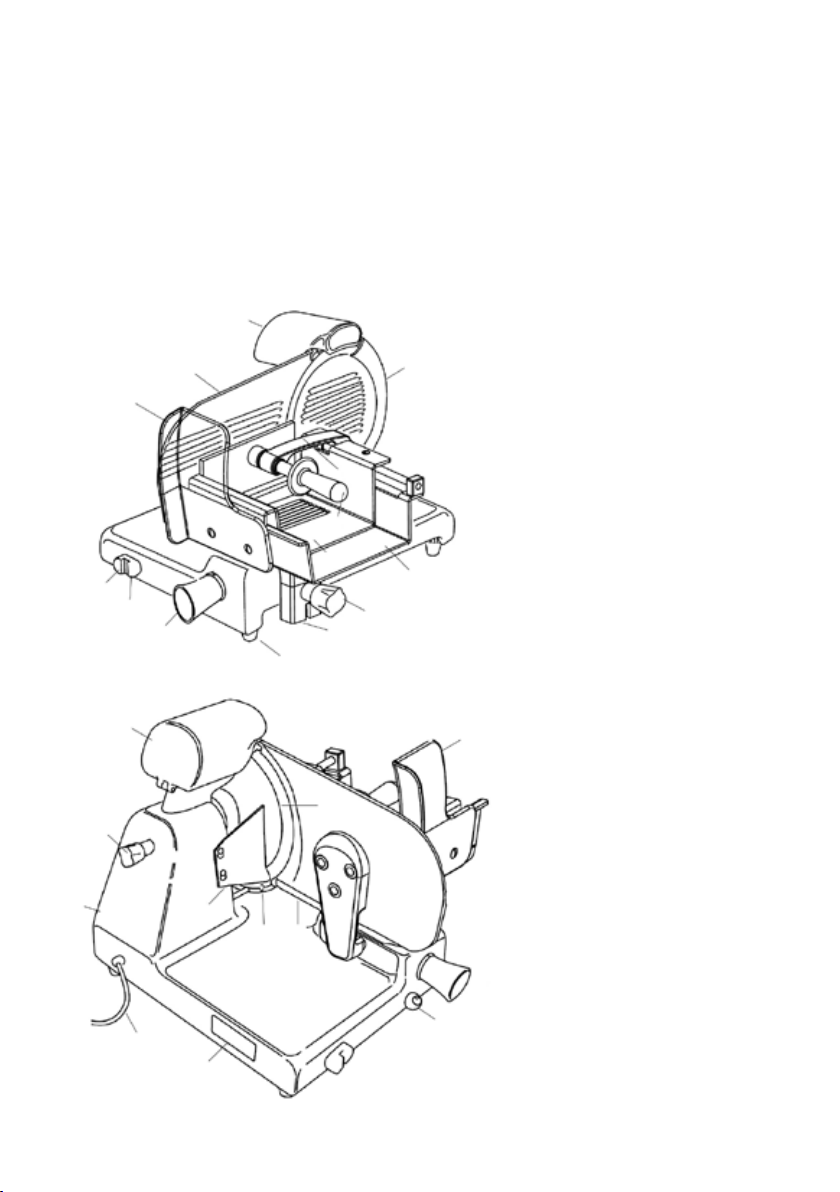

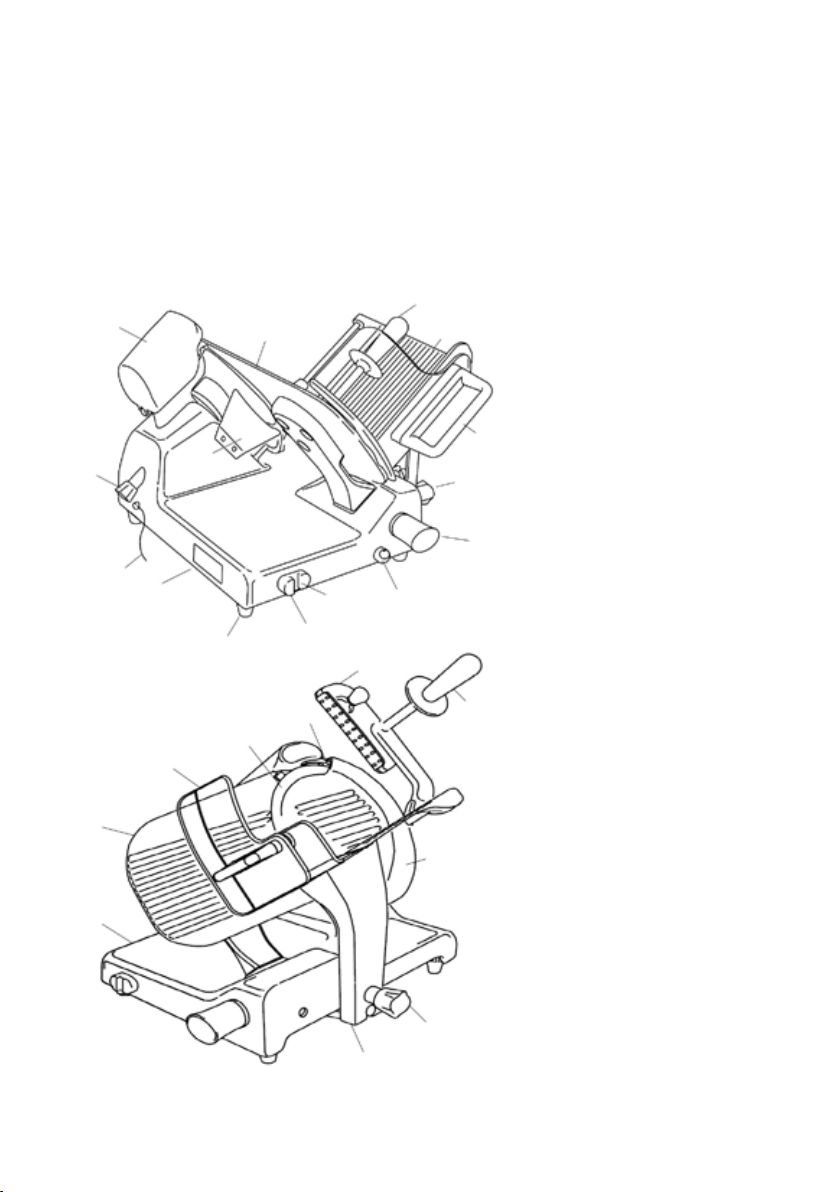

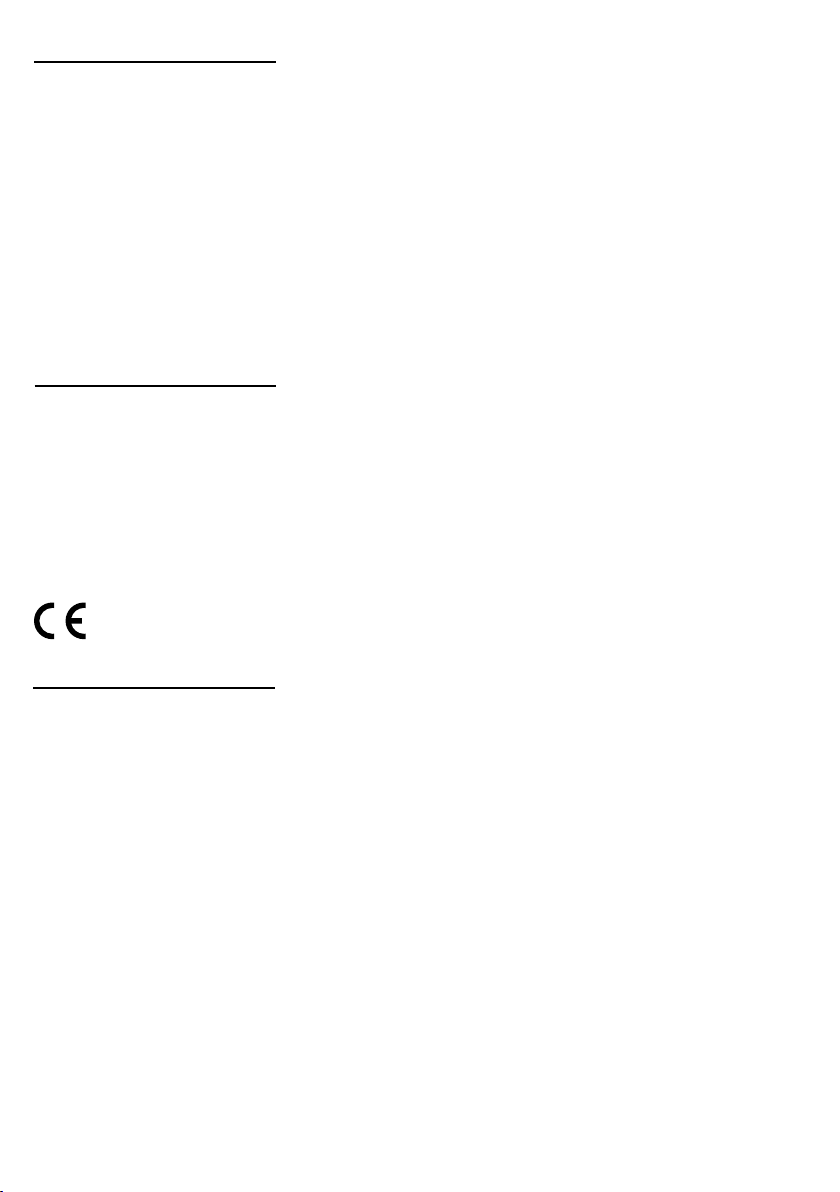

DESCRIPTION

Circular blade professional

slicer machine suitable for

cutting only the food products

of the types and within the di-

mensional limits indicated in

this manual. The main parts of

the machine are shown in the

general component diagram

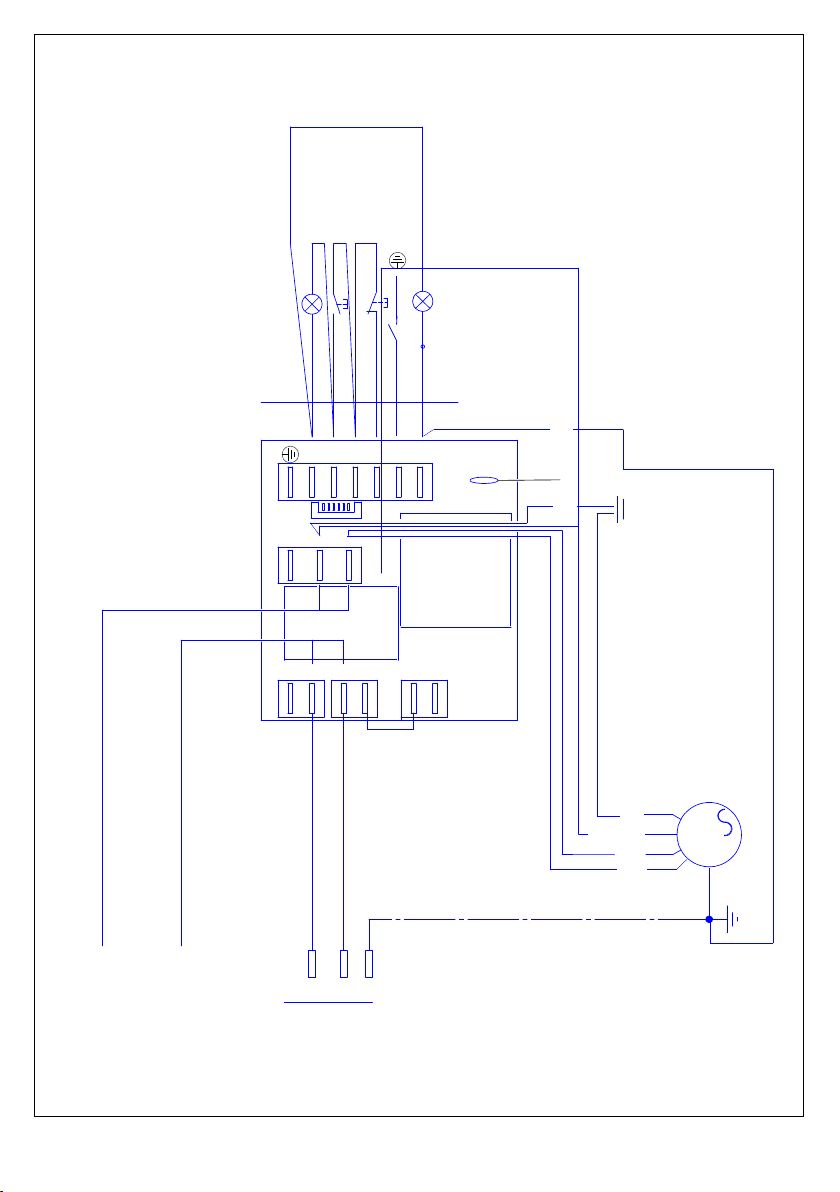

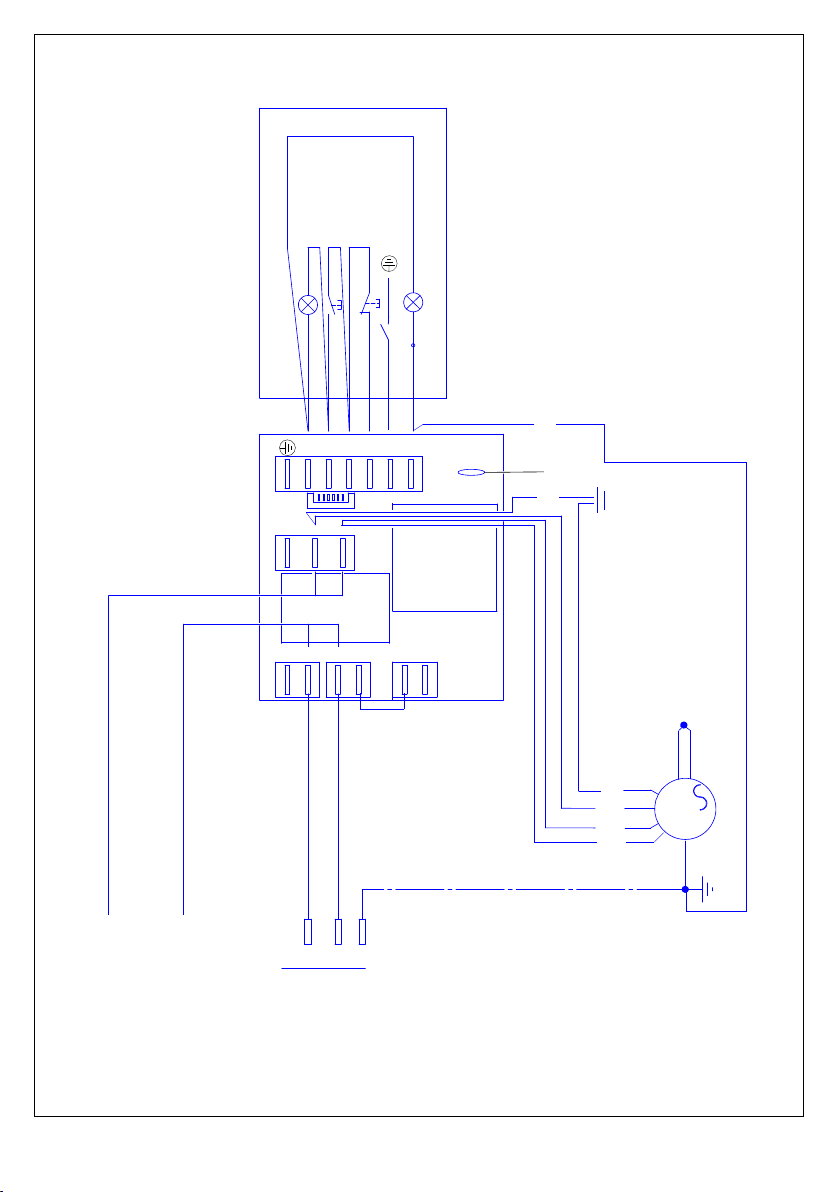

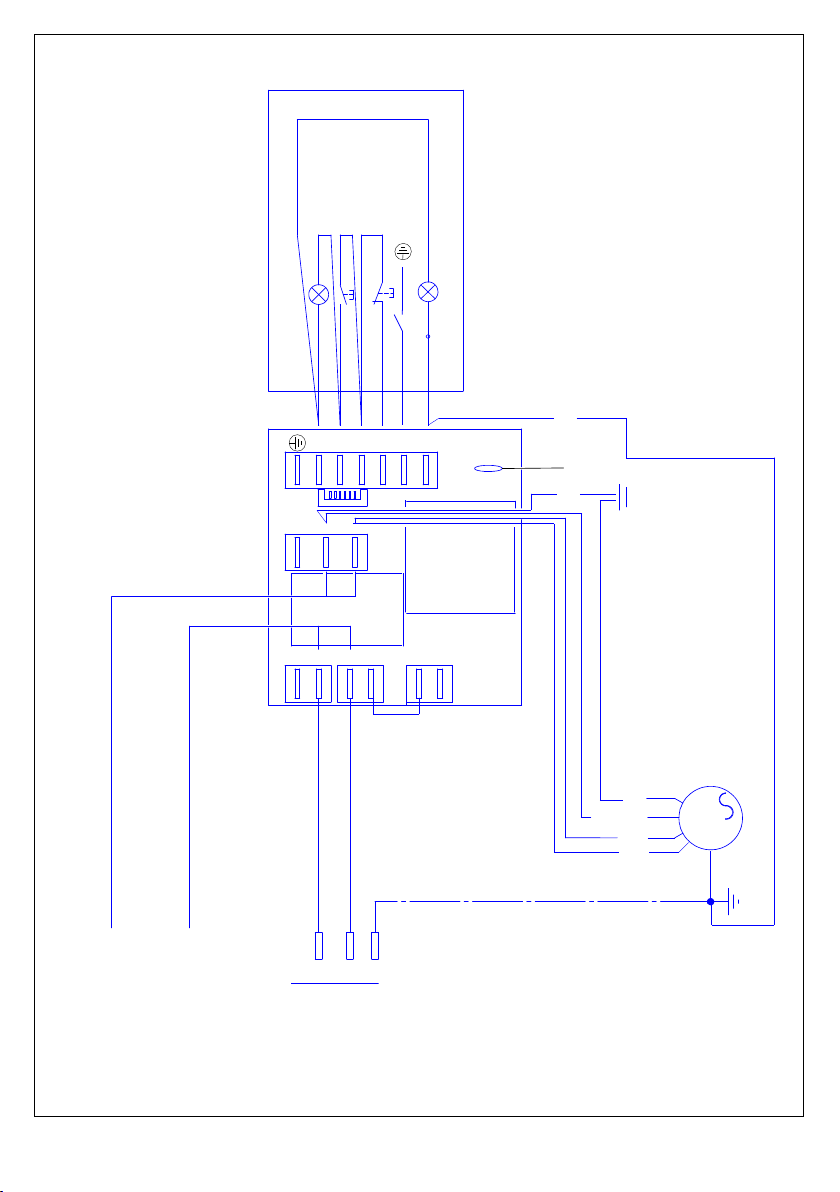

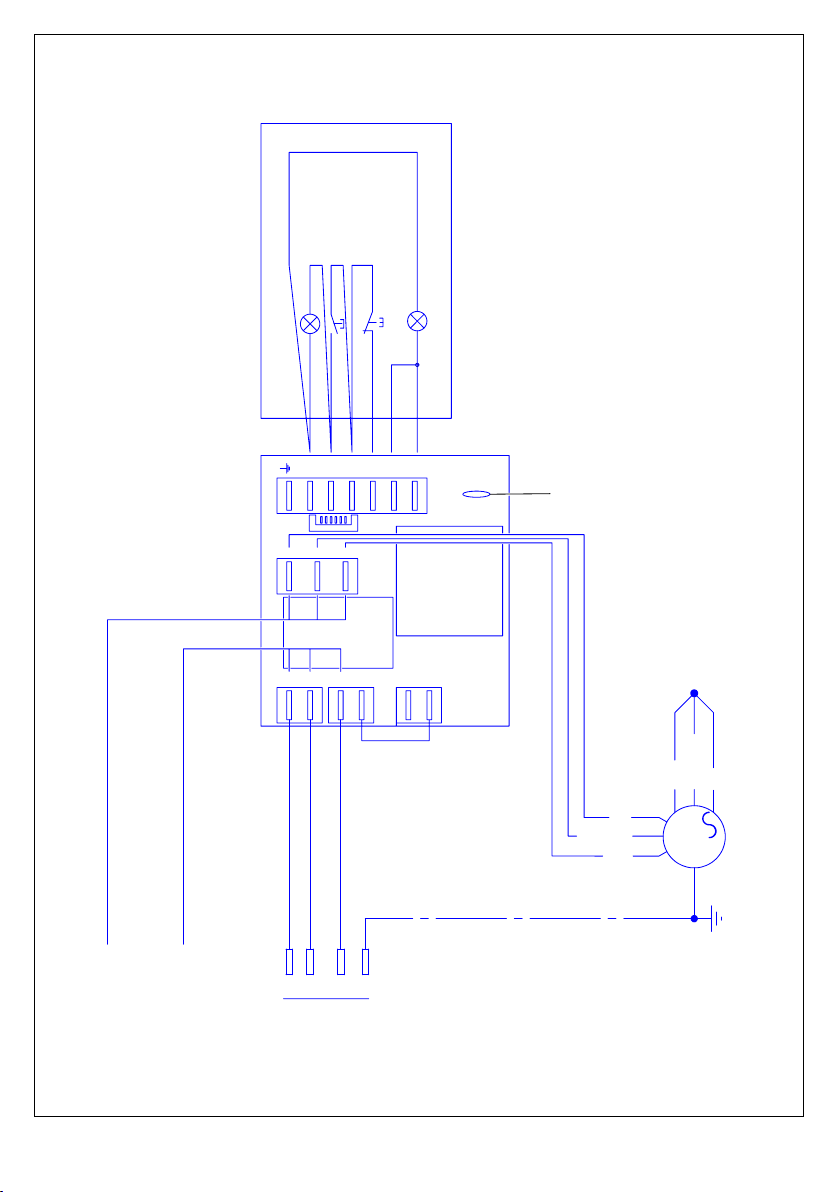

reported in picture 2. Electrical

diagrams are reported in pic-

ture 1.

DECLARATION

OF CONFORMITY

The machines described in this

manual comply with Direc-

(EC) 1935/2004 and related

harmonized standards as EN

SAFETY

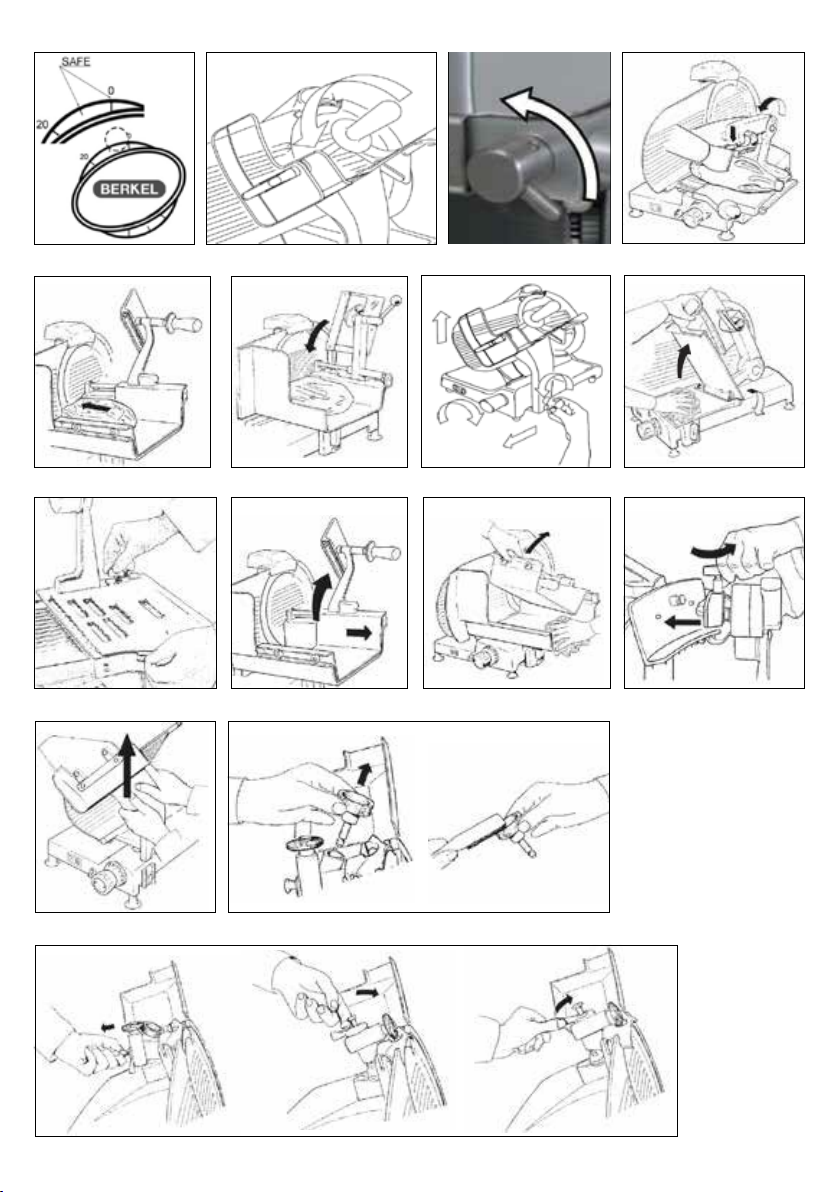

Pay attention to the following

basic safety precautions:

- read all the instructions be-

fore using the machine;

- this product is not intended

to be used by children;

- operate the machine only if

properly trained and in perfect

psycho-physical conditions;

- do not use the machine in any

way other than what indicated

in this manual;

- use the machines only in full

-

- install the machine in con-

formity to the instructions

indicated in the “Installation”

section;

- install the machine in a loca-

tion out of the reach of person-

nel unauthorized to operate it

and especially out of the reach

of minors;

- stay highly concentrated

when using the machine and

avoid any distraction during

use;

- do not allow the machine to

be used by others who have

not read and fully understood

the content of this manual;

- do not wear baggy clothing or

clothing with open sleeves;

-

-

proach during product cutting

operations;

-

modify the tags located on the

promptly;

- do not remove the transpar-

ent guards and do not modify

or bypass any mechanical and

electrical protective devices;

- slice only the permitted prod-

prohibited type products;

- always keep clean and dry the

the work area all around the

area;

- do not use the machine as

a resting surface and do not

place any objects on it other

than food used for cutting op-

erations;

-

-

tance between the edge of

the blade and the blade guard

contact the manufacturer or to

one of the Authorized Service

Centers to change the blade;

- do not use the machine with

temporary or non-insulated

-

sion cords;

- periodically check the condi-

tion of the power supply cord

on the machine body. When

-

sonnel replacing it;

- immediately stop the ma-

-

- before cleaning or carrying

the machine from the electri-

cal supply;

- use protective gloves for

cleaning and maintenance op-

erations;

- place and remove the goods

to be sliced on the sliding plate

only with the carriage com-

pletely pulled back and with

the thickness adjustment knob

placed in the safety position

(on the 0 position);

- for movement of the meat

table during cutting operations

use only the handle located on

the arm or the product presser

grip;

- never put your hands on the

food product while slicing. Al-

ways keep your hands behind

the protection devices and far

from the blade;

- use of cutting accessories

which were not provided by

the manufacturer with the ma-

chine is prohibited.

The manufacturer declines any

responsibility coming from in-

and/or repairs carried out by

the user or unauthorized per-

parts that are not original or

model.

The machine shall not be used

in open areas and/or areas

which are exposed to atmos-

pheric agents and in environ-

corrosive and/or abrasive pow-